-

Laser preheating in three-dimensional printing

02/07/2023 at 08:27 • 1 commentThe aim is to construct prior art to circumvent US11192298B2 (Stratasys)

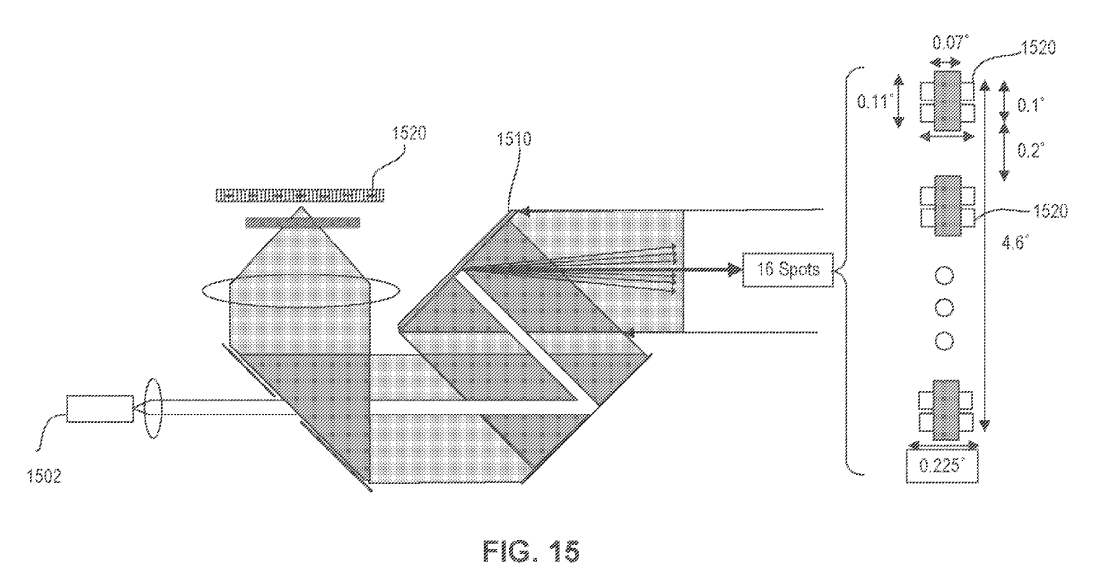

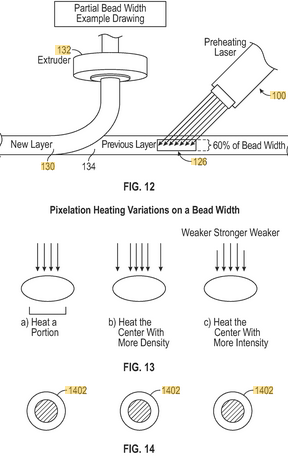

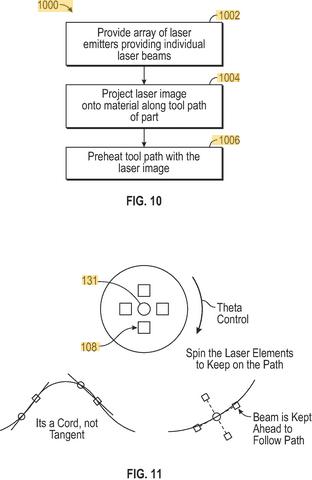

Stratasys envisions the preheating process as follows

![]()

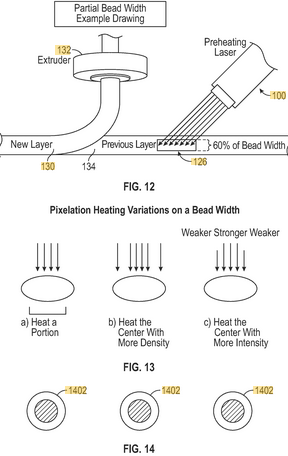

The projection is along the filament line and less wide than the beam width.

The laser is kept on the filament using theta control.![]()

Stratasys seems to think it it necessary / optimal that the laser image has a width less than a commanded bead width of the bead.

I propose the following a laser prism scanner projects a line orthogonal to the filament path.

This circumvents the patent as the projection is greater than 50-75 percent of the bead width.

It also no longer requires theta control. Only the part of the scanline is used which optimally preheats the filament is required. Intensity could be altered over the filament.It might be beneficial to extend the prism and use a plurality of emitters (lasers or leds). As it allows for a more careful preheating of the filament.

