I started out with a simple idea: make an open-source UV index measurement device that could fit on my keychain. There are a few other projects already out there that have the same functionality (see blog for links). This project scales the idea down, both in size and cost.

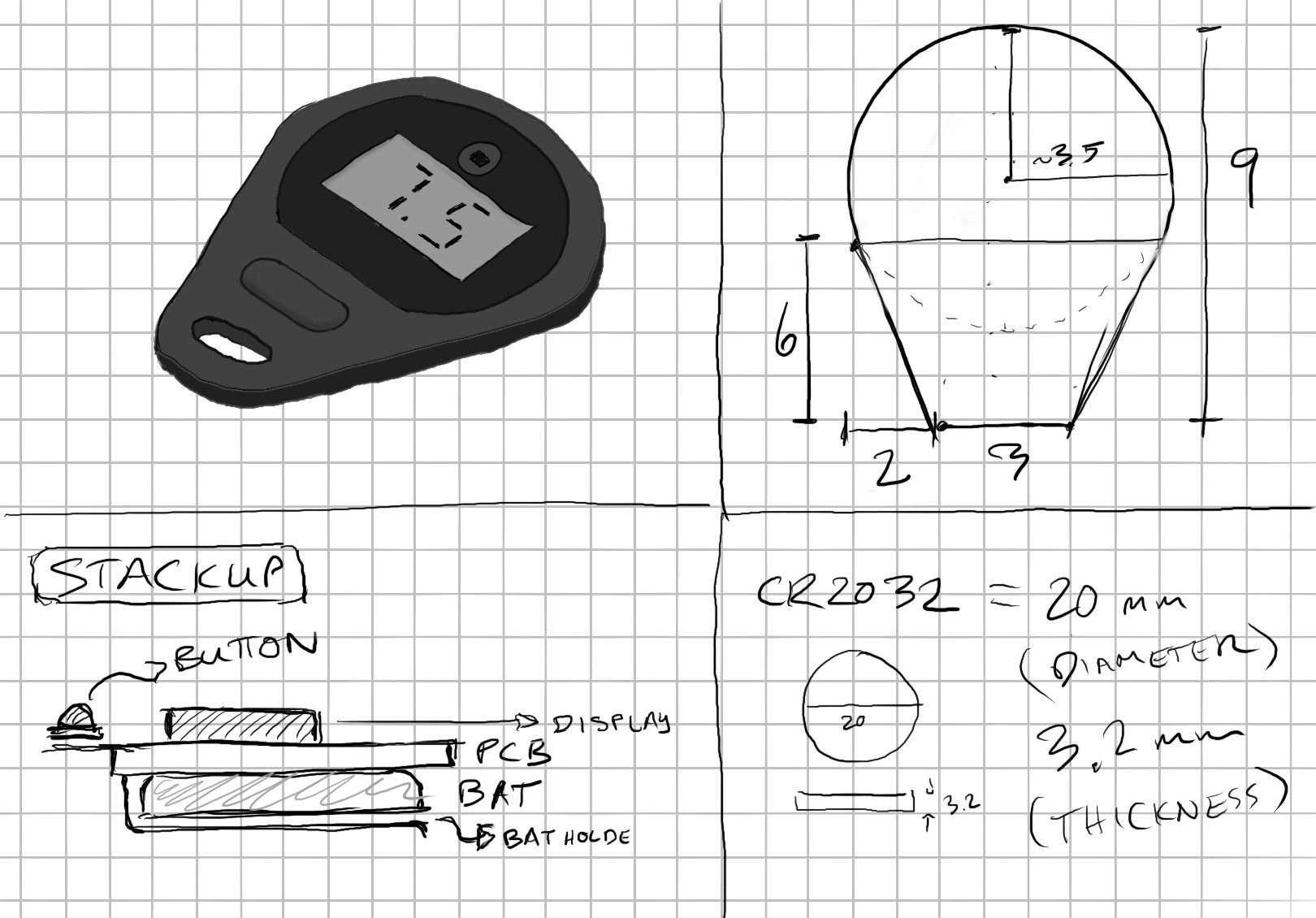

The initial concept looked like this.

