-

The project continues.

07/12/2017 at 14:29 • 1 commentIt's been a while since the last update of this project. All the team members were very busy with exams, among other things. The next goal is to make the sensor work using the Particle Elektron as a microcontroller. This is quite a challenge, as there is not as much information available as for the Arduino. I will try to write as much as possible about the progress here on Hackaday and reply to all your comments and questions.

-

Ping! Internet of things!

05/23/2017 at 13:23 • 0 comments23/05/2017

It has been a little while since we informed you. We have been busy with several things.

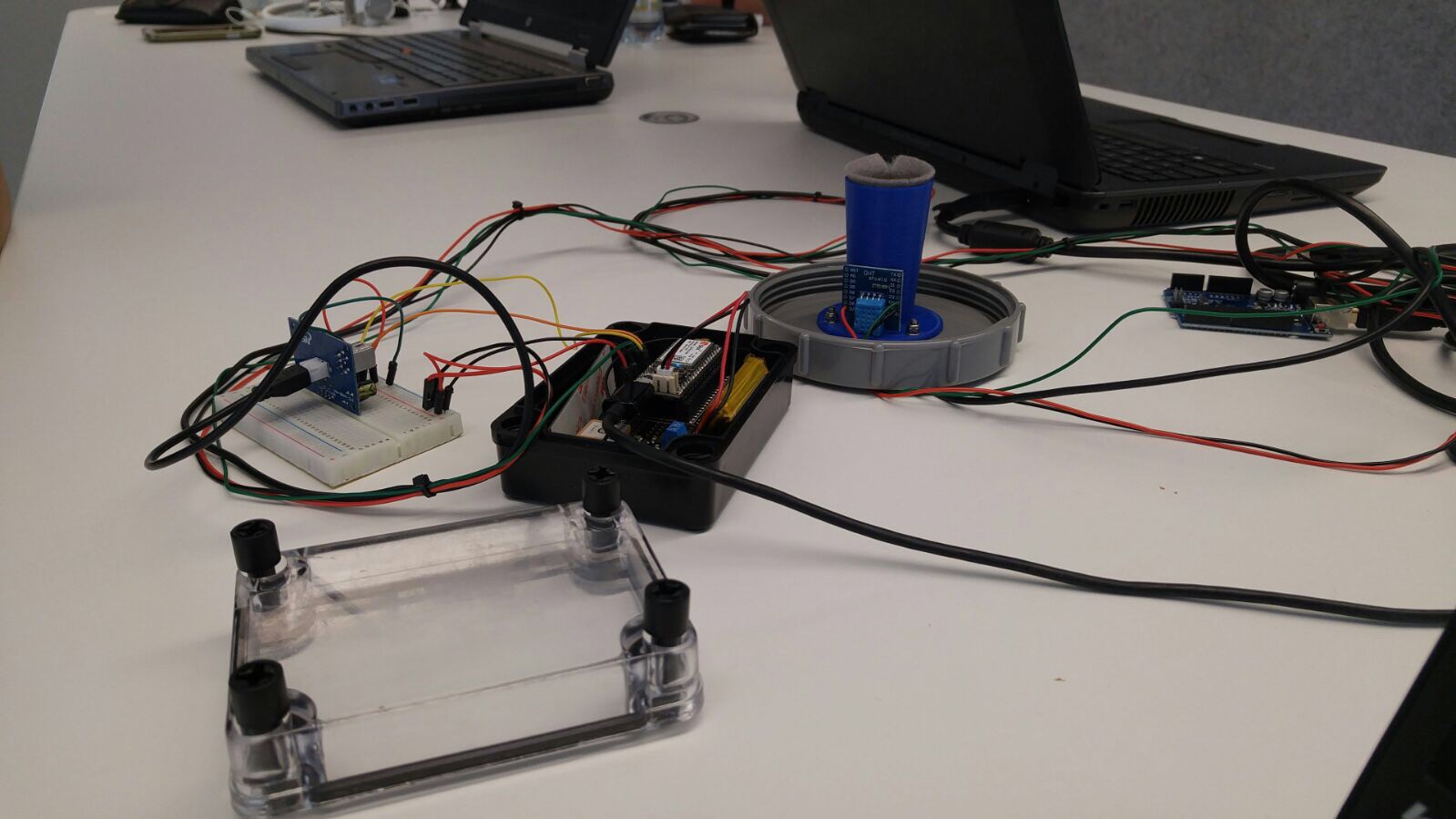

We just transferred the arduino code for the Ultrasonic sensor to Particle.io. An electron 3g is used to send the data to this platform. We faced some problems while doing this, because slightly different libraries are used in de particle firmware. Currently, we are trying to make the data a so called "variable" to request the information as a replacement of the serial monitor used in the arduino software. We still face some problems doing this, but we expect to find the solution soon.

Besides this transferring to the cloud, Jelle did research on working principles of the sensors. To really understand what our device does, we had to get our head around how all components of the system work. The working principles of the following sensors were examined:

- Ultrasonic sensor

- Sharp Infrared sensor

- Laser distance sensor

- Radar

- Pressure sensor

- Float-operated shaft encoder

