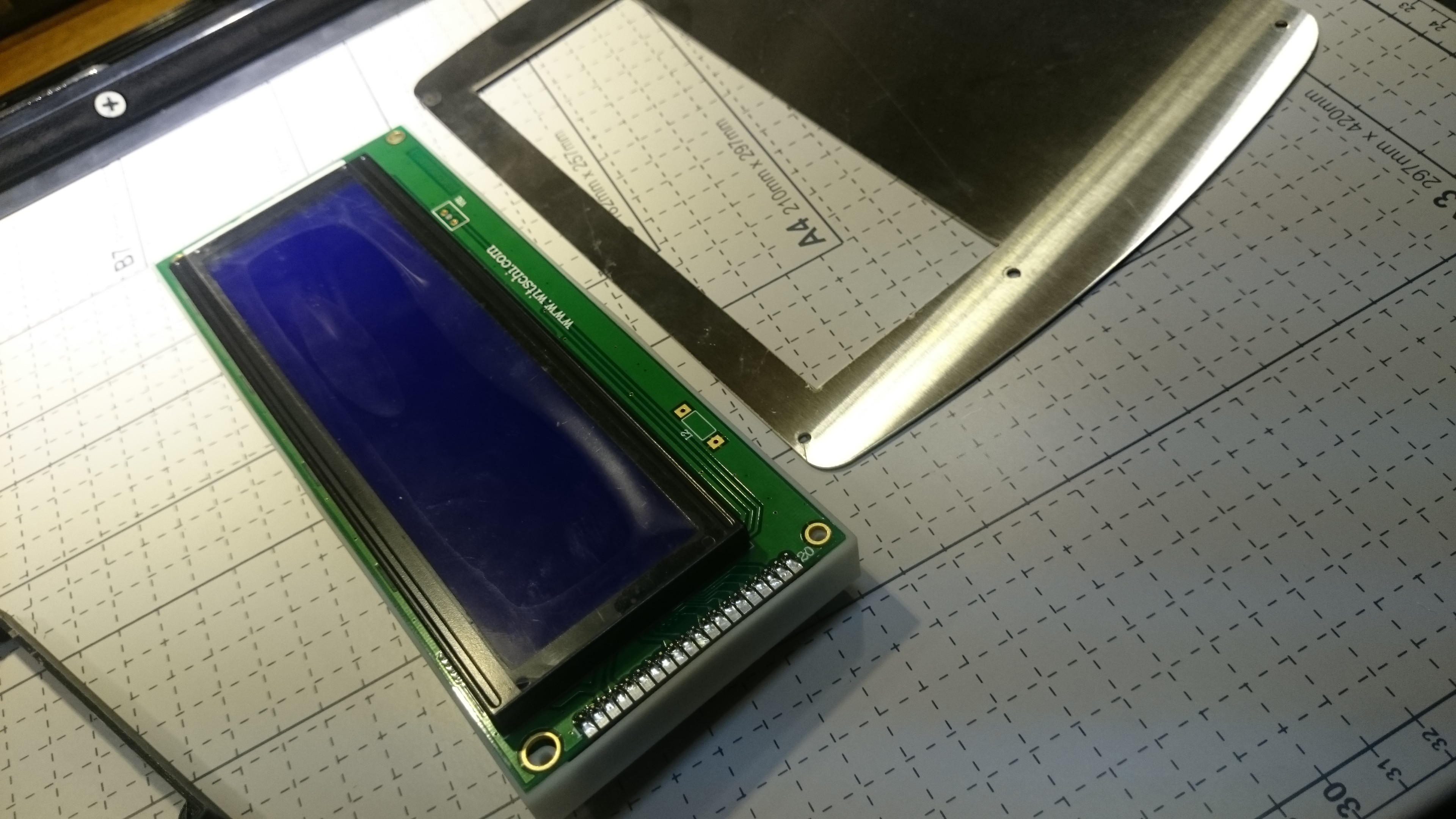

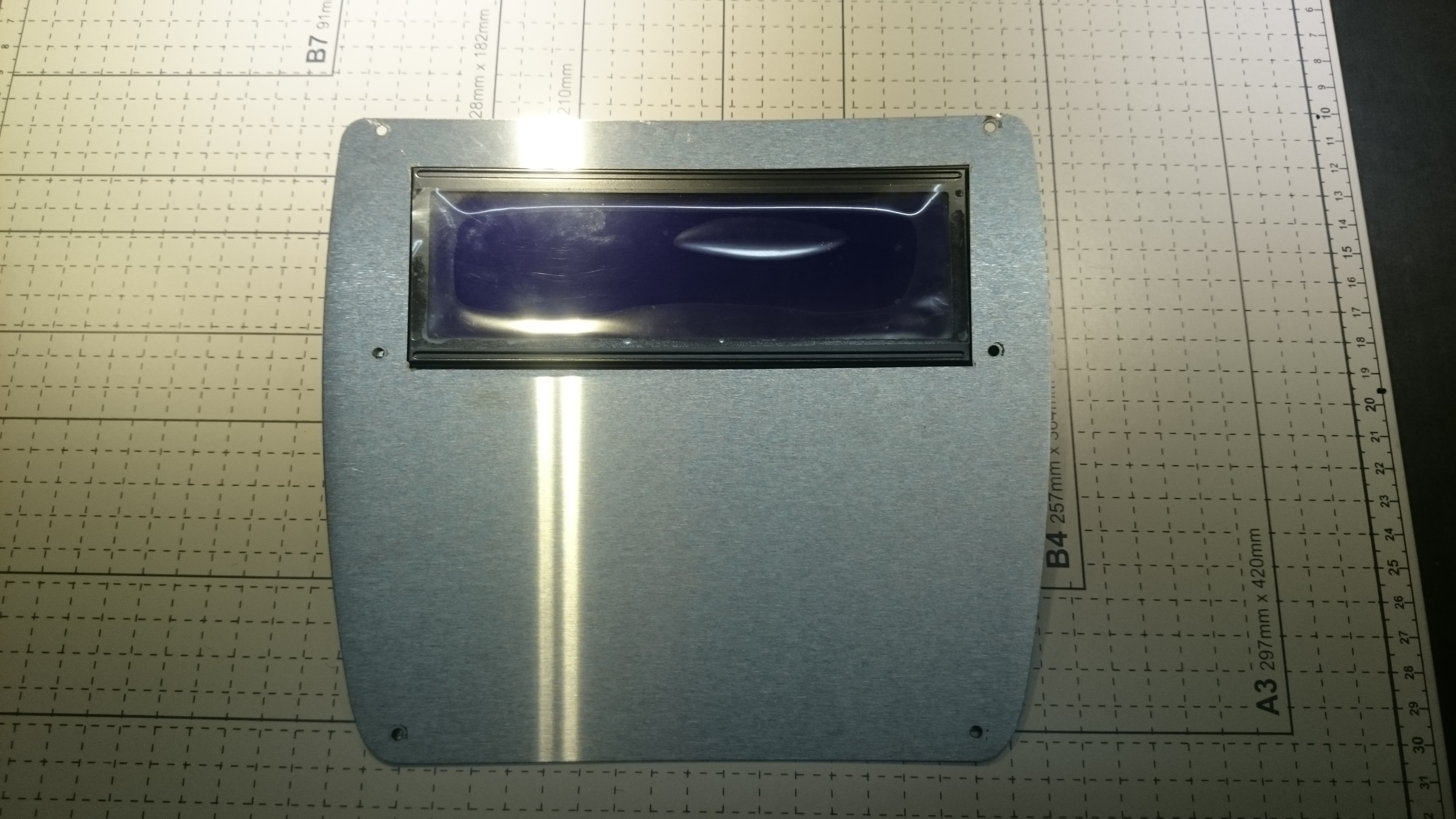

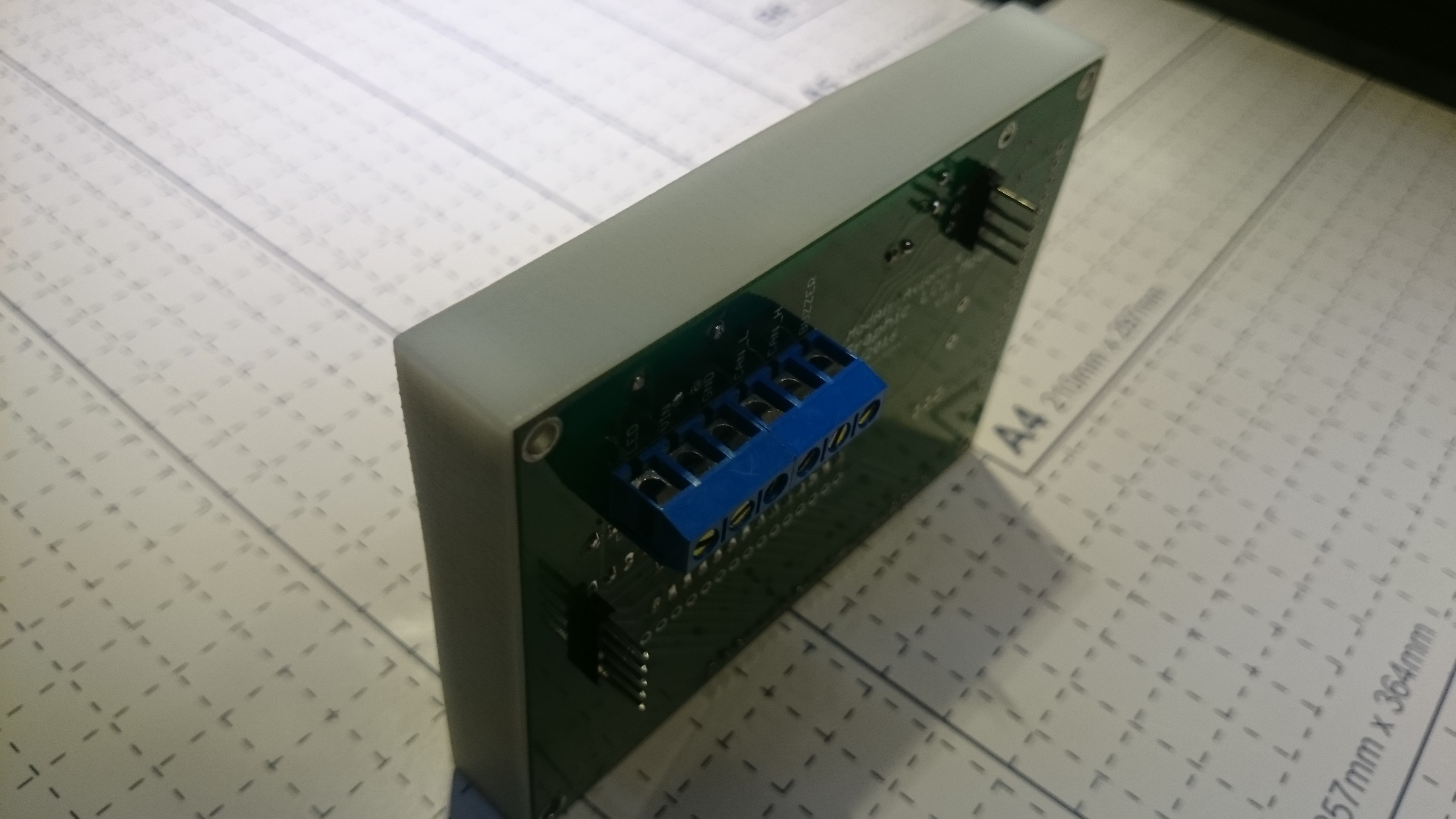

The idea with the controller and LCD sandwiches is to mount them directly behind a front panel. I had a front panel cut from 0.9 mm brushed stainless steel (about $10 from a local metal manufacturing company), but unfortunately I only discovered the scratches underneath the protective plastic when I got back home.

