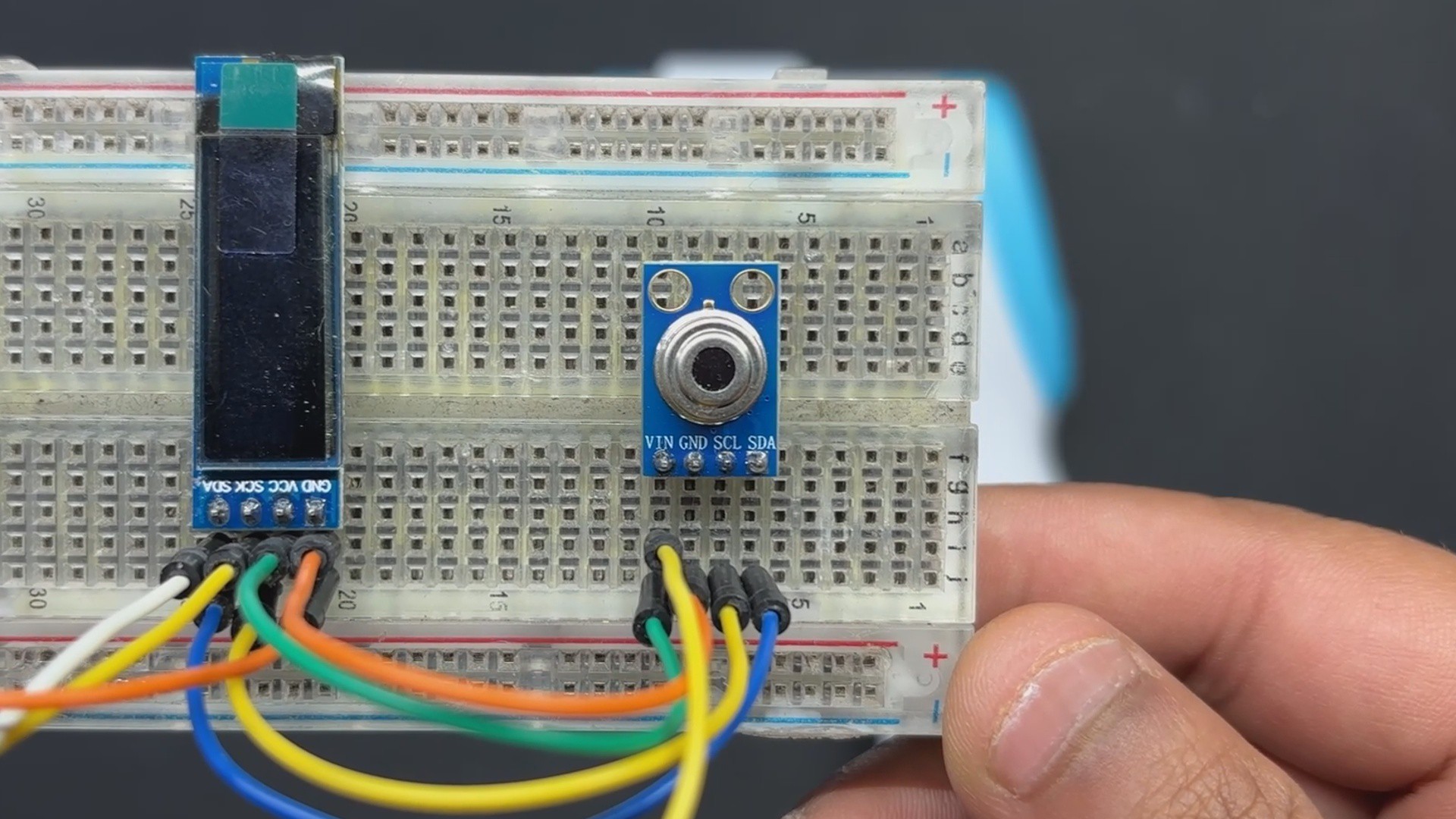

It provides two output modes: PWM (pulse width modulation) and SMBus (I2C). The 10-bit PWM output has a resolution of 0.14°C, whereas the I2C interface has a resolution of 0.02°C. We are now using the I2C mode.

