First session :

We have grouped together with Charlotte and Lily and Kana. And worked on a project dedicated to Yousra who has mobility problems with her hands (especially fingers).

Two weeks before we talked to her and she said that some students already gave her a prototype for an object to be able to cut food. But this prototype is not “aesthetic” and the protection is not cleanable and finally the magnet uses too much space (and so the protection is not smooth).

So first we were thinking about making the knife less large to prevent it from taking too much space, so we put the finger holes directly on the handle. But after testing it ourselves we understood that it was a mistake because the knife was no longer inclined as it was.

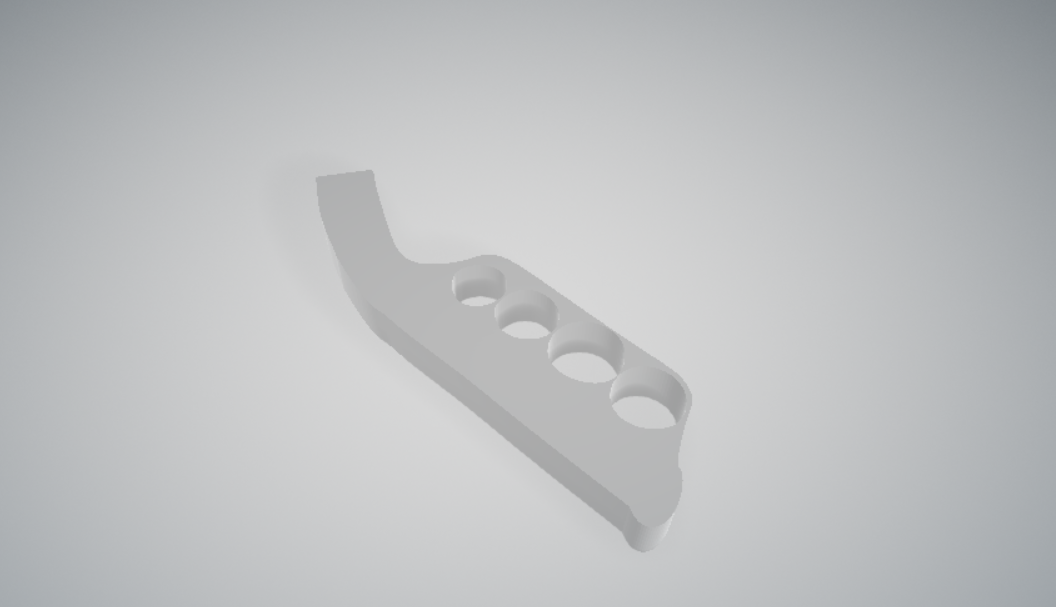

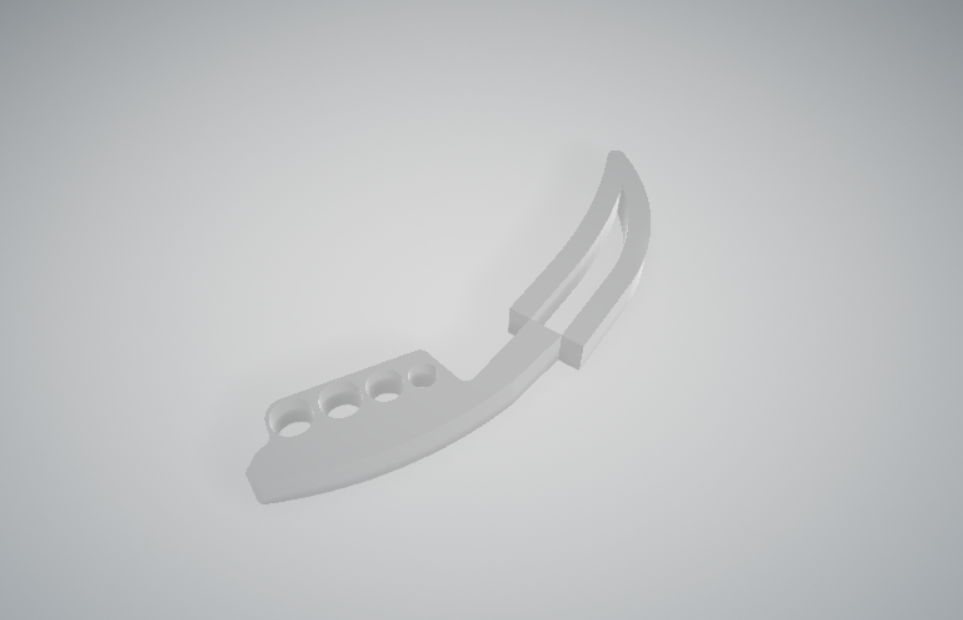

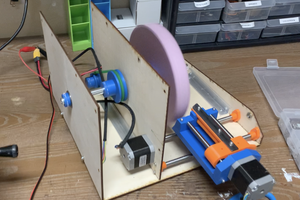

Here is the prototype :

And we were losing the “goals” of the project (that is the issues that we talked about at the beginning).

So we came up with those ideas :

-Using a 3D printer to redo the protection so that the material can be cleanable. We need now to think about which material to use and also know how to use the 3D printer.

We tested if some materials in the lab could be “burned” to make the surface look smoother.

And actually it is possible but complicated, depending on which material we use.

-Putting the magnet inside the protection.

-Making the handle in wood (Yousra likes it). We searched for which wood to use (a light one).

Second session :

For the first time, we learnt how to use FUSION AUTODESK to modelize a 3D system.

Each of us tried to modify the knife.

Third session :

