Some time we may come accross to delete the old EPROM or Microcontroller with EPROM and reprogram the device due to CRC or check sum error. We may also want to upgrade the firmware.

If we do not have any EPROM eraser, we can easily build a EPROM eraser using just 2 components.

We need a UV-C LED and a current limiting resistor.

If you refer to any EPROM datasheet, it will be all the same original Intel datasheet with Cut and Paste.

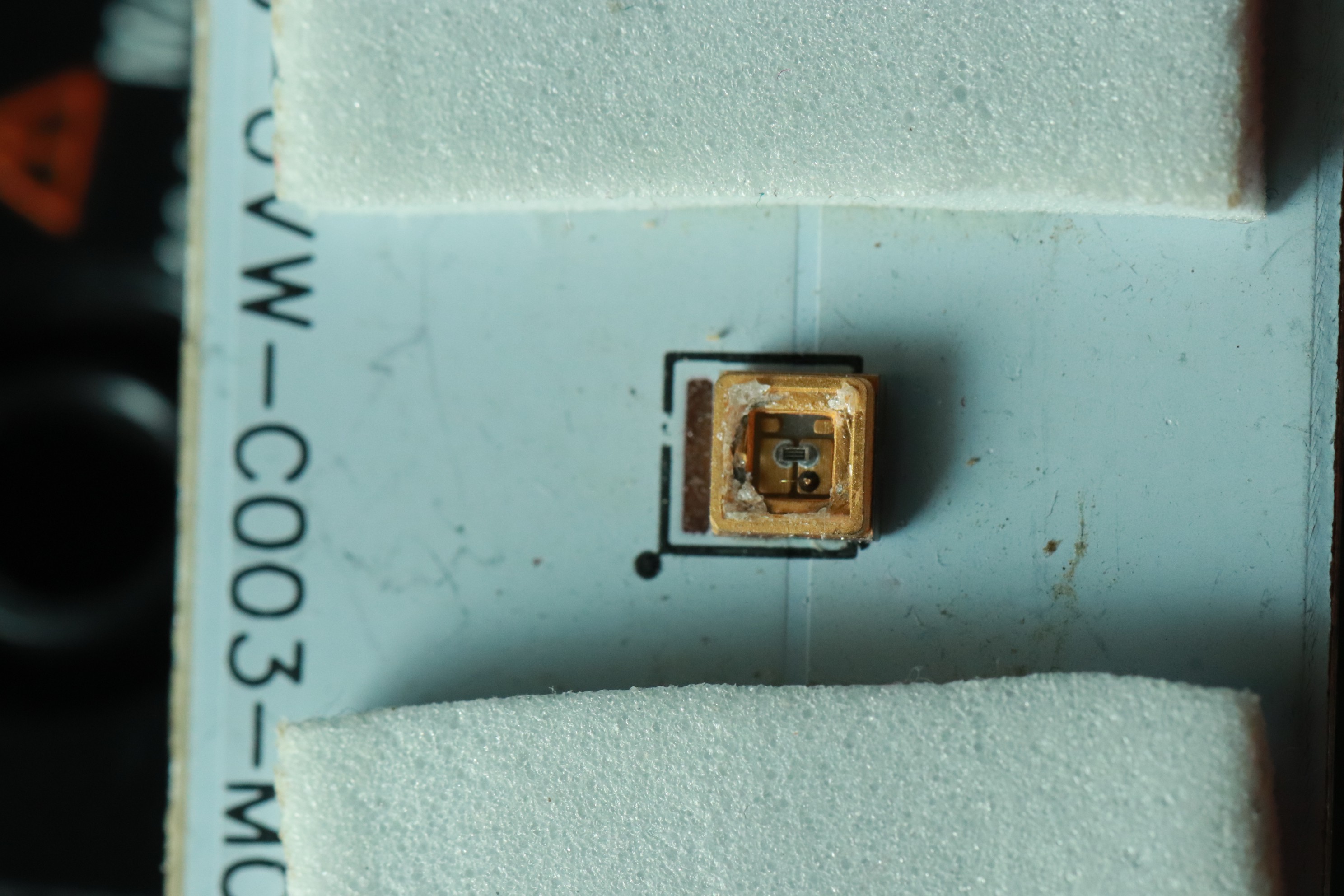

I am not able to procure the 253.7nm UV-C LED. But I am very easily able to get 3535 size SMD275nm/1W UV-C LED for $1. The UV-C comes in diode or diode mounted on a Al base plate along with polarity marking and soldering pads. This one is much easier to handle the LED in our application.

CONNECTION:

Just connect the UV-C LED along with a series current limiting resistor so that we are operating with in the UV-C LED power rating and there is no excess or thermal issue due to large current flowing through the LED.

For 12V DC source with a 150 Ohm resistance is good enough and working. In this case the Diode drop measured is 6.17V DC for the Supply voltage of 12.11 V DC.

The current through the UV-C LED is 0.0396666666666667A

The power dissipated by UV-C LED is 0.2447433333333333W

We are well below the power rating of the UV-C LED and does not require any additional cooling.

Just place the UV-C LED above the quartz window of the EPROM. Do not look at the LED without anh proper eye protection. I have used the Double sided tape to hold the LED above the EPROM window.

OBSERVATION:

Tested this setup with 2716, 2732, 2764, 27128, 27256, 27512, 27C010, 27C4002 from different year of manufacturing and different vendor. Also tested intel 87C51 with 4kB and 8kB EPROM versions.

OLD EPROM manufactured many years ago with larger micrometer technology erases faster.

There are GROUP of bytes behaves the same way as nearby bytes. Location and structure effect.

There is no major time difference between isolated device with UV-C LED or keeping the EPROM on EPROM programmer. Periodical reading and verifying does not have much effect on EPROM eraser. When we place the EPROM on the programmer, the programmer provides supply voltage to the EPROM during read, verify operation.

CONCLUSION:

Capable of erasing between 20 to 45 minutes.

Using 253.7nm UV-C LED may be more effective than currently used 275nm. We can have multiple UV-C LED in series or parallel for more devices or more power.

Increase in current through the UV-C LED may result with faster erasure. Hope with a pulsed LED with few kHz using a 555 astable with smaller duty cycle may be more effective.

Additional log will be updated and added after testing the pulsed version.

mit41301

mit41301