The Concept

Modern robotics hardware for the hobby market has been reduced to a series of modules, from servos to processors. The only things connecting these together are wire and chassis, and I've been experimenting with using easy to obtain materials to build those chassis. Polycarbonate and polystyrene, polyethylene, sheet aluminium etc were natural choices.

Mark's IO made me think again about the validity of cardboard as a working material, and we began a dialogue that culminated in this collaboration.

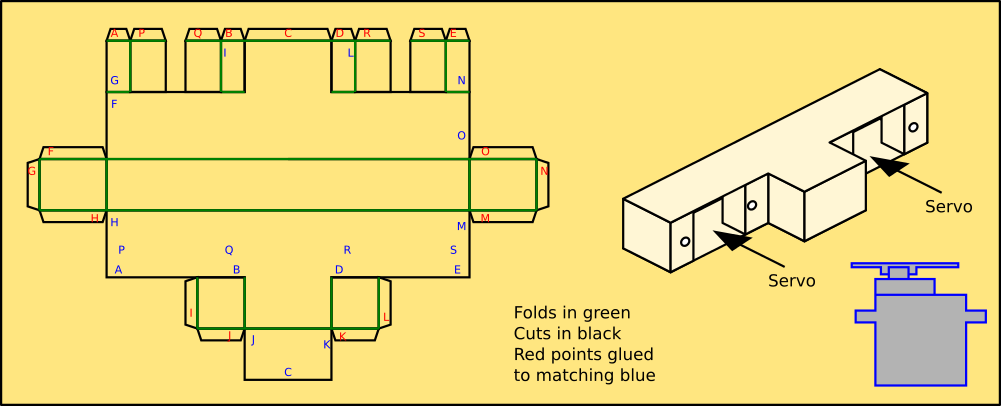

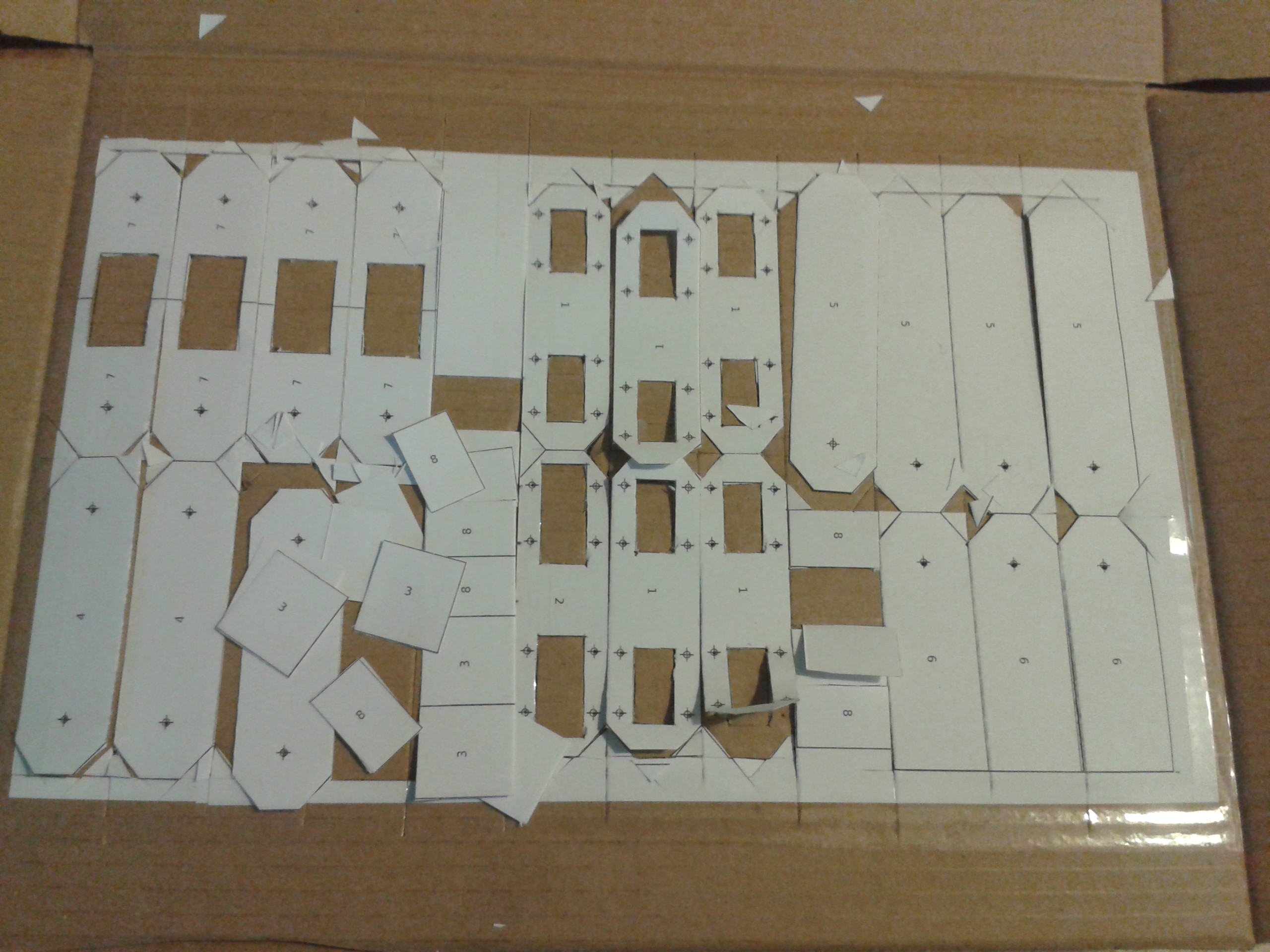

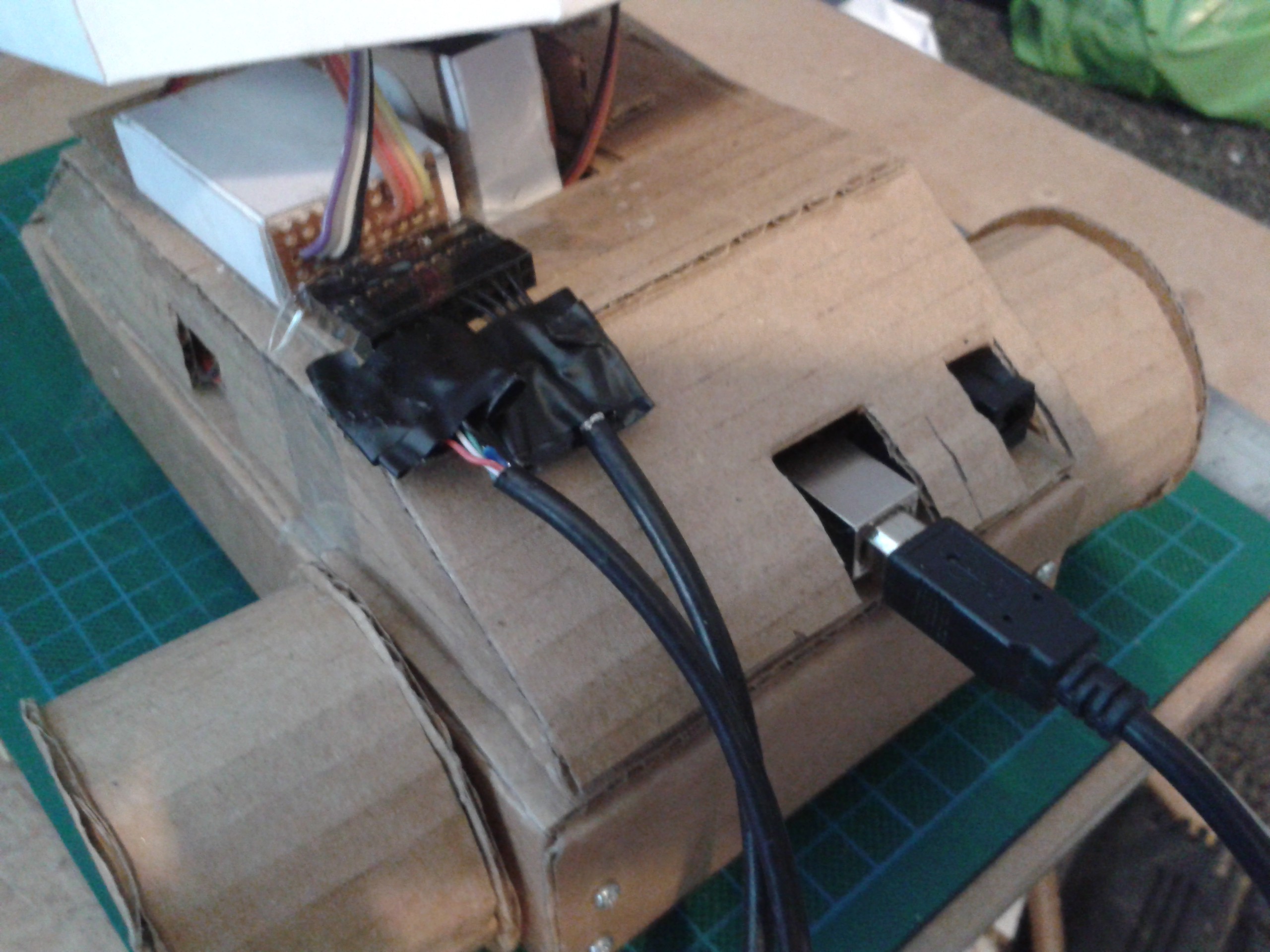

The idea was to use a single sheet of craft card and a printed template to create chassis units that connect the electromechanical building blocks together.

We have since iterated over a few changes to the design, incorporating better geometry to give the parts strength, room for cabling and better overall appearance.