First thing I did was make a clay dummy for size:

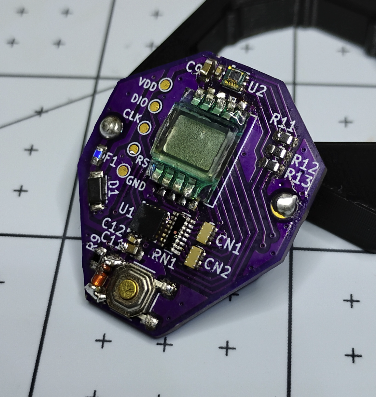

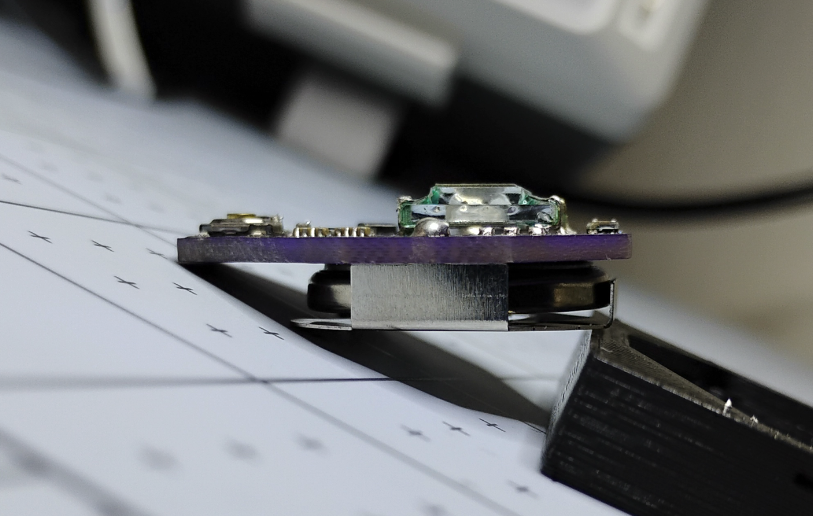

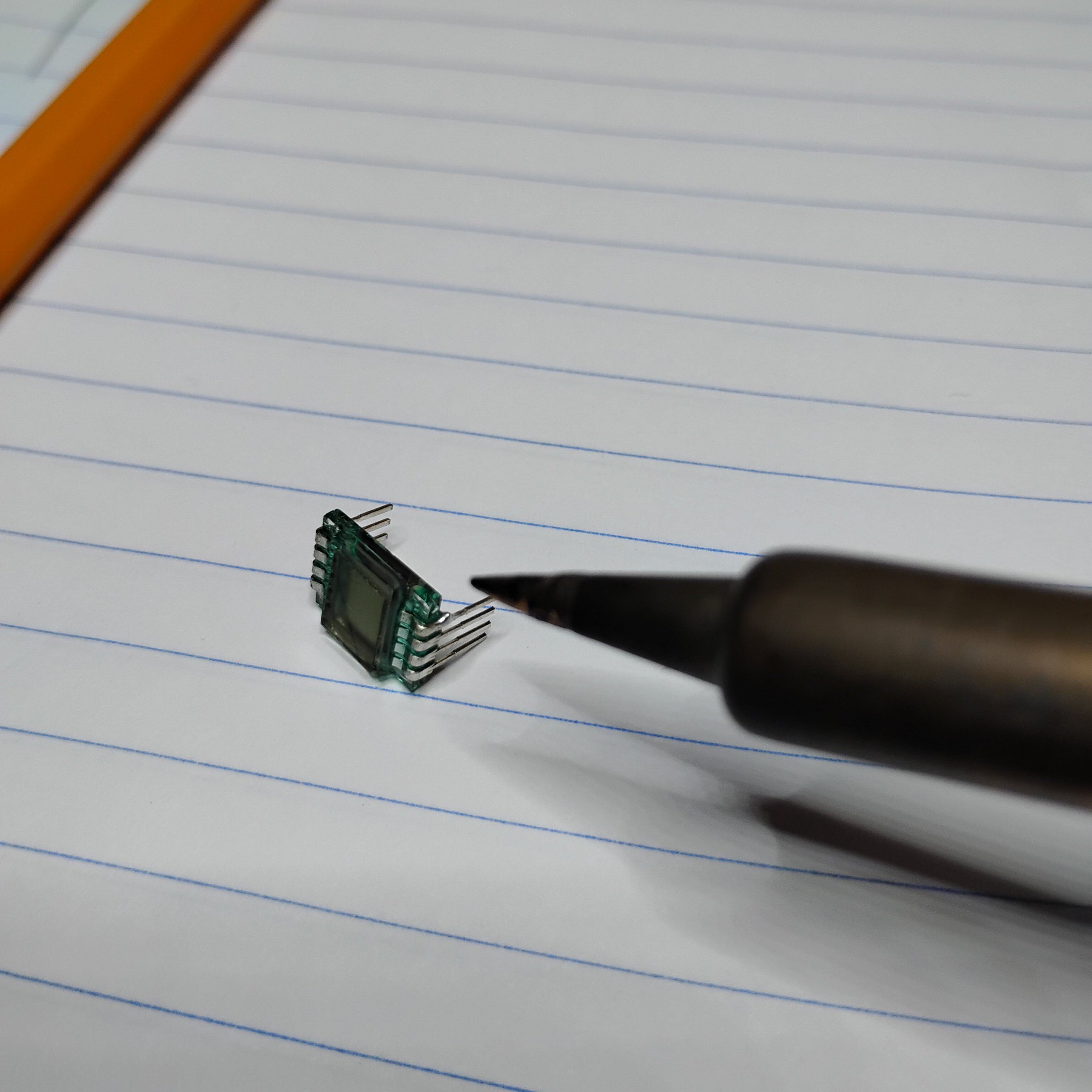

