I removed the exhaust headers from the engine last night, after battling with rusty nuts and bolts under the car. Managed to get them apart by drilling a hole at an angle through the seized nut and bolt. After working through various drill sizes I was able to break the bolt with a hammer and chisel.

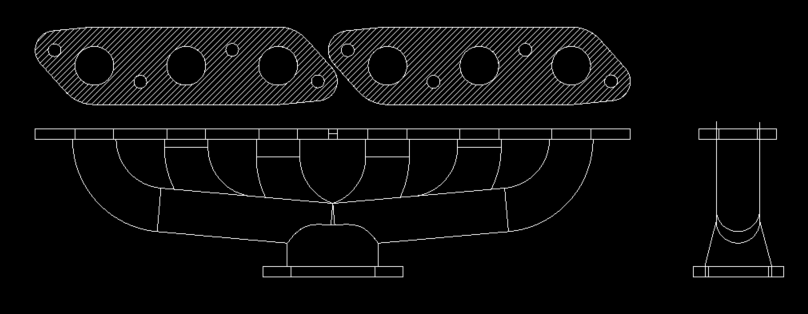

Once removed I could measure up the flange dimensions and design the exhaust manifold. I will be using hand rail weld in elbows from http://www.dciron.co.uk/welding-elbows/ . These are super cheap, only £1.40 a bend! The 33.7mm outside diameter bends are a good match for the engine exhaust port size.

Obviously messing about with the bolts took ages and I was working by

torchlight putting the car back together (with new bolts of course). I live in a flat on

a fairly upmarket London street. My neighbours think I am very unusual. Lots

of, 'mummy what is that strange man doing to that car?'!!!

Rory

Rory

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.