I apologize for the long overdue update. It's been a rather obnoxious couple of weeks. I've been attempting to re-print the rotor section and got through most of the pieces, then when printing the first (and largest) rotor, my printer broke. So after fixing it, I just finished printing, and assembling the rotor section.

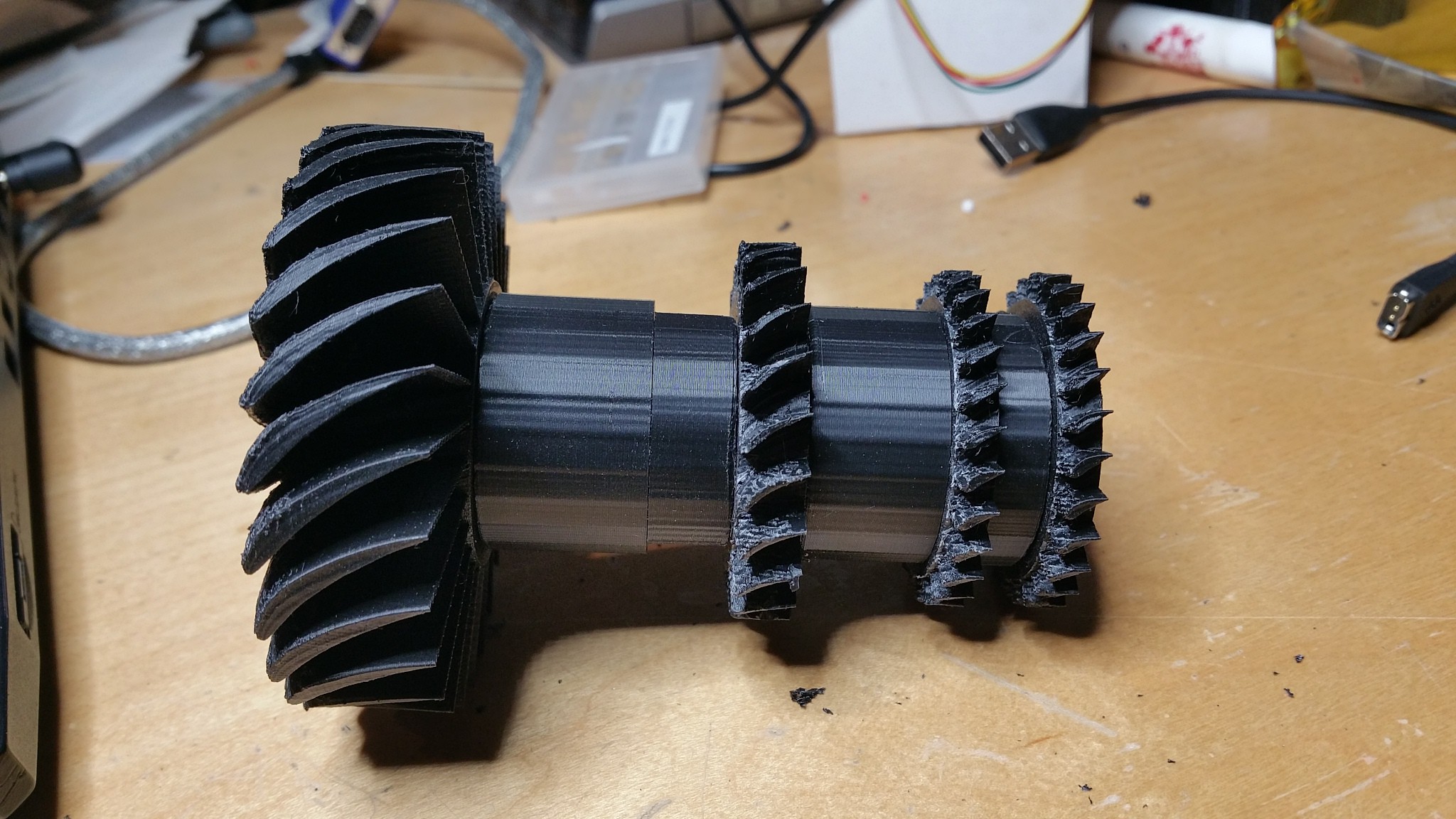

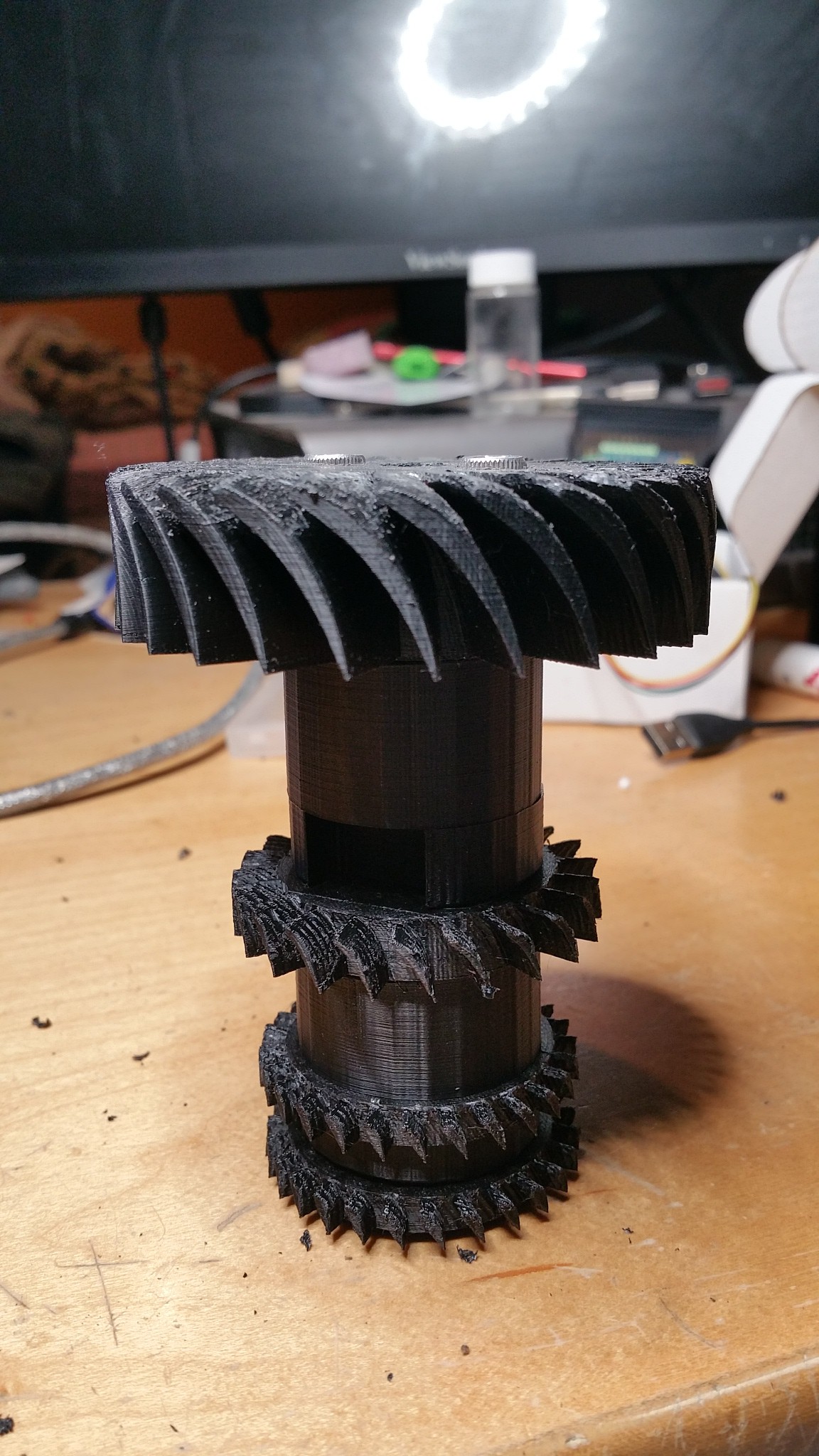

To my surprise, I designed this very well and everything fit together. So these picture of it the separators and rotors screwed together.

What I need to do now is give them an acetone vapor path, smooth out those rough edges.