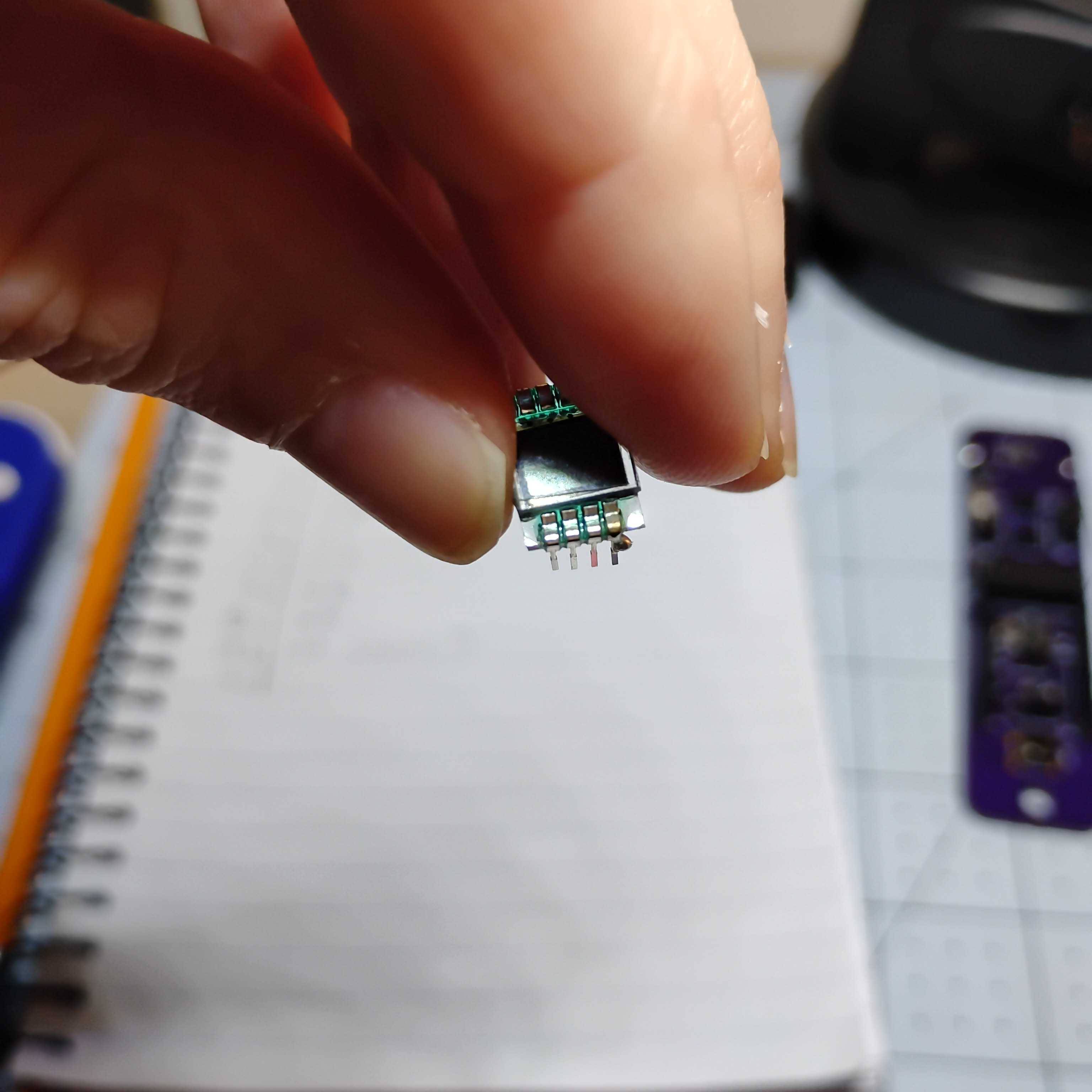

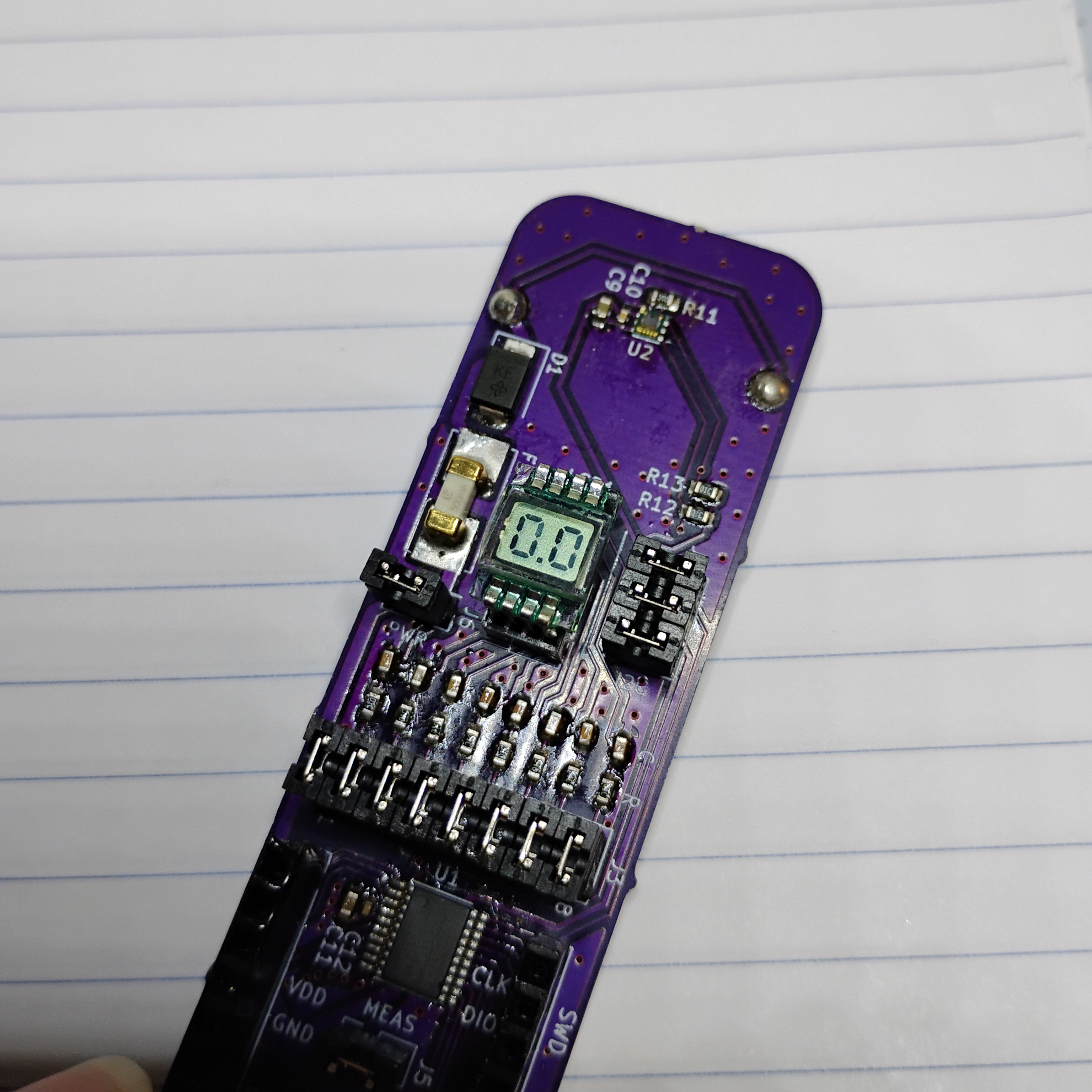

