Please find all details inside the original GitHub repo.

Special thanks to Kezi, Kowalski, K3lite & Baobots for the efforts spent into debugging & flashing all the units during Camp.

And for going the extra mile and designing a custom case that solves many assembly issues, a very felt thank to k0bld.

The badge is higly experimental, it was designed as a very high risk blind shot at transparent flexible PCBs with dual-side assembly.

It turned out ok, but we did have some production issues, where the manufacturer baked a couple of panels too much, ending up all wrinkled - but still we managed to flash and use them!

Component Abuse Challenge 2025 entry summary:

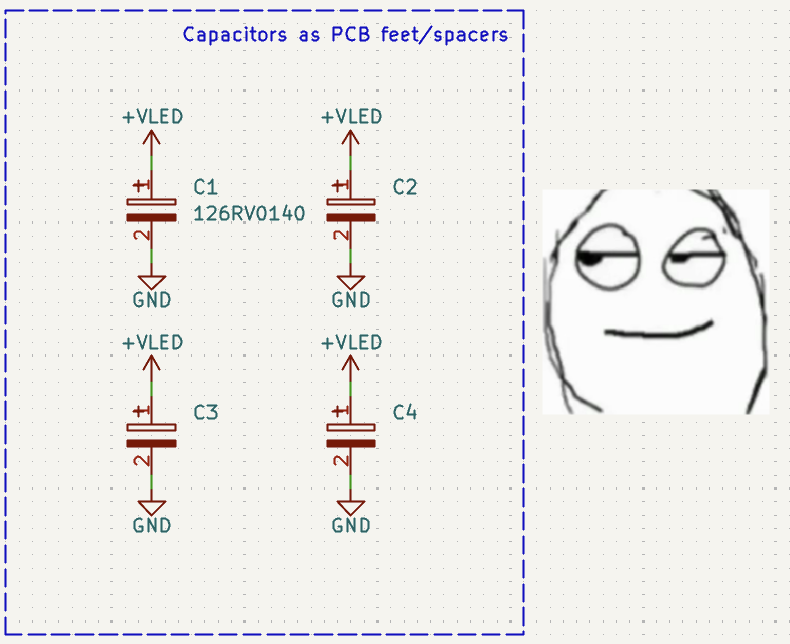

- Capacitors used as feet, while still decoupling the LEDs

- Resistors used as thickener for the Type-C connector

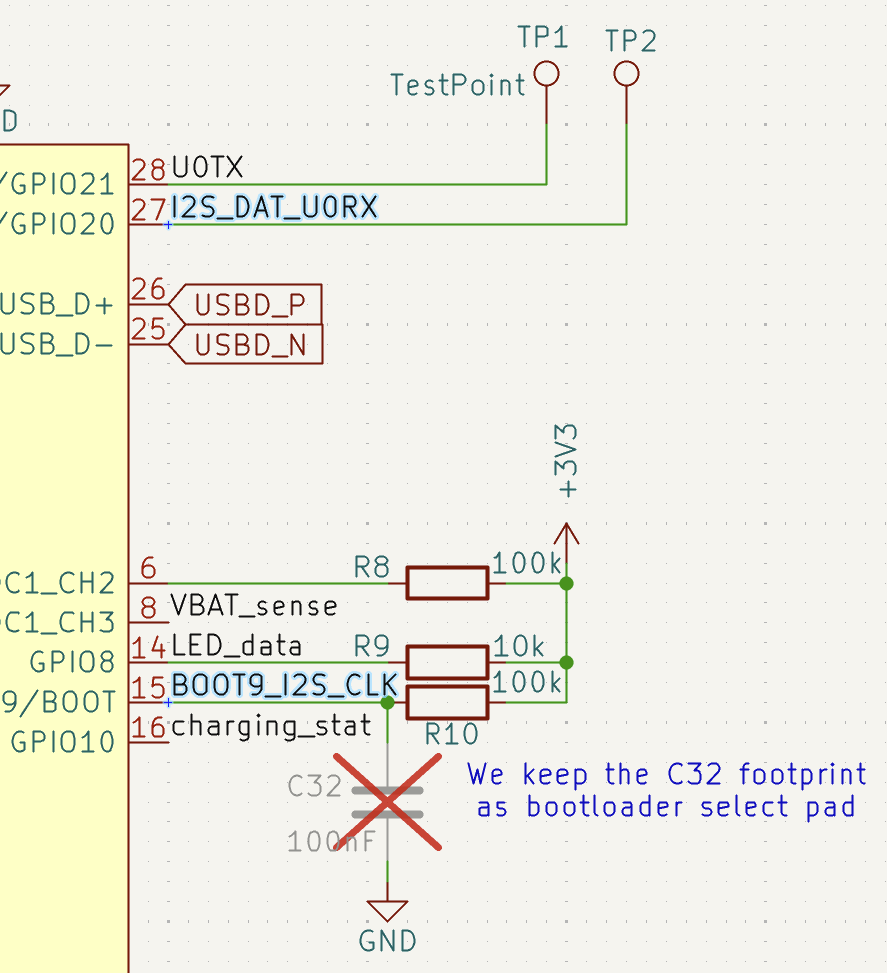

- i2s line shared with MCU bootstrapping pins

The badge has:

- An ESP32-C3 chip, the cheapest and smallest ESP with embedded flash.