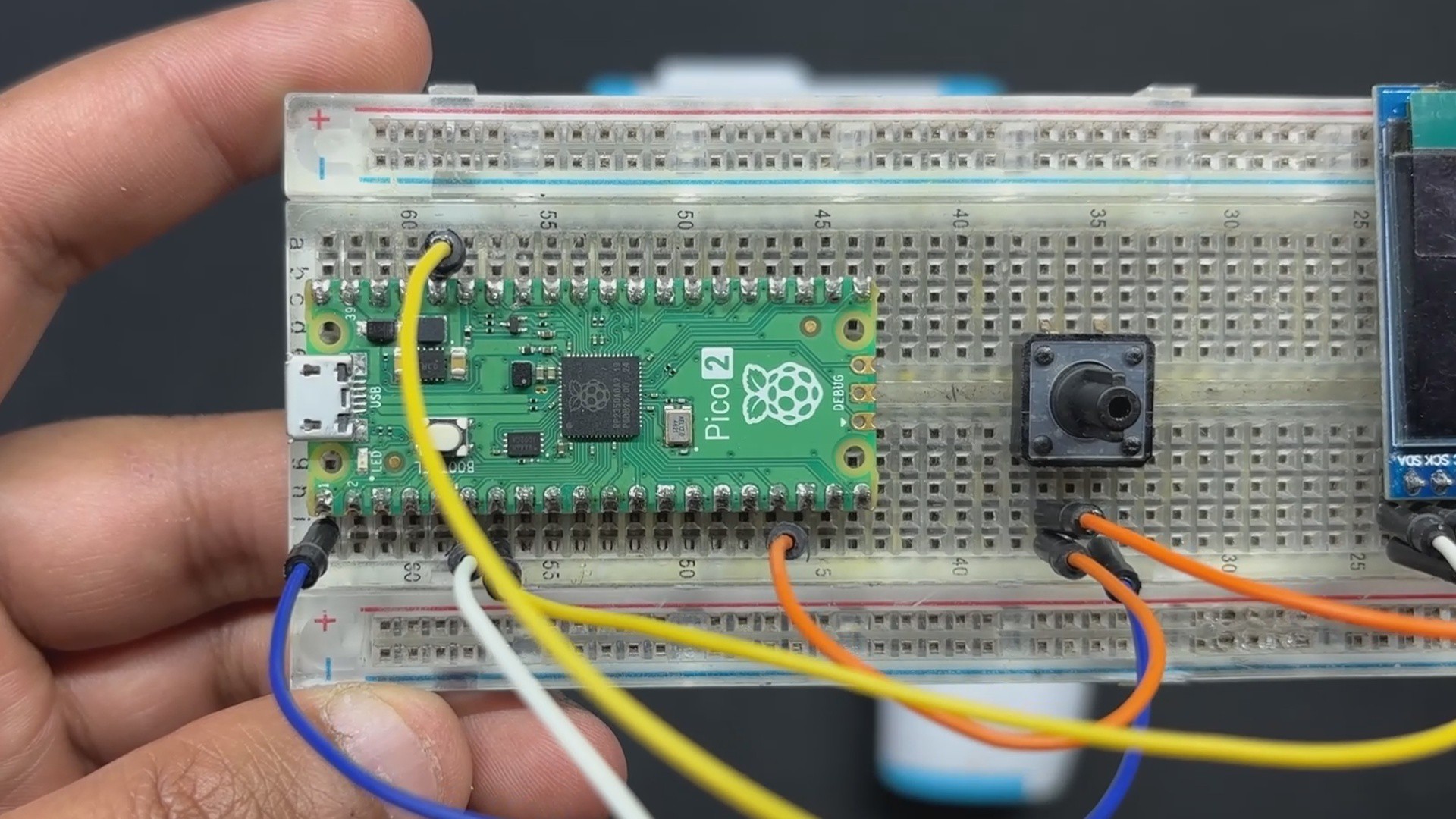

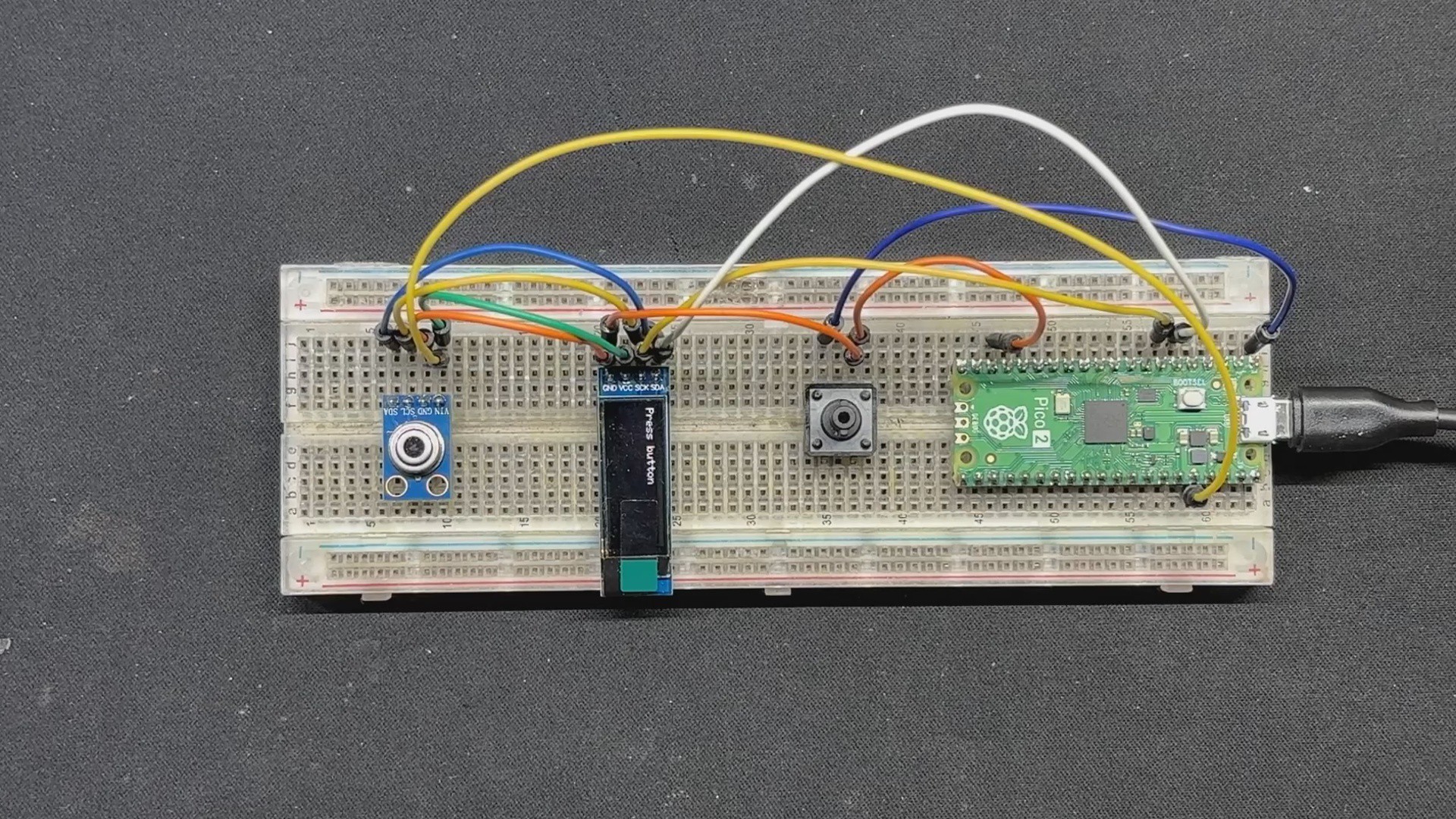

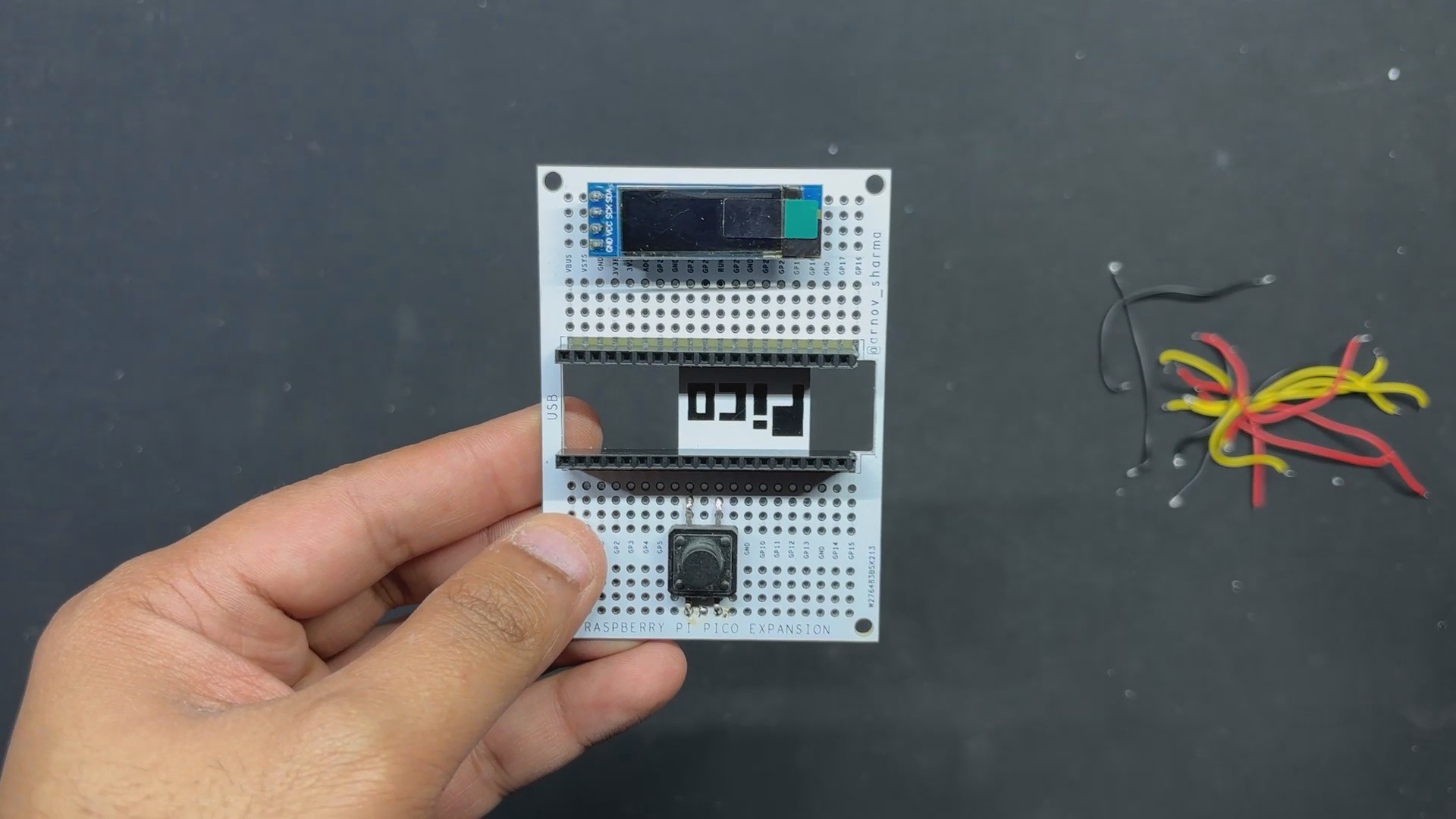