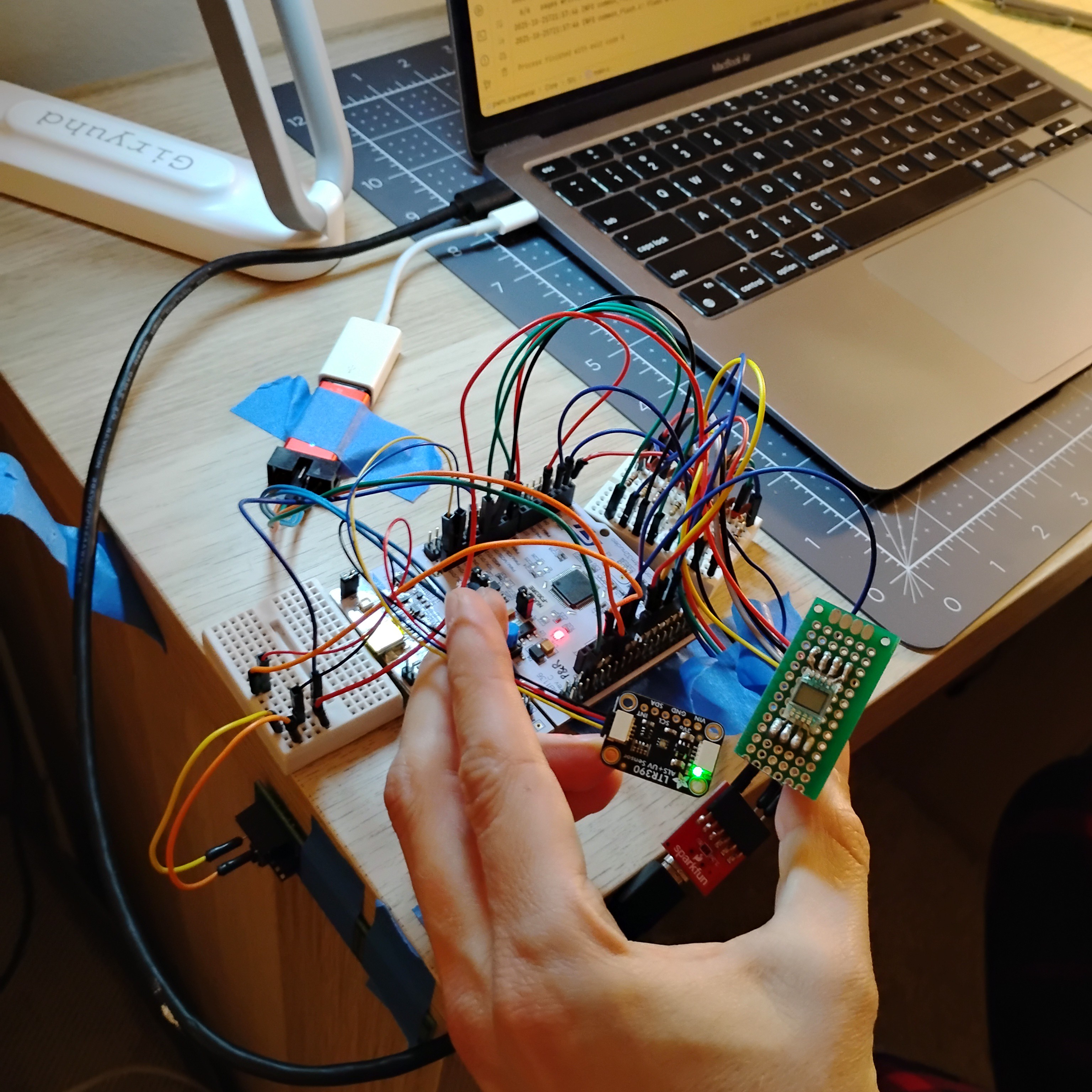

The first working version looked like this:

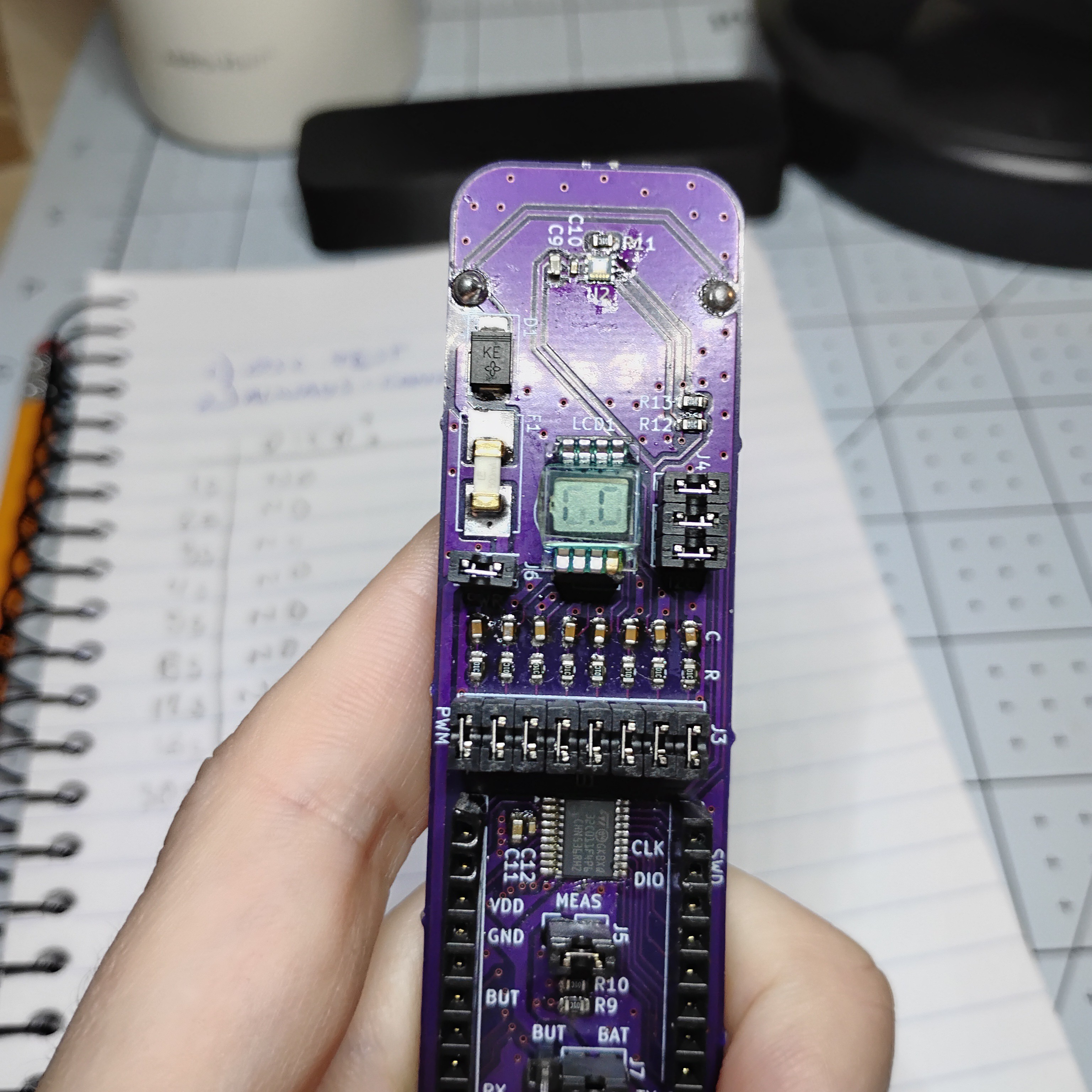

Then the second version, more portable:

And the latest version, roughly the size of the clay dummy, small enough to fit on a keychain:

If you like this idea, let me know! I'd love to make it better (smaller, cheaper, longer lasting).

rex

rex