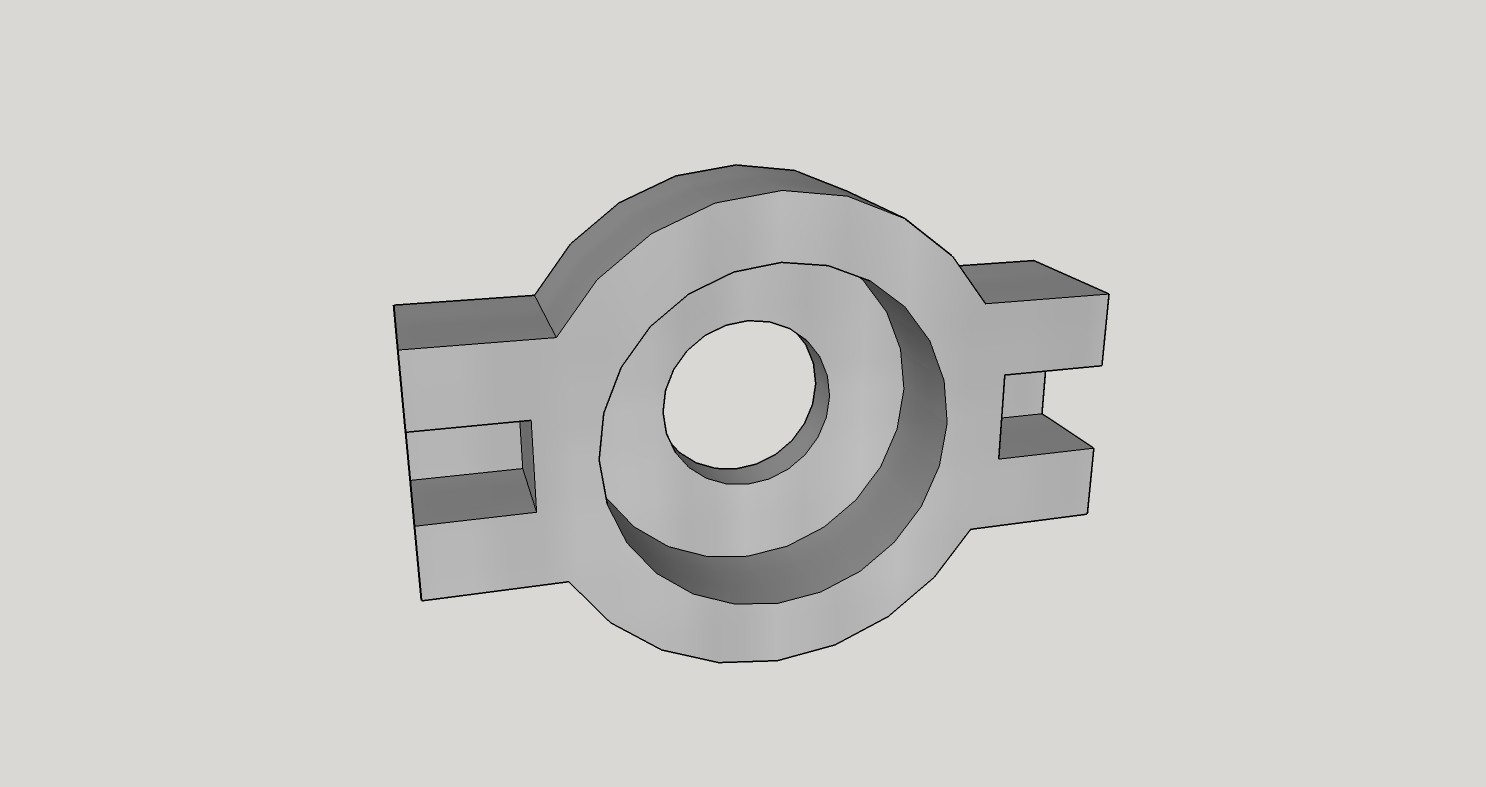

Whats next is to get my CNC up and running. This is just one of those Chinese desktop CNCs, real cheap and easy to use. I'll be using the CNC to build the ball-bearing housings out of aluminum.

I can't 3D print this for a number of reasons:

- The bearings generate a considerable amount of friction heat

- The oil used to lubricate the bearing might not mesh well with plastic

- The alignment and the major stress of the compressor on placed upon the bearing housings, so having them 3D printed won't give as accurate of a shape as milling them.

I'm also going to commision the compressor casing to be printed so I'll be looking into hubs on 3DHubs.com

To be continued

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.