- The TDK ICS-43432 i2s digital microphone, as it was the only one available for assembly at the time, works great!

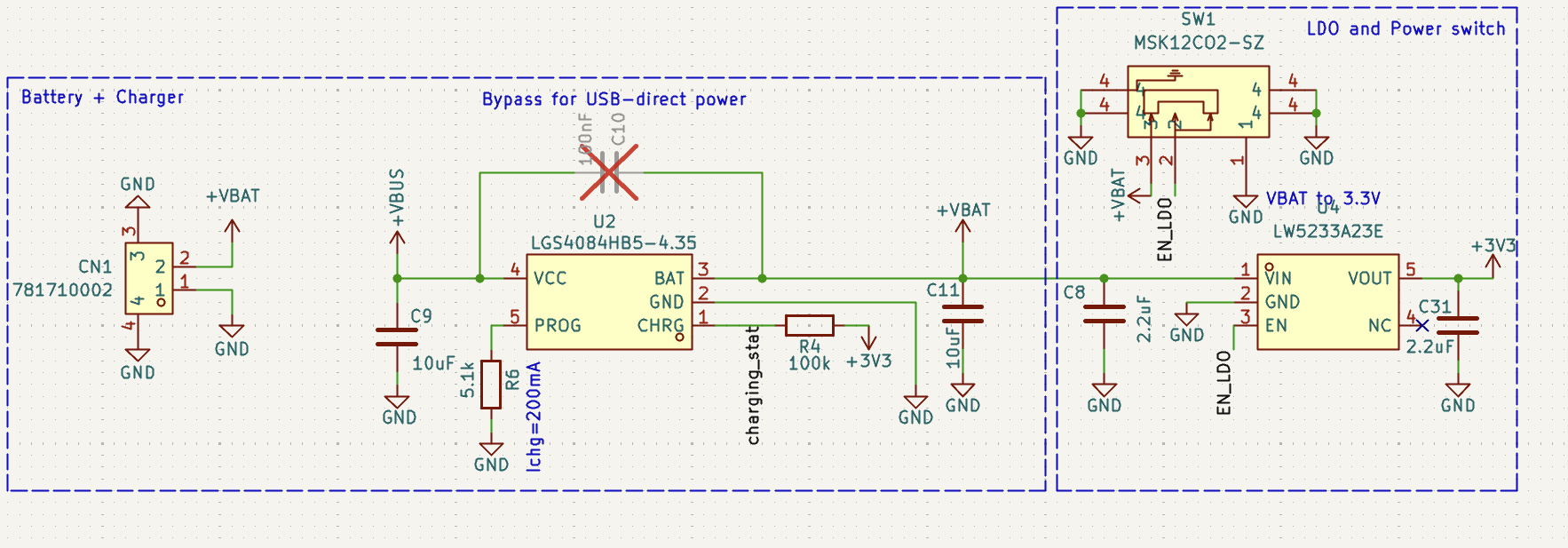

- A 4.35V li-ion battery charger.

- A custom made 4.35V, 500mAh battery with a Molex MXL connector, extremely energy dense 5.5(thick)x26x26mm shape.

- 4 hours of battery life with SoundReactive effects.

- Foldable, reversible, transparent, cool AF, flimsy USB Type-C flap acting as a male end.

- 42(!!) addressable 1x1mm super tiny WS2812 LEDs. Actually there are 43, but one is wired in parallel as we used it to test dual side assembly for tiny pads.

- The LEDs are powered straight from the battery, through an 87mOhm MOSFET, doubling efficiency compared to powering through the onboard LDO.

- Tiny (I'm not joking) chip antenna blasting 50 meters of Bluetooth. Luckily were we live we don't have the FCC.

- Battery voltage sensing that is enabled only when the LEDs are to avoid having any idle current discharging the battery on its own.

I've done some, somewhat clever trickery since I was out of gpios.

Can you tell I've had some fun designing the power path? You can see by yourself what it generally does, but essentially:

- I didn't want the battery to wear down while charging, so it's limited to 200mA (0.4C).

- I wanted the battery to be as isolated as possible once the power switch is flicked.

- I wanted to be able to bypass the battery in case someone was looking to power it over USB only as desktop lamp. Why the hell would you have a desk lamp with an embedded battery?

I was trying to have dinner when something flashed in my brain. Capacitors. Are. Feet.

jacopops

jacopops

Peter Lyons

Peter Lyons

Thijs Koppen

Thijs Koppen

deʃhipu

deʃhipu

Yohan Lasorsa

Yohan Lasorsa