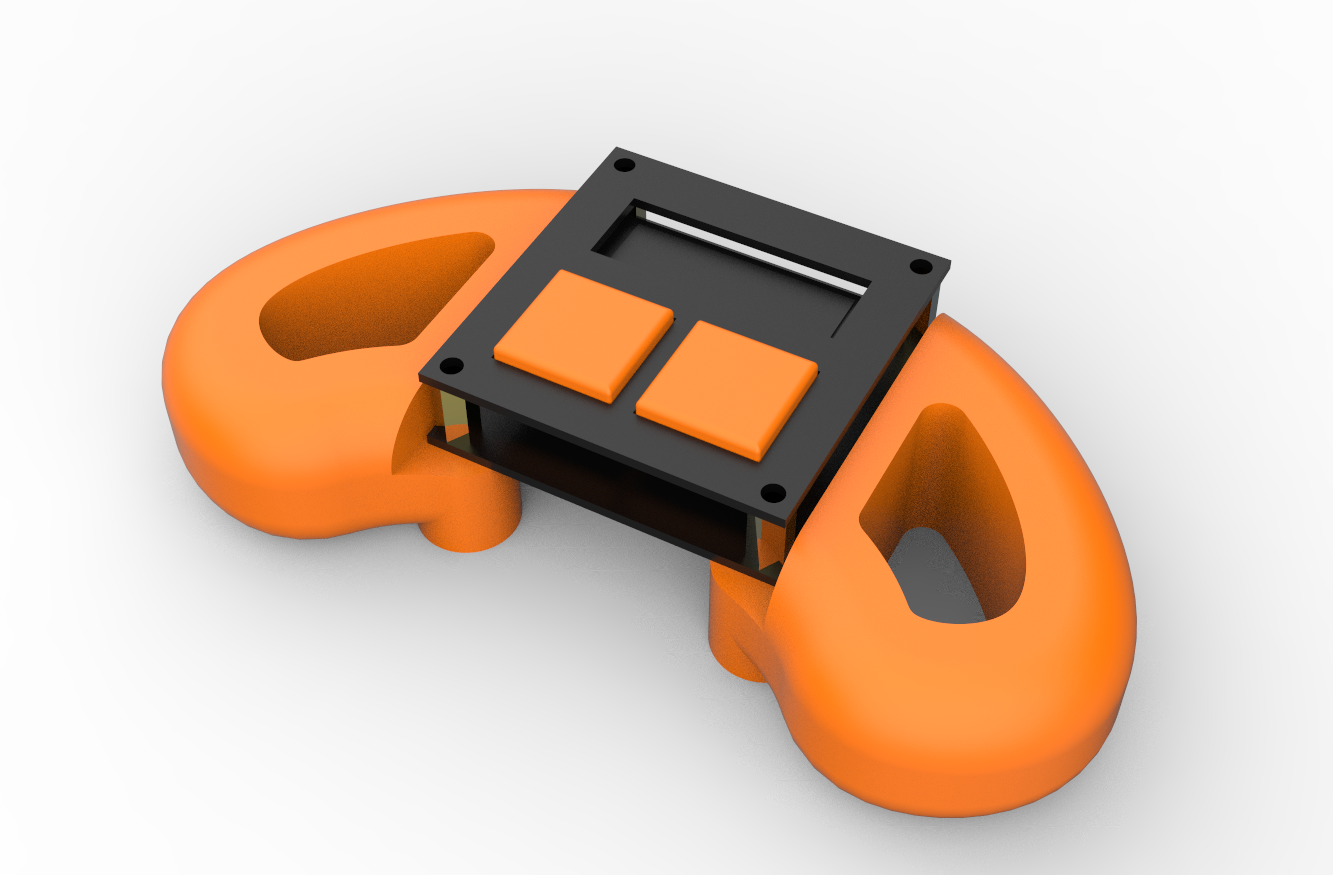

This project is based on our previous Macropad project's PCBs, which is essentially an ESP32 breakout with two buttons attached to the microcontroller and a 124x32 OLED display. Modeled two handles and transformed the project into a fully functional PONG gaming console.

