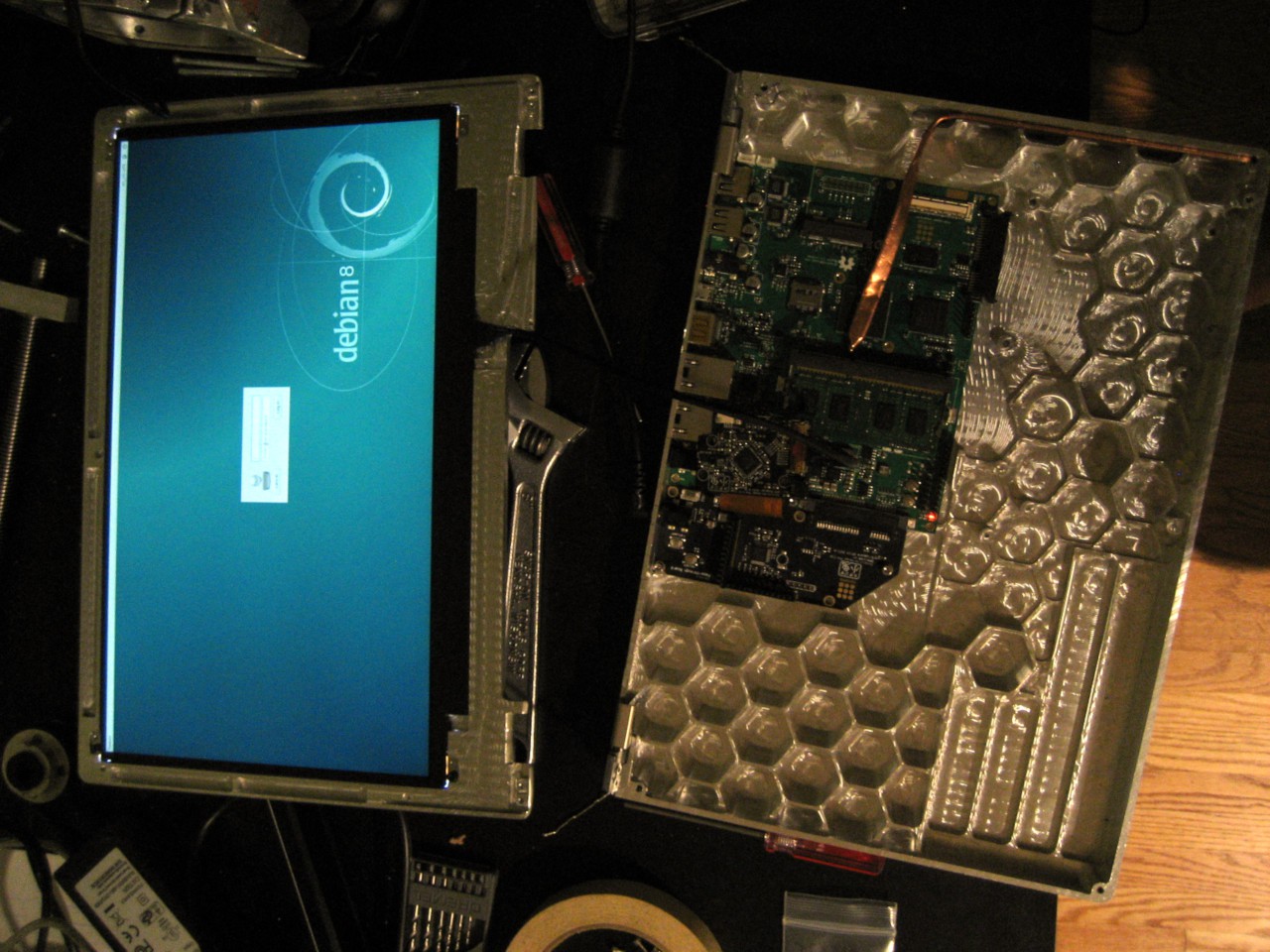

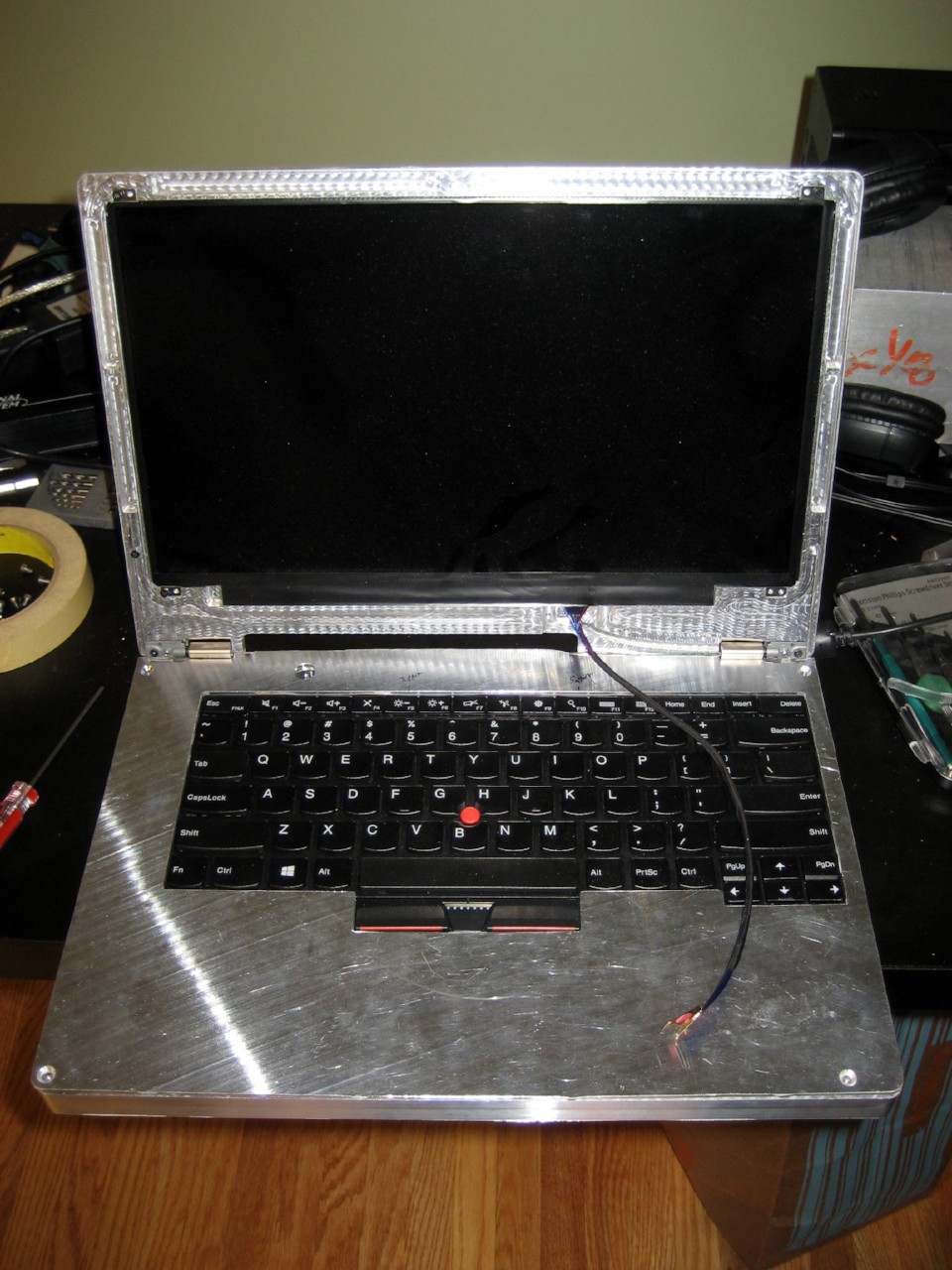

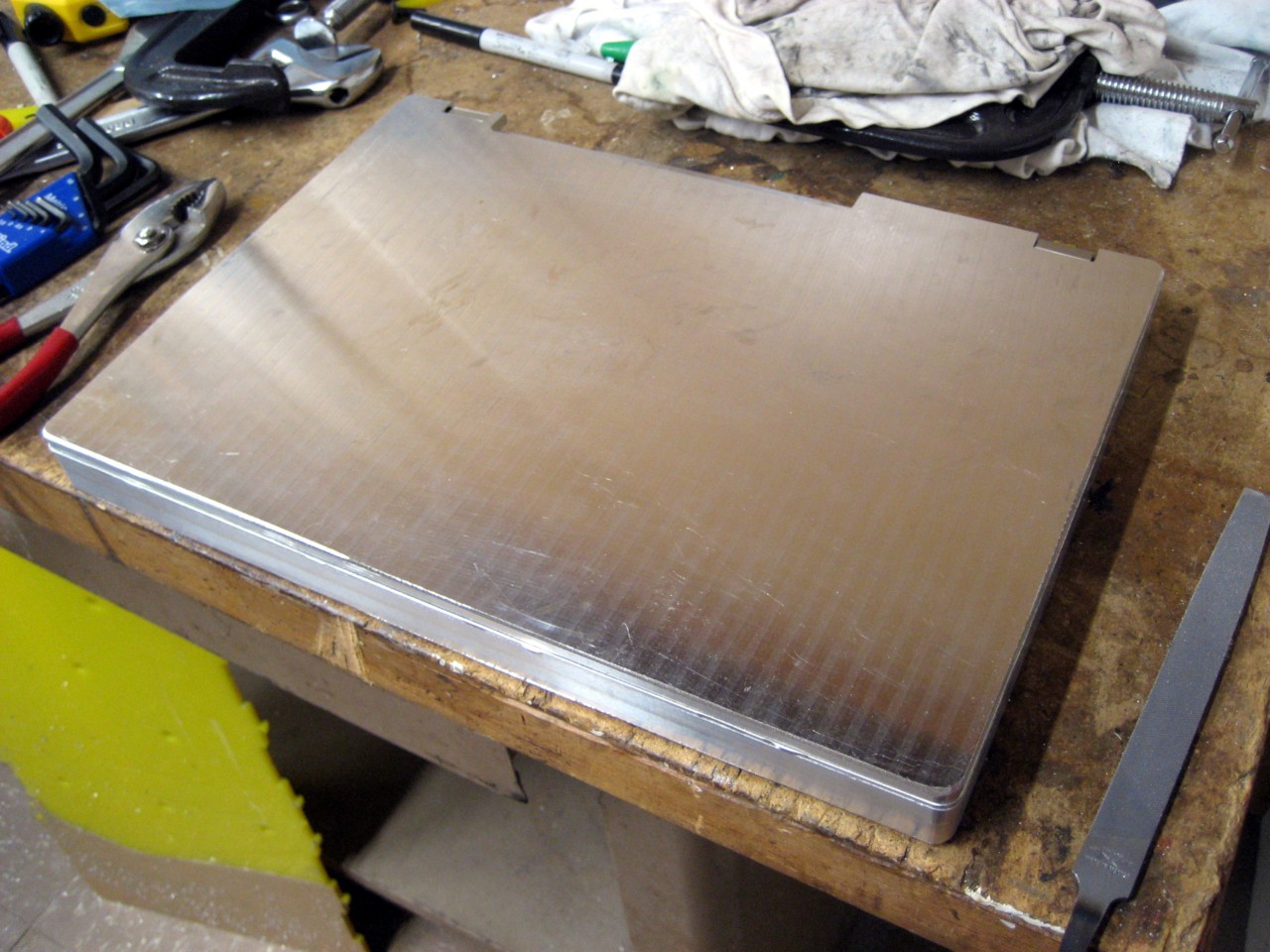

