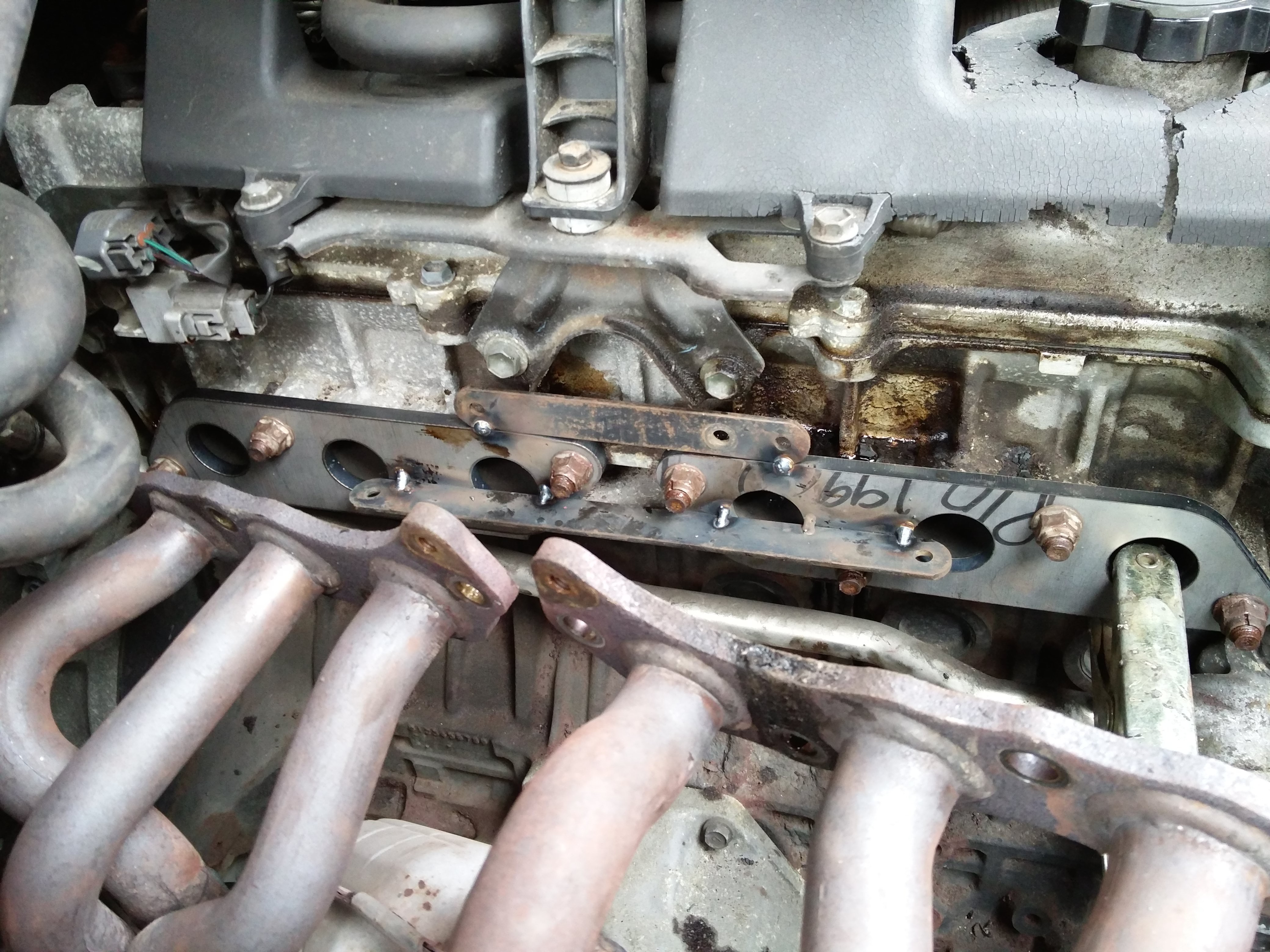

I removed the stock headers and checked the fitment of my laser cut flanges. Luckily the fit is spot on.

To keep the flanges flat while I am building the manifold (welding heat would distort them) I need to bolt them to some thick steel plate. To save complicated measuring to make sure they are in the right place relative to each other I tacked on some steel bar while they were bolted to the engine.

And here they are bolted to some 13mm thick L section:

Rory

Rory

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.