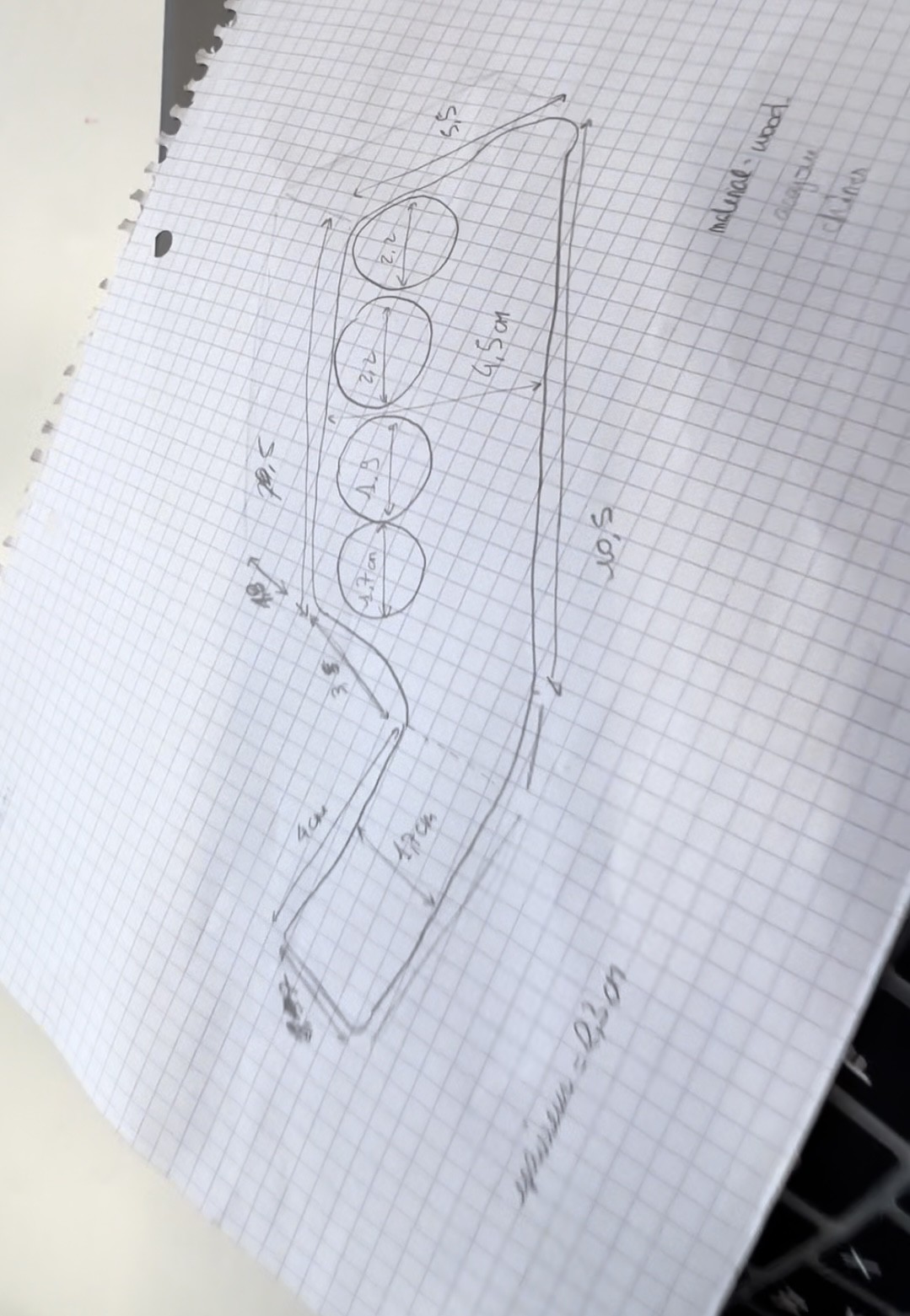

We mesured the knife and modified them to make the new prototype. And so, we searched in the lab with Dimitri the right wood to use for the handle. And we draw the prototype above the wood.

Fourth session :