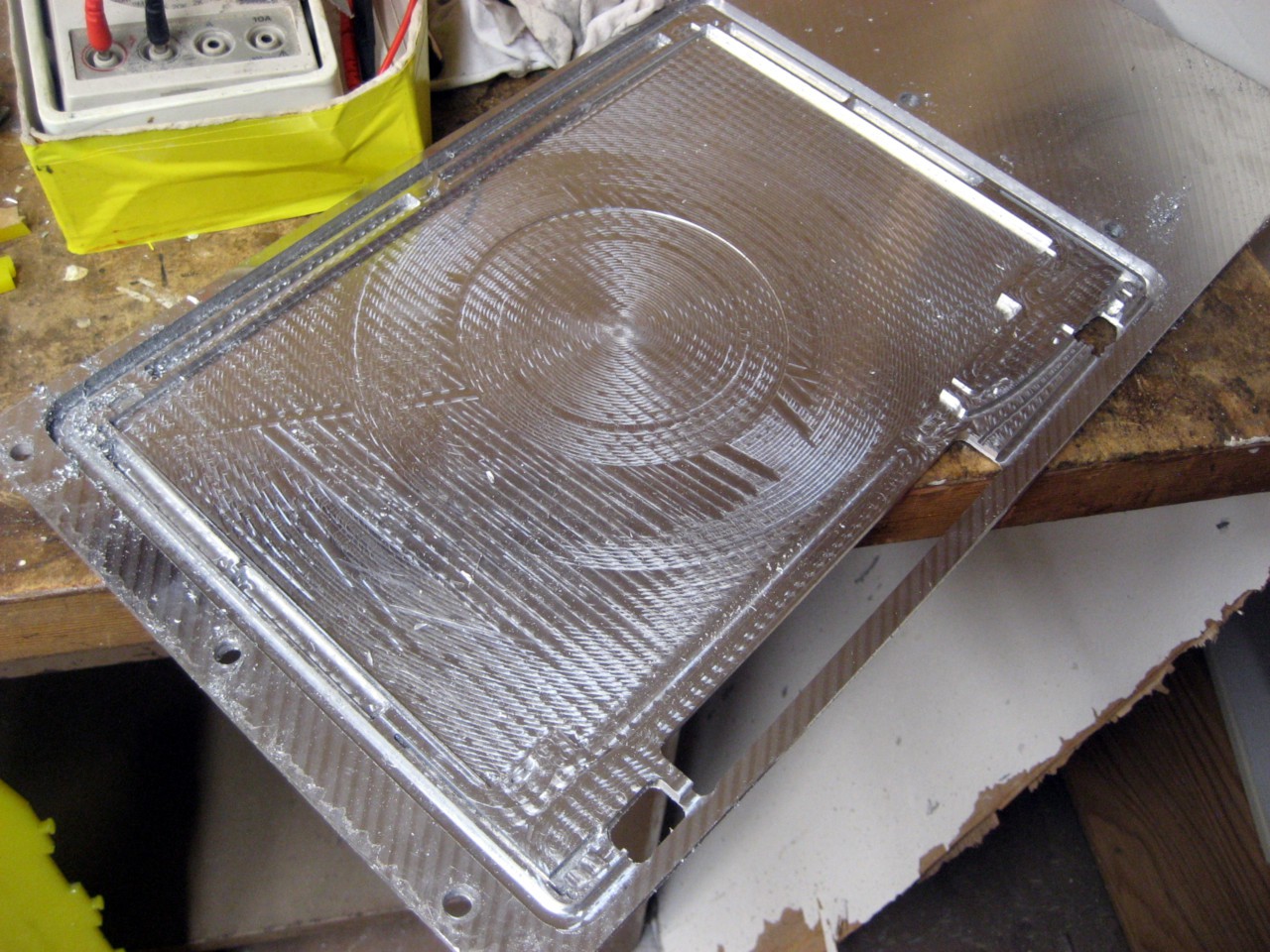

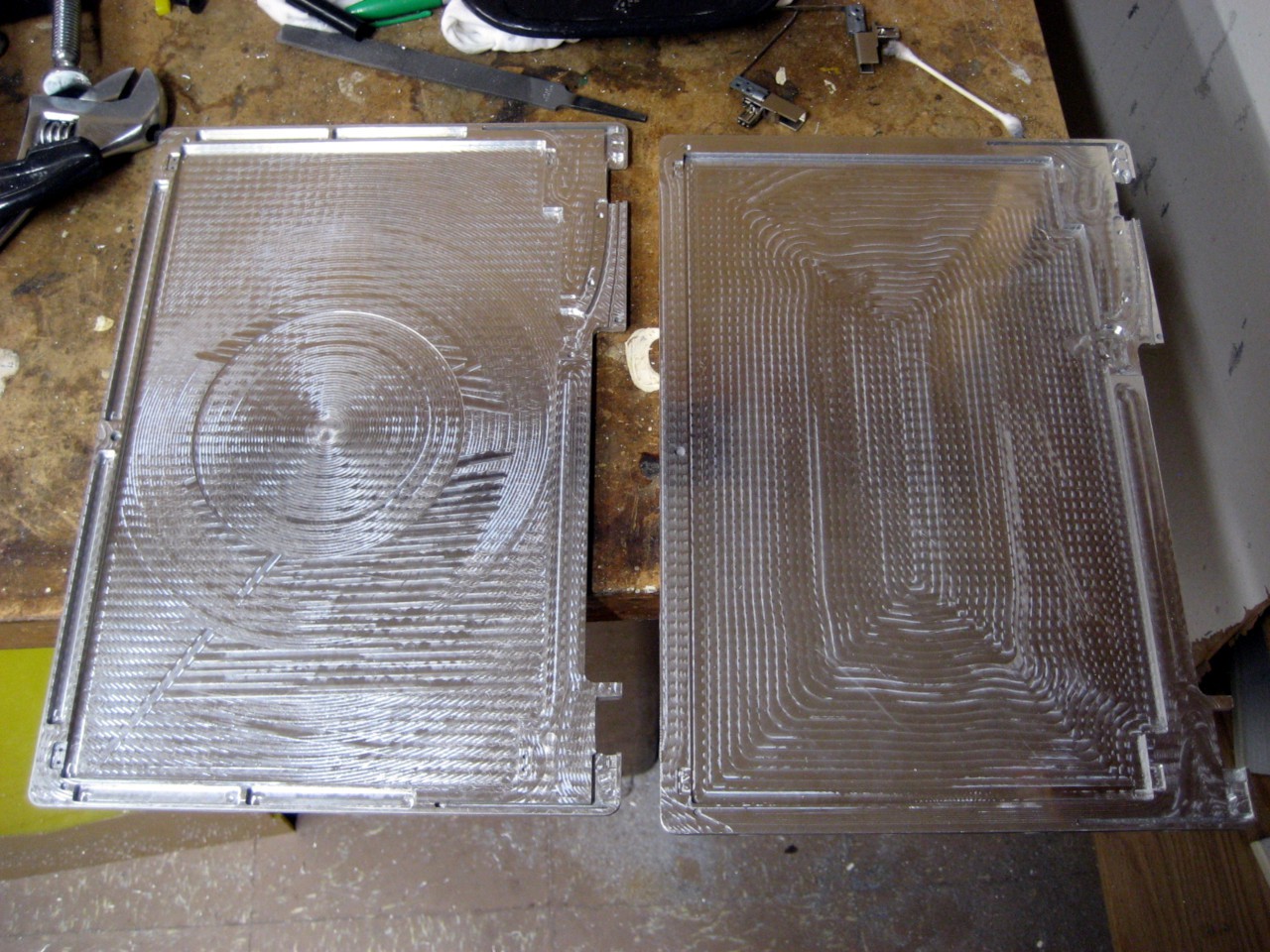