3D Model

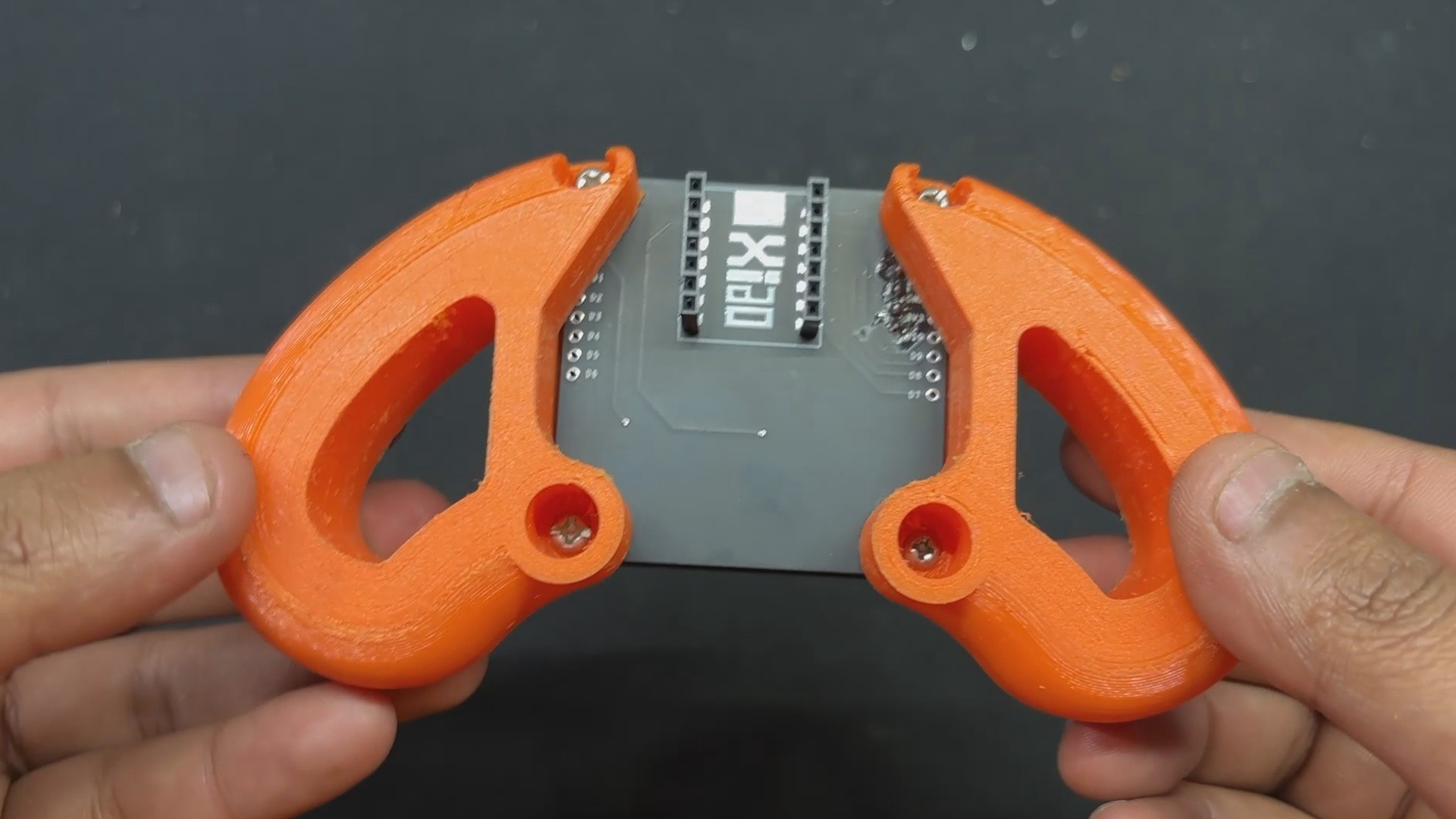

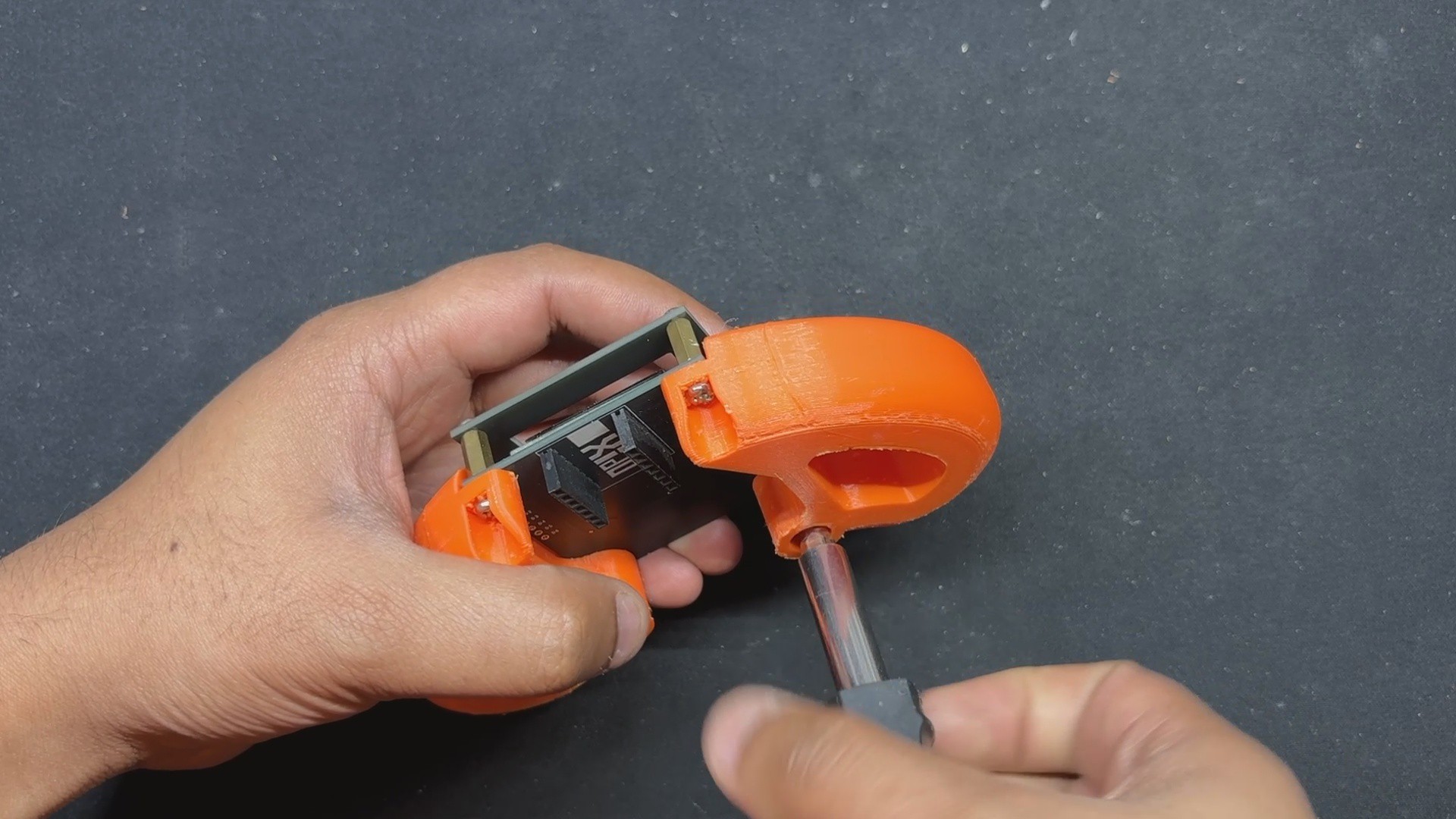

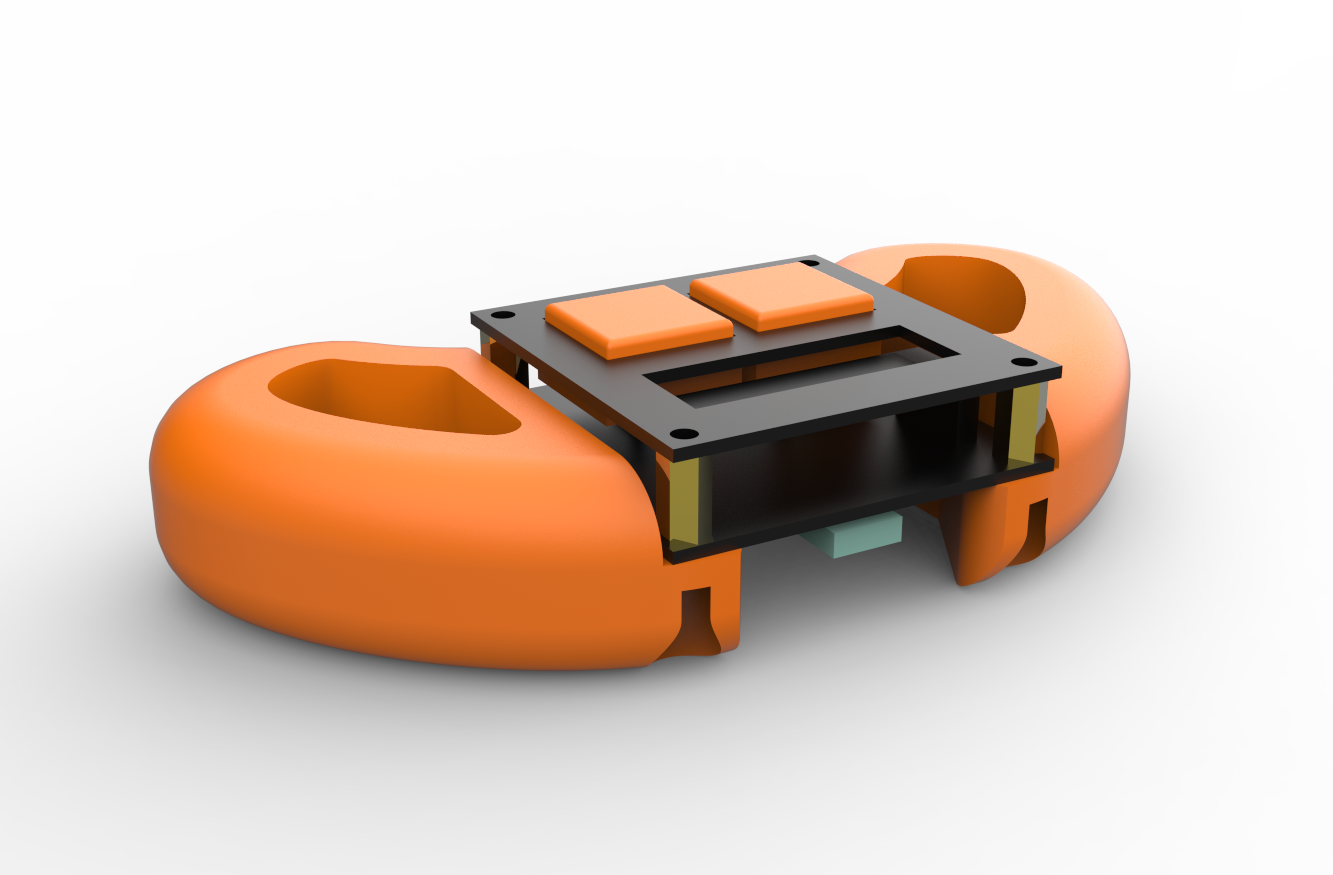

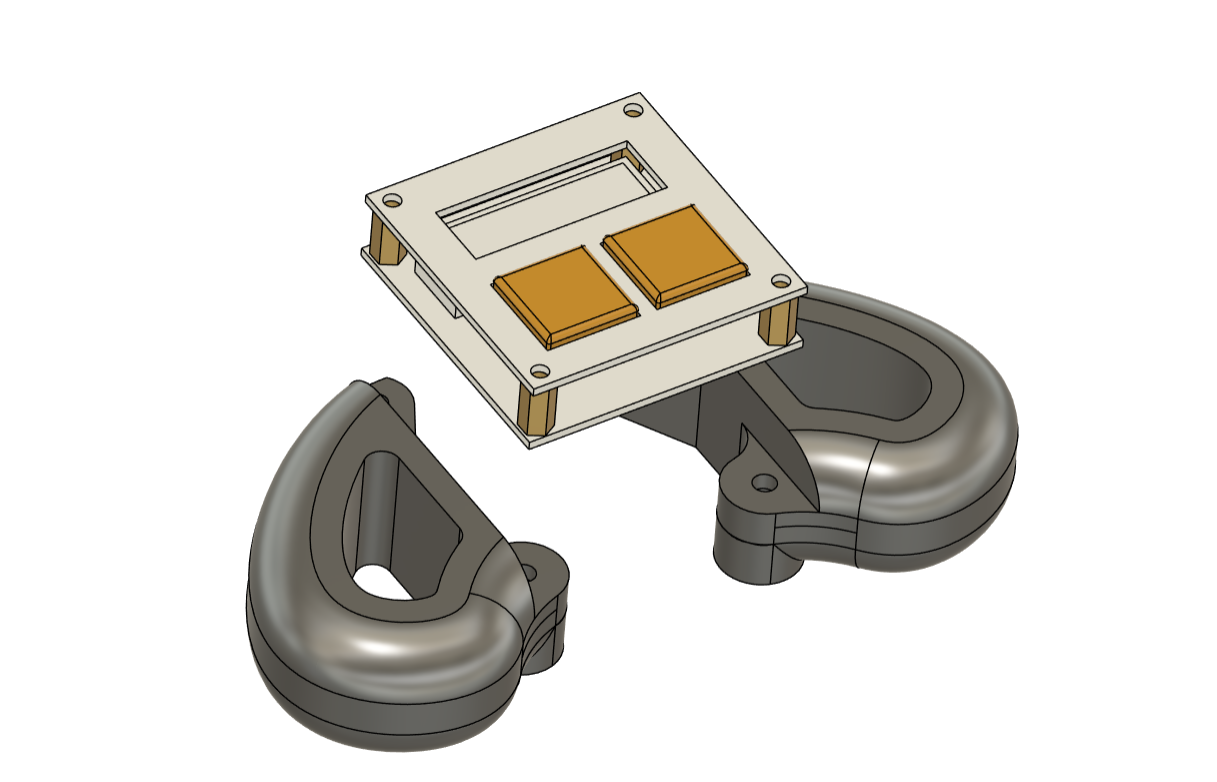

The 3D model of this project consists of the original Macropad Assembly, which is made up of three layers: the top layer, the middle layer, and the bottom layer, all of which are joined together by M2.5 PCB standoffs. For this design, we deleted the bottom layer and just kept the top and middle layers.

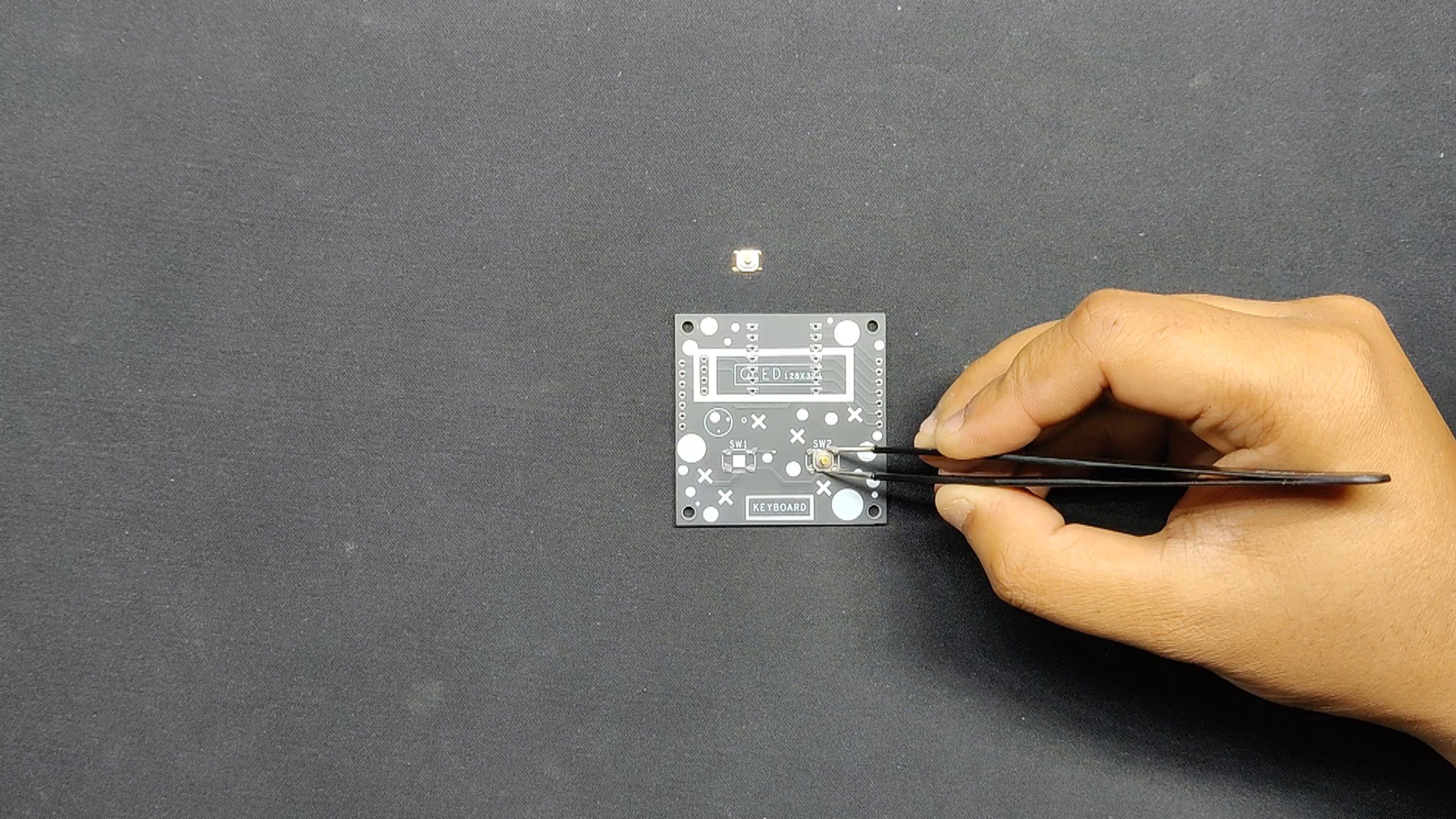

The middle layer holds all of the electronics components, which include the ESP32 microcontroller board, an SSD1306 OLED screen, and two SMD push buttons. The top layer serves as an aesthetic cover for the midlayer, which has three openings: one rectangular aperture for the OLED display and two switch actuators.

The switch actuators are modeled and positioned between the top layer's switch opening slots and the SMD switch knob.

Because the switch actuator and switch knob are positioned perfectly on top of each other, squeezing the switch actuator also presses the knob, resulting in a switch click.

To hold this console ergonomically, we took inspiration from the Sega Genesis Controller and designed two grip parts secured using M2.5 PCB standoffs used to connect the two PCB layers.

After finishing the model, the switch actuators and handgrip were exported as mesh files and 3D printed with orange PLA and a 0.4mm nozzle.