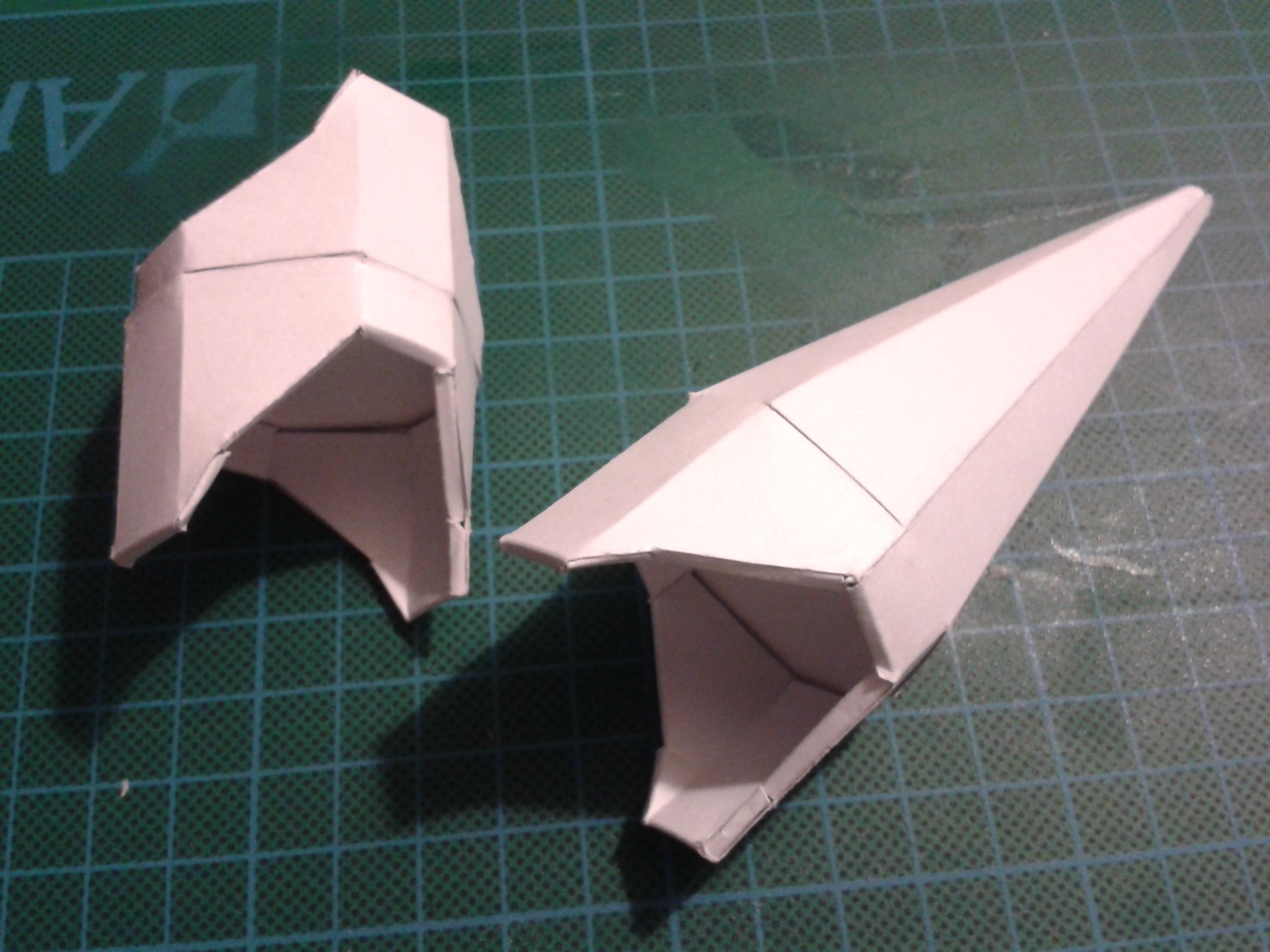

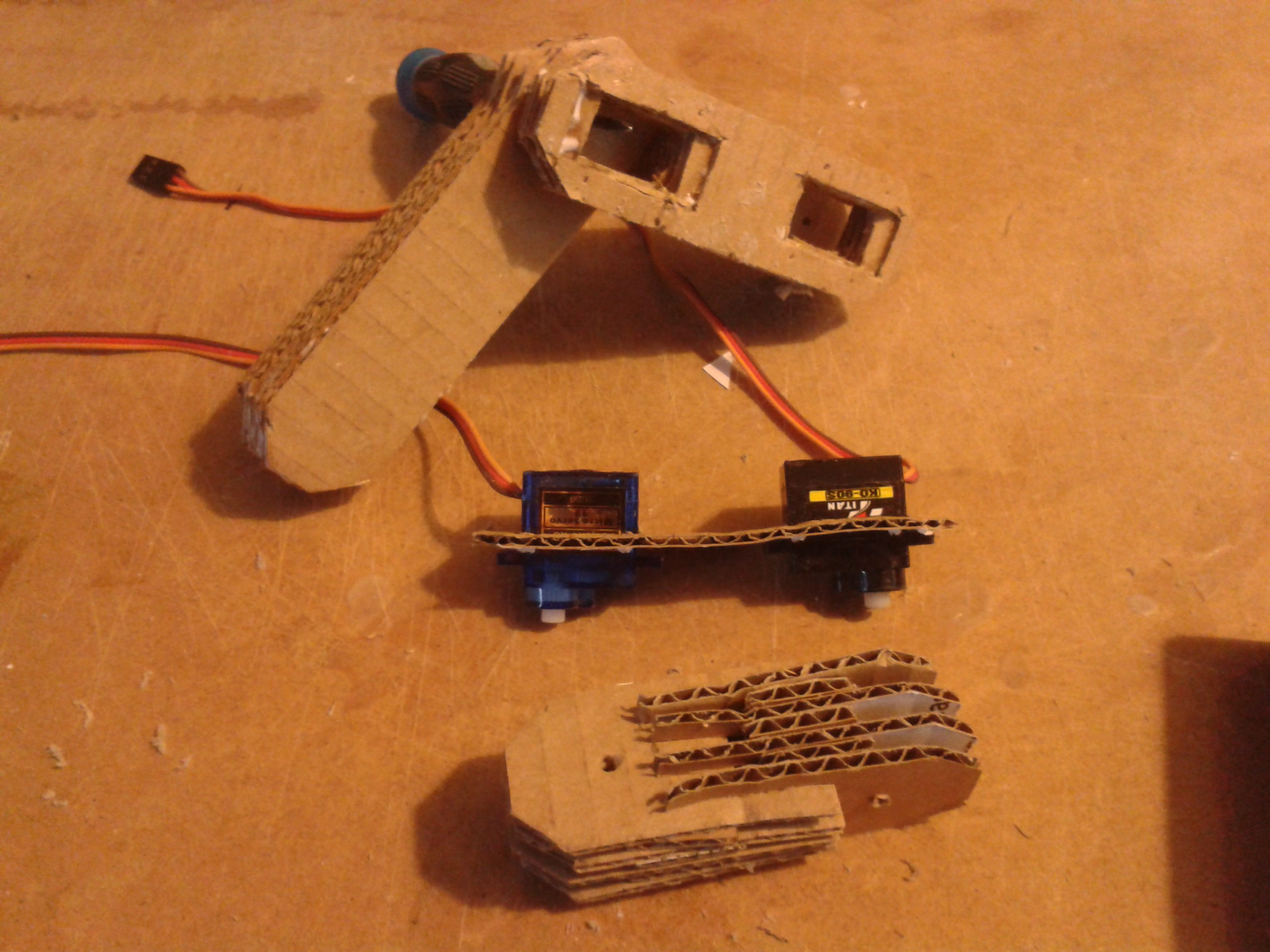

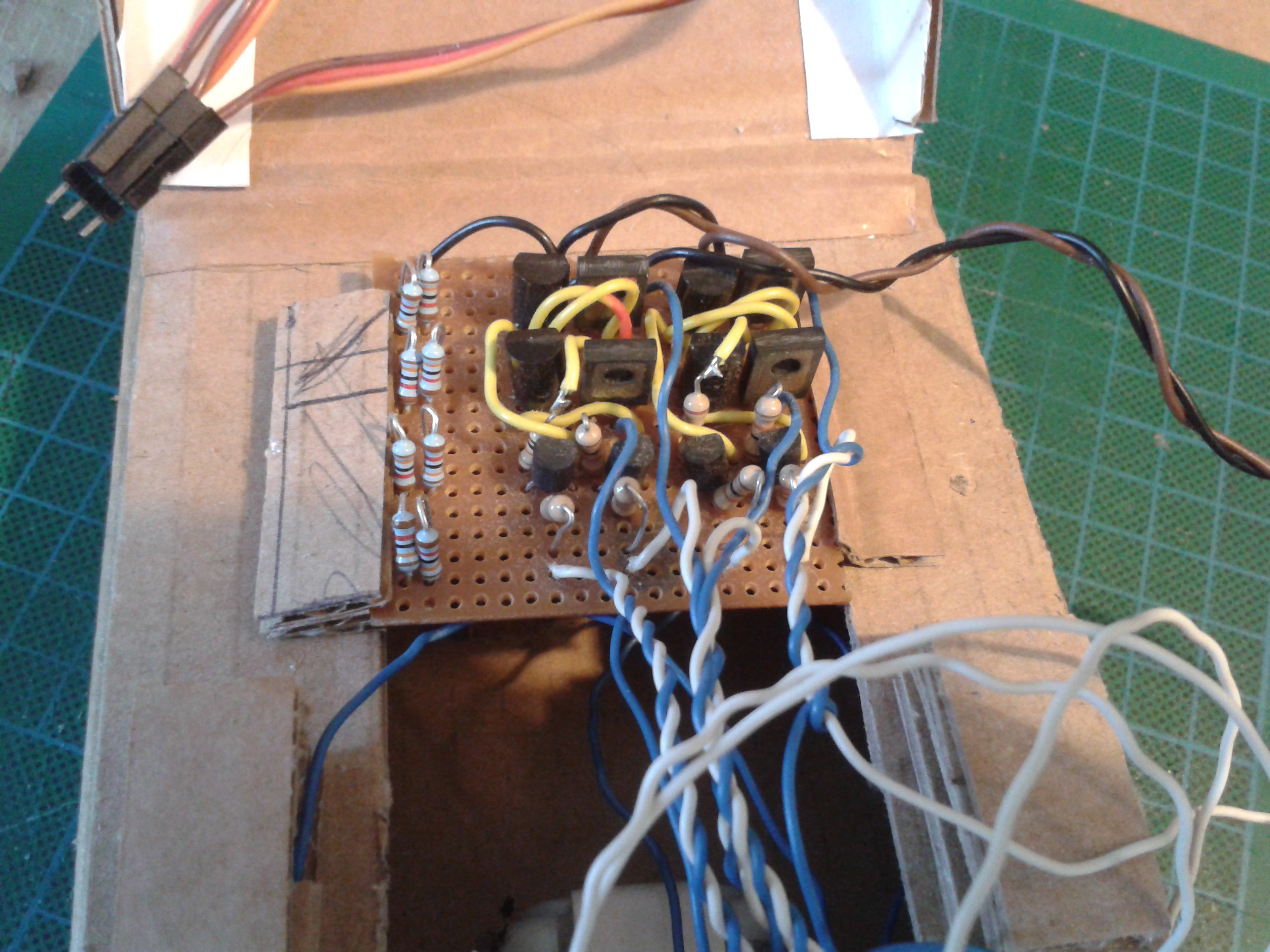

