JASPER: Peltier cooler for lasers

Peltier cooler for lasers used in FTIR and Raman spectrometers, maintaining temperature and wavelength stability for optimal performance

Peltier cooler for lasers used in FTIR and Raman spectrometers, maintaining temperature and wavelength stability for optimal performance

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

Test case simulation.docxdocument - 1.04 MB - 03/11/2025 at 10:29 |

|

|

TEC_Block_Diagram_v04.jpgTEC Block Diagram: ProposedJPEG Image - 100.59 kB - 03/05/2025 at 15:30 |

|

|

We were amazed to see the power of AI when Gemini rendered images of a temperature-controlled laser mount featuring a Peltier element and an annular ring. This visualization sparked our own design efforts, and we're now developing a robust mechanical solution: a laser mount with four Peltier elements!

Stay tuned for our upcoming Hackaday post, where we'll dive deep into our 4-peltier design.

We'll detail the challenges, benefits, and mechanical intricacies of this approach.

Exploring Peltier-Cooled Laser Mount Designs

Laser mounting systems often demand precise thermal management to ensure performance and stability. Here, we outline three innovative design options for a Peltier-cooled laser mount. Each approach leverages the unique cooling properties of Peltier elements to maintain the laser's ideal operating temperature.

1. Single Peltier with a Center Hole or Annular Ring This design features a single Peltier module with a central hole or an annular ring configuration. The laser is mounted in the centre, taking full advantage of the cold surface created by the Peltier effect. The simplicity of this design minimizes material usage and assembly complexity while delivering focused cooling where it’s most needed. However, effective thermal insulation around the laser and the Peltier module is essential to maintain efficiency.

Advantages:

Challenges:

2. Dual-Peltier System with an Aluminum Cold Plate In this design, two Peltier modules are mounted onto a heat sink, with the cold side transferring heat to a front aluminium plate. This plate serves as the cold mount for the laser, ensuring uniform cooling across the laser's surface. The aluminium plate adds structural integrity and improves thermal conductivity, making it ideal for applications requiring moderate cooling performance.

Advantages:

Challenges:

3. Four-Peltier System with a Central Aluminium Cube This ambitious design uses four Peltier elements mounted on each face of an aluminium cube. The cold center of the cube serves as the mounting point for the laser. This configuration provides multidirectional cooling, ensuring excellent thermal regulation for high-performance laser applications. The cube design adds symmetry and maximizes cooling efficiency, albeit at the cost of increased complexity.

Advantages:

Challenges:

Choosing the Right Design: The choice between these designs hinges on your specific application requirements. The single Peltier option is ideal for straightforward setups with modest cooling needs. The dual-Peltier system balances simplicity and performance, while the four-Peltier cube is well-suited for high-performance, precision applications.

Which design do you think will elevate your project to the next level? Let us know in the comments!

Precise temperature control is critical in many applications, from laser diode operation to scientific instrumentation. Thermoelectric Coolers (TECs), also known as Peltier modules, offer a solid-state solution for both heating and cooling without moving parts. This project explores the implementation and optimization of a temperature control system using Maxim's MAX1968 TEC driver.

Unlike traditional heating/cooling systems, TECs can switch between heating and cooling by simply reversing current flow, making them ideal for maintaining stable temperatures within ±0.01°C. However, their control presents challenges due to thermal mass and response lag. This project documents my journey in understanding, simulating, and implementing an effective PID control system for TECs.

Hardware Setup

Initial Setup

I began with a minimal configuration using our custom PCB built around the MAX1968 TEC driver IC and Peltier setup with NTC. The circuit follows Maxim's recommended application with the H-bridge configuration for bidirectional current flow. Initial tests revealed significant thermal lag when using a larger TEC module, resulting in slow CTLI (Control Input) response.

Enhanced Setup

To address the thermal lag issues, I upgraded the testing platform with:

The custom PCB implements the complete circuit shown in the schematic, including the PID control section with operational amplifiers (U7 and U9) configured according to Maxim Application Note 3318. The design includes:

Temperature control using TECs presents unique challenges due to their thermal response characteristics. According to Maxim Application Note 3318, TEC modules behave approximately like a two-pole system:

This slow response creates significant phase shifts that can easily lead to oscillation in the control loop. The PID (Proportional-Integral-Derivative) controller must be carefully designed to maintain stability while providing adequate response time.