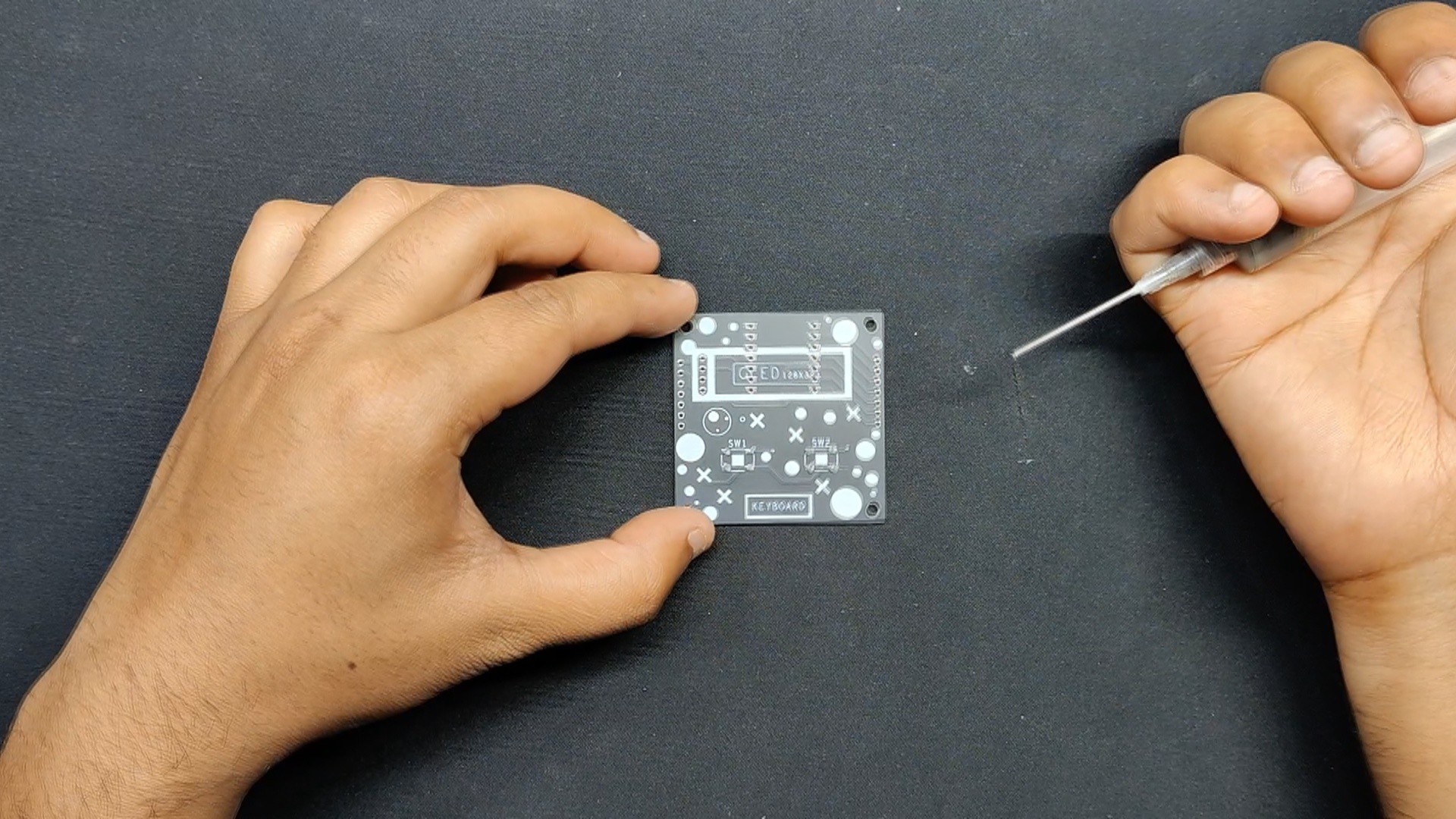

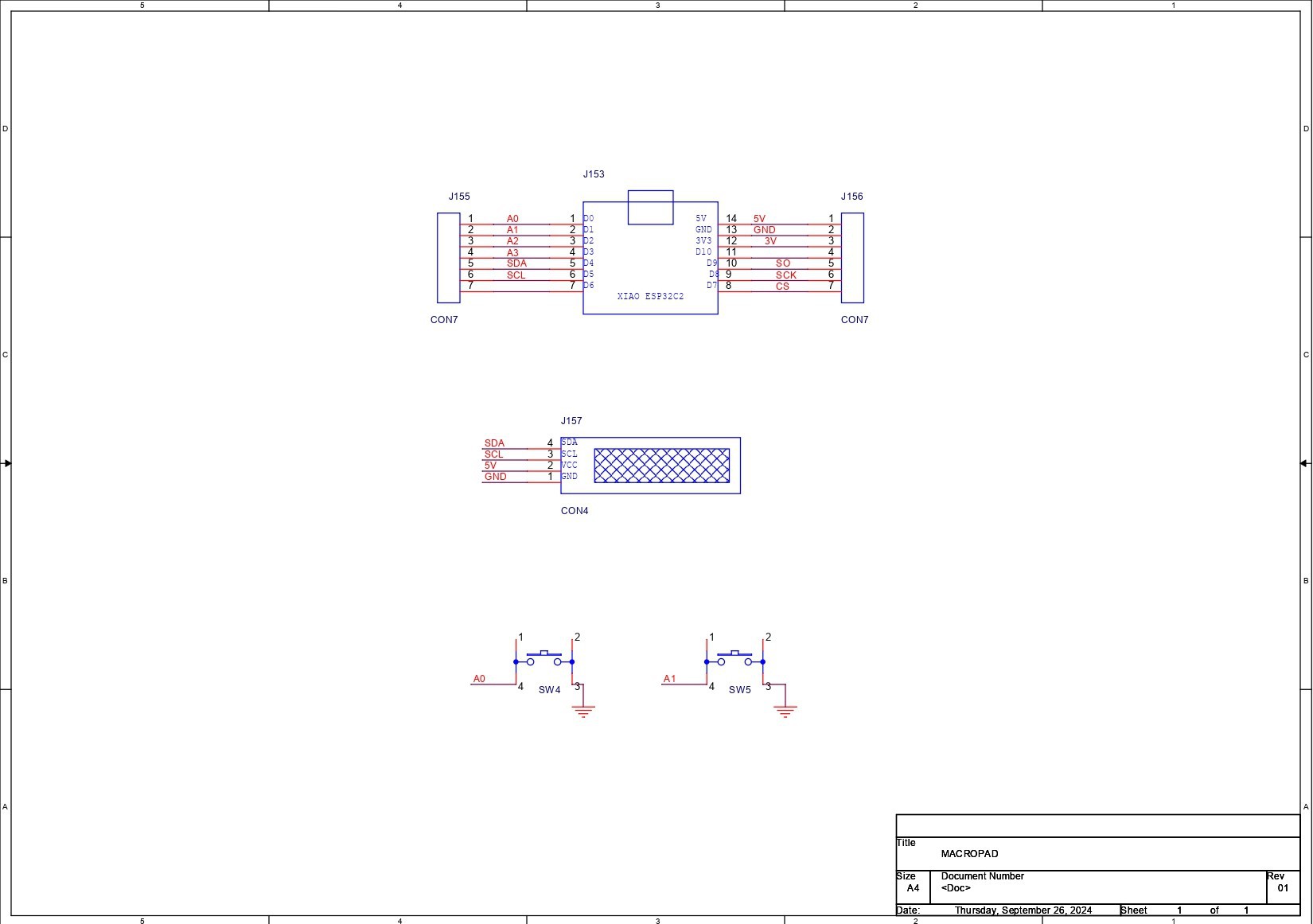

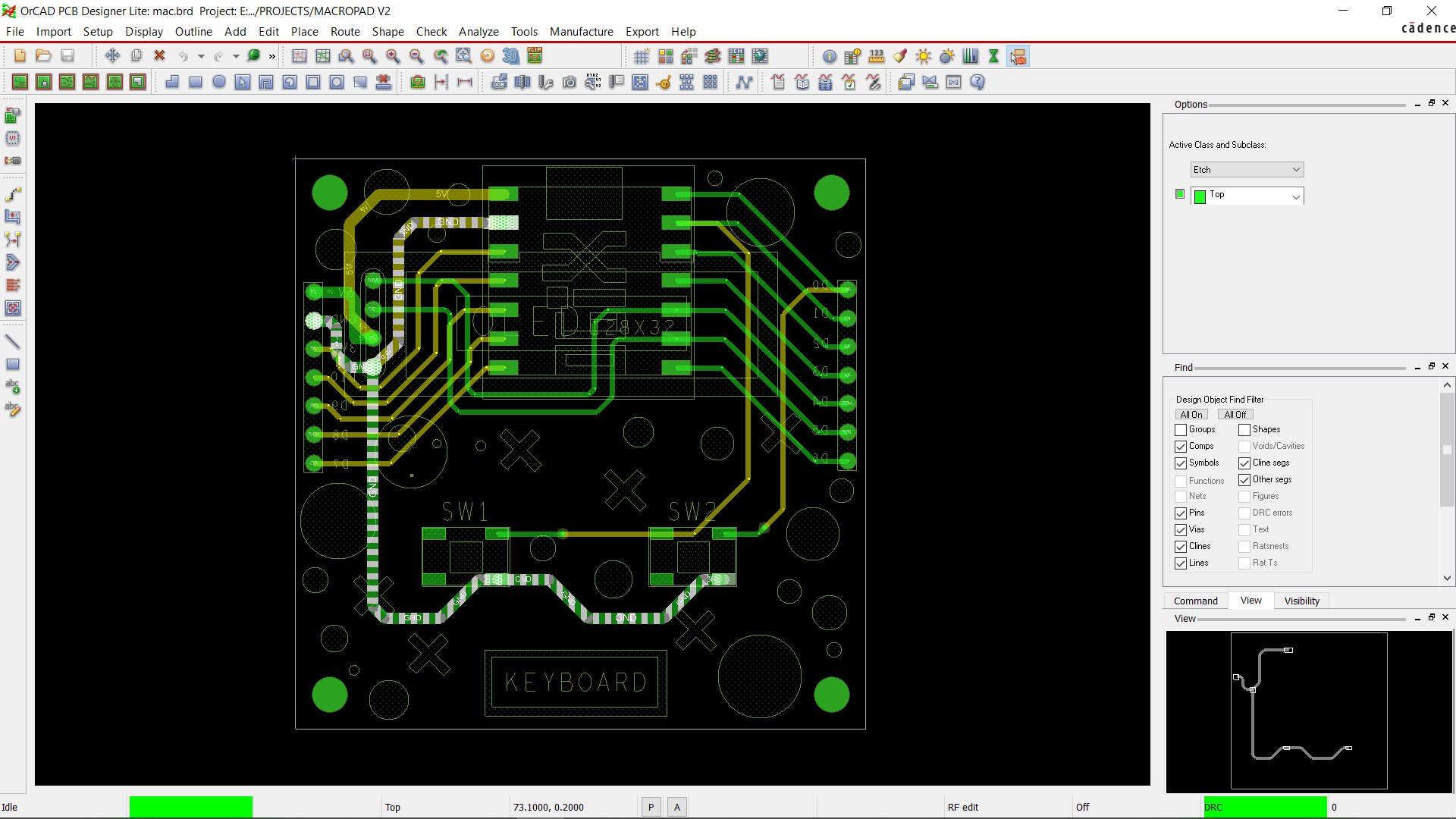

PCB Design

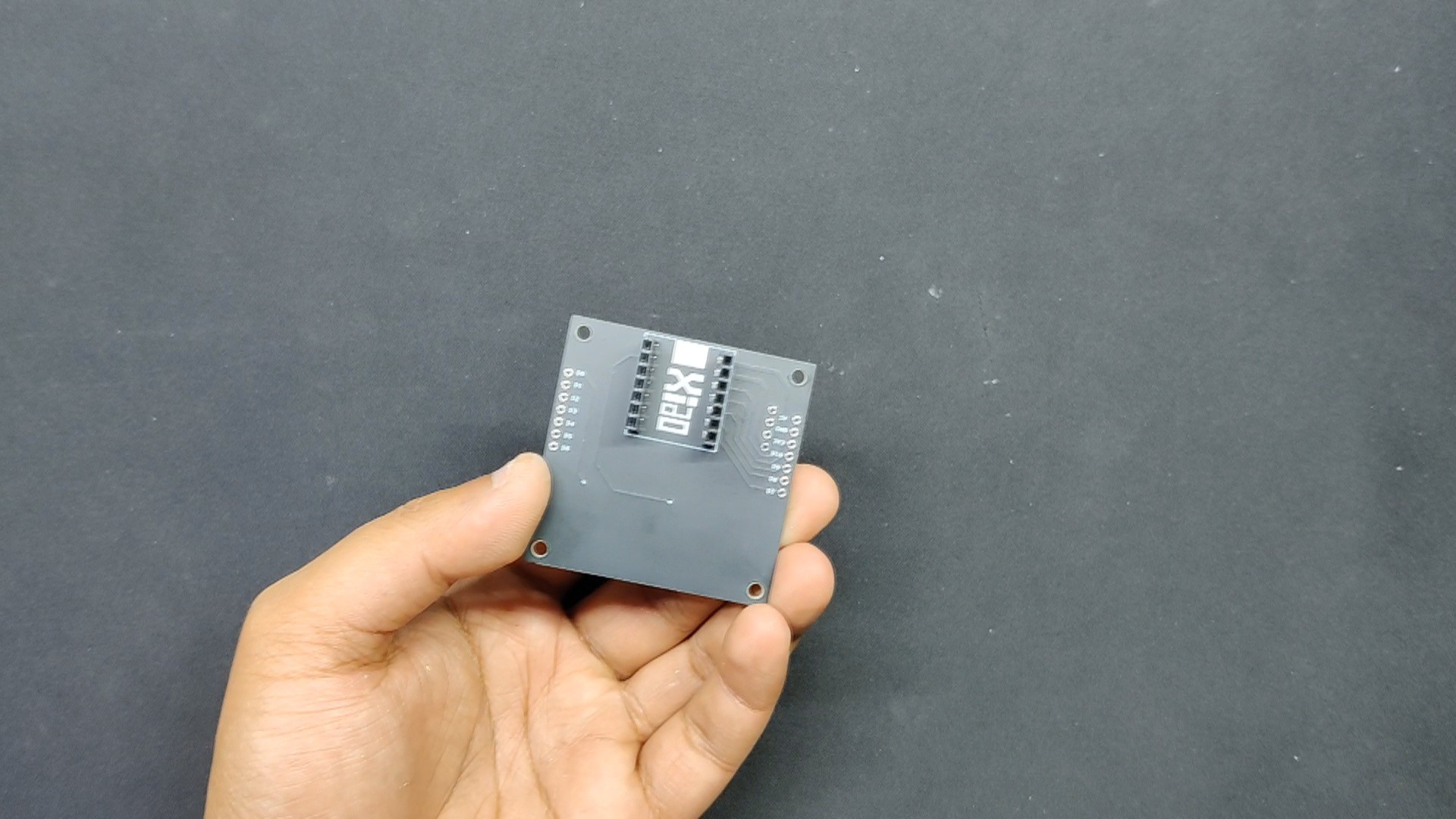

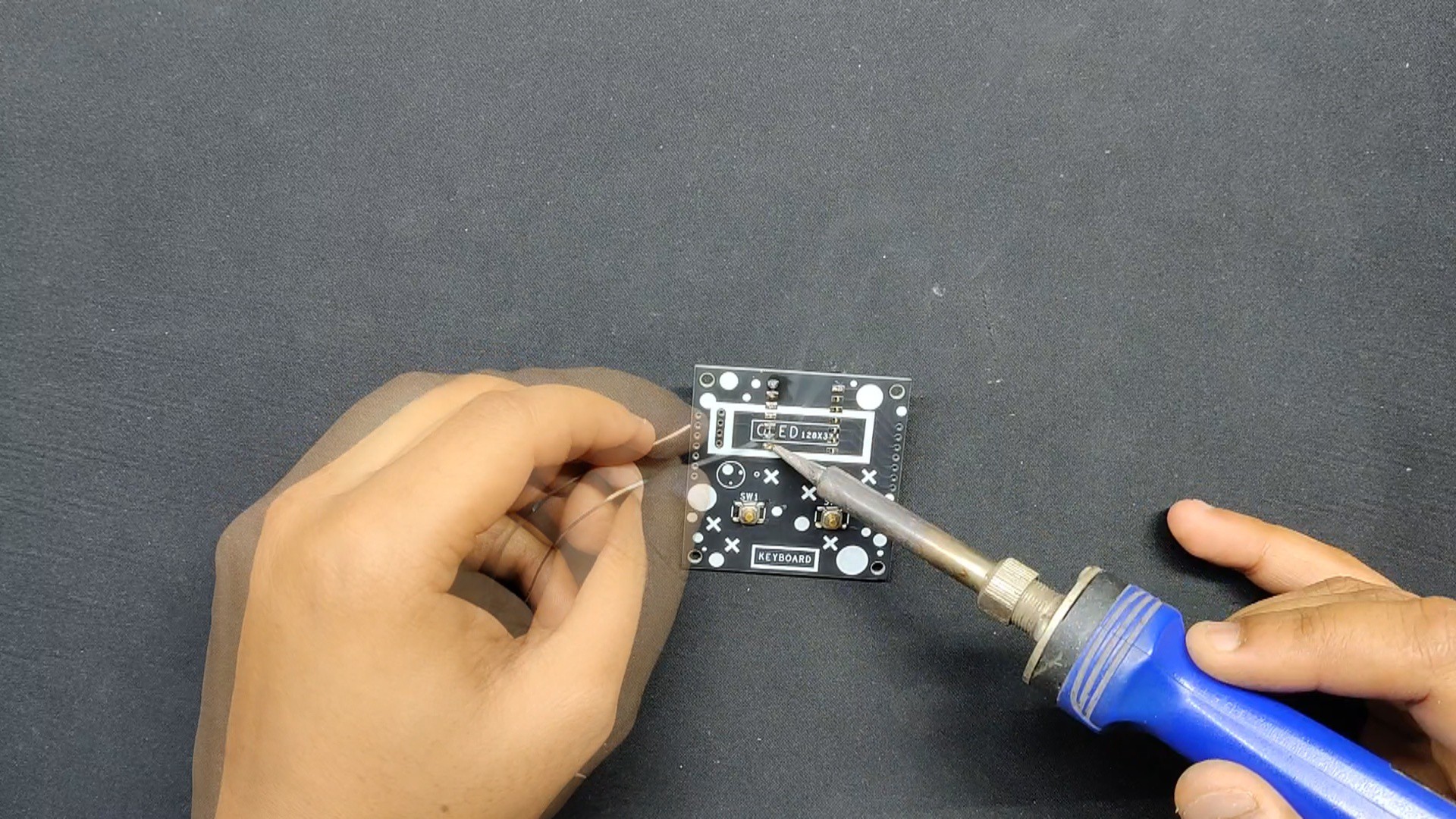

The PCB design for this project was straightforward; we utilized