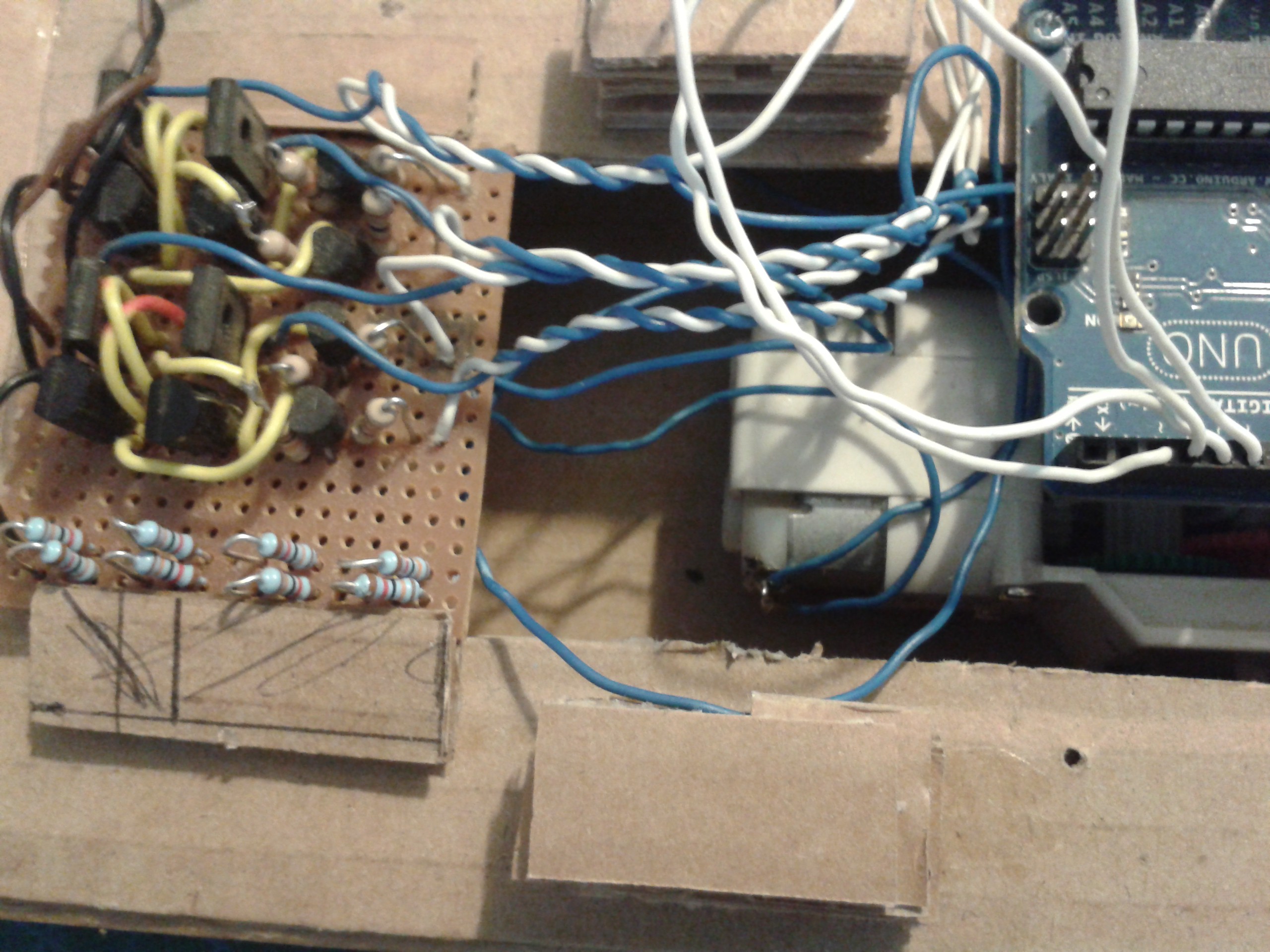

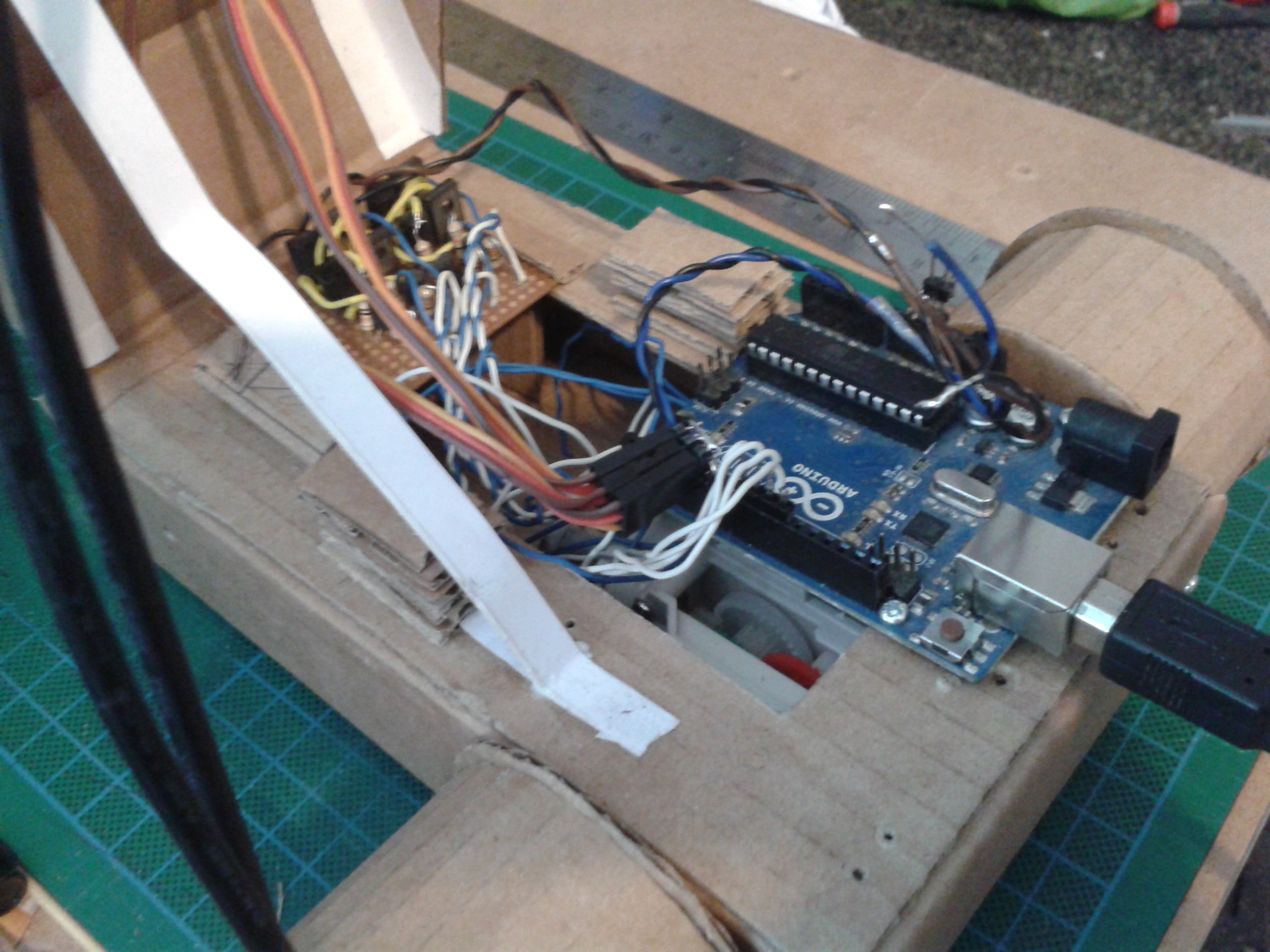