Considering the pros and cons of the methods described above, the most suitable method for measuring a water level is the ultrasonic sensor (JSN-SR04T). The sensor is cheap and waterproof, which is a requirement in the moist working environment. Also, the measurements are accurate and have a negligible deviation. The only physical quantities that might affect the reliability of the sensor are the temperature and the humidity. Using a temperature-humidity sensor, the effect of these quantities on the speed of sound can be taken into account. At just one dollar, the temperature and humidity sensor doesn’t have a big impact on the budget. Furthermore, there are no moving parts used in this sensor and since moving parts require more regular maintenance, this is an extra reason to use the ultrasonic sensor.

Meanwhile, Maarten did research on the ethical perspective of the project. Will our project actually contribute in making a step forward in the development of a country like for instance Myanmar? For safety-reasons, one could immediately say that this will be a step forward. But other factors also influence the development. This is what our ethical research is about. We are working on an essay, which we will post when it is finished.

-

Open Log

05/15/2017 at 10:51 • 0 comments15/05/2017

During the weekend, one of our team members was working on changing the configuration of an Open Log. The data provided by the sensor usually comes in on the serial monitor. Using the Open Log the data will automatically be saved as a .txt file on a SD card. In the future we will configure the Particle Electron to save it's collected data on an SD card and send it to a cloud server as well.

To be continued...