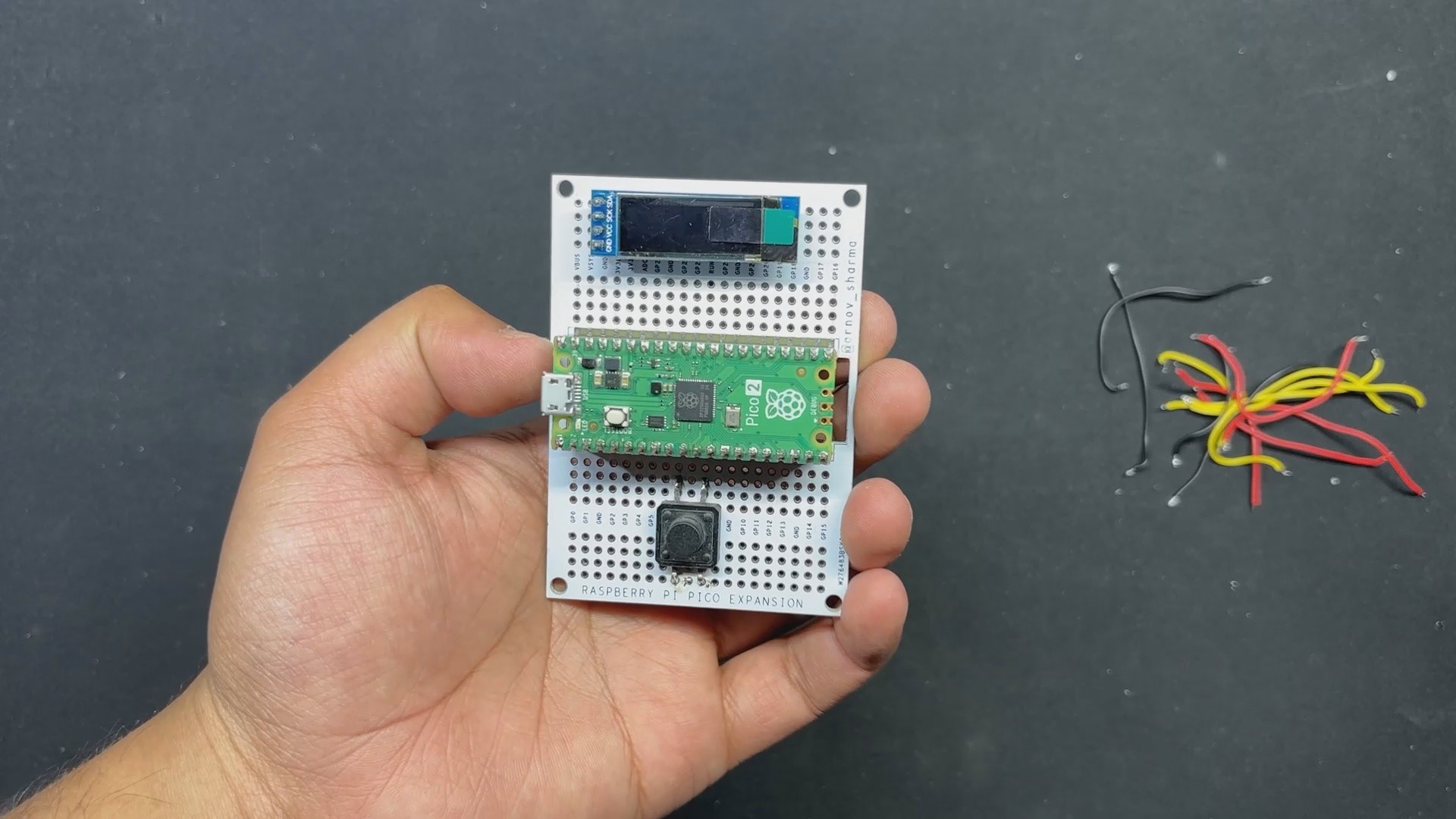

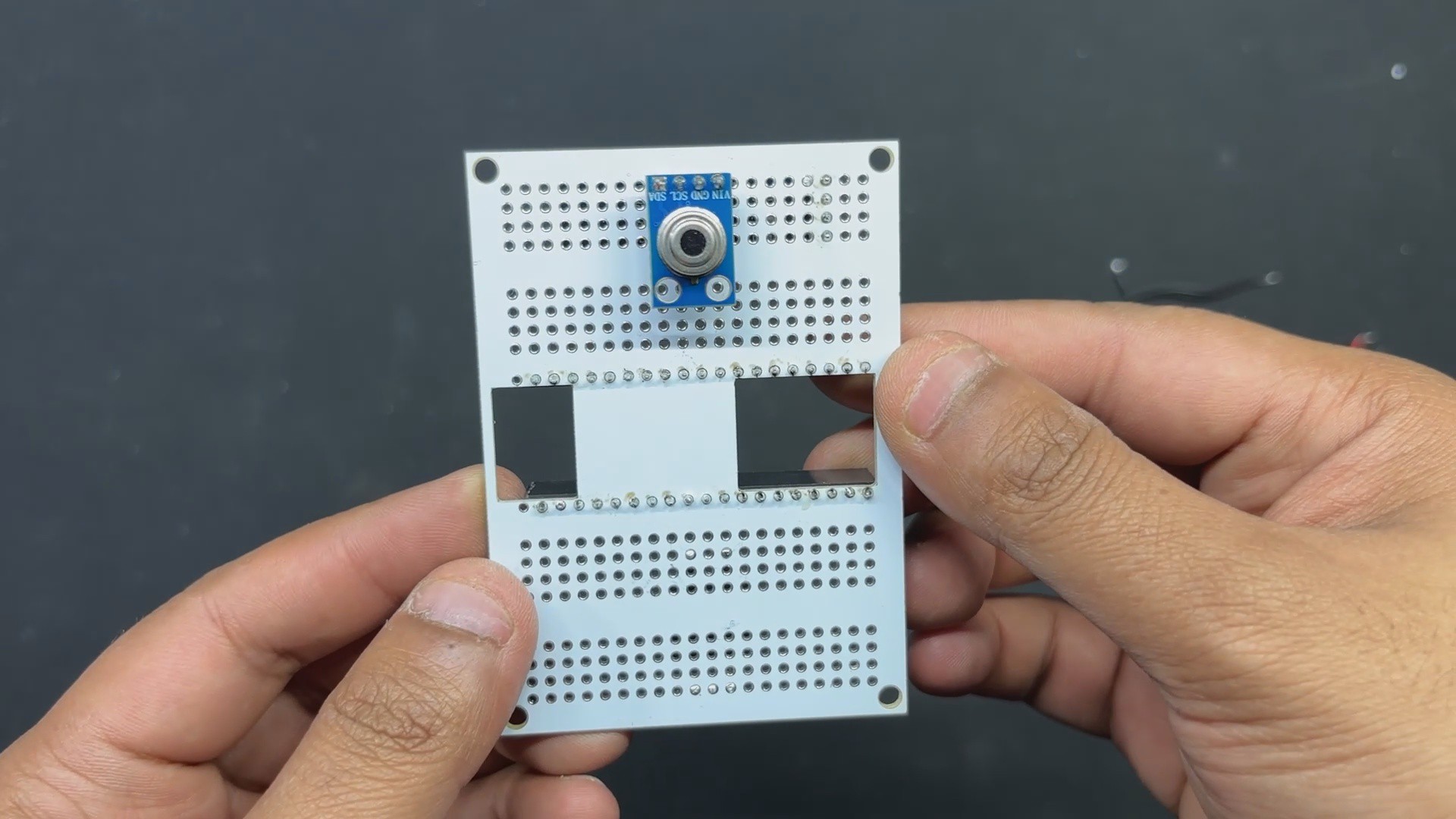

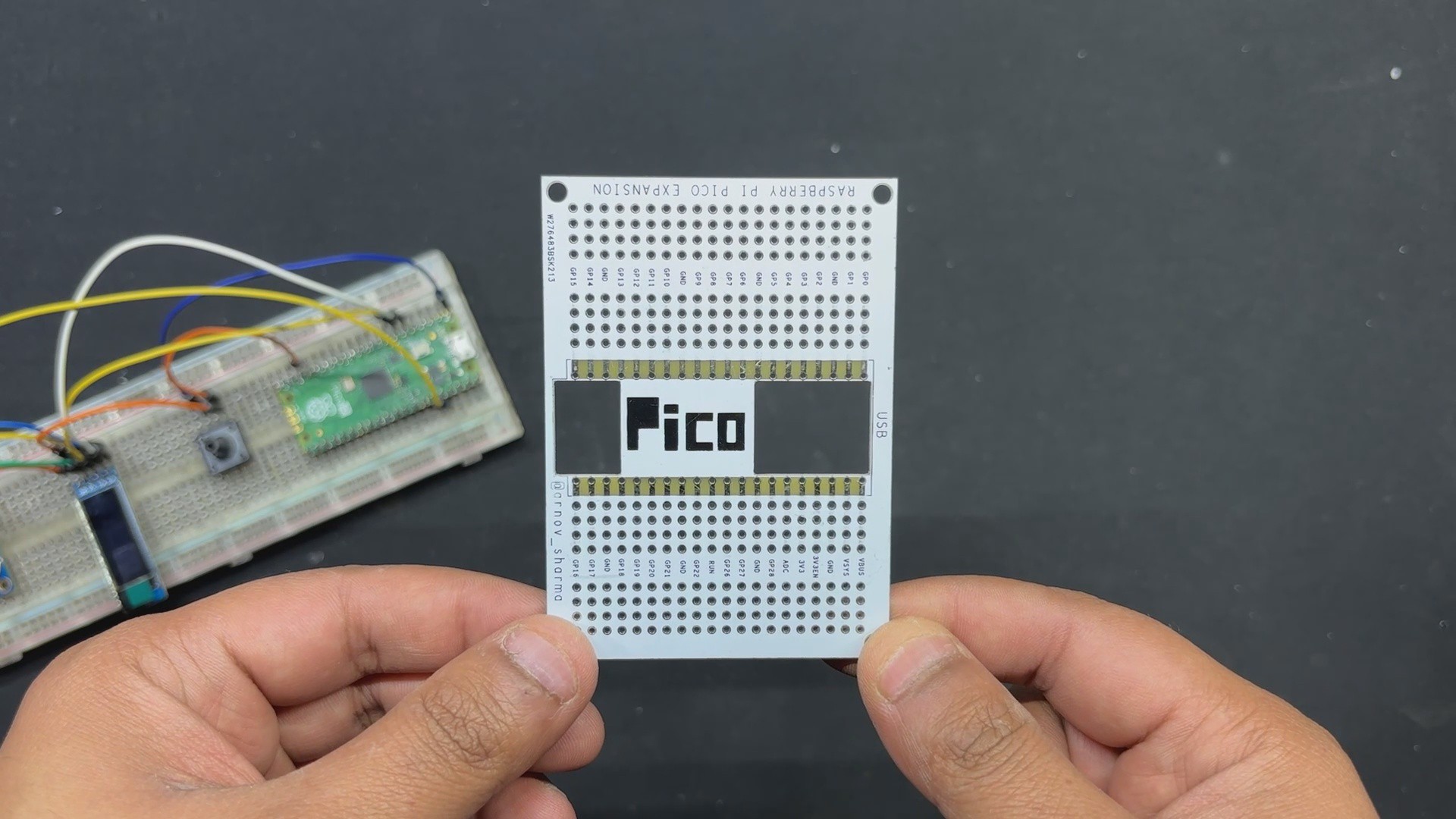

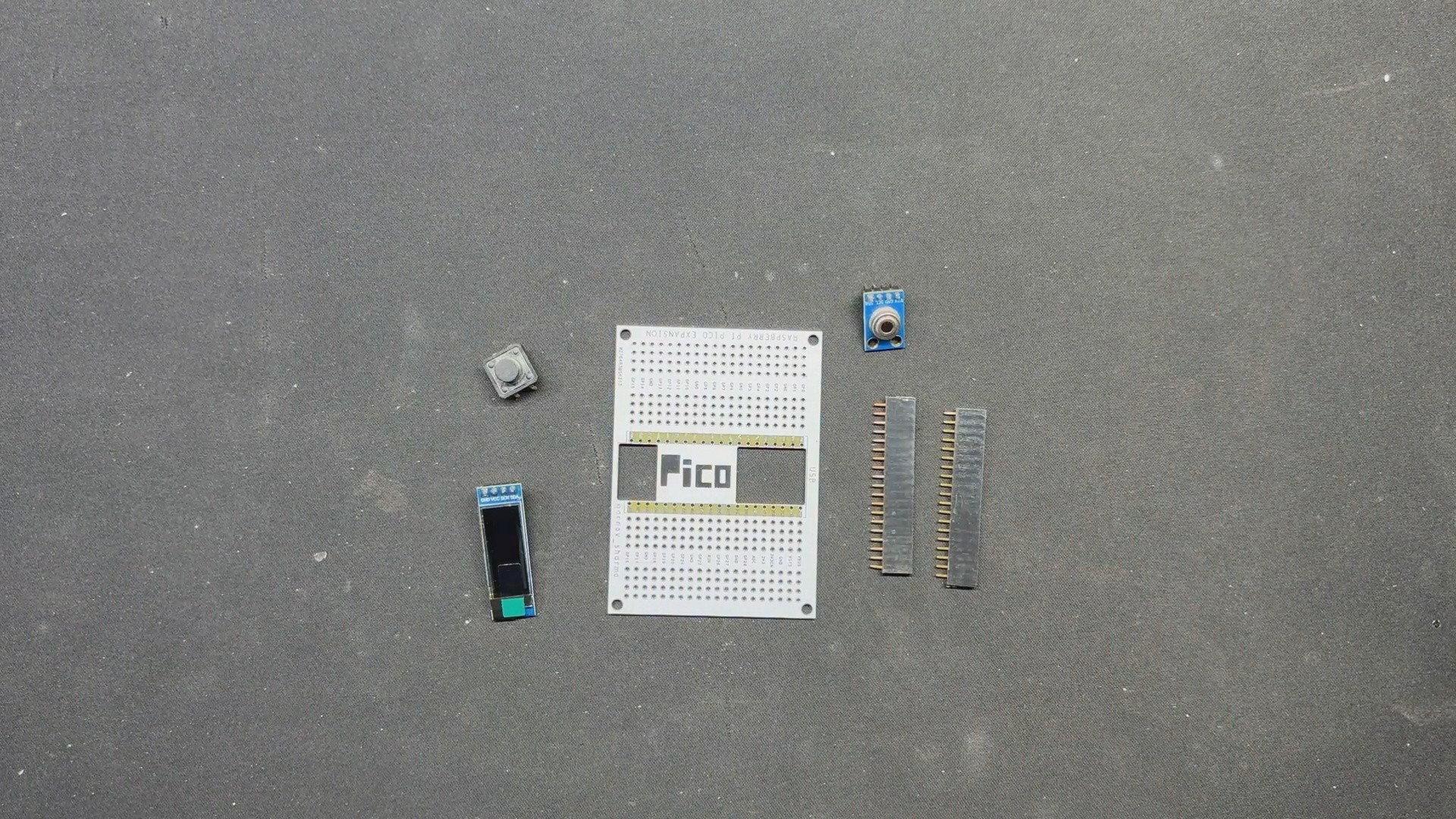

