-

Gregs Wade Extruder Tension

08/21/2014 at 20:59 • 0 commentsI would just like to note that up until this morning we had some pretty bad issues with the E3D hotends, we pretty much had to run them 20 degrees hotter for all materials to get them to extrude properly, this was not the hotend it was our extruder springs! make sure you use the correct springs as this makes a significant difference.

For people in NZ these ones are great (thanks Makershop)

http://www.makershop.co.nz/hardware/ExtruderSpringSet

As a good measure the spring coil wire thickness is about 0.81 mm, in terms testing them yourself they are quite painful to fully compress with your fingers.

-

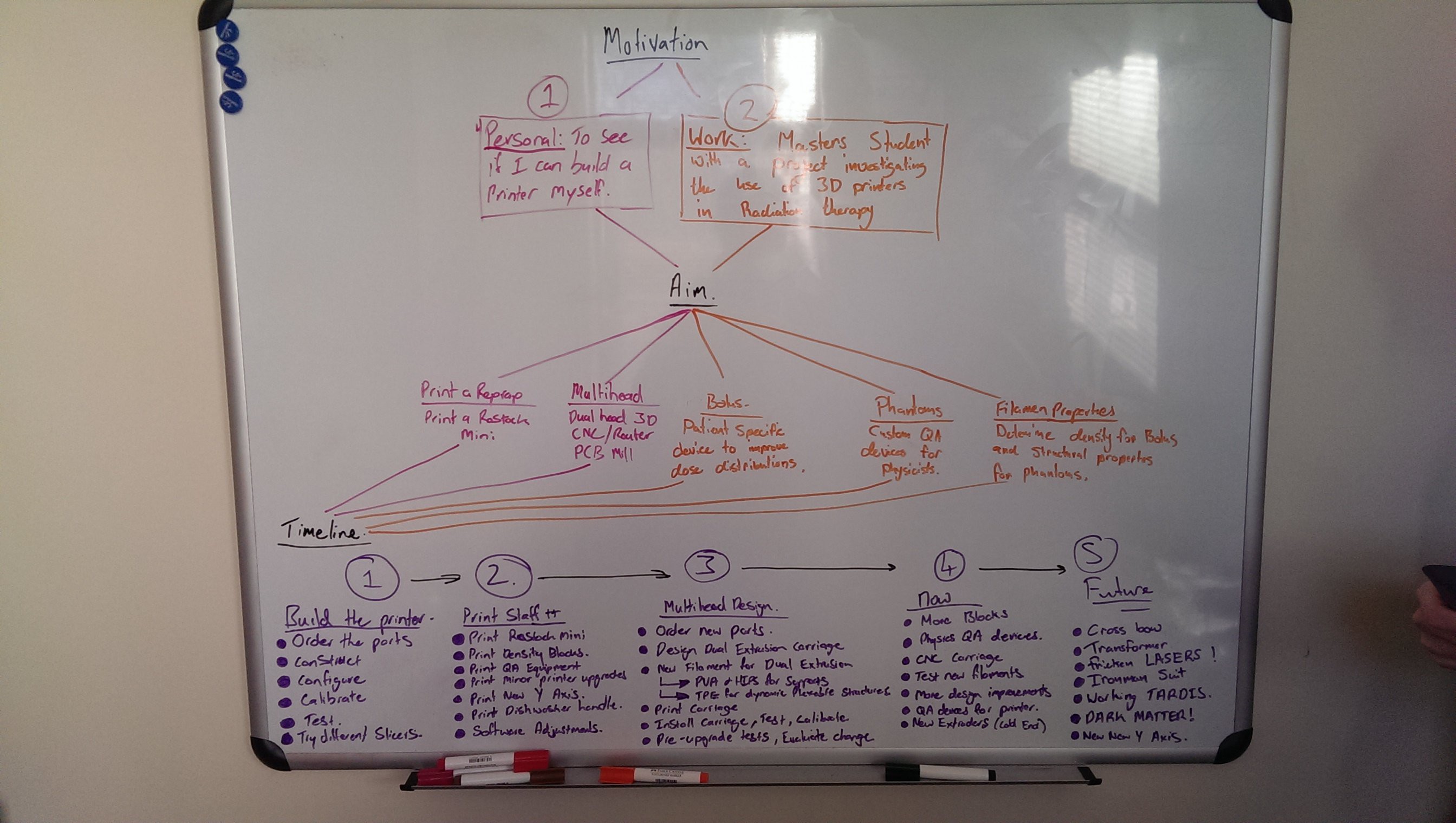

A system design document

08/18/2014 at 04:55 • 0 commentsWhite-boarded this with one of my co-workers today, hope this covers the system design.