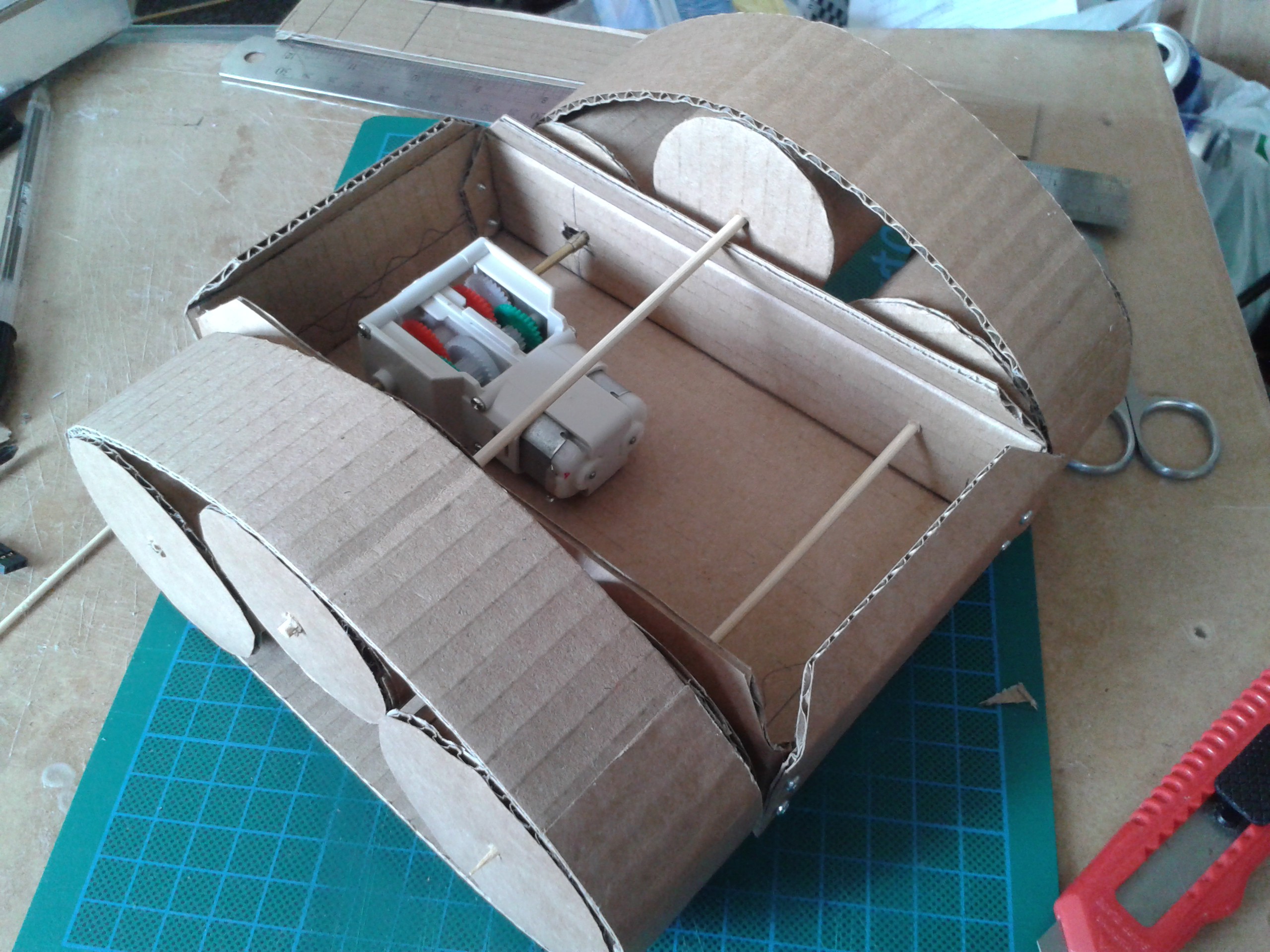

First generation limb built by Mark N during the initial prototyping.