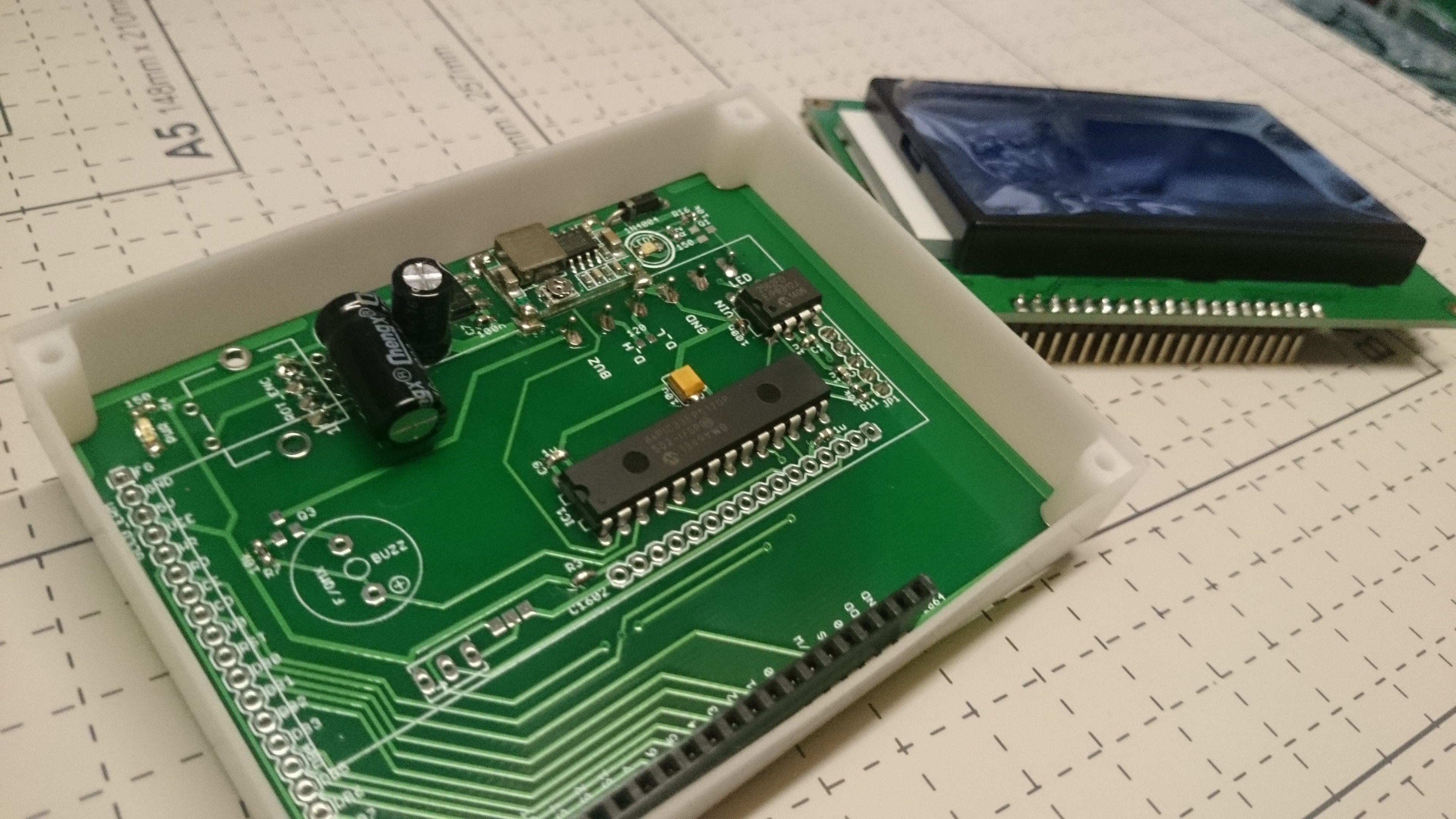

The 3D printed brackets worked perfectly, and aligns nicely with the PCBs on both sides. In the design files I added 0.2 mm on all sides.