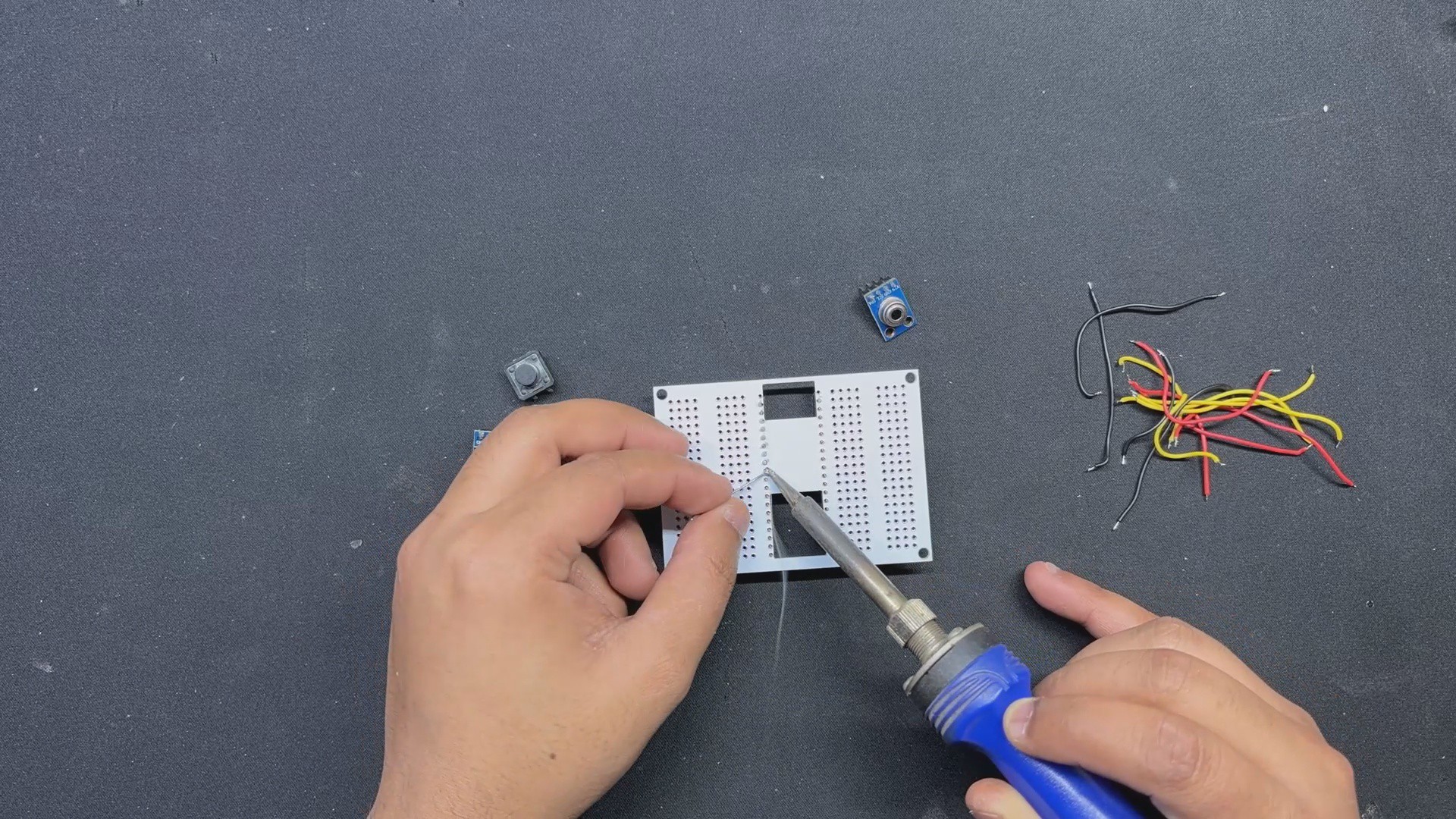

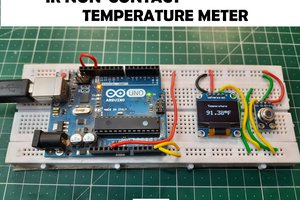

For this project, we created two variants: a breadboard version for simple setup and a prototype PCB version that links all components on a beautiful PCB, making the entire setup easier and more practical to use.

For Version 2 of this project, we will design a customized PCB with a temperature gun-style enclosure as housing and an onboard battery pack.

