-

Laser-cut Rotor Stool Model

04/21/2017 at 21:43 • 0 commentsThe Wankel engine rotor stool design was interesting enough to take it out of the CAD world and into the physical world. Resisting the temptation to jump straight to full-sized CNC routing, we first test the design with a scale model.

While it is possible to use a 3D printer to create the model, the laser cutter is a better choice. A laser cutter works similarly to a router: both cutting into a flat sheet of material stock. And the material can be similar as well: a laser cutter can cut wood like the CNC router.

The target material for the full-scaled project is 18mm thick plywood. Out of the material on hand for the laser cutter, the closest analogue is a sheet of 3mm thick plywood. While the smaller sheet is not made out of the same wood and it only has 3 layers, it is still a better model of behavior for full-sized plywood than a 3D printed plastic model.

Since the small sheet is 3mm in thickness compared to 18mm of the full-sized plywood, it is easiest to make the model scale 1:6. Here is the test model with a U.S. Dollar bill for size comparison.

With the model built, we proceed to testing. The rotor stool model proved very capable holding static vertical load. We placed two blocks of aluminum stock on top and the stool didn't even quiver. We then start adding some heavy reference books on top of the aluminum. The weight of the books exposed the design flaw.

When the second book was added, the chair stood and accepted the linear vertical load without visible distortion. However, it started twisting a bit, rotating about the vertical axis, demonstrating the design's weakness in handling torsional stress. The mid-deck is capable of helping the legs resist vertical load, but it isn't helpful enough for the legs to resist side load. As a result the whole chair twists.

While we expect the model to hold several more books before breaking, the stack of books is starting to become unwieldy. We then moved on to a test setup with more precise control of load force. The two aluminum blocks are reused as top and bottom of a makeshift vise with a C-clamp to press them together.

As we started twisting the handle of the C-clamp, the model tried its best to stay up but eventually it started twisting. Once the vertical force was translated into a sideways force by the twist, the legs start bending sideways. Not long after the twisting started, one of the legs cracked.

![]()

The model-building and testing phase is a success: design flaws were exposed before time and money was spent on a full-sized prototype. While this design might be sufficiently strong at full scale, let's go back into CAD and iterate the design to address this structural issue.

-

Triangulate on Design

04/18/2017 at 21:38 • 0 commentsTrying to design furniture means dealing with the fact that anything with more than three contact points on the ground would need some means of adjusting those points otherwise the whole thing will not be able to sit properly on an uneven surface. Since this project is aiming for simplicity, designing for the minimalist three contact points seems better than adding adjustable feet.

There was the concern that three legged design would run into problems on the CNC cutter, as it might run into situations where surfaces will need to meet at 60 or 120 degrees instead of the 90 degree edge cut by the router bit. While this might be solvable with a custom router bit, the ambition is to use clever design to work around the need for such joints.

And on top of all the practical concerns, there's also the desire to add a little bit of pizazz, something unique to this project instead of just Yet Another Work Stool. After some brainstorming of interesting three-sided shapes, the winner is the distinctive triangular shape found in a Wankel rotary engine, made world famous by the Mazda RX-series.

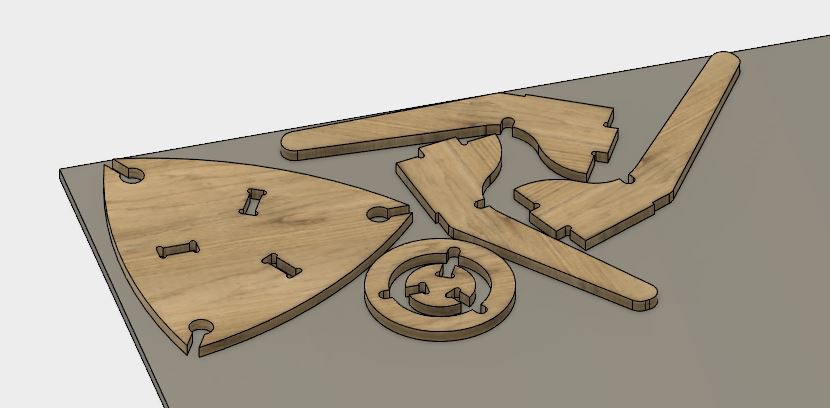

The seat at the top is shaped like the Wankel rotor, including the cutouts made in the real rotor for the infamous apex seals. The circular mid deck echoes the central cavity for the eccentric shaft at the middle of a Wankel engine. Three legs sprout from the middle of each of the three sides.

The pieces laid out for cutting

Before we jump directly into full-scale CNC routing, though, we should make some scale models to test out the idea in the physical world. We could use a 3D printer, our tried-and-true old friend, but the nature of CNC routers on plywood is very similar to that of a laser cutter.

Next step: Using a laser cutter to make 1/6-th scale models.

-

Router Thinking

04/17/2017 at 21:24 • 0 commentsThe first iteration of the project was simply a CAD exercise to practice thinking for CNC routing.

Z-Axis: Individual parts are constrained to the thickness of the sheet of plywood, so there's a hard upper bound on the Z axis. Most CNC routers have some Z-axis control to make partial cuts in the wood, so it is possible to have varying heights. For CNC-routed furniture, this is usually employed to cut slots for other pieces to fit without the slot being visible on the other side.

Edges: The cut edges are, for the most part, vertical. While it is possible to buy router bits of specific profiles, the cost can quickly spiral out of control. Best to stick with simple cuts while starting out.

Interior corners: 3D routers are constrained by the cutting tool radius and can't cut a sharp interior corner. The most common workaround for this issue is to cut a dog-bone shape with the corners rounded out so it is possible to cut.

Here is the first sketch, completely lacking any design excitement, purely for the purpose of shifting thinking from 3D printing to CNC routing.

And here are the pieces laid out for CNC routing.

Since this is just a practice exercise, the decision was made to stop here. This boring (but educational) CAD file was set aside and never made the transition to the physical world.

Small Work Stool

A learning project using CNC routing to build human-scale furniture.

Roger

Roger