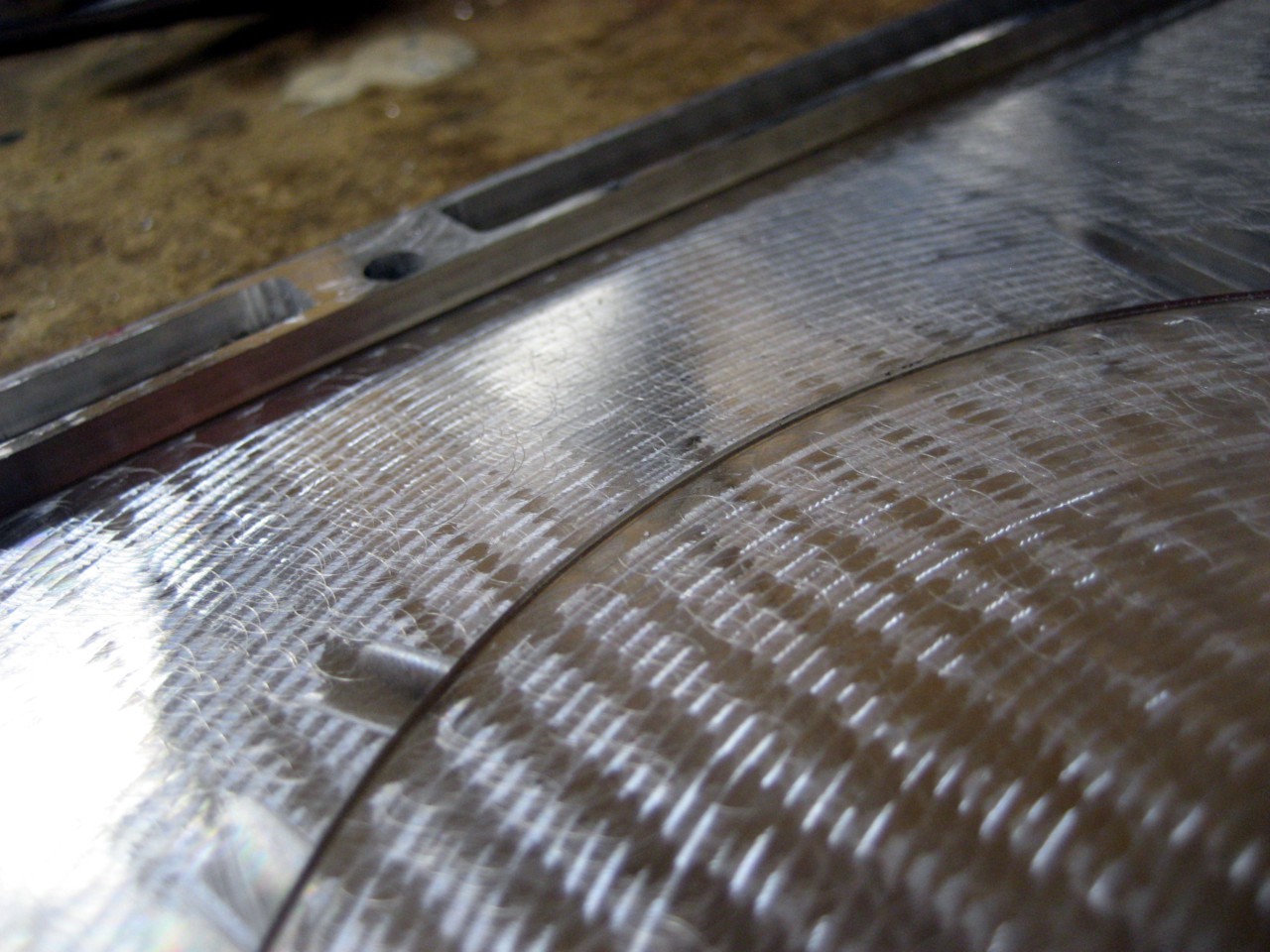

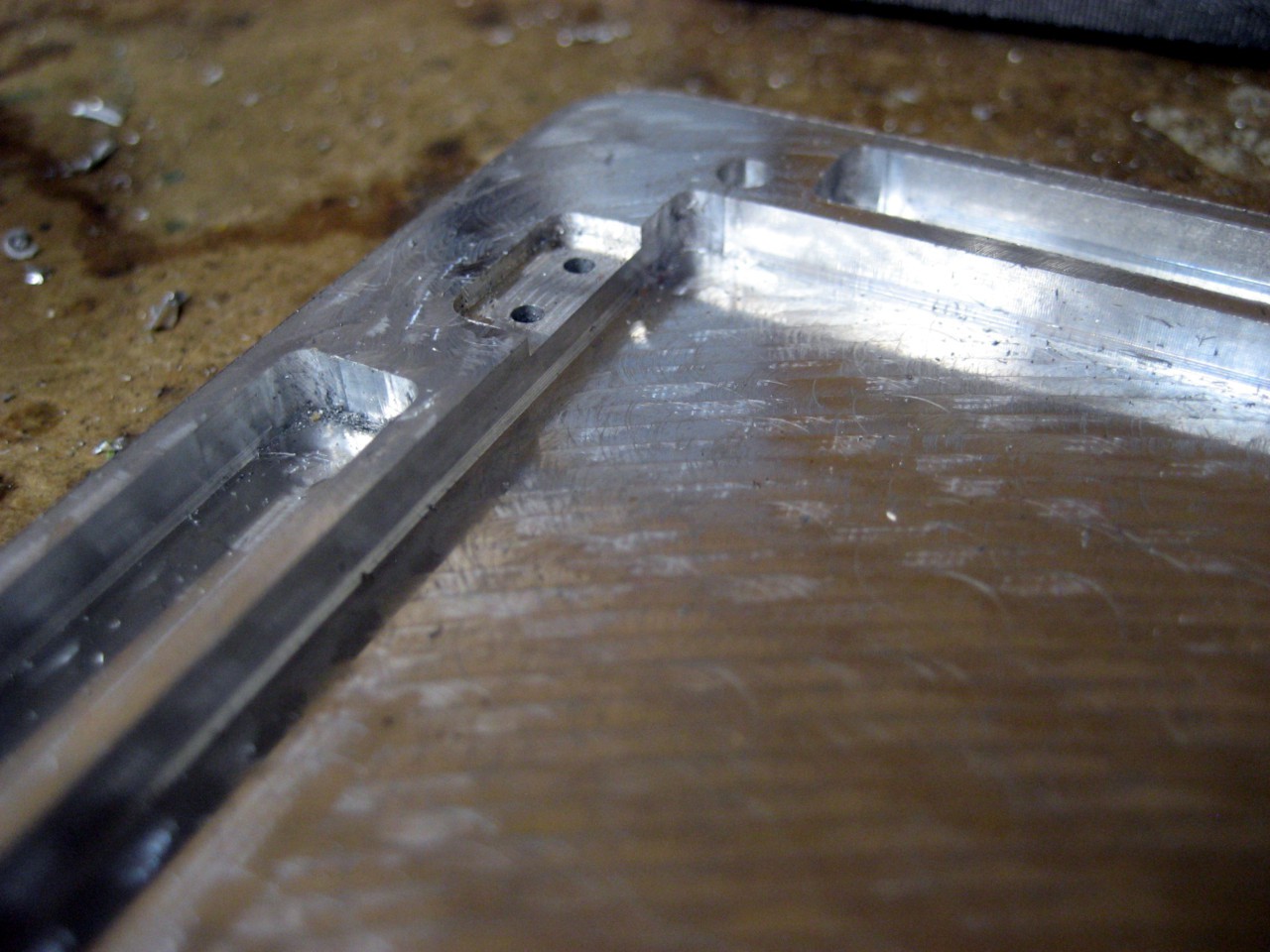

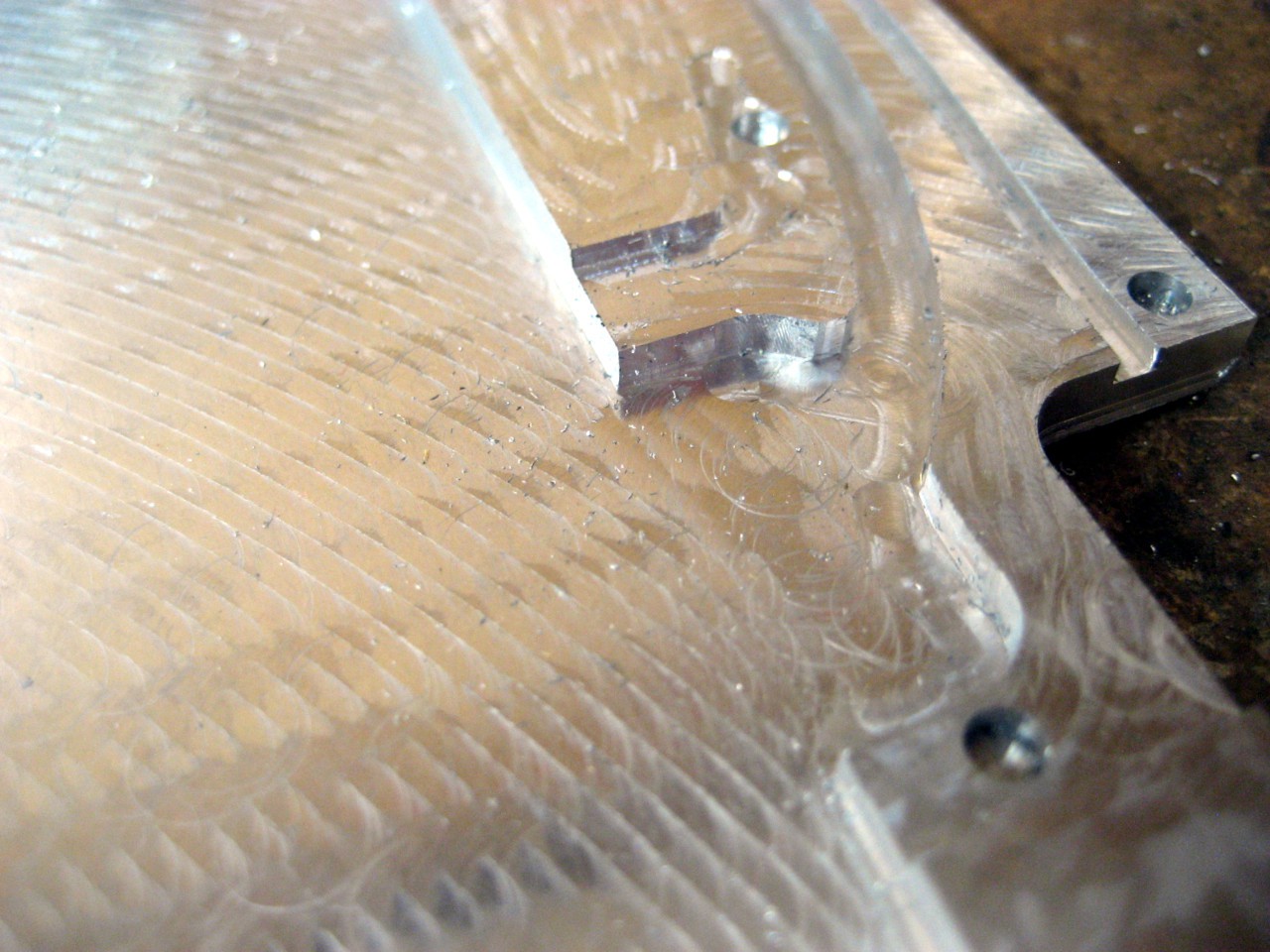

