Normally camera pan / tilt systems have motors attached to the moving parts which makes weather-proofing very difficult or very expensive. With this design has the electric actuators are hidden away remotely under a weather proof canopy or in an enclosure thus reducing the complexity and cost of the mechanism. Torsion springs act against the cables as normally they only operate in a pull mode.

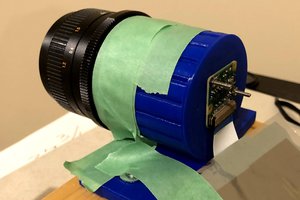

Additionally, there is a square IP68 enclosure for the camera itself. The 16mm video ribbon comes out through a 25mm gland with a slitted blank rubber grommet inserted ensuring no moisture can get in.

Other than the enclosure, the springs, a few long 5mm bolts, a 5mm circlip and the bowden cables, everything is 3D printed in SLA resin for under $60. The FreeCAD files will be made available as soon as the design is finalised, which mostly just depends on getting the springs tested.

These brackets were designed specifically to be used as safety cameras for the WEEDINATOR project. They use the Raspberry Pi Ai cameras for detecting about 80 different objects, most importantly people.

More details to come!

GOAT INDUSTRIES

GOAT INDUSTRIES Tilt seems to be working well, but pan not so good. As can be seen, an extra spring had to be added to the pan axis, which is not great. It seems that the pan cable attachment is a bit to close to the pivot axis, which gives more pan angular movement, but higher forces. Maybe it would work better with a powerful linear actuator, but that would risk breaking the 5mm SLA pin on the lower disc, so I opted to move the pin and the slot away from the pivot bit a bit and sacrifice some angular movement. There's a load more springs on the way from China as well to get the perfect torsions on both pan and tilt. There's quite a few other mods to be made to the 3D prints such as extending the cable sheath restraints and adding drill holes for another type of camera.

Tilt seems to be working well, but pan not so good. As can be seen, an extra spring had to be added to the pan axis, which is not great. It seems that the pan cable attachment is a bit to close to the pivot axis, which gives more pan angular movement, but higher forces. Maybe it would work better with a powerful linear actuator, but that would risk breaking the 5mm SLA pin on the lower disc, so I opted to move the pin and the slot away from the pivot bit a bit and sacrifice some angular movement. There's a load more springs on the way from China as well to get the perfect torsions on both pan and tilt. There's quite a few other mods to be made to the 3D prints such as extending the cable sheath restraints and adding drill holes for another type of camera.

Connor Yamada

Connor Yamada

BBまどーし

BBまどーし

Nick Bild

Nick Bild

Where are all the materials related to this?