-

Absorbent material and temperature influences

05/15/2017 at 10:28 • 0 comments15/05/2017

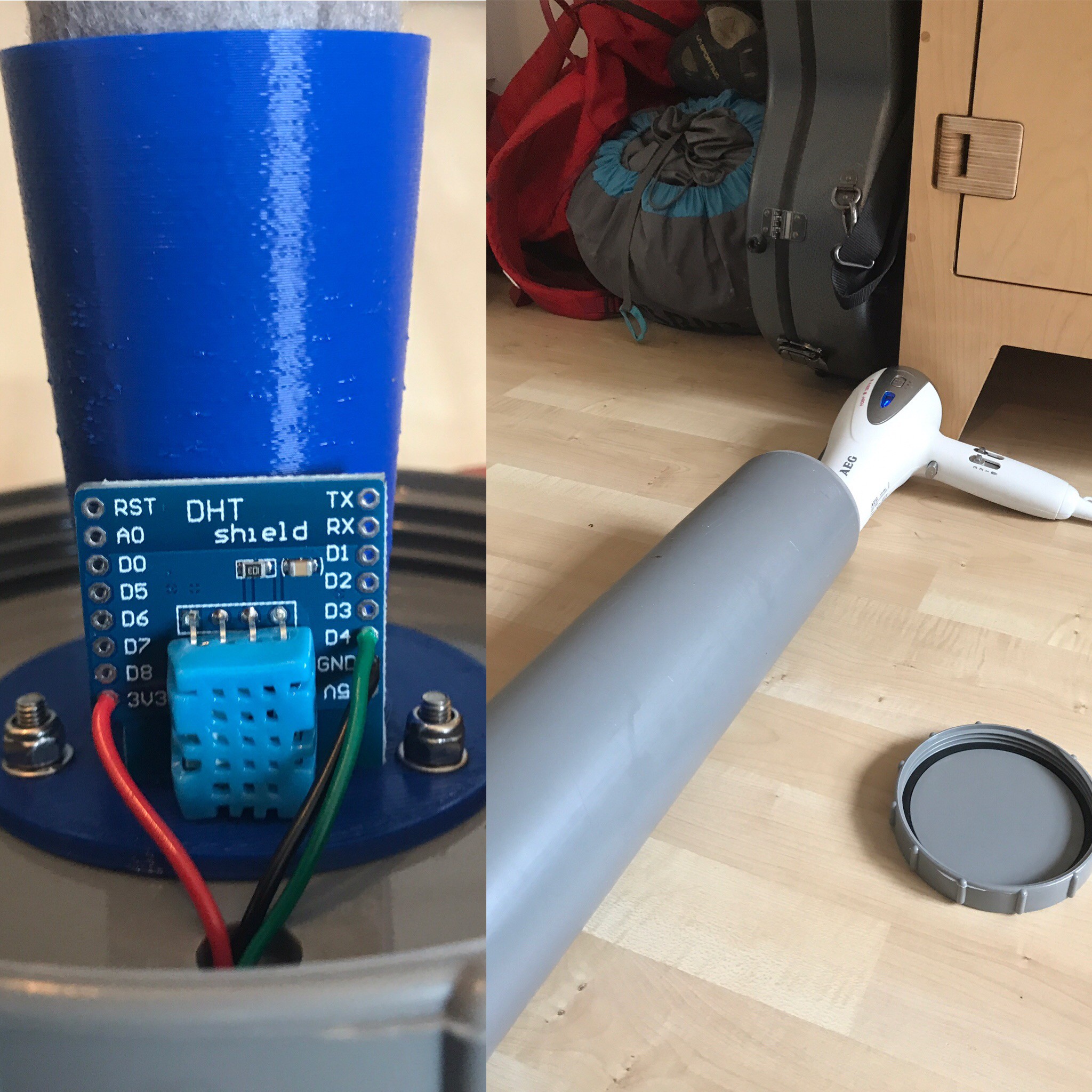

Last Friday we tried three different types of sound absorbent materials. The first one is plastic foam. We placed a bunch of foam at the small funnel and tested the sensor. Until 2.5m everything went well, but at larger distances the foam does not absorb enough. But, the combination of plastic foam with the big funnel worked excellent.

Nevertheless we would like to use as less material as possible, so we tried a second material, which was craft foam. This did not work at all. So we immediately tried a third one: felt. This turned out be the best material for our purposes. The size of the funnel does not matter. However, the possibility of accretion is a big disadvantage.

After looking for the right absorbent material, we tested the influence of a temperature gradient to the sensor. We used a hairdryer to warm up the air inside the pipe. As we expected, when the temperature rose, the measured distance was smaller than it should be. This is because of the higher speed of sound at higher temperature. In order to eliminate this error we added a temperature and humidity sensor. We are now trying to write a code which implement the data of the temperature/humidity sensor into the distance measurement to tackle the temperature problem.

-

Finally got the ultrasonic sensor working

05/09/2017 at 14:51 • 0 comments09/05/2017

First we want to thank the Hackaday jury members for selecting us as one of the twenty winners of the first round of the Hackaday Prize 2017. This is a great motivation and we will continue to work hard on this interesting project.

In addition to this good news, we finally found a solution to the problems we faced with the ultrasonic sensors.