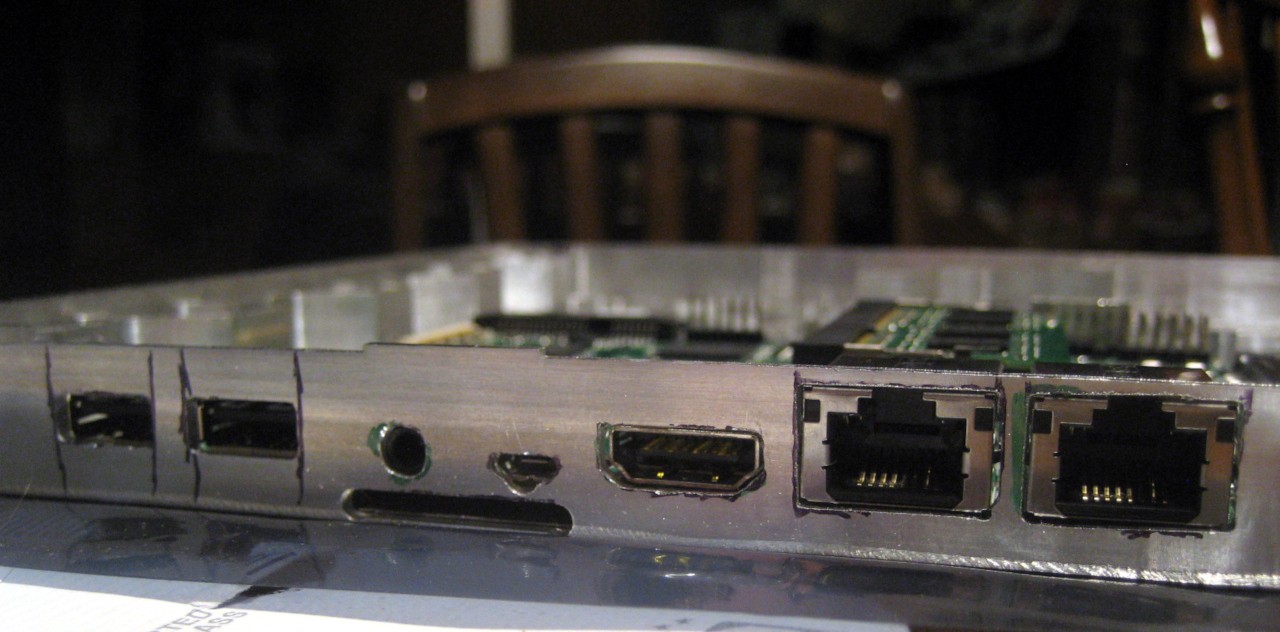

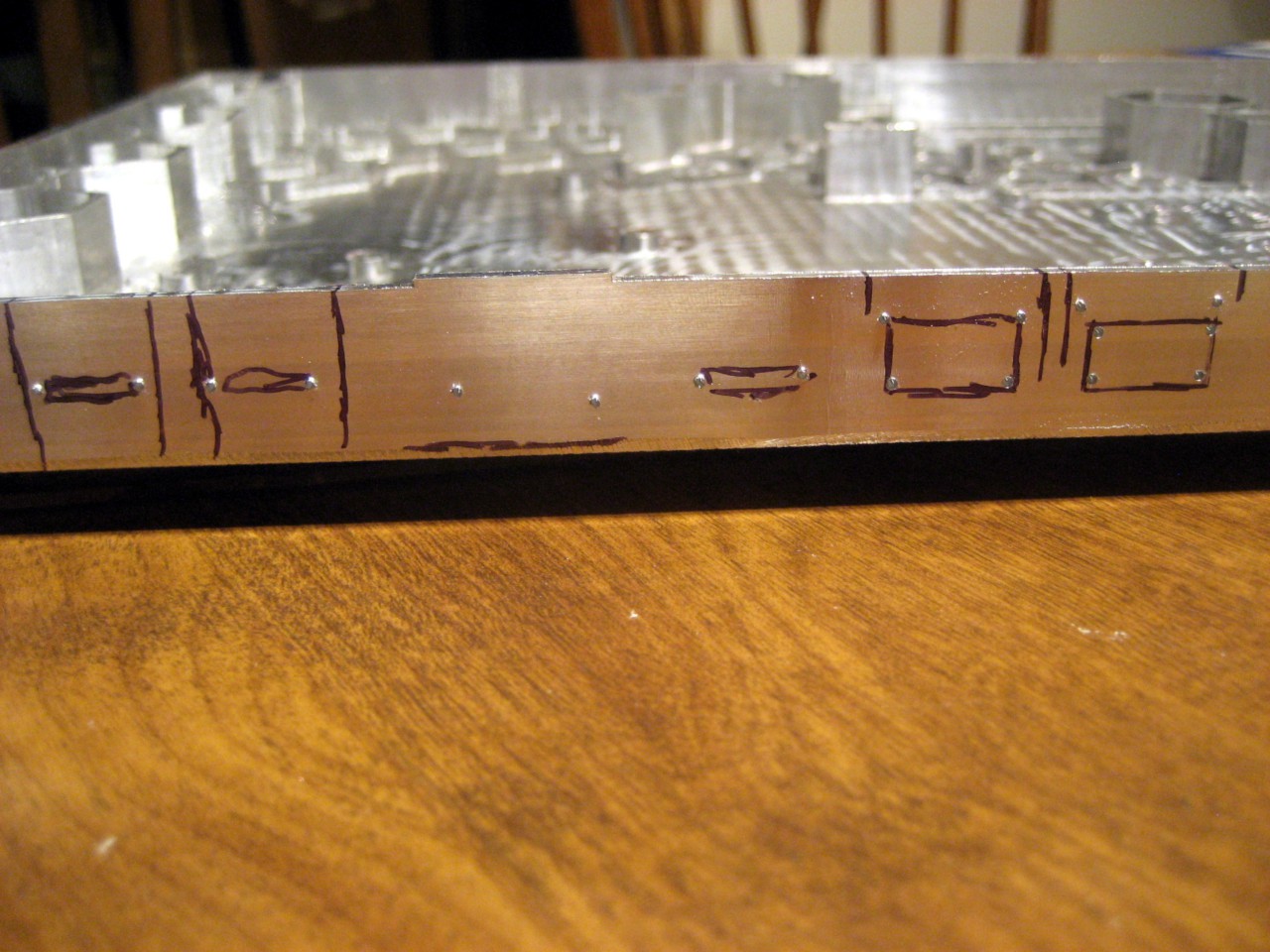

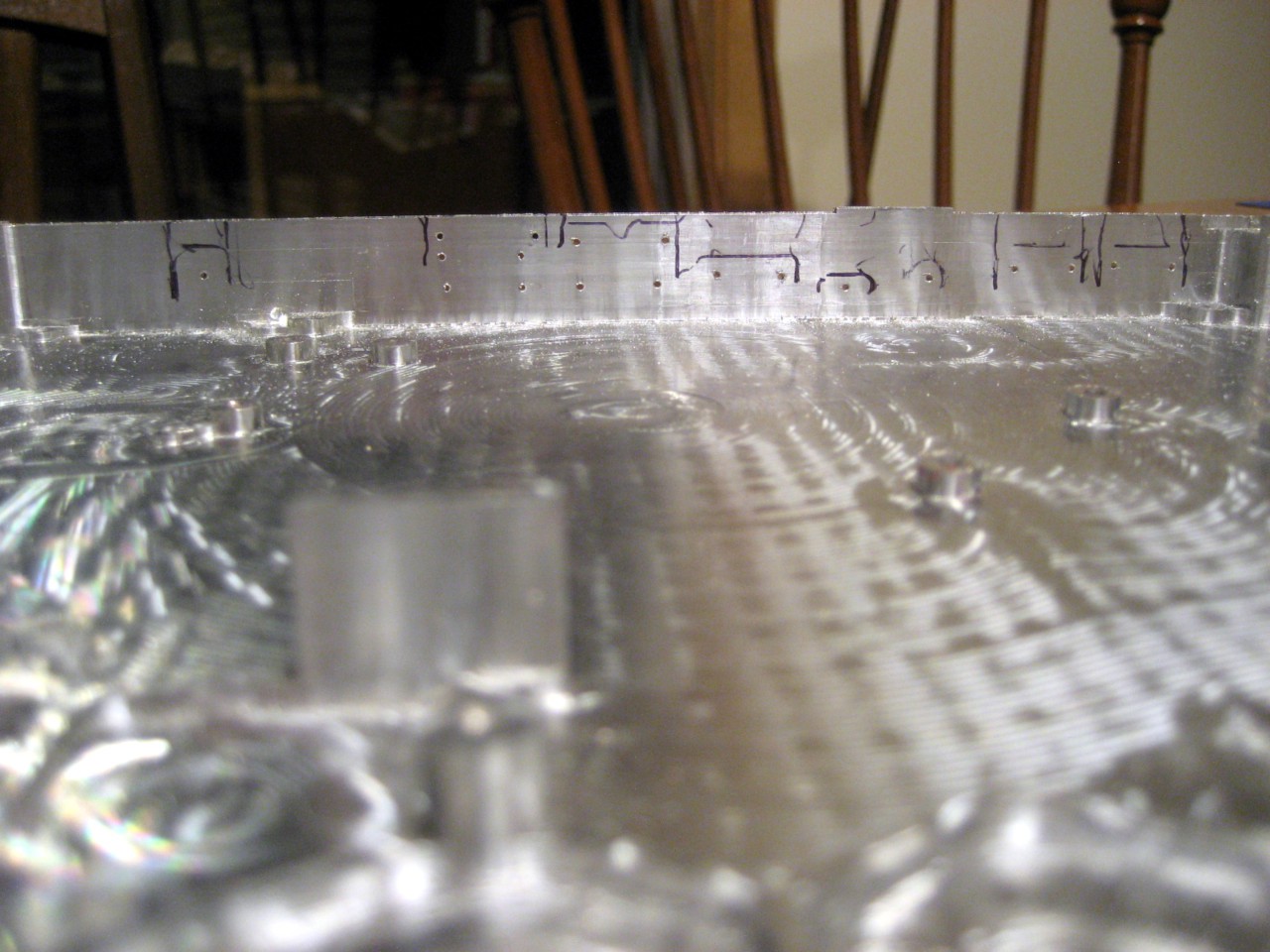

