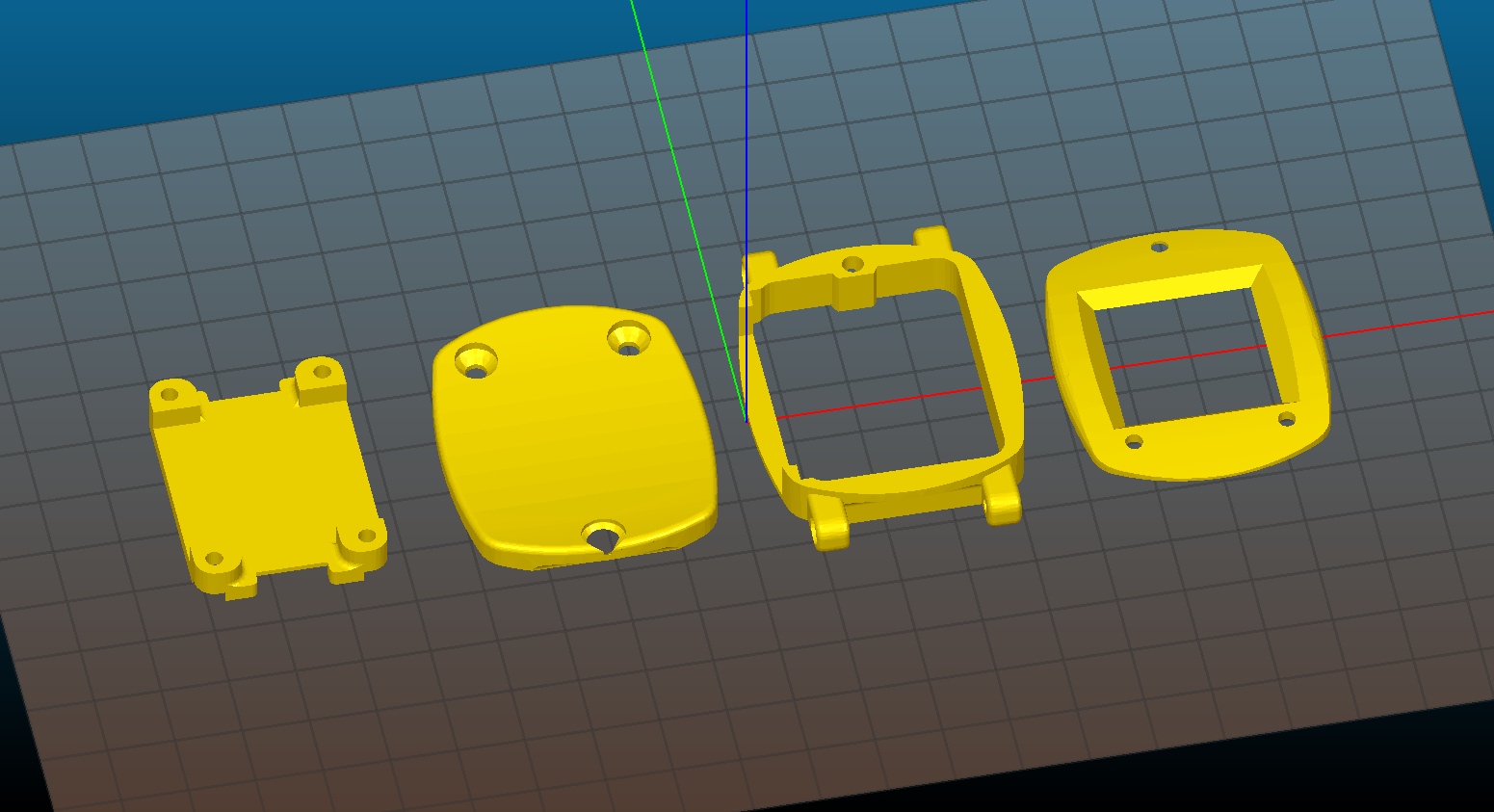

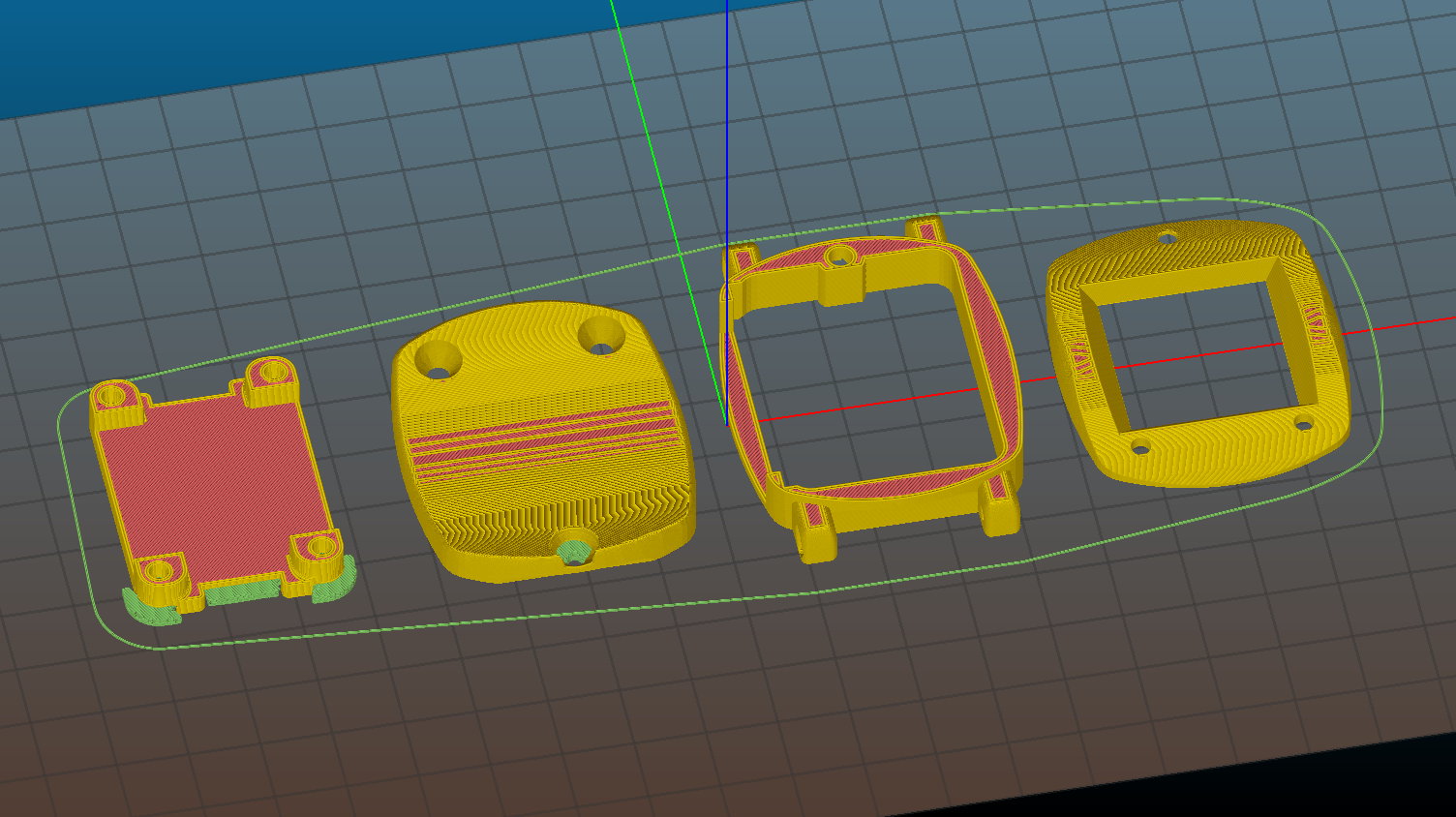

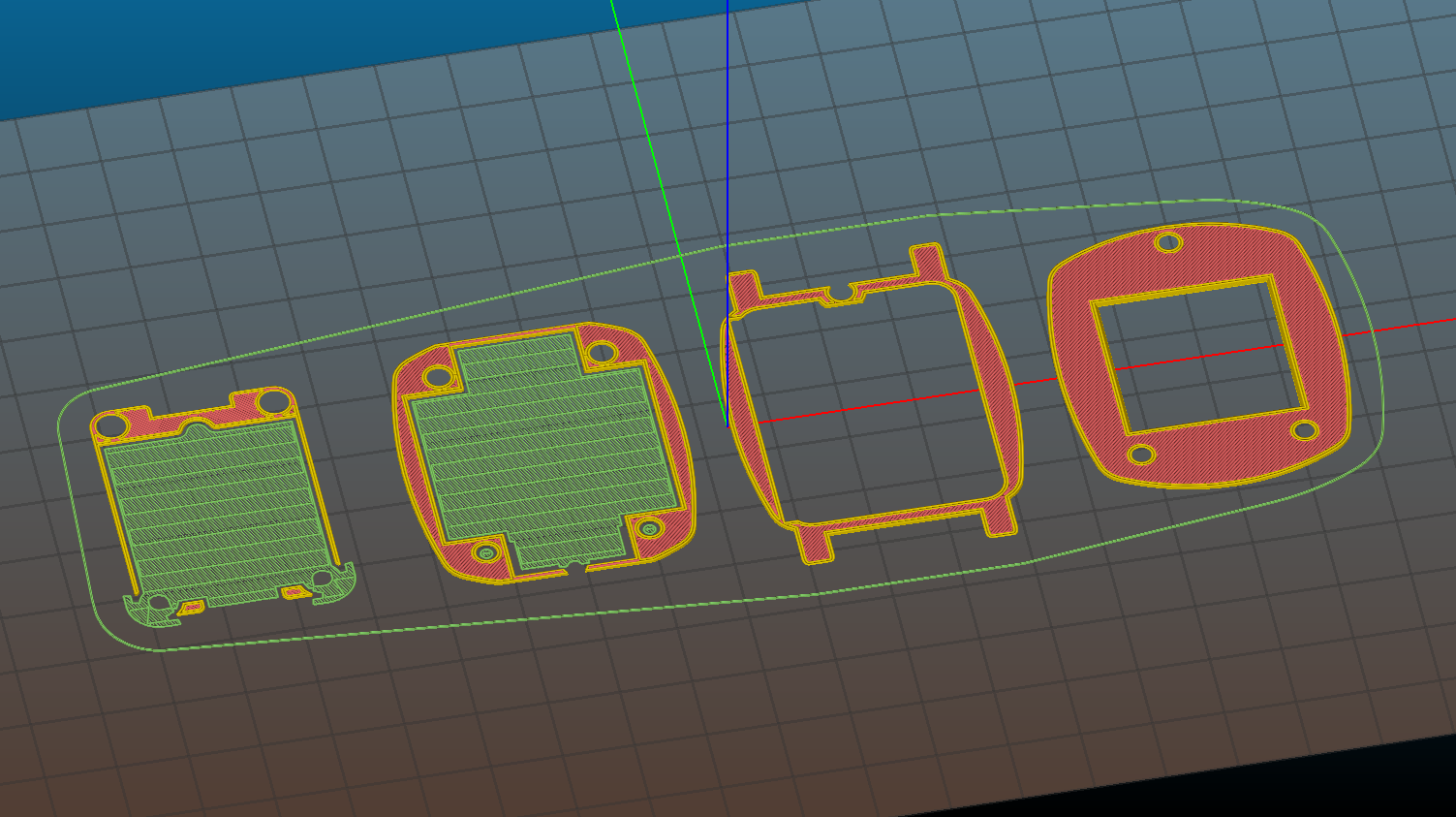

Here's how I printed the parts for the watch. I used Slic3r to slice these. Find out more below.

Everything above except for the leftmost part (LCD support) gets printed with a 0.025 mm layer height. Initial layer height for these were 0.1 mm. The LCD support was printed with the standard 0.2 mm initial and layer height.

All the parts were printed with 100% infill. Setting it below that gives gaps just because of how thin each layer was. This could probably be remedied by increasing the number of perimeters (currently set to 2).

Ramon Imbao

Ramon Imbao

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.