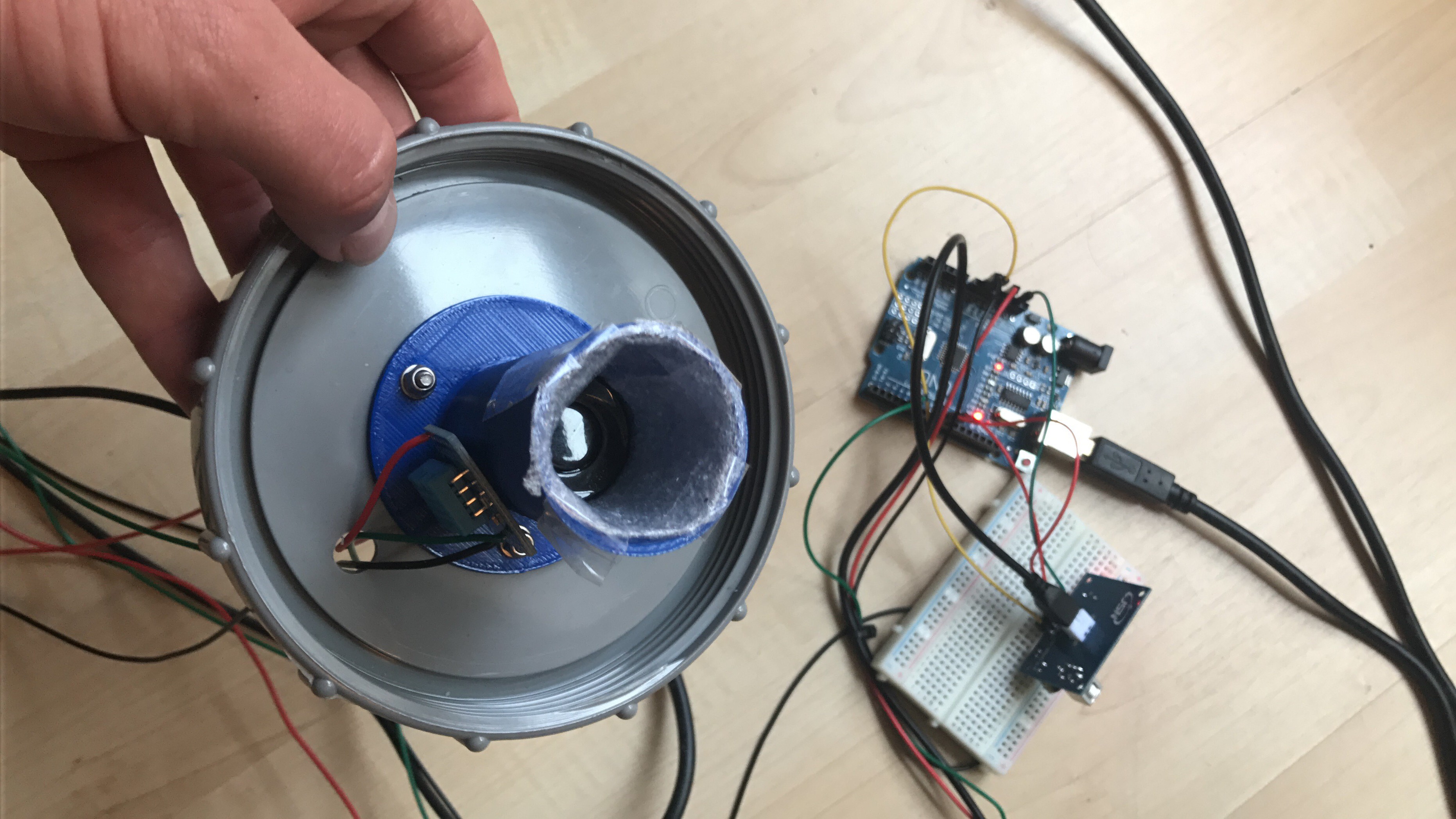

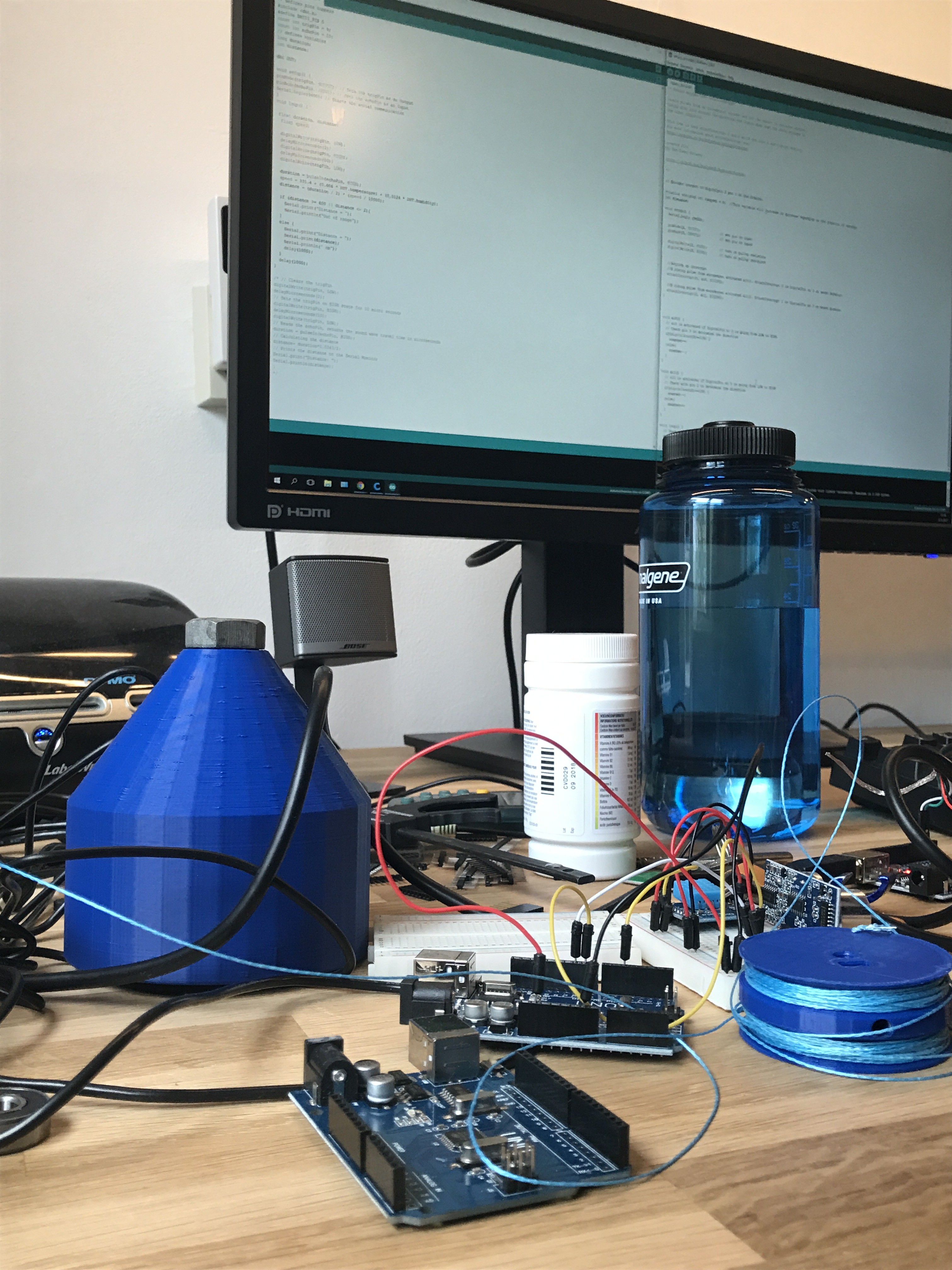

We already made a funnel, with a wide diameter, but this turned out to be insufficient. In order to fix this we first made a funnel with a smaller diameter (see figure), but this did not have the desired effect as well. The walls of the funnels reflected the ultrasonic waves immediately, so a decent water level measurement could not be made.

We thought that the material of the 3D-printed instruments did not absorb the waves enough, which caused the too low values. Therefore we needed a sound absorbent material. The first thing that came in mind to test this was toilet paper. So we pasted some toilet paper on the walls of the funnels. Against all our expectations, this worked perfectly. In the video, one can see the results of the measurement, while the water level was increasing.

Besides the placement of toilet paper on the funnels, we also tried to place some toilet paper on the walls at the top of the pipe and use the sensor without any funnel. This turned out to work perfectly as well. Economically speaking this has even more advantages. It will be cheaper to place only an adsorbent material at the top of the pipe than produce a funnel ánd place an adsorbent material.