The PID controller for a TEC system requires careful component selection based on these formulas:

A critical insight: TECs have approximately four times stronger heating capacity than cooling for the same input current. This asymmetry creates a response variation of up to 6dB between heating and cooling modes, requiring robust phase margin in the control loop design.

For optimal PID performance, these component characteristics are crucial:

Precise temperature control is paramount in numerous optical applications, directly influencing the performance and stability of critical components.

Optical Applications Requiring Temperature Control:

The specific demands of temperature control in optical systems vary significantly across applications. While thermal noise reduction in CCD/CMOS detectors necessitates achieving the lowest possible temperatures, Tunable Diode Laser Absorption Spectroscopy (TDLAS) requires exceptionally accurate and stable temperature regulation. Furthermore, the physical scale of temperature control differs; laser diodes necessitate precise control over a small area, whereas CCD/CMOS sensors require cooling of a larger surface.

Given these contrasting cooling requirements, a single design cannot optimally address all applications. Therefore, we have chosen to prioritize accurate and stable temperature control, focusing initially on laser diodes for spectroscopy applications. This targeted approach allows us to develop a high-performance TEC controller that excels in maintaining the critical temperature stability essential for precise spectroscopic measurements. Future iterations may expand upon this core technology to address the wider range of thermal management challenges present in other optical systems.

Evaluating TEC Controller Reference Designs: A Technical Insight

As we delve into the intricate world of TEC (Thermoelectric Cooler) controller designs, our approach is structured to ensure a comprehensive analysis. Here are the key evaluations and steps we are taking:

At CheckAG, we're currently developing a Thermoelectric Cooler (TEC) control system for precise temperature regulation — a critical part of many of our spectrometry projects. I wanted to share the initial steps of implementing PID control for the TEC and some design choices we've made along the way.

PID control — Proportional, Integral, and Derivative control — is a widely used feedback control method for dynamic systems. It works by continuously calculating the error between the desired setpoint (target temperature) and the current value (actual temperature), then adjusting the output (PWM to the TEC module) based on three terms:

The control signal is computed as:

Output=Kp×Error+Ki×∫Errordt+Kd×d(Error)dt Output = Kp \times Error + Ki \times \int Error dt + Kd \times \frac{d(Error)}{dt}

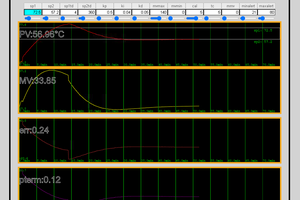

In our setup, we used these initial PID constants:

float Kp = 420, Ki = 32, Kd = 1365;

A key design choice we made is to use unidirectional control rather than bidirectional control. Typically, bidirectional control allows a Peltier module to both cool and heat by reversing the current flow. However, we opted for unidirectional control for two reasons:

Our control logic works like this:

The PID controller's output is simply mapped to a PWM signal controlling the MOSFET’s gate:

analogWrite(PELTIER_PWM, controlSignal);

Tuning the PID gains is crucial to getting stable and accurate temperature control. We used the Ziegler-Nichols method for tuning, which follows these steps:

| Kp | Kd |

|---|---|

| 0.5 * Ku | 0 |

| 0.45 * Ku | 0 |

| 0.6 * Ku | Kp * Pu / 8 |

After tuning, we landed on:

Kp = 420; Ki = 32; Kd = 1365;

This unidirectional control design simplifies the hardware and leverages natural thermal dynamics to heat the TEC. The PID controller, tuned using Ziegler-Nichols, balances responsiveness and stability.

I'll continue to share updates as we refine the system further. Let me know if you'd like to dive deeper into any part of this — from the PID algorithm to the hardware design!

What do you think? I'd love to hear your thoughts, suggestions, or even experiences with TEC control systems!

Create an account to leave a comment. Already have an account? Log In.

Become a member to follow this project and never miss any updates

Mild Lee Interested

Mild Lee Interested

Robert

Robert

justin.richards

justin.richards

Carmine Moleti

Carmine Moleti