![]()

-

New calibration print.

08/17/2014 at 21:01 • 0 commentsI have created a calibration print for use in calibrating settings in the marlin firmware, this files is available on my github, its pretty basic but easy to use, there is 15cm between the cuts as shown in the image below, measure this with calipers if its incorrect you can adjust and reprint.

![]()

-

*Sigh* couldn't get Github soon enough

08/17/2014 at 20:45 • 0 commentsSo small setback somehow I lost the configuration for dual extrusion in trying to calibrate the printer, I had just installed github on my comp but hadn't uploaded anything yet, serves me right I guess for not having it from the start, will upload the current settings I have but they are not working at the current moment.

Hopefully this can be fixed today!

-

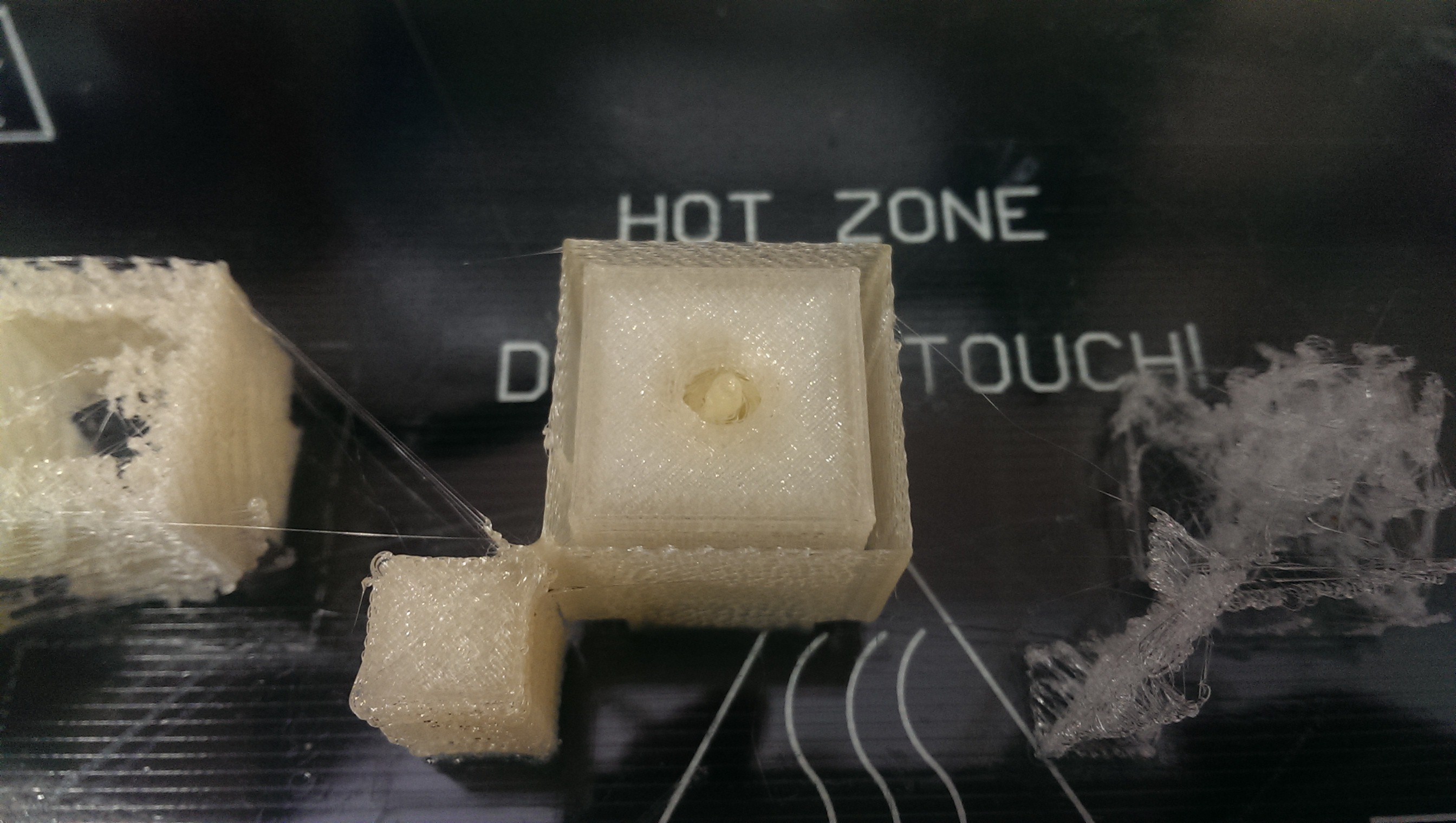

Lets print some in some new materials.