From now on we will look to find a more durable adsorbent material to place at the top of the pipe.

-

Test sessions

05/08/2017 at 13:25 • 0 comments03/05/2017 - 08/05/2017

Wednesday the third of May we joined the laboratory tour, which was mandatory before doing our experiments. After the tour we immediately began testing, starting with the encoder. This method worked out very well. The values given by the sensor matched perfectly with the real water level values. Just small errors occur, since the diameter of the pulley changes when the water level changes.

We also tested the non-waterproof ultrasonic sensor. Unfortunately this sensor had some trouble with a small notch in the beginning of the pipe. The ultrasonic waves were bounced back immediately by the notch, and not by the water surface. In order to fix this error we pasted some tape over this notch, to make the pipe surface smooth. This did not have the desired effect.

On Thursday we went on trying to fix the problems of the non-waterproof ultrasonic sensor, as well as starting with the waterproof ultrasonic sensor. Also on this day, an infrared distance sensor was made available by the University.

In order to make the ultrasonic sensors work, we designed a funnel, so that the notch is skipped. For the IR sensor we designed a bearer, which should help the fixation to the pipe.

On Monday we first started by testing the IR sensor. The respons was good, but the values fluctuate in a range of 10 centimeters. The ultrasonic sensors still didn't work, despite the funnel.

We are now discussing how we should make the ultrasonic working. We consider to get some help from experts of the University.

-

Preparing experiments

05/02/2017 at 10:30 • 0 comments02/05/2017

As the test setup present in the laboratory was not suitable for our experiments yet, it needed some modifications. The tubes did fit threaded caps, so six of these were purchased to attach the different sensors to. This will make sensor placement and removal easy. An extra advantage of using these caps is that they close off the tubes and thus the conditions in the tube (e.g. temperature, humidity) can be varied.