an XIAO ESP32 board with D0 and D1 I/O pins to connect it to two SMD switches. We also combined an OLED display with the microcontroller, which is connected to the XIAO's I2C ports.

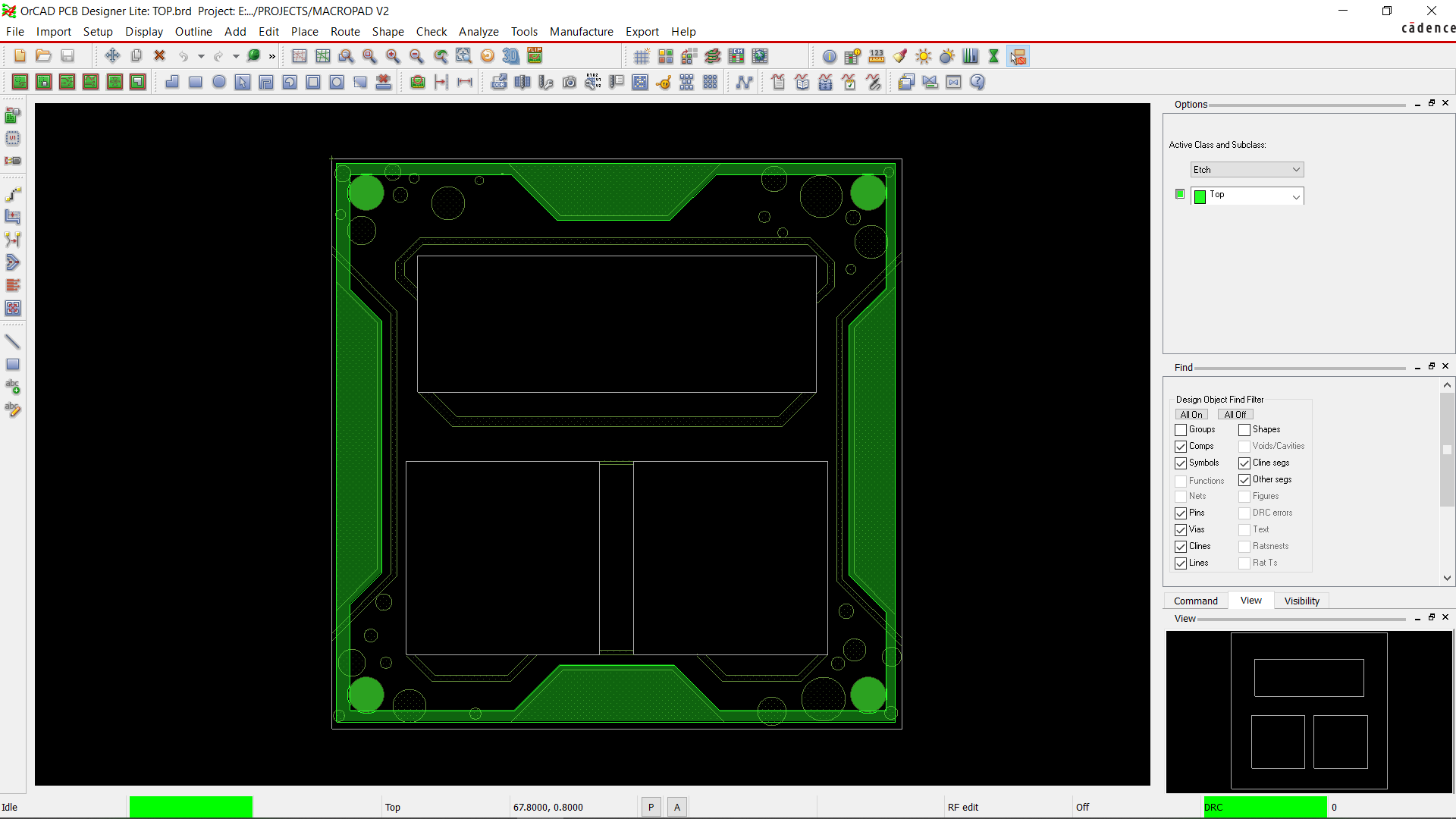

We created two boards based on the model's dimensions: the top layer board and the middle layer board. Because the midlayer board and the bottom layer share the same form and mounting holes, we will use it for the bottom layer.

HQ NextPCB Service

After completing the PCB design, we export the Gerber data and send it to HQ NextPCB for samples.