This would then bring us into the legal domain of US10114289B2 and the activities of my former colleagues (AMsystems).

You are using a plurality of emitters through a rotating prism.As alternative a combination of two rotating prism could be used with a single laser.

A stack of laser laser prism scanners could be used. That is multiple laser prisms scanners are placed in front of the extrusion. This could be beneficial if the distance required is sufficiently large.

That it is more cost effective than a single prism with a plurality of radiative sources.As outlined earlier, I claim all the above for the case this is done after the extrusion.

This is possible beneficial as well. -

Thermal Radiation Heating Patent Loophole

02/06/2023 at 08:50 • 0 commentsI studied the thermal radiation heating patent US20210387401A1, a bit more.

Orion AM basically claims it solved the homogeneity issue for fused filament printing, see picture.![homogeneous structures Strong interlayer bonding]()

This is big. At first sight, there seems to be an issue with their patent.

If you look at the actions from the US patent office, you see that the first 11 claims are withdrawn and the 12th claim is amended.

It has one big loophole; " at least one print heating device for applying thermal radiation"

Thermal radiation is electromagnetic radiation generated by the thermal motion of particles in matter.

Solid state lasers and LEDS do not create electromagnetic light via thermal motion.

As such, you are able to circumvent it.

Reason seems to be that using lasers to increase bonding between layers has been patented by Mark Gordon in 2016 US9339972B2.The patent expired due to fee issues. Someone seems to have made an expensive mistake here.

There seems to be some other patents, one which also uses a roller.

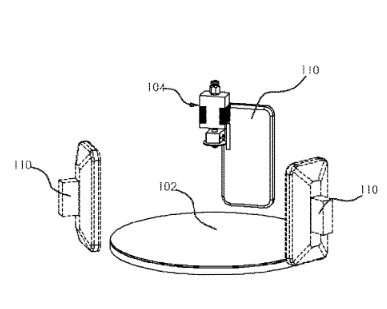

A crucial one is by Stratasys (https://patents.google.com/patent/US9339972B2/en)![]()

Key seems to be that they apply the laser prior to deposition. Stratasys seems to envision some sort of of theta control.

-

Thermal Radiation Heating using laser scanning

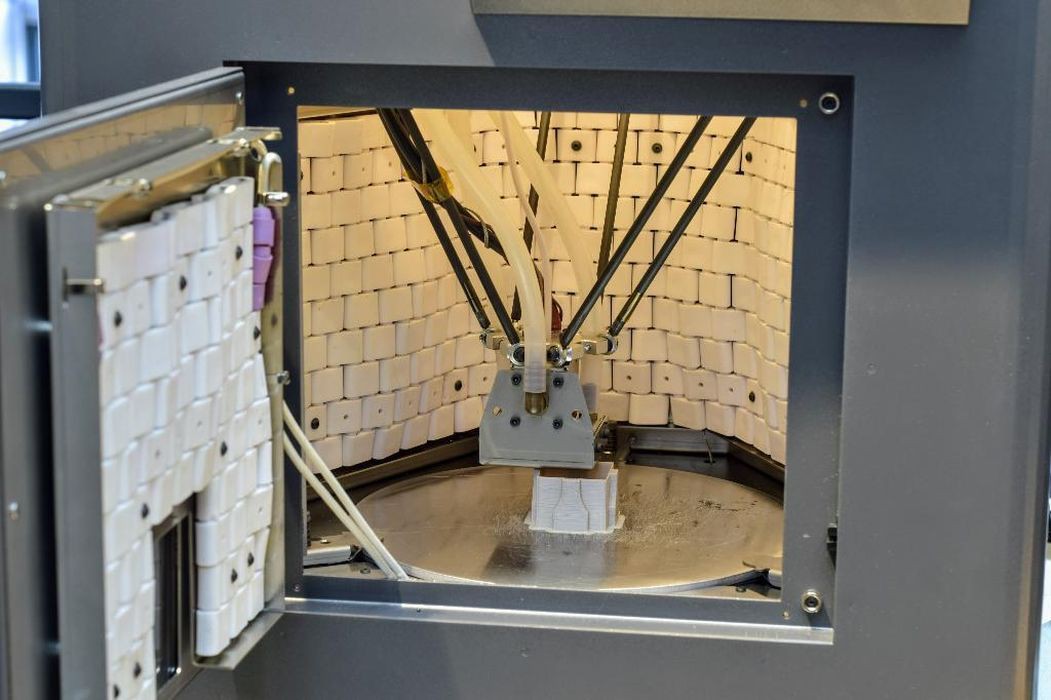

02/01/2023 at 10:12 • 0 commentsFused Filament Fabrication (FFF) suffers from weak interlayer bonding, delamination and warping because the material cools down after being deposited.