08/07/2014 at 04:16 • 0 commentsToday I made sure we could print in 2 new materials we just got also to check quality and confirm heat settings, one is NinjaFlex and the other is HIPS, once we are happy with the qualities we will likely print something in each to CT and test the density of the objects

HIPS - Kindly provided by Diamond Age

![]()

NinjaFlex this was purchased from E3D

![]()

-

Lets print some in some new materials.

08/07/2014 at 04:15 • 0 commentsToday I made sure we could print in 2 new materials we just got also to check quality and confirm heat settings, one is NinjaFlex and the other is HIPS, once we are happy with the qualities we will likely print something in each to CT and test the density of the objects

HIPS - Kindly provided by Diamond Age

![]()

NinjaFlex this was purchased from E3D

http://e3d-online.com

![]()

-

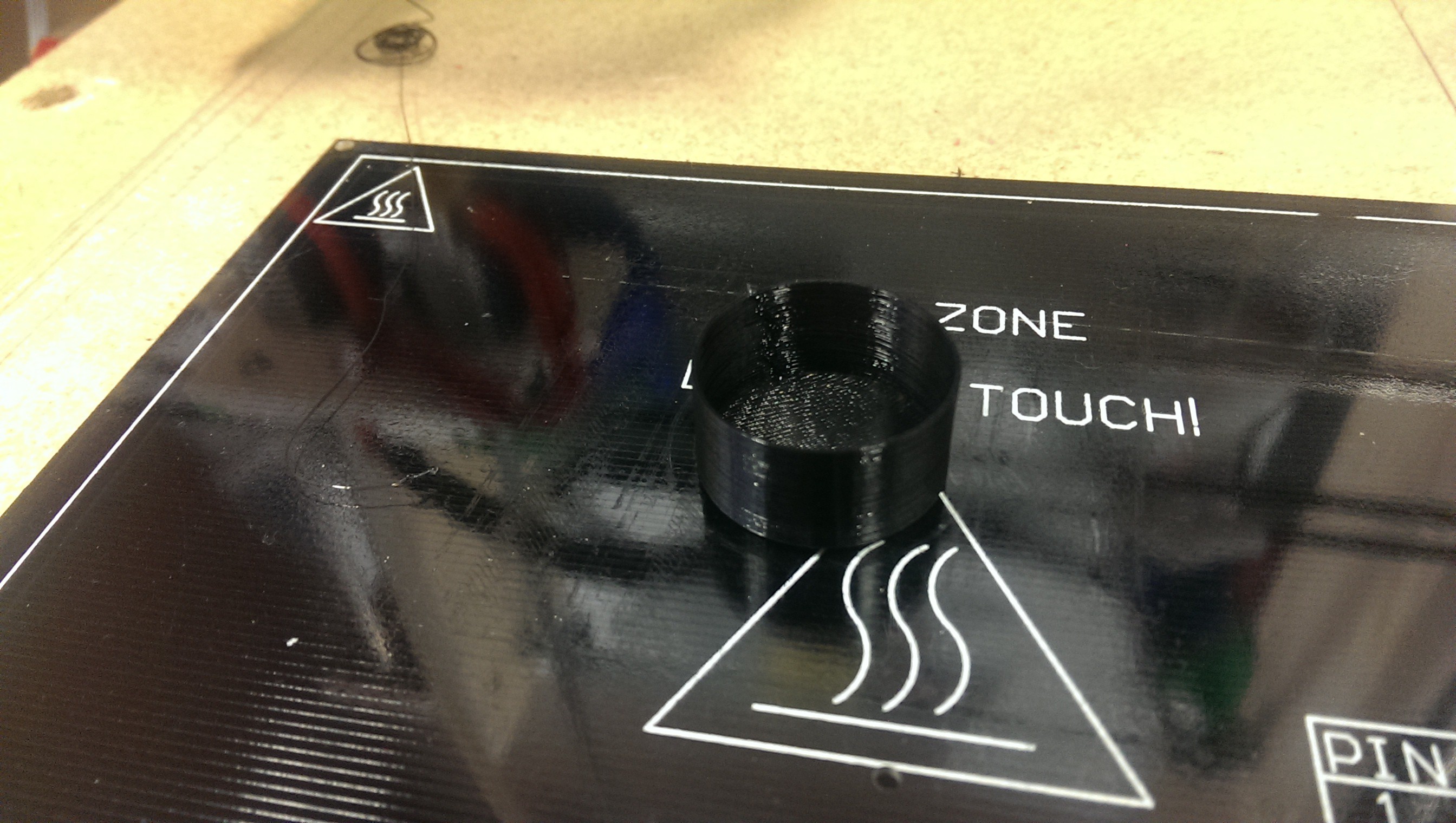

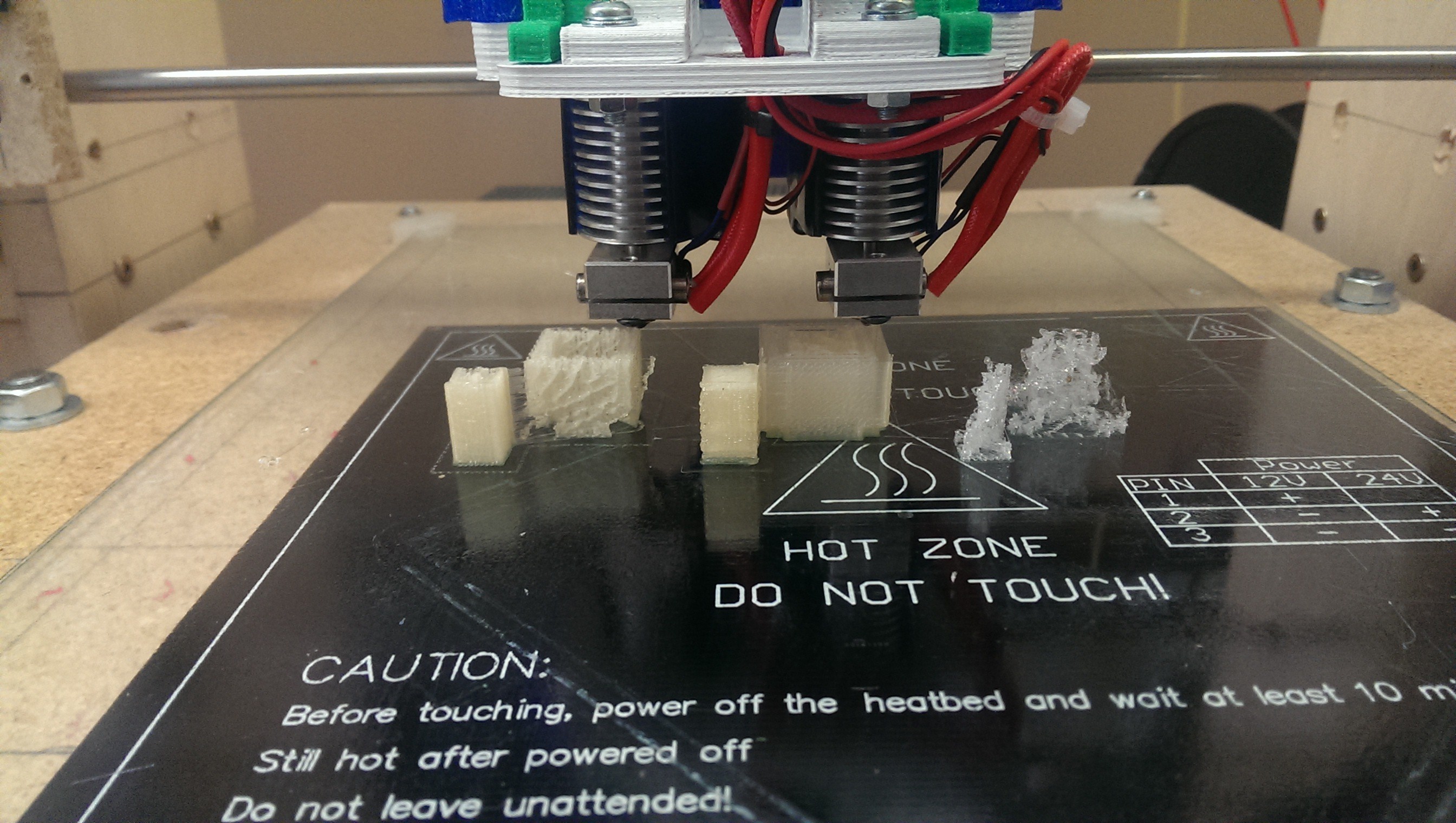

Printing with PVA

08/06/2014 at 20:28 • 0 commentsPrinting with PVA and PLA, still got some kinks to work out with the new E3D Heads, as you can see we are seeing considerable oozing when it comes to PVA and a little with PLA, created a nice little test object to print with too.

http://www.thingiverse.com/thing:419854

PVA seems to print well at 220 but maybe thats a little hot considering the oozing...