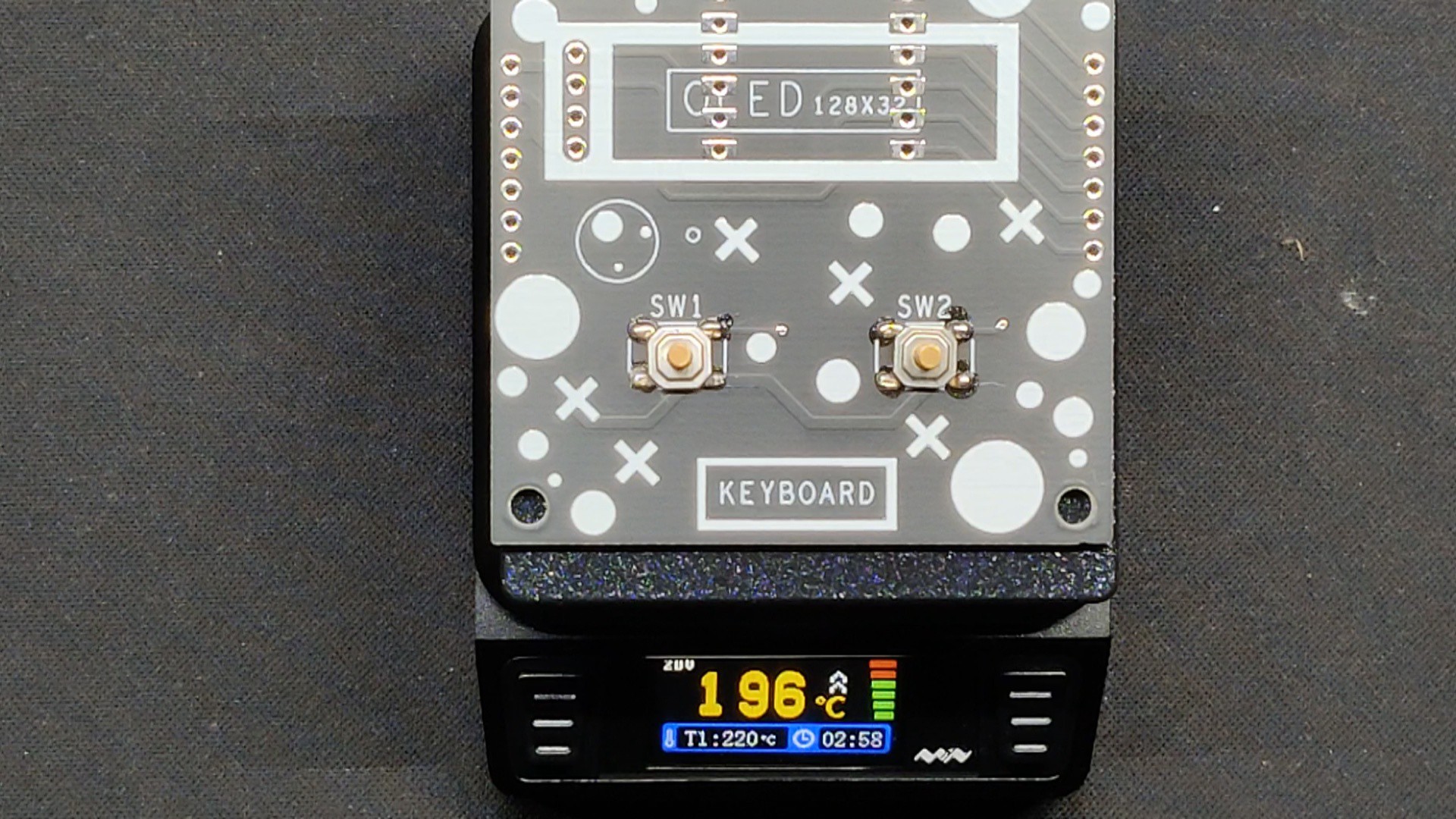

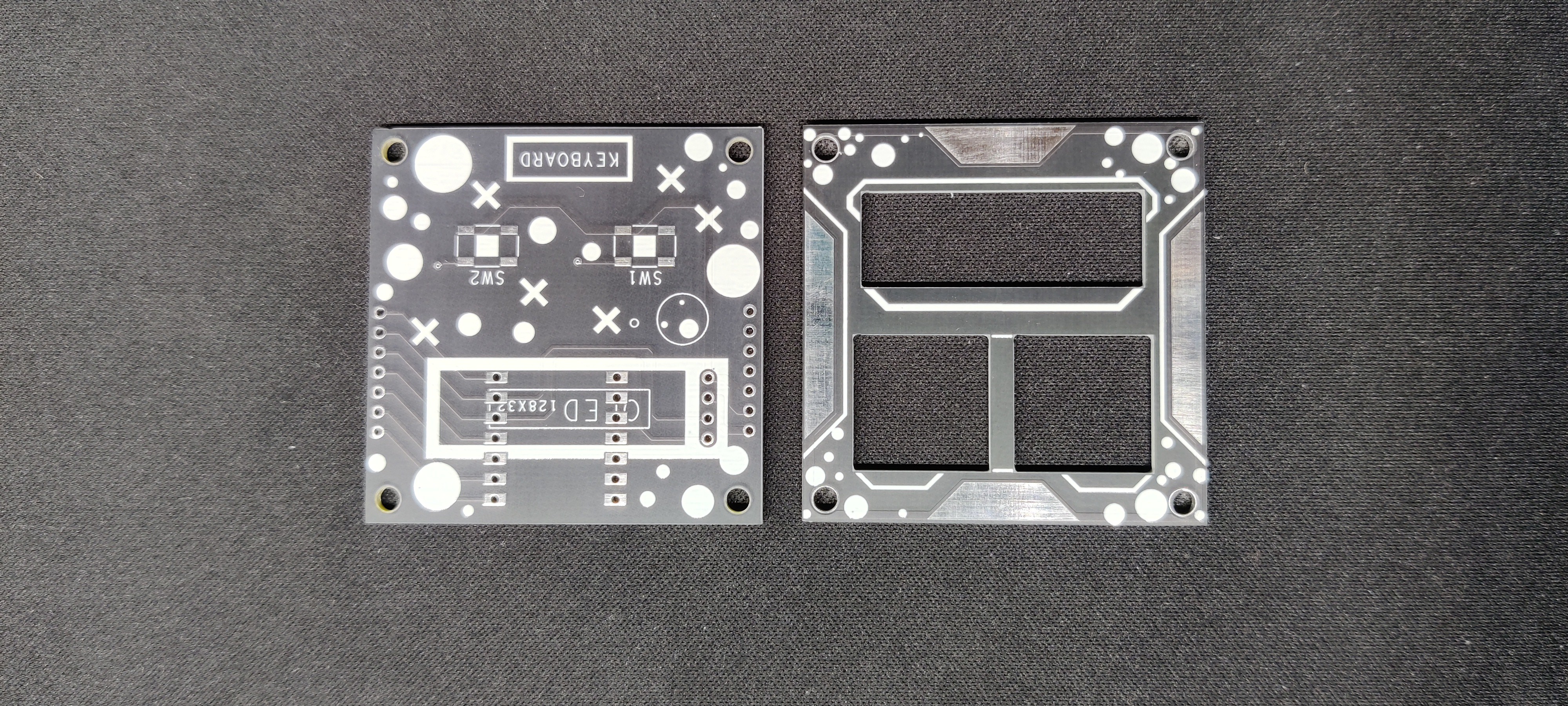

For the mid and top layer boards, two orders were placed. We ordered a black Solder mask with white screen for the mid- and top-layer boards.

After placing the order, the PCBs were received within a week, and the PCB quality was pretty great.