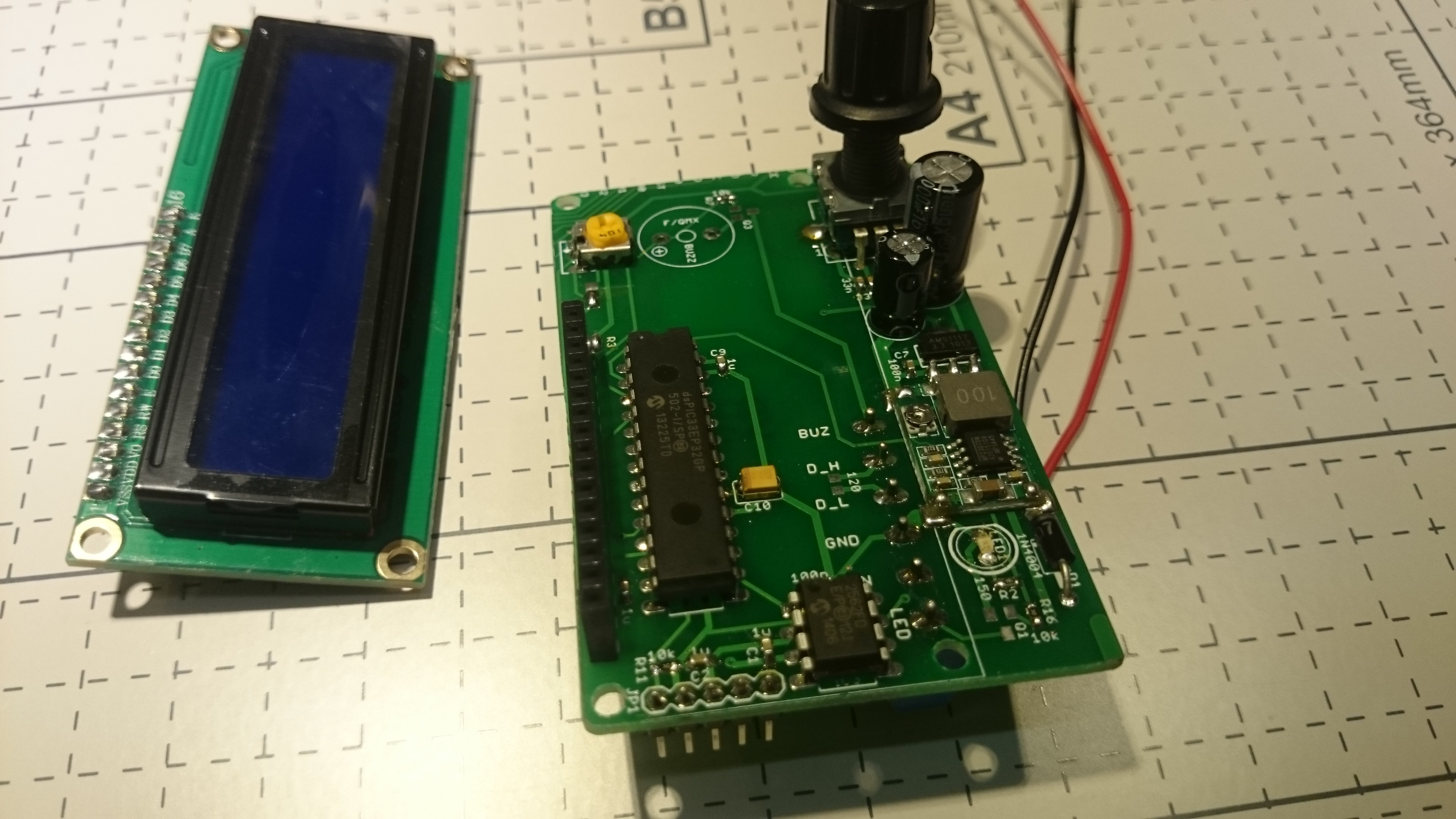

For the 1602 LCD, the PCB is cut smaller with a hacksaw. For this module, the rotary encoder is mounted on the base PCB (rather than being attached with a ribbon cable).

Rene

Rene

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.