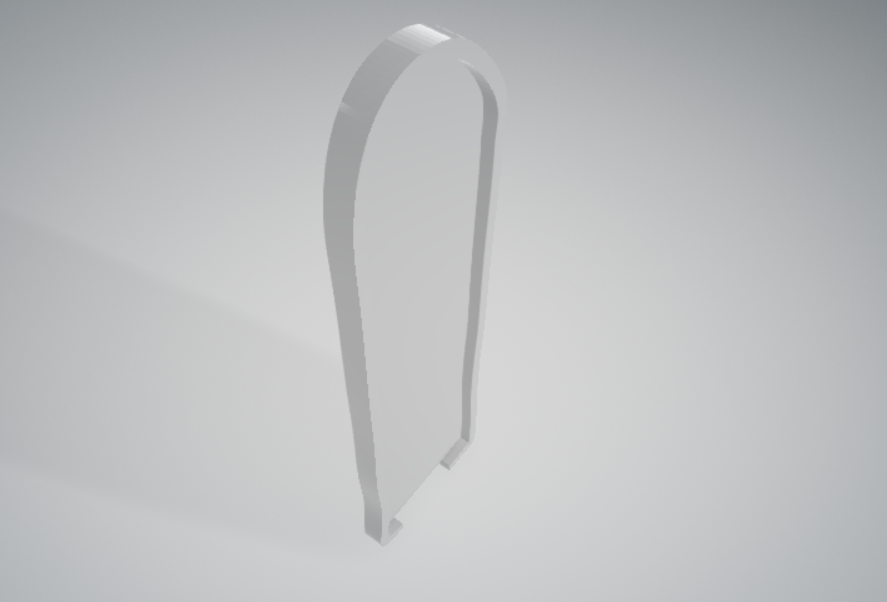

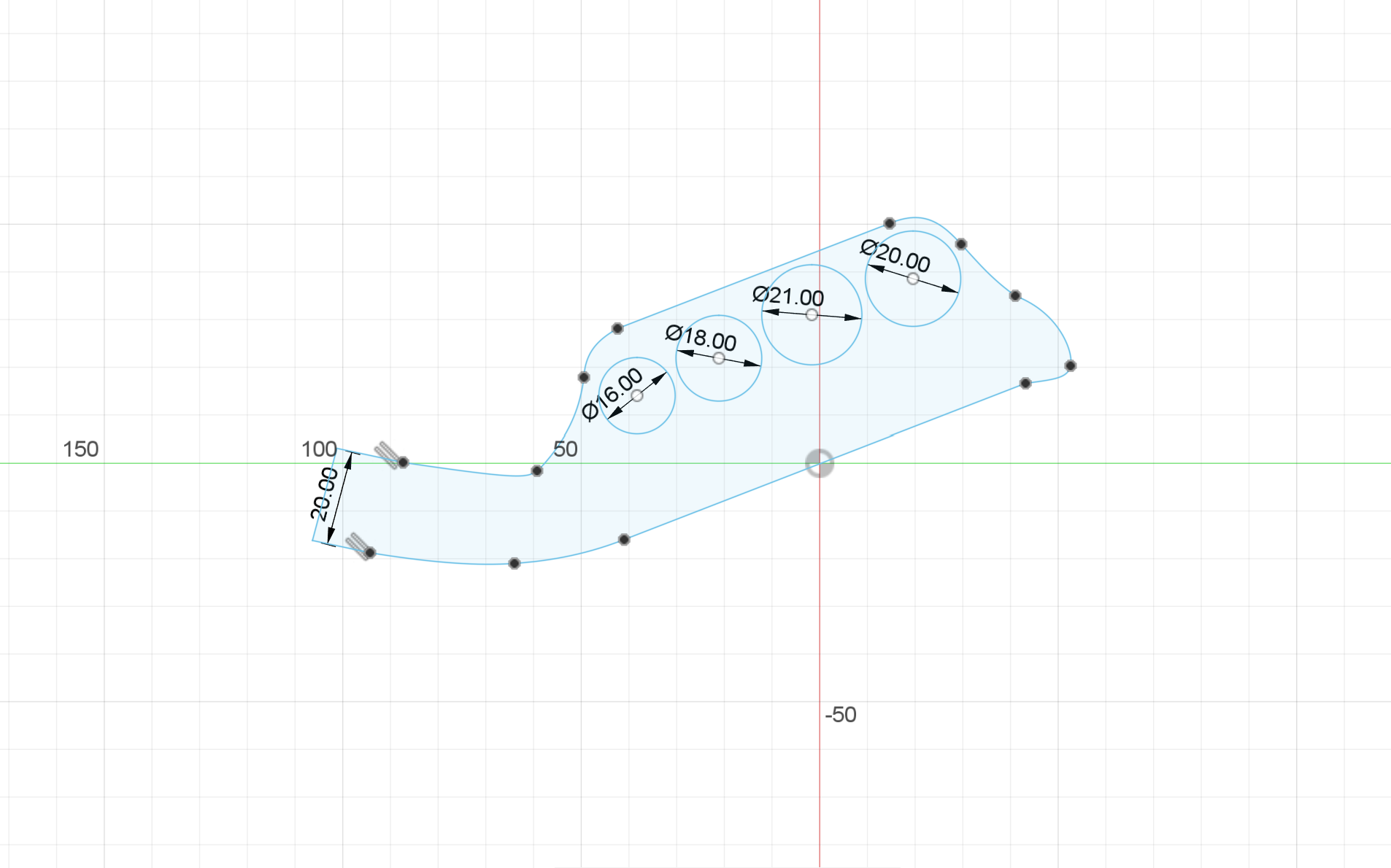

First of all, we used FUSION to do the handle : We imported the picture and put it into scale and we used 'lines' to put point and used the 'tangent' to curve the side of the handle.

We used the laser cutting to see how the handle would be. And we talked to Yousra about it. She agreed so now we need to make it into wood.

kana.ito-russo

kana.ito-russo

nurdamla

nurdamla

aurelie.pavy

aurelie.pavy

Jamie Matthews

Jamie Matthews