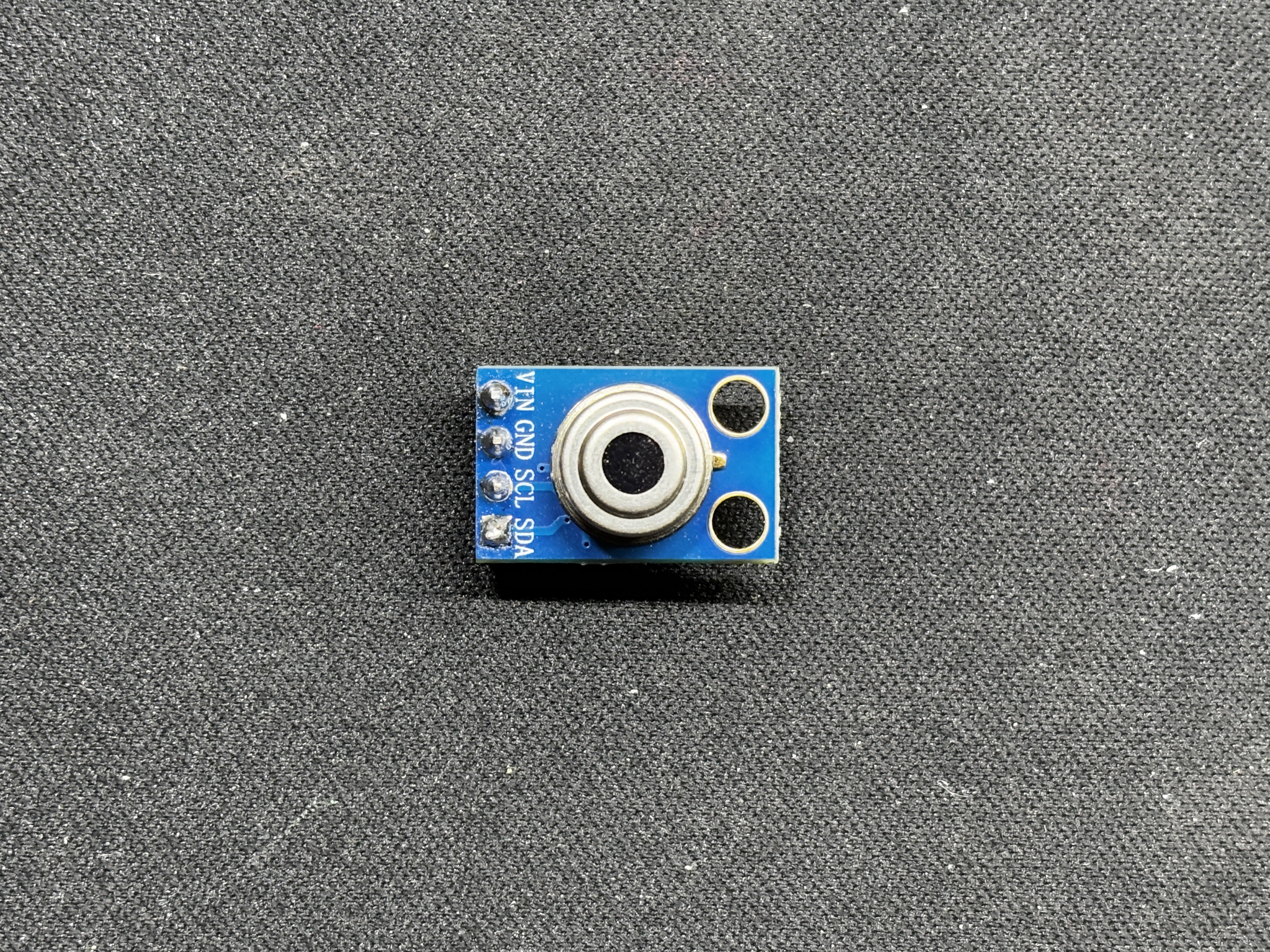

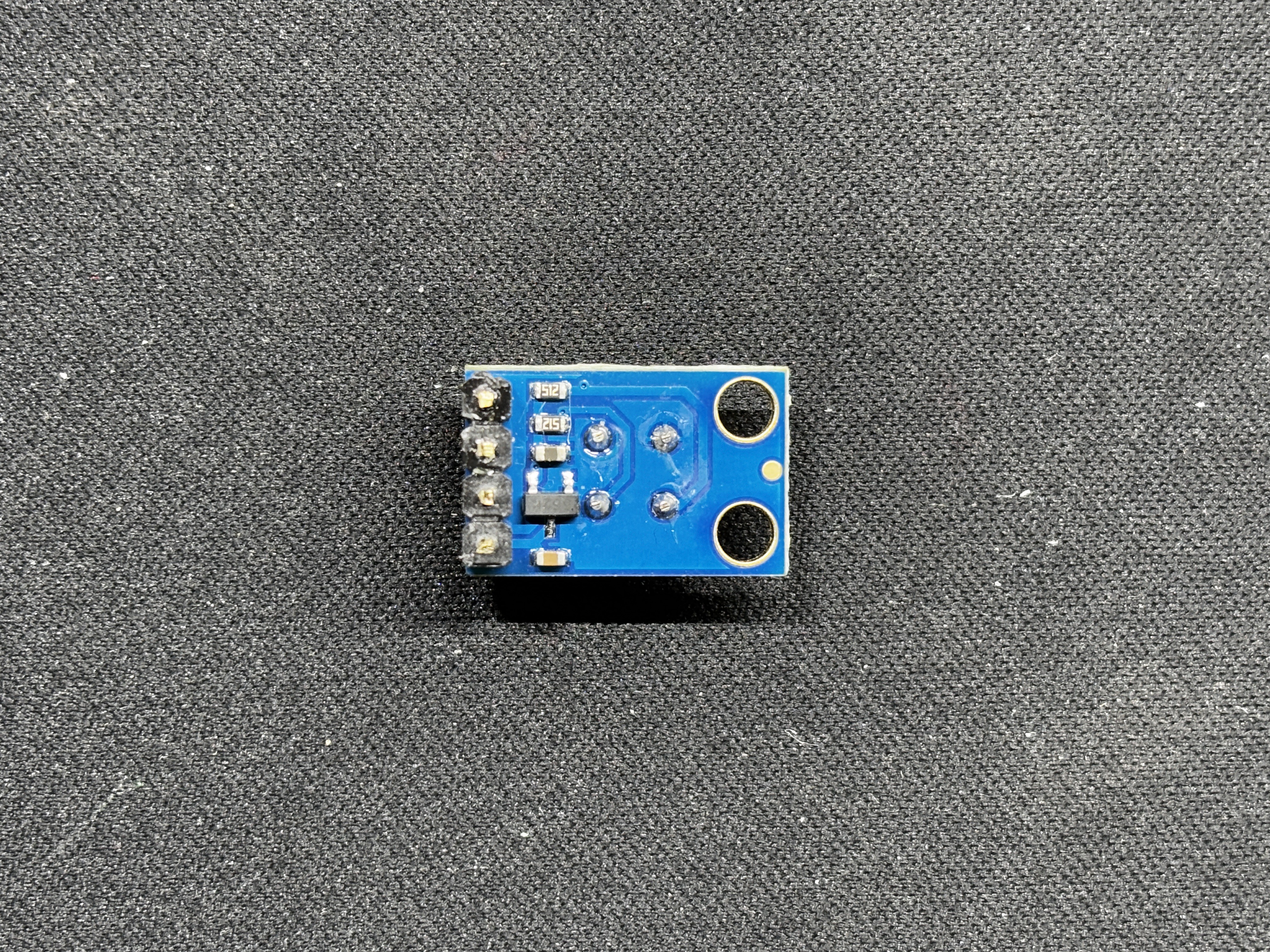

GY-906 Infrared Temperature Sensor Module

The GY-906 (MLX90614) infrared temperature sensor is a very precise and adaptable device that is commonly used for non-contact temperature readings. It functions over a wide temperature range, from -70°C to +380°C for objects and -40°C to +125°C for the sensor.

The sensor is highly precise, with a resolution of 0.02°C and an accuracy of ±0.5°C about ambient temperature.

The sensor's dual output techniques (PWM and I2C) allow for versatility in a variety of applications. Users can obtain 0.14°C and 0.02°C resolutions using a 10-bit PWM output and an I2C interface.

It can perform properly with voltages ranging from 3.3V to 5V.

This sensor employs infrared technology to determine the temperature of a surface without making physical contact. This is especially beneficial in instances where direct contact is not an option, such as moving items, sensitive surfaces, or hazardous compounds.

Fun fact: during COVID, these sensors were commonly utilized to manufacture temperature guns.

All objects emit infrared light as a function of temperature. An infrared temperature sensor detects the infrared radiation emitted by an object, converts it to a voltage, processes this signal to calculate the temperature, and then communicates this information to a microcontroller via the I2C interface.

This non-contact approach enables accurate and reliable temperature measurements without requiring physical touch with the object being measured.