![]()

![]()

-

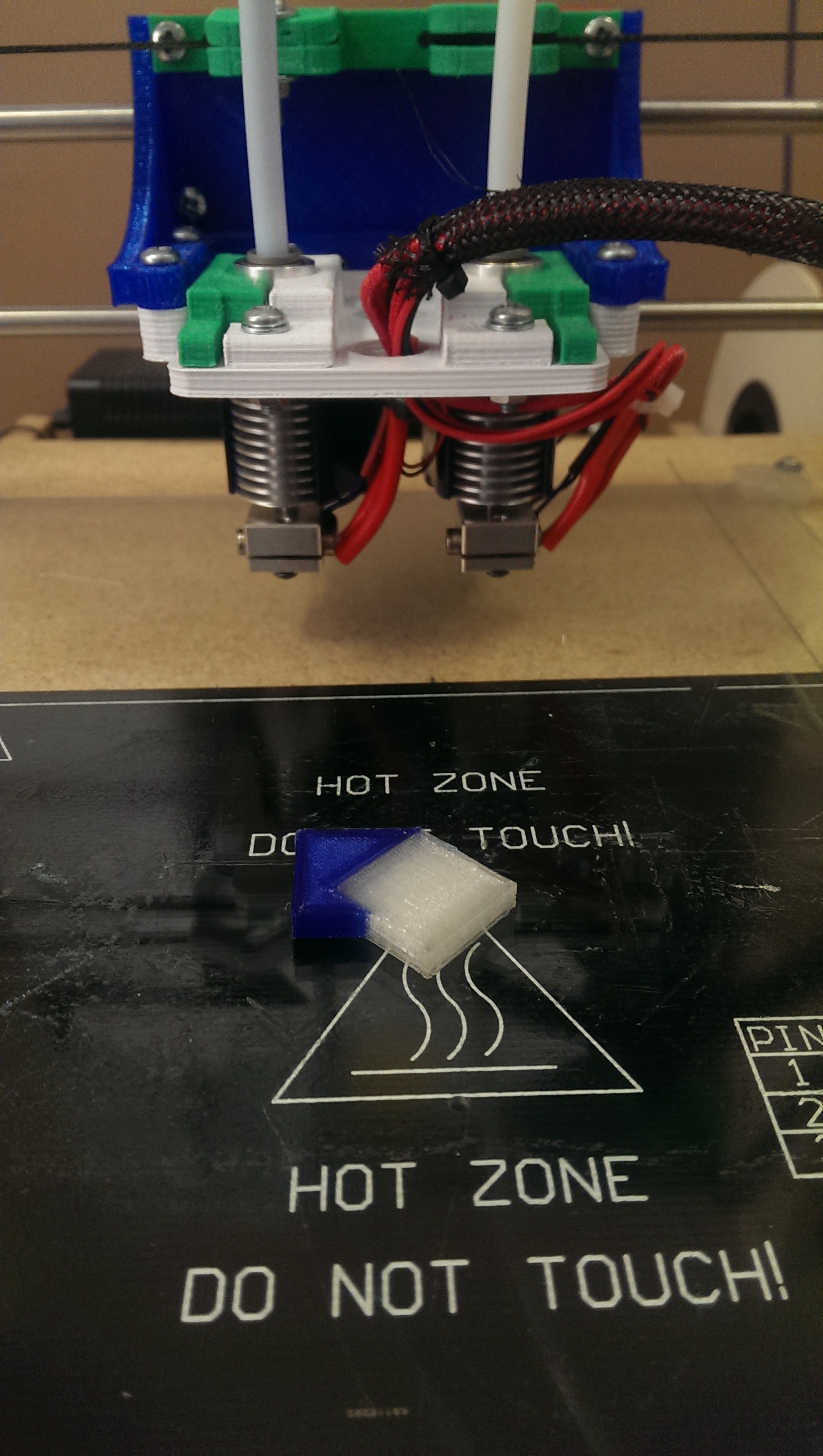

Dual Extrusion is working!

08/05/2014 at 20:39 • 0 commentsI got dual extrusion working yesterday Yus!

![]()

MDFStrap 3D Printer made with MDF

From slow single hotend semi accurate 3D Printer to fast and accurate dual hotend 3D Printer.

Terry Bates

Terry Bates