Orion AM uses thermal radiation, the heat penetrates through the material, allowing the layers to truly fuse together. This results in parts that are more uniform in strength, more dense and stronger.

With pictures, Orion AM shows it is able to increase the strength in the z-direction 10 times (https://www.orion-am.com/thermal-radiation-heating) .

I am not surprised it is possible, but impressed by the proof they gave.

Adam Rumjahn filed a patent US20210387401A1. The first 11 claims have been withdrawn.

Adam outlines it is key to match the spectrum of the IR source with the absorbance spectrum of the filament. I can imagine that a lot of heat is absorbed at the interface between the layers.The following figure is from the patent.

![]()

In reality this looks a follows;

![]()

I think laser scanning or a laser could add a lot of value here. I want to claim the following and add to the public domain.

The material would be deposited with fused filament fabrication. After deposition, a laser scanner would use IR or UV radiation to perfect the bonding between the layers. The laser scanner could use optical coherence tomography or simply look at the scattered light to monitor the bonding process. Key seems to be that the heat penetrates through the part and heats up the interface.

An alternative would be to apply the laser radiation prior to fused filament or liquid deposition.

I can imagine that using a laser to heat up the previous layer before a layer is placed on top of it could also work. This might simplify things as it does not needs to penetrate through the previous

layer.

In a preferred embodiment, the laser head is integrated with the fused filament deposition head.

I assume that the laser heating process is much faster than the deposition.

Naturally, the whole process takes place in a heated build chamber. The advantage of using a laser scanner would be that you can more precisely apply and monitor the addition of IR or UV radiation. You could better control the fusing process.

Besides the applications outlined by Orion AM a very good application could be glass printing.

Delamination is a big issue here as it make the resulting glass structure not uniform. This is very apparent. So here heating the previous layer with a power full laser before extrusion of the glass, might also fix the de-lamination issue. -

PID controller in Amaranth HDL / FPGA

01/31/2023 at 11:57 • 2 commentsI finished the PI controller. Speed seems very stable like 1998-2002 RPM when the target is 2000 RPM. Next step is to restructure the code base and add laser measurments.

-

Plan for an improved BLDC controller

01/05/2023 at 10:32 • 4 commentsRotating polygon laser scanners need to keep track of the angular position of the

prism or mirror.

In an earlier version of Hexastorm, this was achieved with a Sharp A160 polygon

motor. This board has a NIBC3111 chip. Motor speed could be

controlled by sending a PWM signal to this chip.

Using Hall sensors,

the internal circuitry of the board was able to stabilize the rotor

speed.

I added, a photo-diode and FPGA to accurately track the prism position.The current approach has several limitations;

- the control algorithm is not open-source and hard to port to the PCB motor

- the performance improvement by the photo-diode is not known,

the design would be much more compact without photo-diode and just hall sensorsAs a result, I decided to develop a new control algorithm. Let's say I want the energy to be uniform within 10 percent. This implies the angular velocity must be constrained within a Mean Average Percentage Error (MAPE) of ten percent. I need to know the angular position of the rotor within a MAPE of 0.005 percent. If it is assumed the line length is 24 mm, and the angular speed is uniform (in reality it is not but close), the exposure accuracy is 24*(0.005/100)=1.2 microns. In my experiments so far, I used a speed of 2000-3000 RPM.

My experimental setup has several constraints. I don’t uses a micro-controller, so I try to avoid divisions and multiplications in my control algorithm. The hall sensors produce six states but these are not evenly spaced. I already have a controller in place, which was implemented in 2022.

The current controller first speeds up the rotor by flipping to the next state after a given time.

This ensures the rotor is rotating. Once rotation is established, the controller switches to hall feedback mode. It simply enables the “right” coils given the currently measured hall state.

Speed can be measured by counting the time it takes to transition between 12 Hall states (i.e. 360 degrees).The critical path is seen as follows;

1. Measure the speed of the rotor

There are 2x6 states in one rotation. If the new hall sensor state is not equal to the old hall sensor state. The old hall sensor state is updated AND one count is added to the number of states seen. If the total is six, the counter is reset and its value represent the time for six states.