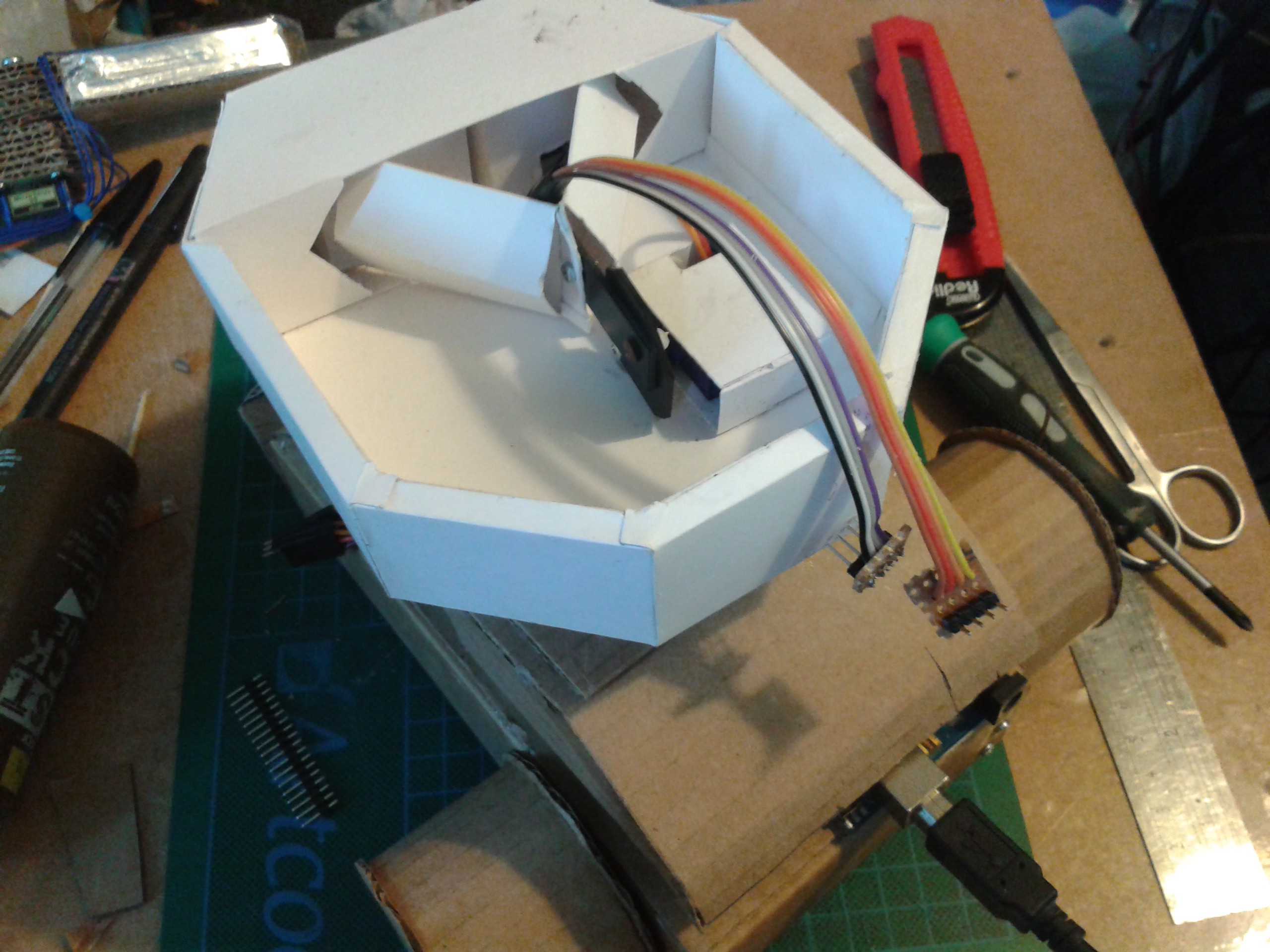

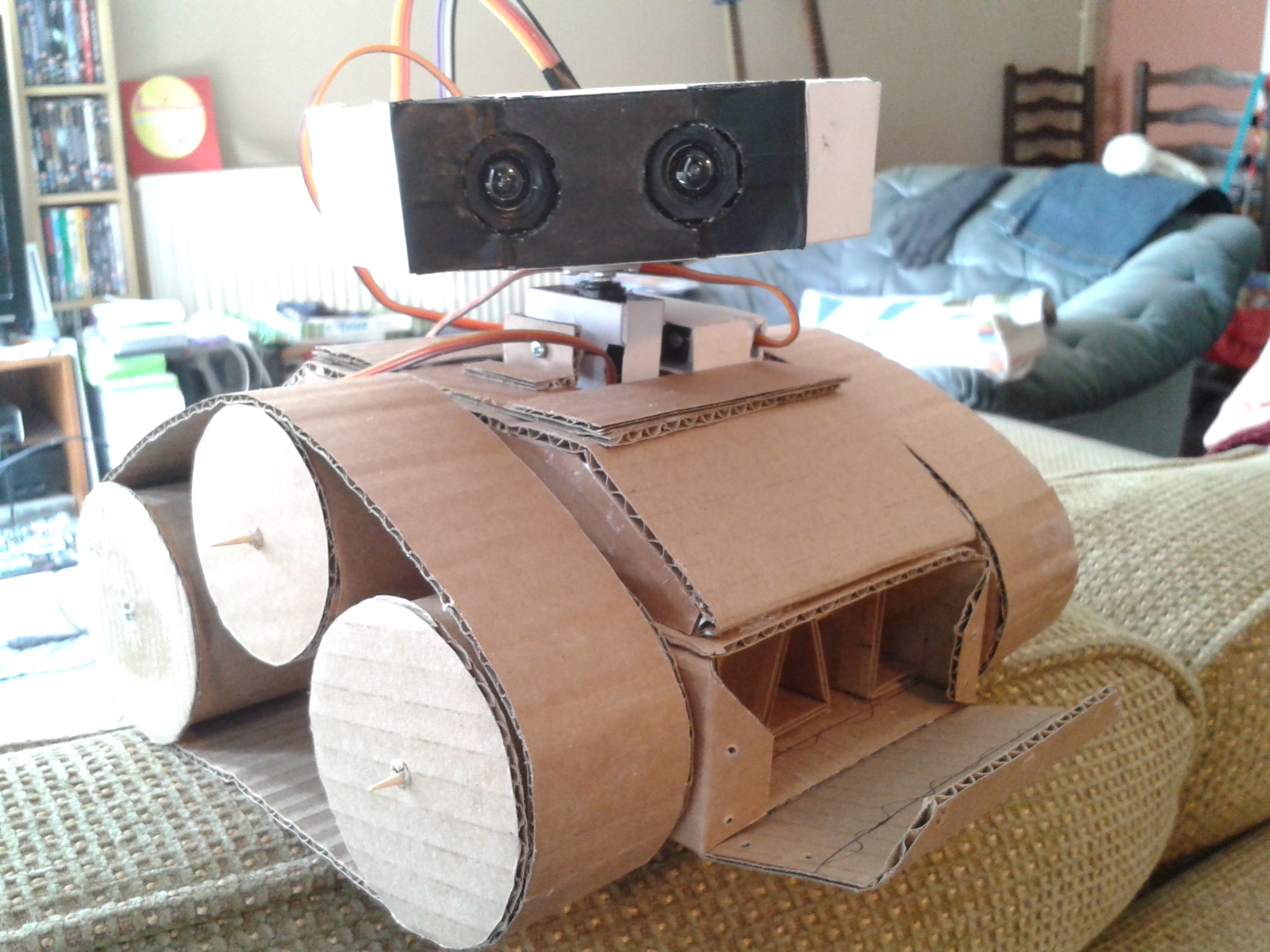

Origaime - The next generation

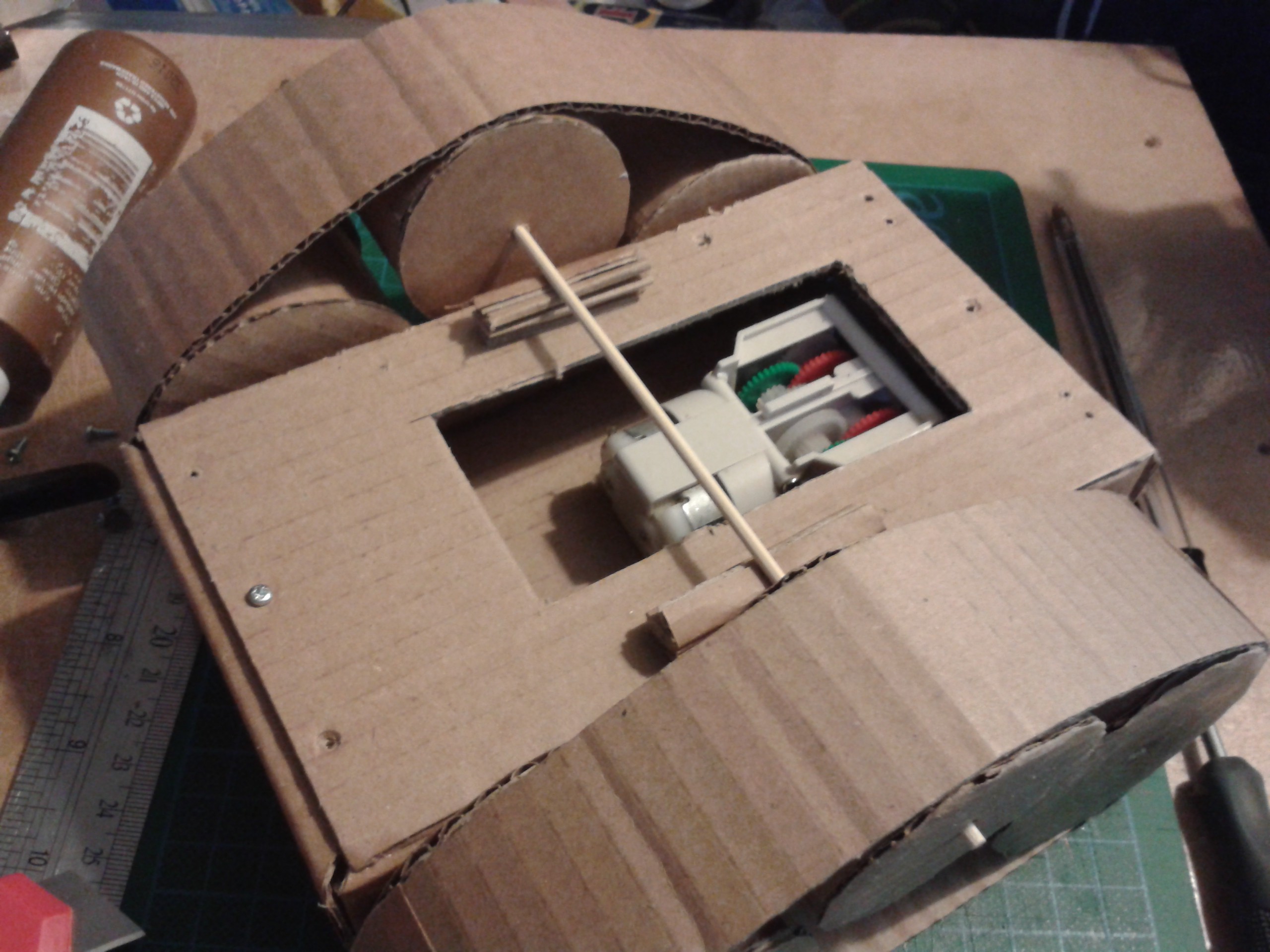

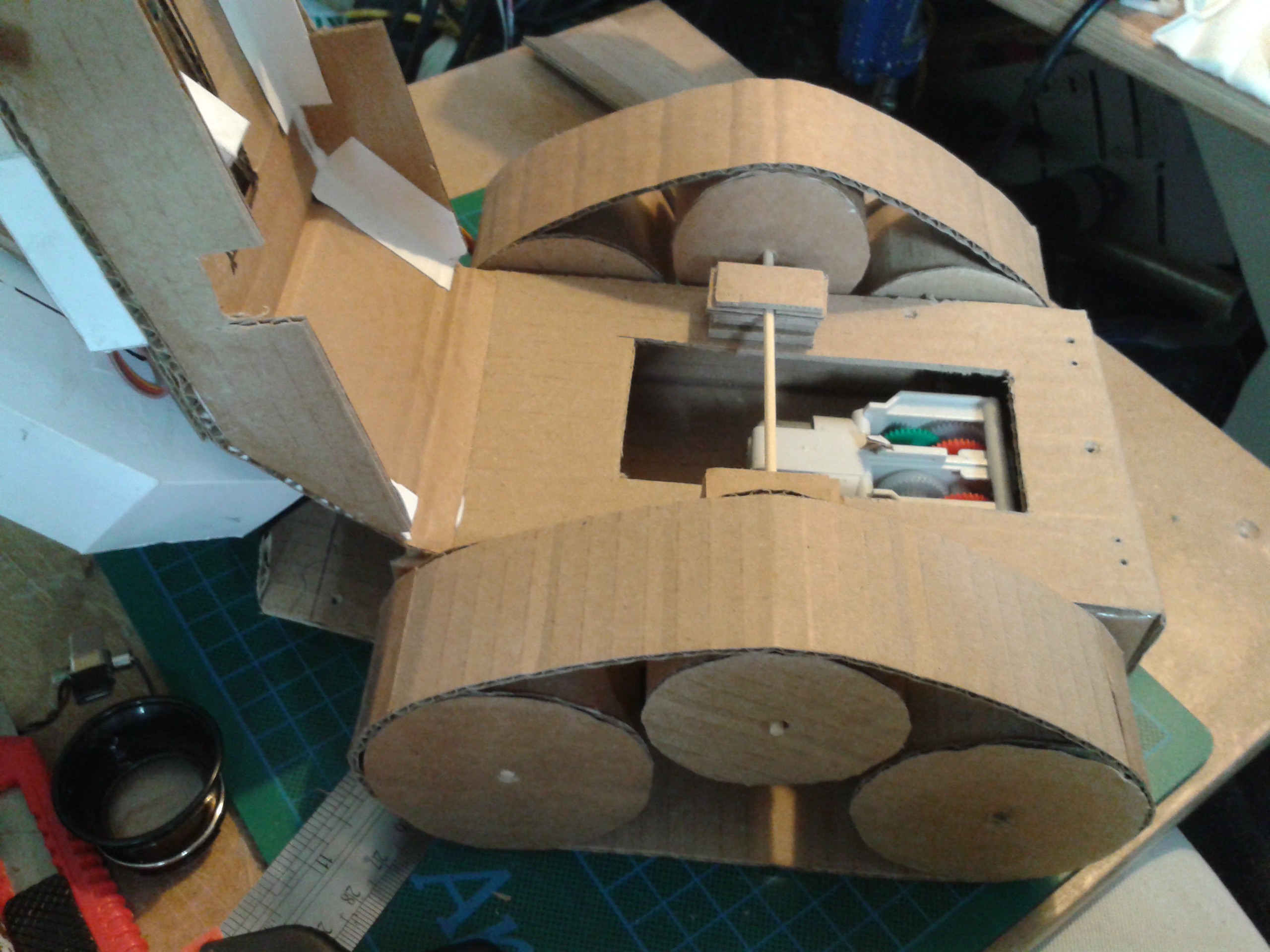

The updated parts built in exactly the same way as the first set, they fold up

from a single piece of cardboard to make a modular piece for the robot.

Mark calls this Origaime, after the original robot that inspired

everything and the art of folding. :-)

Other MaterialsWe've

looked at other materials besides cardboard after realising that

self-recycled materials were also a possibility. The initial discussions

for the project touched on the fact that paper and card were already a

recycled material besides their other qualities, but the inclusion of @markgeo

to our collaborators brought this to the front quite literally as he

attempted a build of the early generation limb parts using cardboard

scavenged from cereal packets. This was necessary as he is developing

Cardware in Thailand where card stock and other things we take for

granted are not so easy to obtain. MarkG is using this ability of the

system to promote robotics in education there, as other resources needed

to teach the subject are not easily available.

