The kiln has two heating elements, each about 33 inches (84 cm) long - this is determined by the physical construction of the kiln. We are looking for a heater power of 1500W at about 110AC, so this gives us a heater resistance of about 8 ohms and heater current of about 13.6 amps. The resistance of the heater will increase slightly as it heats up, but for sizing purposes we'll use the cold resistance so we don't trip the (15 amp) breaker when the kiln starts up. There are two options: two 16 ohm heater elements in parallel, or two 4 ohm heater elements in series.

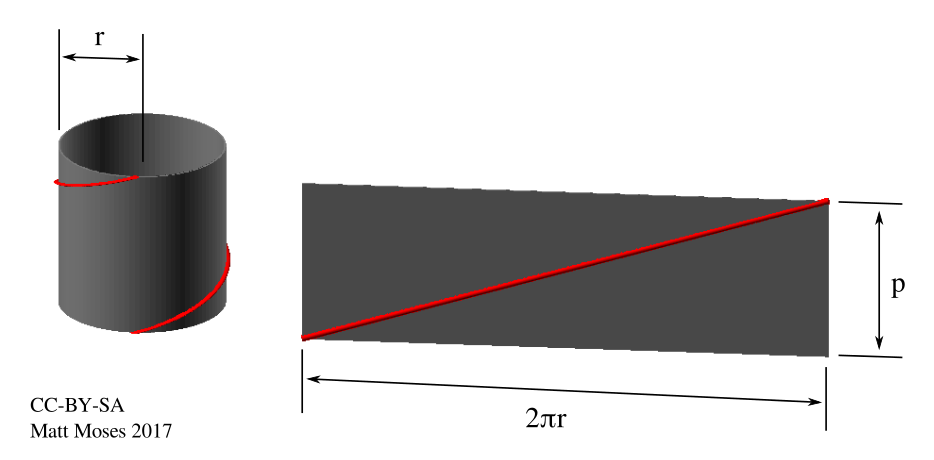

It is likely that the heater will be wound into a coil, so we need to know how to calculate the length of a helical path. Referring to the figure below, we have the length of one turn of a helix as

where r is the helix radius and p is the pitch (distance traveled along axis for one turn). L_helix is the length of the red trace shown in the image below. The total length of the heater wire is

and the total length of the coil is

where N is the number of turns.

The next step is to size some candidate heater elements using parameters for some common nichrome heating wire. According to this table on the Wikipedia Nichrome page the recommended wire gauge for a 1500W heater operating at 110-120V is B&S No./AWG 12-16.

As an initial check, let's pick the Nichrome 80 alloy (this appears to be the same as "Nichrome V" in some sources). According to Wikipedia, this alloy has a composition of 80% nickel and 20% chromium, and a resistivity of 1.09E-06 ohm meters. With these numbers, a 16 ohm wire would be 19 meters (63 ft) long. That's a little long. A 4 ohm wire would be 4.8 meter (16 ft) long. So let's go with two 4 ohm heaters in series.

OK, on to the next step. Let's stick with 16AWG Nichrome 80 for the moment. We'll need about 5 meters of wire (16 ft) for each 4 ohm heater.

At this point, we have several constraints on the heater coil:

16AWG, Nichrome 80

L_coil = 0.84 m (33 inches)

L_wire = 5 m (197 inches)

r = 3mm (0.12 inches) - this is set by the desire to have a winding mandrel of 3/16 inch diameter

These constraints completely determine the shape of the coil, and we can solve the above equations for the pitch p. First let's write down this relation

and then we can plug this into the very first equation up top and rearrange to get

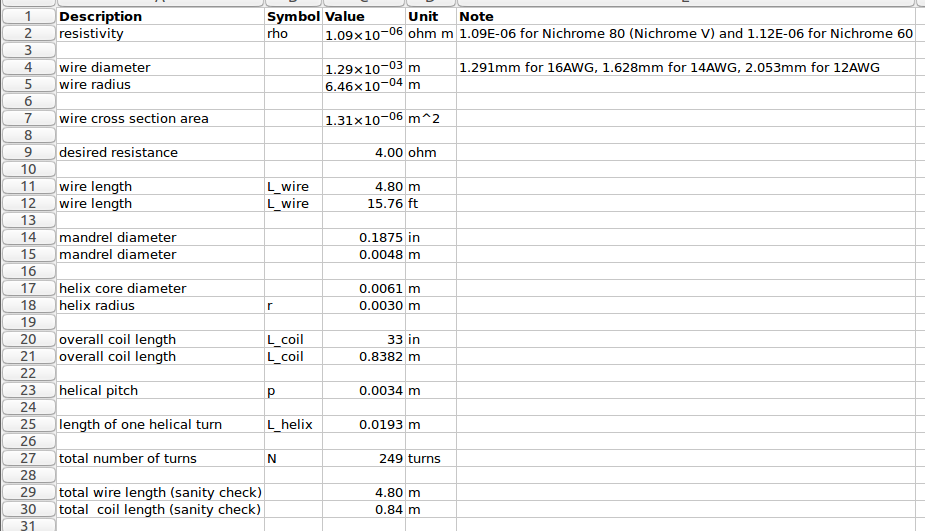

Finally! Now we can get the pitch of the coil and figure out if this is something we can wind by hand using the little Sherline lathe. There is a spreadsheet to perform these calculations on the Repkiln Github repo called heater_coil_calculations. Here is a screen capture,

So the pitch is 3.4mm (0.134 inches). It should work out fine to wind this by hand on the lathe. Stay tuned for that in a later update!

So the pitch is 3.4mm (0.134 inches). It should work out fine to wind this by hand on the lathe. Stay tuned for that in a later update!

SUMMARY: There will be two heater elements, each 4 ohms, in series, for a total heater resistance of 8 ohms. Each heater will be made of 5 meters (16ft) of 16AWG Nichrome 80 wire. Each heater will be wound in 250 turns on a 3/16 inch diameter mandrel, with a pitch of 3.4mm (0.134 inches), for a coil length of about 33 inches (84 cm).

Matt Moses

Matt Moses

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.