If the hall sensors are sampled at a "too high" frequency this results in a lot of noise.

It turned out to be key to divide the clock frequency from 12 MHz to 14kHz2. Determine the distribution of the Hall States (finished)

There are 2x6 states in one rotation. The Hall state is determined a thousand times. If it is assumed the distribution is uniform, the rotor should be 1/6 of the time in a given state.

However, the distribution is not uniform. The following is measured;state degrees cumsum

1 33 33

2 30 63

3 37 100

4 9 108

5 45 162

6 18 180These values are stable and the measurement is repeatable.

I therefore conclude that the discrete set [angle0, .... , angle5]

+ offset_angle, describes the actual position where the motor should be triggered.

I still don't know the offset angle. Note, that ideally the angle would be [30, 60, 180] degrees and offset is 0 degrees. The values I have are far from ideal for state 4 and 6.

My measurements imply;

- the rotor is not pulsed optimally at the moment (a lot of power is lost)

- the incorrect pulsing could result in noise (I do see my speed drifts over time).

It oscillates whereas I except speed would slow down due to heating of the motor, i.e.

not an oscillation.3. Improve the virtual distribution of the Hall States (finished)

First let's run a counter which goes from 0 to a 180 and then goes back to 0.

I then determine 5000 times the angle which is computed.

If I bin my data in 6 buckets with the edges [0,30,60,90,120,150], I arrive at the following distribution (note that the total is one).1 0.167

2 0.167

3 0.167

4 0.167

5 0.167

6 0.167I determine the time required for six states. I use this to determine the time for one degree.

The time for one degree is the time for six states divided by 180.I use the trick that a division can be interpreted as an addition of a series of right shifted values;

input*2^-a + input*2^-b + input*2^-c

ergo

1000.000/180 = (a>>8)+(a>>10)+(a>>11)+(a>>13)+(a>>14) (where a = 1000.000)which is slightly smaller and has an error of 0.45 percent. An error of 0.08 degrees.

I then run a counter from 0 to a 180 degrees, and reset this counter when I get a new speed measurement. I add one degree if my time counter reaches the time for one degree.

This results in the following distribution.1 0.18

2 0.167

3 0.167

4 0.165

5 0.164

6 0.155Note that this distribution should be in sync with the motor states and is much better than the one from step 2. Ergo this should result in better pulses.

Still it is not perfect, and speed seems to be "slightly" underestimated. The distribution is skewed to 1I can improve this by using the values from step 2. So IF I measure state 2, I set my angle counter to 63 degrees (i.e. cumsum).

This results in the following distribution

1 0.172

2 0.165

3 0.165

4 0.173

5 0.165

6 0.158This brings me to my new hypothesis.

- the rotor can be pulses better using this new distribution

4. Verify New pulsing scheme is better (finished)

I tried the following formula for the hall sensor positions;

beta = -15

hall_degs = (np.array([0, 33, 63, 100, 108, 162])+beta+180)%180Varying the beta from -15 to 30 has a big impact on the performance.

Motor power got better than the pure hall feedback mode or the motor would

not function at all.Note that the negative angle indicates I have to switch on a specific motor state earlier

than expected.

If I look at source https://hackaday.io/project/167173-custom-bldc-motor-board-using-fpga/log/174271-featuring-v07. I read;

The key word here is dead time insertion. It essentially refers to the mosfets not being ideal switches and not turning on or off instantaneously, but with a certain delay.

This implies it would need to be varied with speed.5. PID Controller (done)

Thorlabs provides a guide and brief explanation on tuning a PID controller.

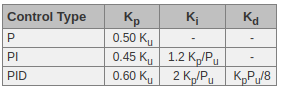

The derivative term is seldom used in practice and that's why I use a PI controller.The Ziegler-Nichols method for PID tuning offers a bit more structured guide to setting PID values. Again, you’ll want to set the integral and derivative gain to zero. Increase the proportional gain until the circuit starts to oscillate. We will call this gain level Ku. The oscillation will have a period of Pu. Gains are for various control circuits are then given below in the chart.

![]()

An interactive example can be found here http://grauonline.de/alexwww/ardumower/pid/pid.html.

As Pu is hard to determine, the Ki can also be determined manually.

You should have an offset with P controller, it can not reach the set point as the error would be zero. This is fixed by the integral term.The PID controller is implemented but not fully tuned.