Other ways of using the materials available

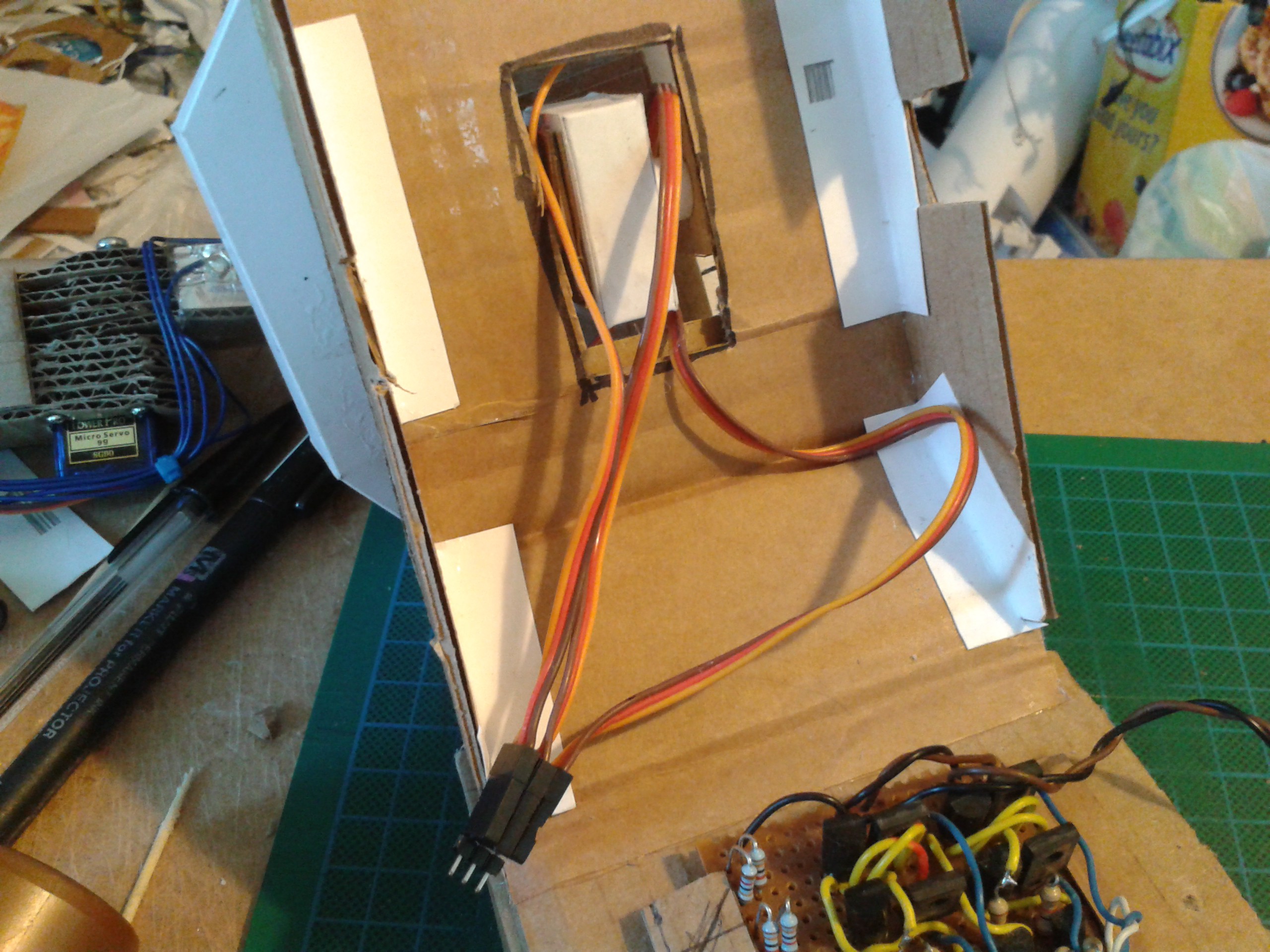

Exoskeletons are one way of using planar geometry to build 3 dimensional shapes. Planes can also be applied equally to laminar technology to make solid forms.

Once the cardboard has soaked up a generous amount of PVA glue it becomes a composite more in keeping with building technologies like MDF. Laminar technologies are also extremely strong and accurate, using averaging to spread loads and imperfections in their design to achieve military precision.

Origarmy

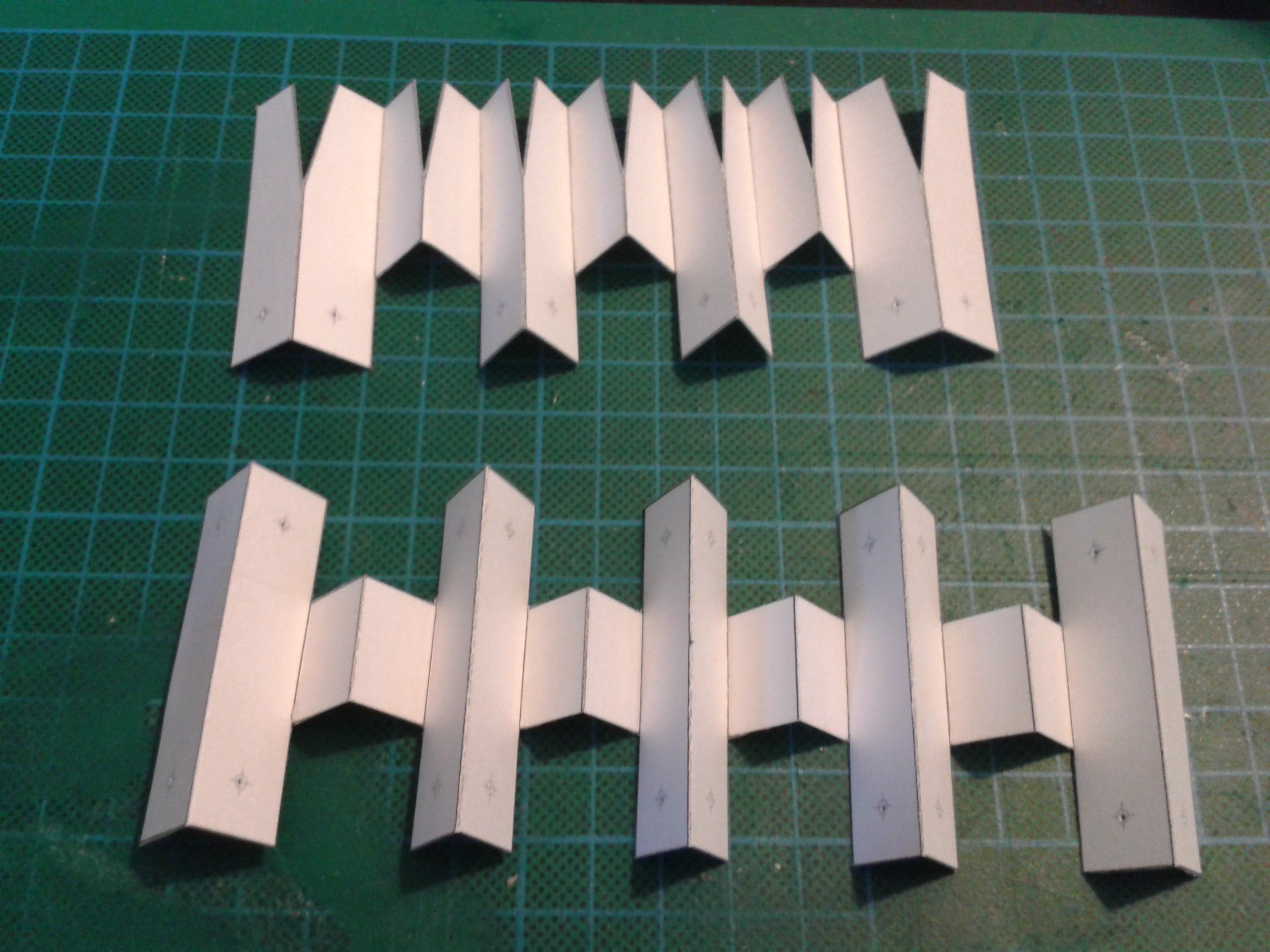

Extending a finger in the direction of solid forms. Repeated accuracy has always been a problem with hand built machinery. Those days are gone with laminates.

Not just fingers either, the AIME hand mechanism was deliberately scalable even though it never really saw the light of day. Inspired by Mark's #Uglytech - The cardboard relay I went back to the drawing board for the limb parts and thought about hybridisation.

Still a printed template but uses much crappier materials. MarkGeo highlighted that good cardstock is not always available and Cardware Exoshells require a narrow window of weights to work properly due to the card being too thick and stiff for the small tabs, and problems like de-lamination crop up as well.

I looked at how Mark Nesselhaus was stacking the material and realised that garbage corrugated card was actually fine, just real ugly and required special considerations.

It cuts out cleanly and quickly with a craft knife. You can be lazy about this, providing the holes for the bearing pins are punched accurately, you could hack the rest out with a butter knife and it would still work. This is a deliberate response to the immediate reaction to Cardware - because it looks pretty, it must take monumental skills to build - which is in error. Yes, there is technique, I have built it into the paradigm so it teaches you as you go. Providing you dont jump in with the hardest part of all - Hip Yokes.

These are still a pain to construct, but are easier laminated.

The Sensor...

Read more » Morning.Star

Morning.Star

Paul Crouch

Paul Crouch

kevinj

kevinj