At the moment, the project is being developed in Fusion 360, but if anyone is interested, I’ll try to port it to FreeCAD and OpenSCAD. I’ll definitely be uploading new STL files as quickly as possible after each post about a new tray.

Solder Grid

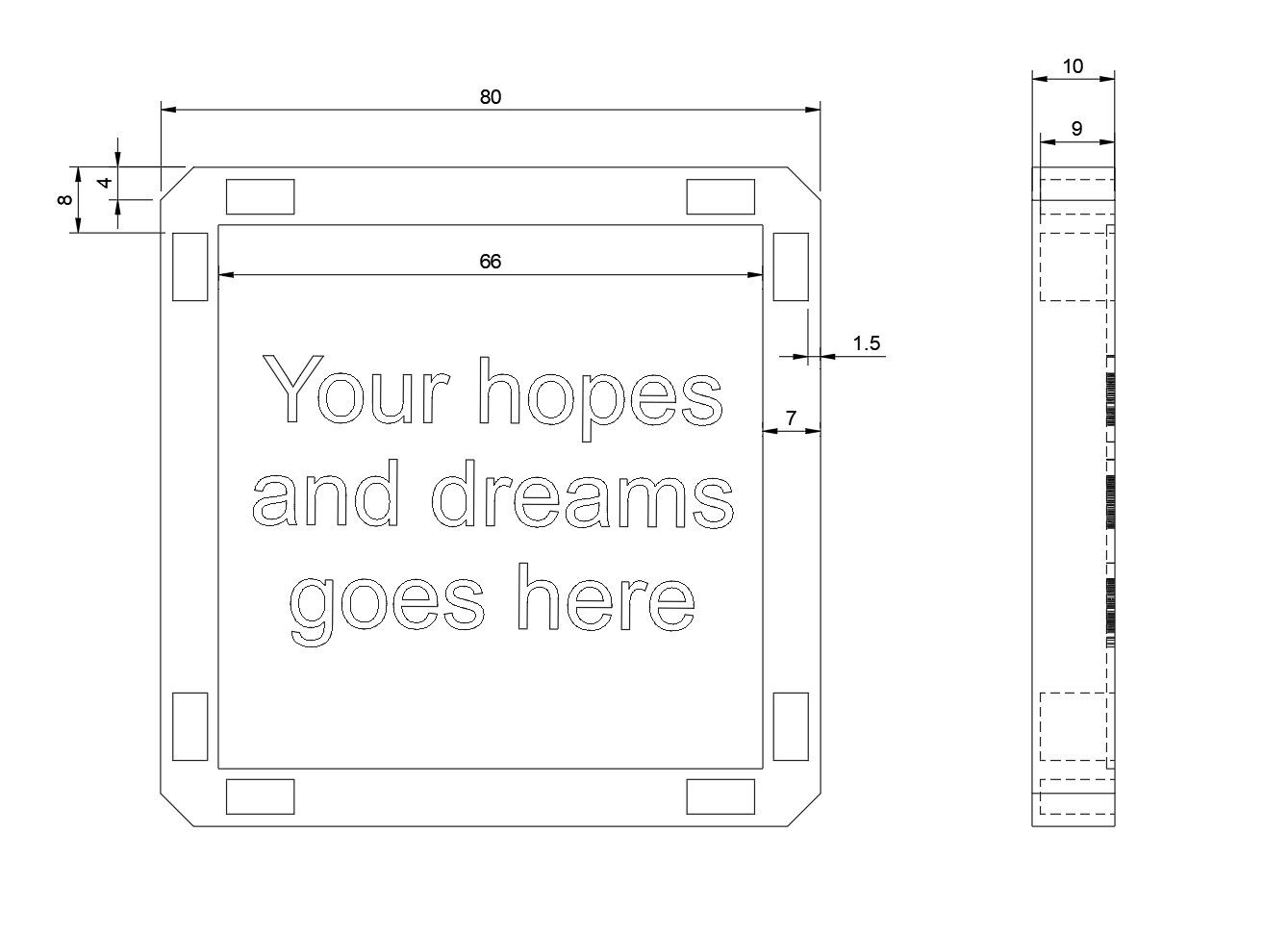

Simple grid tray system for all the soldering accessories

szynyszyl

szynyszyl

Ted Yapo

Ted Yapo

Elite Worm

Elite Worm

MasterOfNull

MasterOfNull

notme

notme