6. Tune the controller (in progress)

Other topics:

Kalman filter

I briefly looked into Kalman filter. This could be used to increase the way the position and speed of the rotor is measured.

This is only done if it is needed.In steady state, the speed is constant and our system is described with

the equationsHere p is position and v is velocity. With a Kalman filter, I could combine measurements to get a better estimate of the position and velocity, see source.

I foresee the following challenges;

- multiplications and divisions on a FPGA are complex (this seems required by the

Kalman filter)

- The measurement error is probably not Gaussian

As a result, Kalman filter theory might not apply.

My aim is to end up with a system in a very steady state. Rotor speed should be constant.

As a result, I would guess that even if Kalman theory applies. The Kalman gain should be constant.

So using Kalman theory for dummies, I simply assume![Kalman Filter - quick insight]() where Kalman gain K is a constant, I could try to figure out the best Kalman gain by simply trying some values and seeing what works best.

where Kalman gain K is a constant, I could try to figure out the best Kalman gain by simply trying some values and seeing what works best. -

Kingsburry Aerodynamic bearing

12/14/2022 at 10:34 • 6 commentsThe following video outlines the Kingsburry aerodynamic bearing.

The cool thing about it is that it does not require external pressure. It should be possible to produce it cheaply in bulk as glass syringes seem to fit the requirements. These are shown early on in the video, at around 10 seconds in. As the prism, is already out of quartz it cannot be hard to add this. -

Wedge vs Circular coils

11/22/2022 at 07:59 • 0 comments@atomic14 answered my question regarding the coils (https://github.com/atomic14/kicad-coil-plugins/issues/1)

Thanks and great video!! -

PCB motors suited for laser scanning

11/09/2022 at 16:39 • 3 commentsAbstract:

PCB motors seems suited for laser scanning;

- speeds seem sufficient

- cross scan error is not affected by pcb coilsAngular stability needs to be improved but this is seen a relatively trivial issue.

Video:

Measurement details:I changed my sliding bearing with the one from a BLDC motor extracted from a laser printer and redid the measurement. This did not improve the results.

I moved to a prism which I used to make the pcb shown on this webpage.

An exposure result is shown below;An earlier measurement with the BLDC motor can be found here.

Earlier I measured a cross scan error of 115 microns, at a distance of 30 mm. Now I measure a cross scan error of 162 microns at a distance of 40 mm. I expected an error of 4/3*115=153 microns, a difference of 6 percent.The facet lines are stable over time. I do not see any vibrations or movement introduced into the prism exposure (dynamic scan error). The scan error seems static, related to imperfections in the prism or mounting.

I therefore conclude that PCB motors are suited for laser scanning;

- speeds seem sufficient

- cross scan error is not affected by PCB coilsI will move on to improving and testing the angular stability of the PCB motor.

-

Laser line exposure

11/05/2022 at 12:34 • 0 commentsI was able to do a measurement with the PCB motor and my custom sliding bearing.

My custom sliding bearing seems not of sufficient high quality.

NOTE: conclusion turned out to be incorrect; prism was mounted with insufficient quality -

Innoviz Technologies files LIDAR patent for prism scanner

10/31/2022 at 14:44 • 0 commentsInnoviz Technologies files patent for LIDAR system which uses prism scanner (WO2022053874A2)

It turn out the claims have been heavily amended and all mentions of prism seem to be removed.

So going to drop this for now.

I Note that you can file preissuance claim via USPTO. , if you are within the legal window of 6 months. This procedure is free.Original claims are:

1. A LIDAR system, comprising: a laser emission unit configured to generate a plurality of laser beams; and an optical system configured to transmit the plurality of laser beams from the laser emission unit to a common scanning unit, wherein the common scanning unit is configured to project the plurality of laser beams toward a field of view of the LIDAR system to simultaneously scan the field of view along a plurality of scan lines traversing the field of view.

2. The LIDAR system of claim 1, wherein the common scanning unit includes a light-transmissive scanning prism.Public source predating this application is here Revision history of "Open hardware fast high resolution LASER" - RepRap.

I added to the public domain exactly on 05:34, 5 June 2019 Henri Starmans (talk | contribs) . . (52,188 bytes) (+1,044) . . (improved lidar section, removed type, added some background history of MEMS)

Hexastorm

Hexastorm

where Kalman gain K is a constant, I could try to figure out the best Kalman gain by simply trying some values and seeing what works best.

where Kalman gain K is a constant, I could try to figure out the best Kalman gain by simply trying some values and seeing what works best.