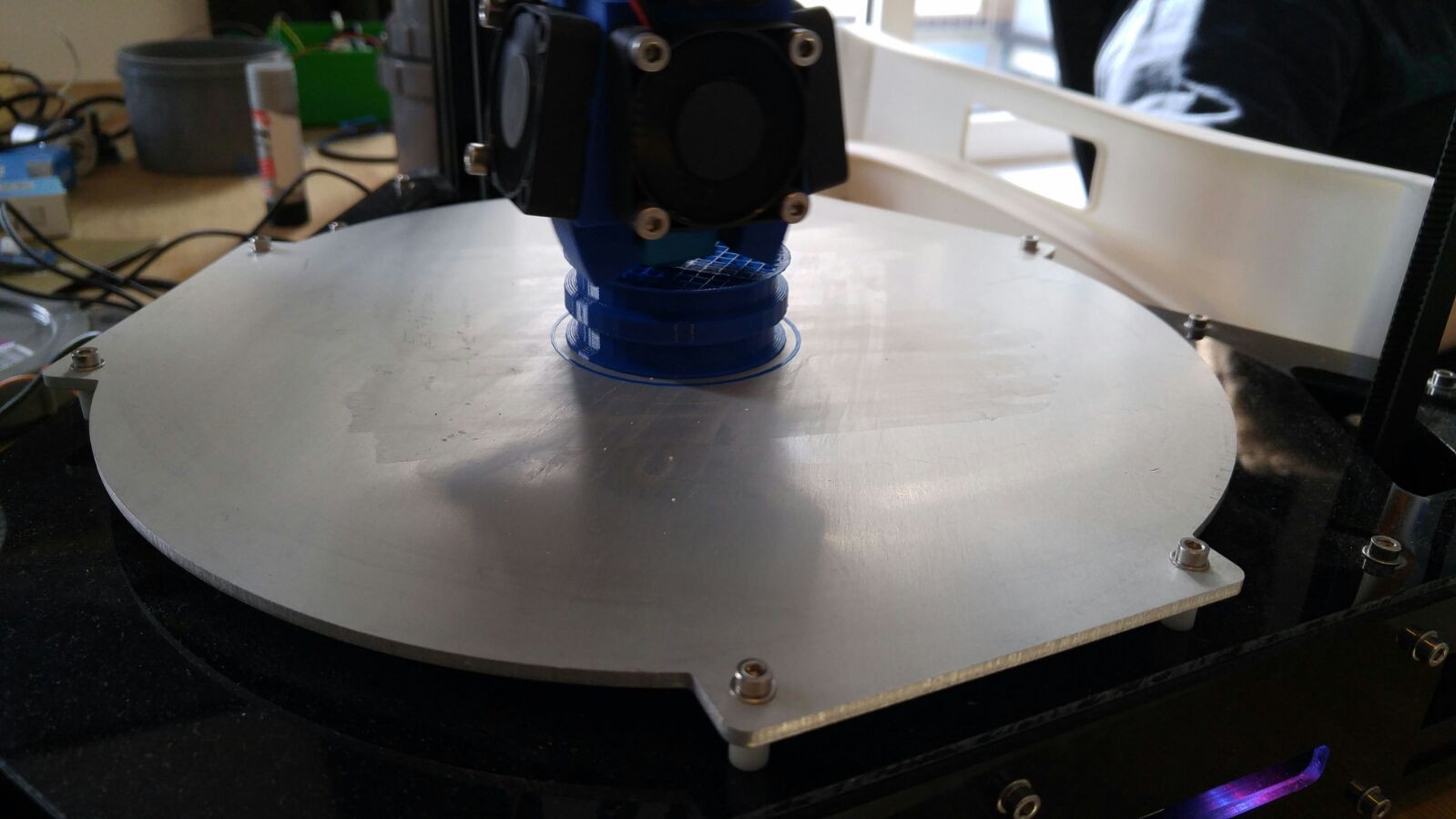

The caps had to be modified to fit the sensors. Holes were drilled to attach the ultrasonic sensors and an adapter was 3D-printed for one of them. To fix the encoder on a cap, an encoder base is designed and printed.The method with a float, of course needs a float. So this measure instrument is designed and printed too.

After producing and assembling all the test equipment, programming starts. All methods are programmed and temperature and humidity influences are taken into account, except for the waterproof ultrasonic sensor. So when this code is written, all experiments are well-prepared in order to pick the best measuring method.

Tomorrow (Wednesday the 3rd of May) we will have a tour through the laboratory and hopefully we can start with some of the experiments

-

Preparing for sensor selection

04/30/2017 at 14:04 • 0 comments28/04/2016 In order to determine the best measuring method for water levels, we went through the following proces. First we looked at all the different options that are out there. Water levels can be measured with: pressure sensors, ultrasonic sensors, radar, laser, float with pulley and encoder, variable resistor, camera's and sattelite imaging. In order to find the most affordable, accurate and reliable sensor, we made an initial selection based on price, specs and availability. Next we ordered a bunch of different sensors, that came out as good options.

In order to test the performance of these sensors, we have prepared a test setup based on a tube in which the water level and temperature can be altered.

![]()

We have prepared a bunch of different holders for the sensors we would like to test and we have written some code, which will allow us to analyze the sensor performance. The code can be found in the dropbox folder.

![]()

![]()

Next week we will test the sensors and hopefully select the best candidate, so we can start designing our first prototype.

Affordable Water Level Measuring Station

An Affordable cloud connected water level measuring station for developing countries.

Nevertheless we would like to use as less material as possible, so we tried a second material, which was craft foam. This did not work at all. So we immediately tried a third one: felt. This turned out be the best material for our purposes. The size of the funnel does not matter. However, the possibility of accretion is a big disadvantage.

Nevertheless we would like to use as less material as possible, so we tried a second material, which was craft foam. This did not work at all. So we immediately tried a third one: felt. This turned out be the best material for our purposes. The size of the funnel does not matter. However, the possibility of accretion is a big disadvantage.

Tomorrow (Wednesday the 3rd of May) we will have a tour through the laboratory and hopefully we can start with some of the experiments

Tomorrow (Wednesday the 3rd of May) we will have a tour through the laboratory and hopefully we can start with some of the experiments