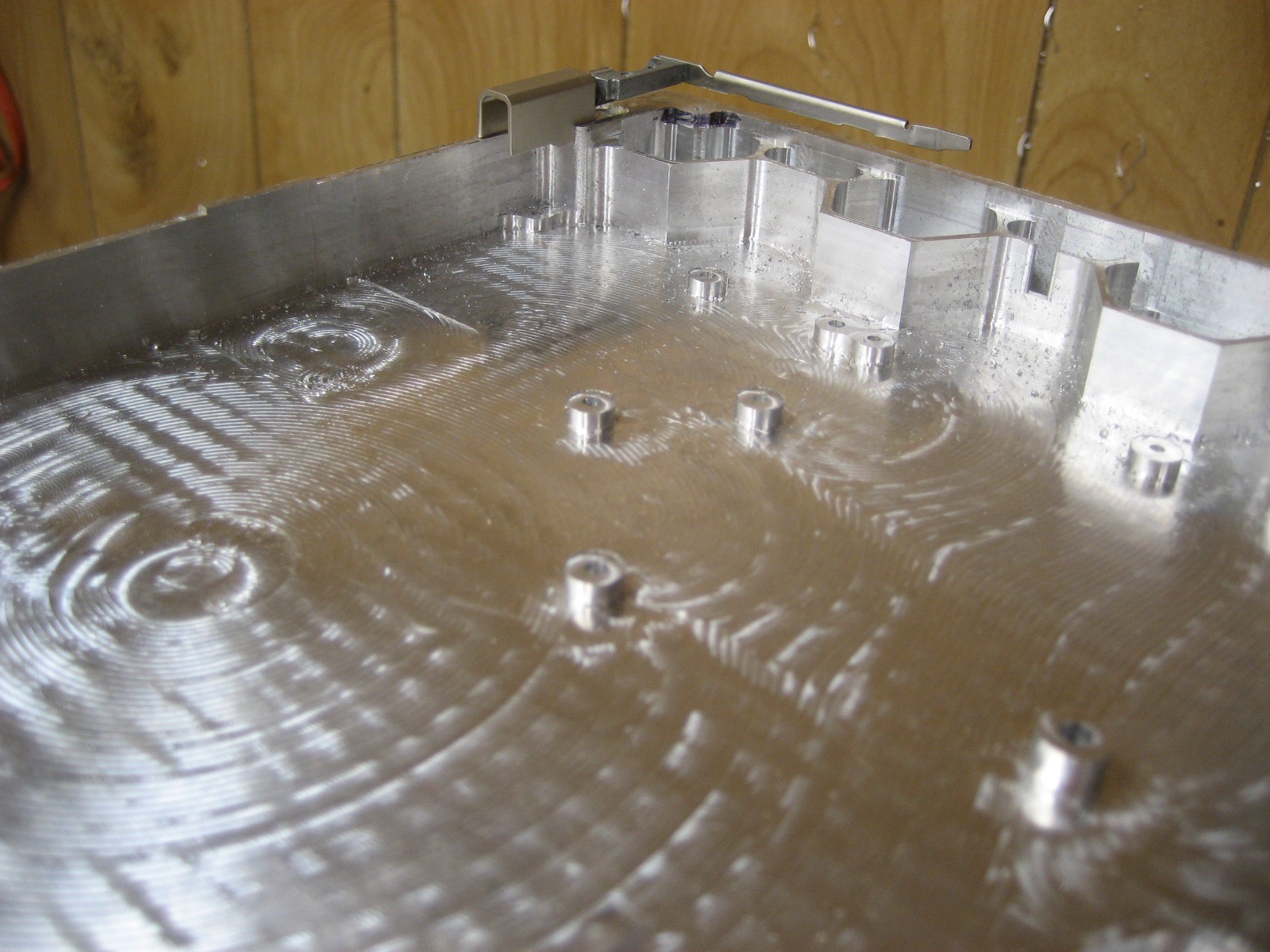

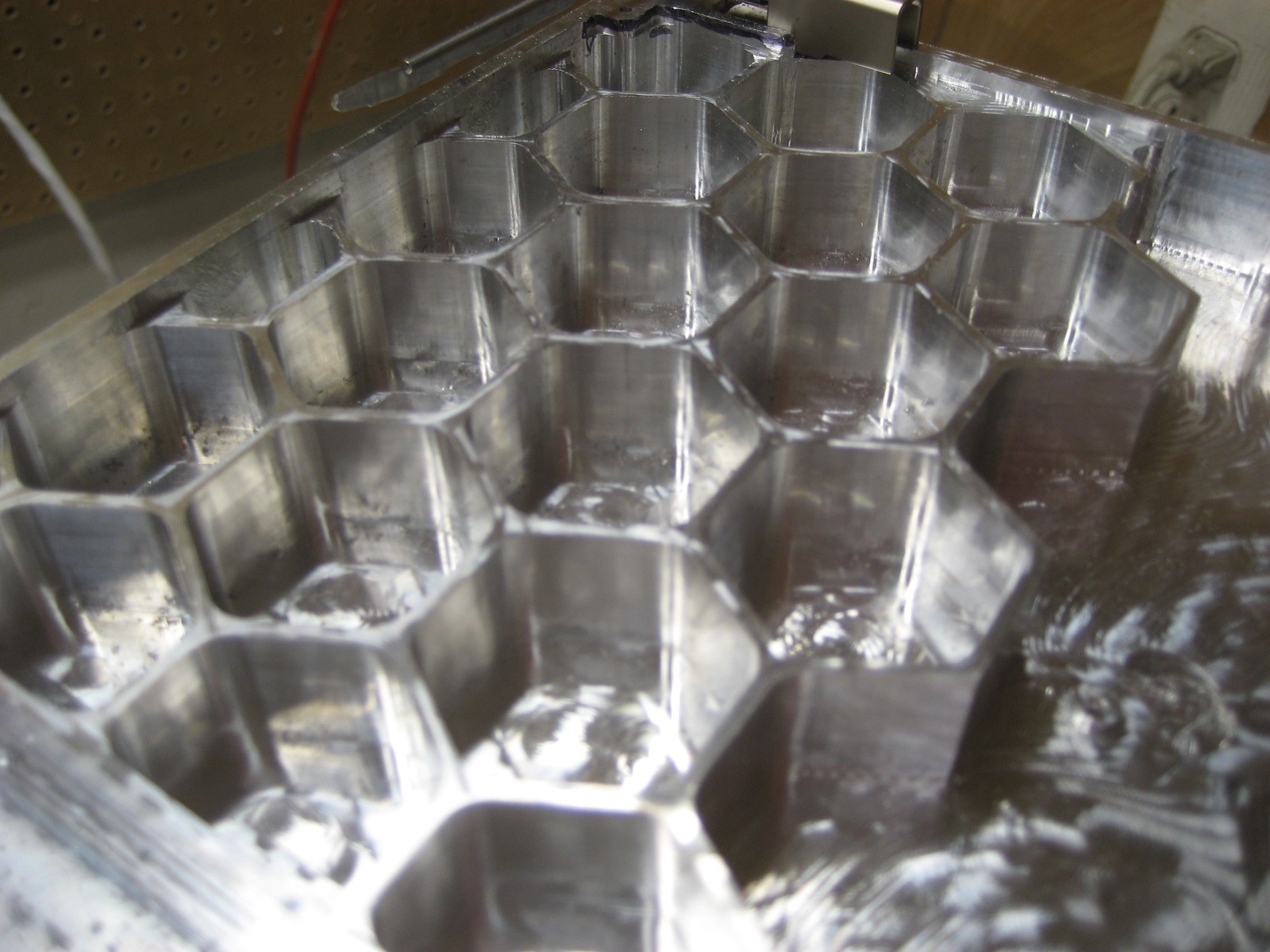

This is my effort to turn the Novena open-source "laptop" into a REAL laptop. I've designed a new case around he boards and other parts from the original Novena CAD, and am machining it on my CNC mill out of aluminum.

The Novena project took care of all the hard stuff- I just need to make a box!

dbtayl

dbtayl

Any further progress on this cool laptop?