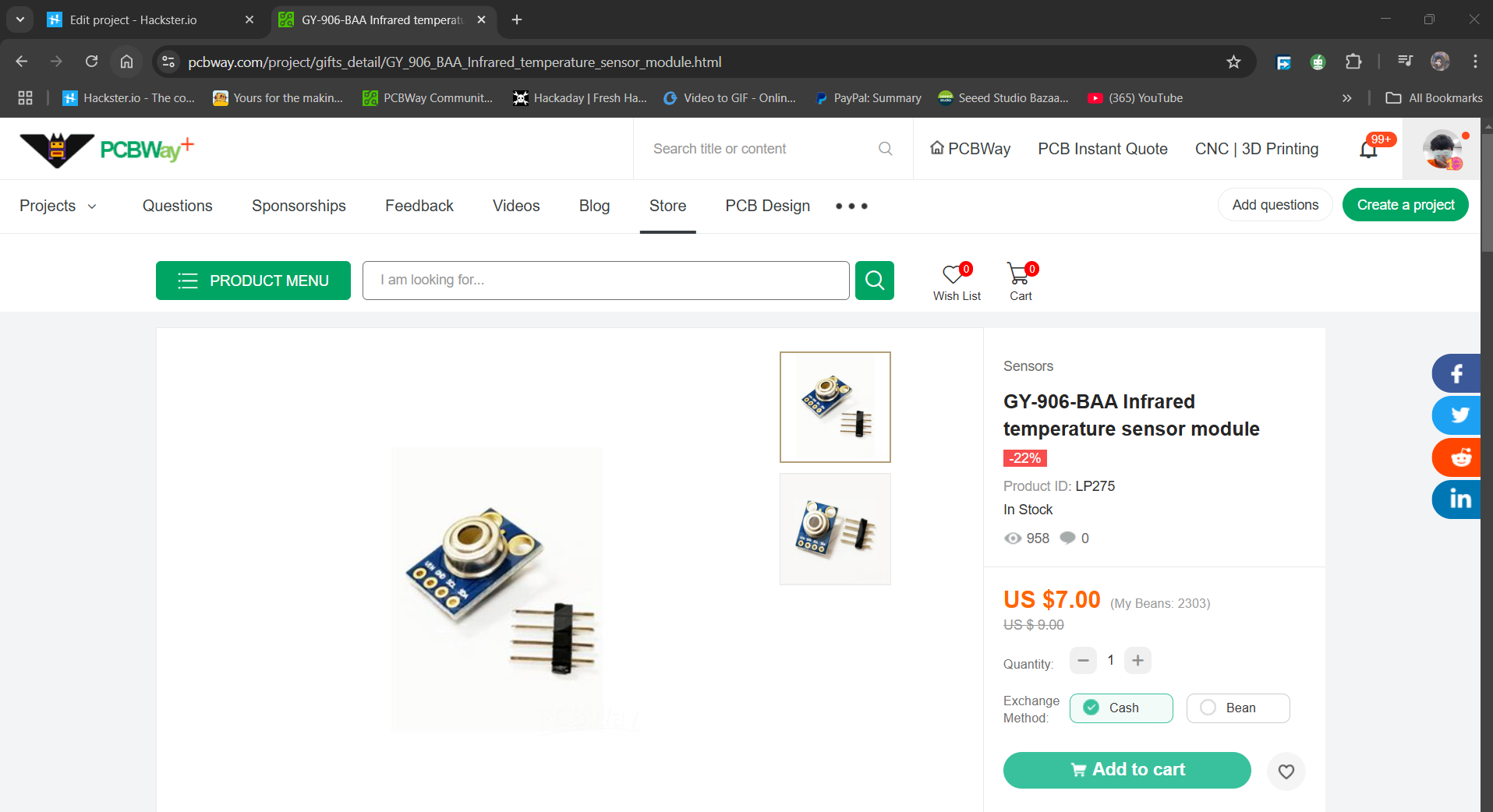

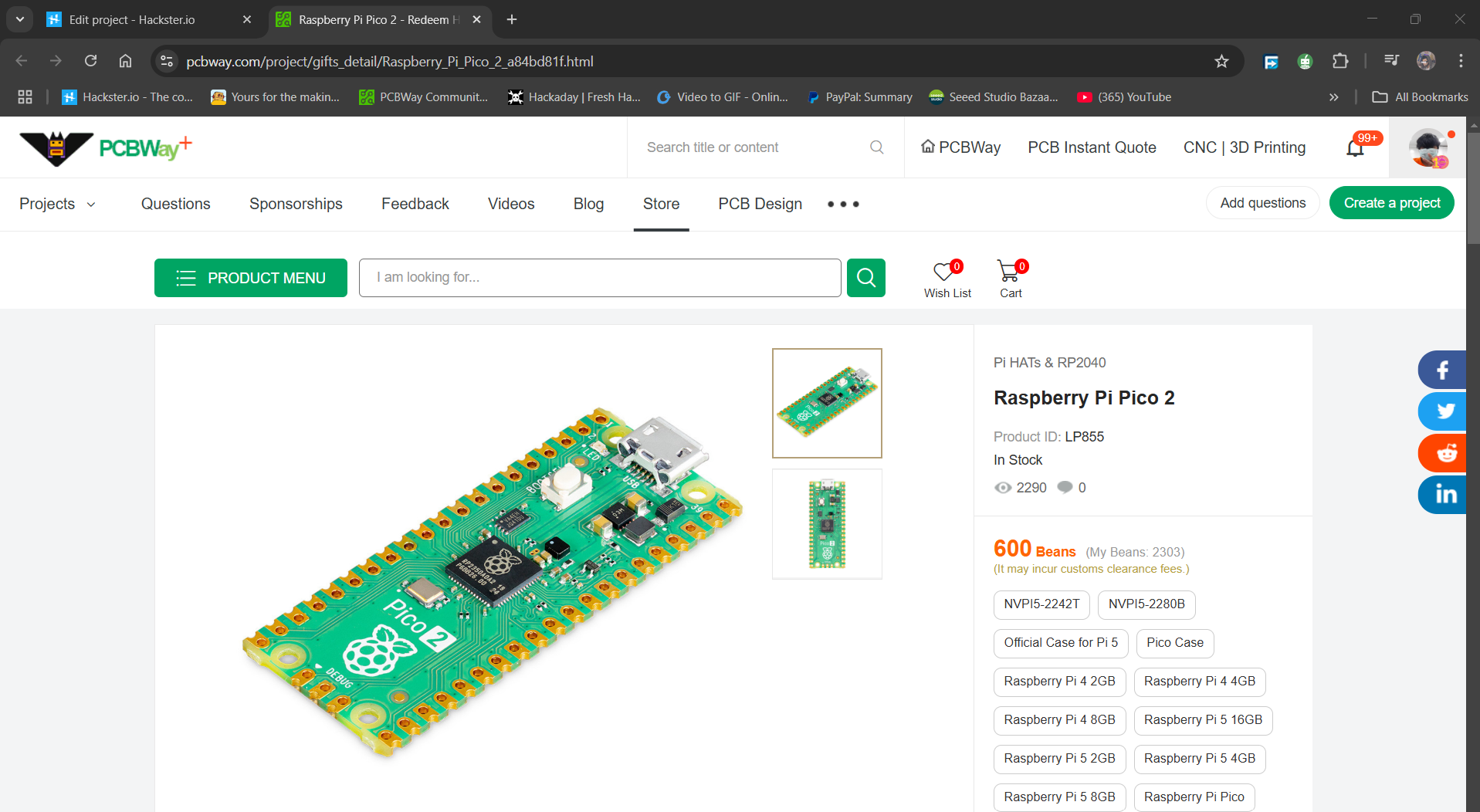

PCBWAY Giftshop

As for sourcing the GY906 temperature sensor along with PICO 2 we used in this project, we got them from PCBWAY's Giftshop.

PCBWAY gift shop is an online marketplace where you can get a variety of electronics modules and boards for their genuine price, or you could use the PCBWAY currency, which is called beans.

You get beans after ordering something from PCBWAY as reward points, or you can also get them by posting any project in the PCBWAY community.

Also, PCBWAY is organizing a PCB badge-making competition to mark their 11th anniversary, inviting designers and makers to showcase their creativity by designing badges that celebrate the company's legacy and envision a bold future. Participants must incorporate the elements "PCBWay" and the number "11" in their designs and can use PCB, PCB+SMT/THT, or PCB+3D printing techniques. Submissions can be posted in the comments, emailed, or shared on social media with the hashtag #PCBWay11BadgeContest.

Prizes include cash, PCBway coupons, and free prototyping services for all qualifying entries.

You guys can check out PCBWAY if you want great PCB service at an affordable rate.

Arnov Sharma

Arnov Sharma

Lithium ION

Lithium ION

ToniTheAxe

ToniTheAxe