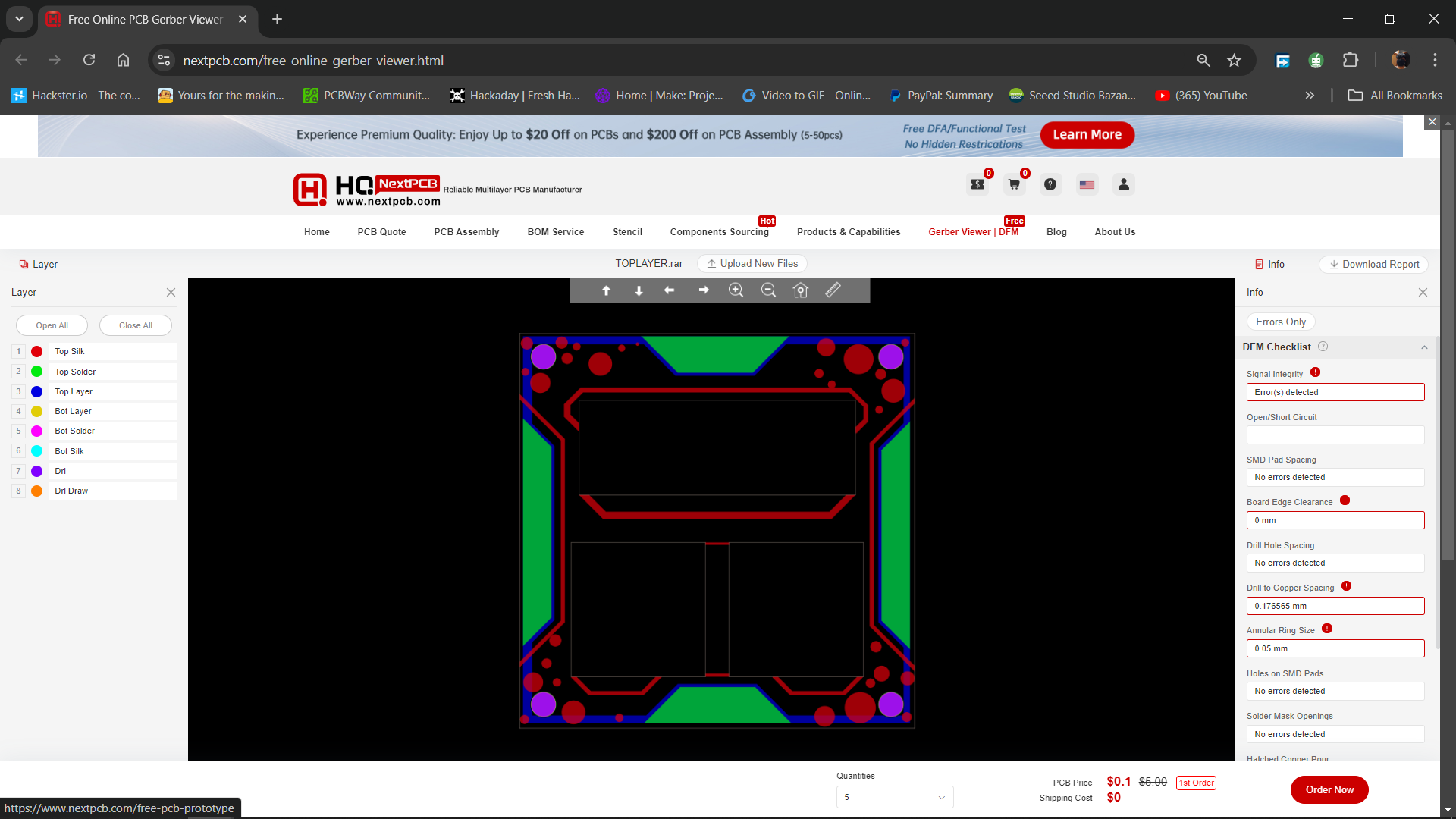

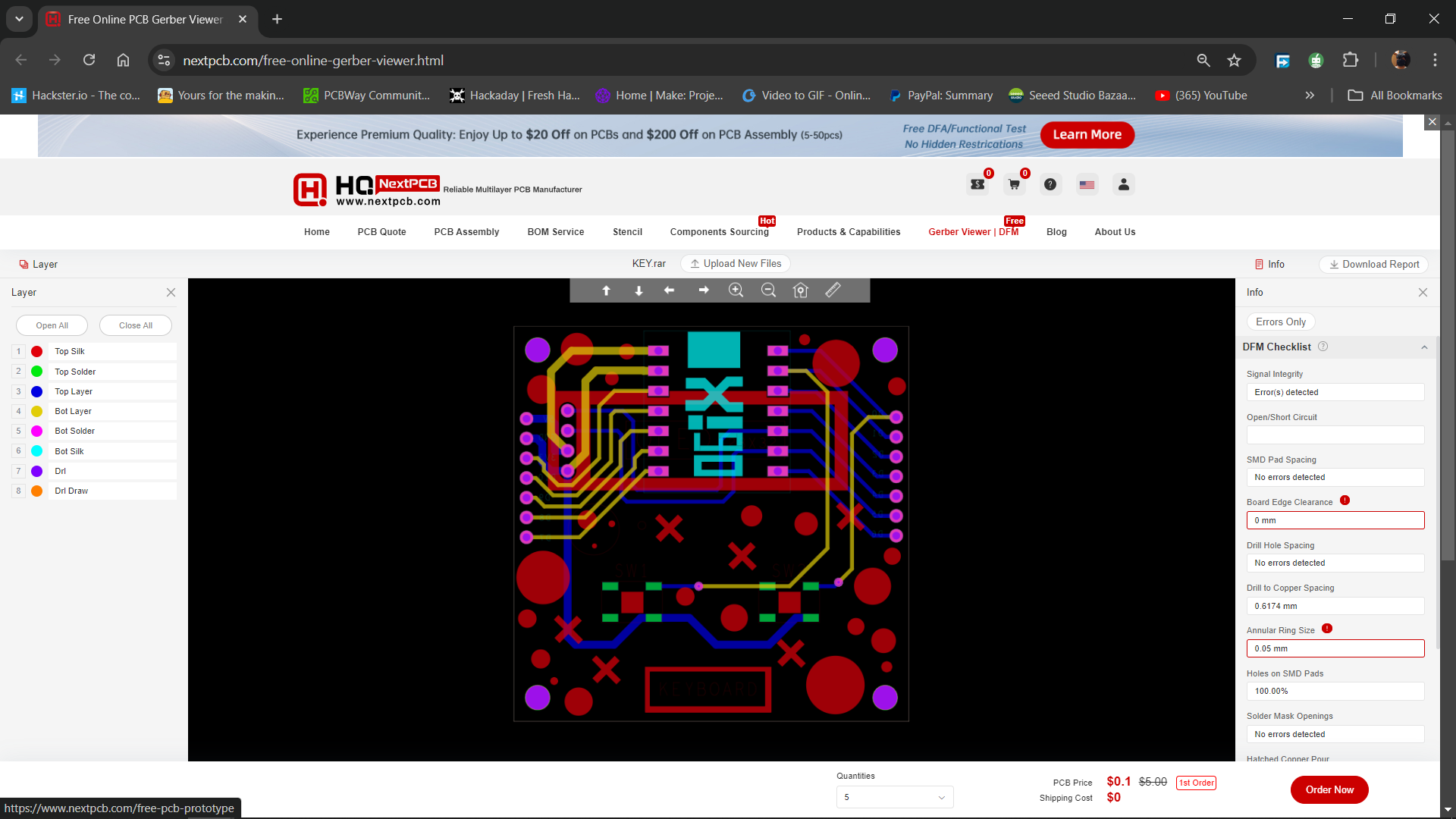

In addition, I have to bring in HQDFM to you, which helped me a lot through many projects. Huaqiu’s in-house engineers developed the free Design for Manufacturing software, HQDFM, revolutionizing how PCB designers visualize and verify their designs.

Take advantage of NextPCB's Accelerator campaign and get 2 free assembled RP2040-based PCBs for your innovative projects.

https://www.nextpcb.com/blog/rp2040-free-pcba-prototypes-nextpcb-accelerator

This offer covers all costs, including logistics, making it easier and more affordable to bring your ideas to life. SMT services can be expensive, but NextPCB is here to help you overcome that hurdle. Simply share your relevant project, and they'll take care of the rest. Don't miss out on this amazing opportunity to advance your tech creations!

HQDFM: Free Online Gerber Viewer and DFM Analysis Tool

Also, NextPCB has its own Gerber Viewer and DFM analysis software.

Your designs are improved by their HQDFM software (DFM) services. Since I find it annoying to have to wait around for DFM reports from manufacturers, HQDFM Is the most efficient method for performing a pre-event self-check.

Here is what online Gerber Viewer shows me. Would not be more clear. However, for full function, like DFM analysis for PCBA, you need to download the software. The online version only provides a simple PCB DFM report.

With comprehensive Design for Manufacture (DFM) analysis features, HQDFM Is a free, sophisticated online PCB Gerber file viewer.

It provides insights into advanced manufacturing by utilizing over 15 years of industry expertise. You guys can check...

Read more » Arnov Sharma

Arnov Sharma