-

1Step 1

Dream It!

Inspiration

- Google search on science fair boards

I used Google image search to look at what other projects looked like. There were some real good looking projects but little innovation in the boards themselves.It is time to break away from the same tri-fold board that has been used for the last 50+ years. Innovation and interactivity has touched almost every part of our lives in that time. So why not science fairs? With today's inventions like X-Box and smart phones we have become accustomed to interacting with the products we use.

- Failed attempts on last years board

Last year I entered the science fair I added a few new features to my board. I had signs that you could flip up and a wheel you could spin. These were not used because the rules were look but don't touch. Science is not abut that. In science you need to be hands on. So I decided there needed to be a change.

- Learned how to use Arduino

Over the summer I worked my way through the "Experimenter's Guide for Arduino". This taught me the basics of Arduino programming. With the knowledge of what was possible I began to imagine what a modern science fair board could be.

-

2Step 2

Brainstorm

- What features do I want

I wanted the ideas that failed on my last board to work on this one. So a big spinning wheel placed behind the board with a cut out window to show different photos was a must. Another thing that I wanted was flip up doors to show additional information. I also wanted a "attention getter" something moving on the top of my board to attract kids and parents to my display. Once you learn Arduino you know LED's are a must have feature so that also made the list.

- How to make it work

After the features were picked the question of how to make the board work needed to be solved. I would use an Arduino for the brain but how would the students be able to interact with the board was the next problem to solve. Big buttons is my solution. Who dose not like big glowing buttons? By using the buttons to control the different features people could interact with what the board was doing. This would increase the effectiveness of the points I was trying to communicate. Also by connecting with your viewers they will be more likely to remember your project even after the fair.

-

3Step 3

Can it be done?

- Do I have access to the parts

Most of the parts I needed to test my idea were included in the Arduino experimenters kit. Specialty parts like the big buttons could be purchased online latter. Thanks to online vendors like adafruit.com and sparkfun.com just about anything I could imagine could be built.

- Can I get help if I am stuck?

When you are pushing the edge of your knowledge it is nice to know there is someone out there to help if you get stuck. I used the Arduino forums and adafruit.com learning guides to fill in any gaps. Both of these communities are eager to help and will give you quick responses to any question.

- How long will it take

This was a hard one. I had no idea so I started way early. Then news came down that my school might not have a science fair this year. Talk about disappointment. When I heard this I quit working on my project. What a big mistake. The school changed it mind and now I found myself behind. The best advice I can give is start early and finish with time to spare. Or you can do what I did and work all night every night leading up to the fair and just barley get it working so you have something to display.

- Will it break any rules

According to the Intel science fair rules I was in the clear. You are allowed to use a power strip and my project fit the size requirements. But my school had a wiring hazard clause in their rules. If this is the case it is time to talk to your teachers and beg for a exemption. I had to explain that there was little risk because everything was powered by less than 9 volts. Although my wires were a mess I used heat shrink and good soldering practices to prevent any short circuits. Plus I used puppy dog eyes when I asked.

-

4Step 4

Design It

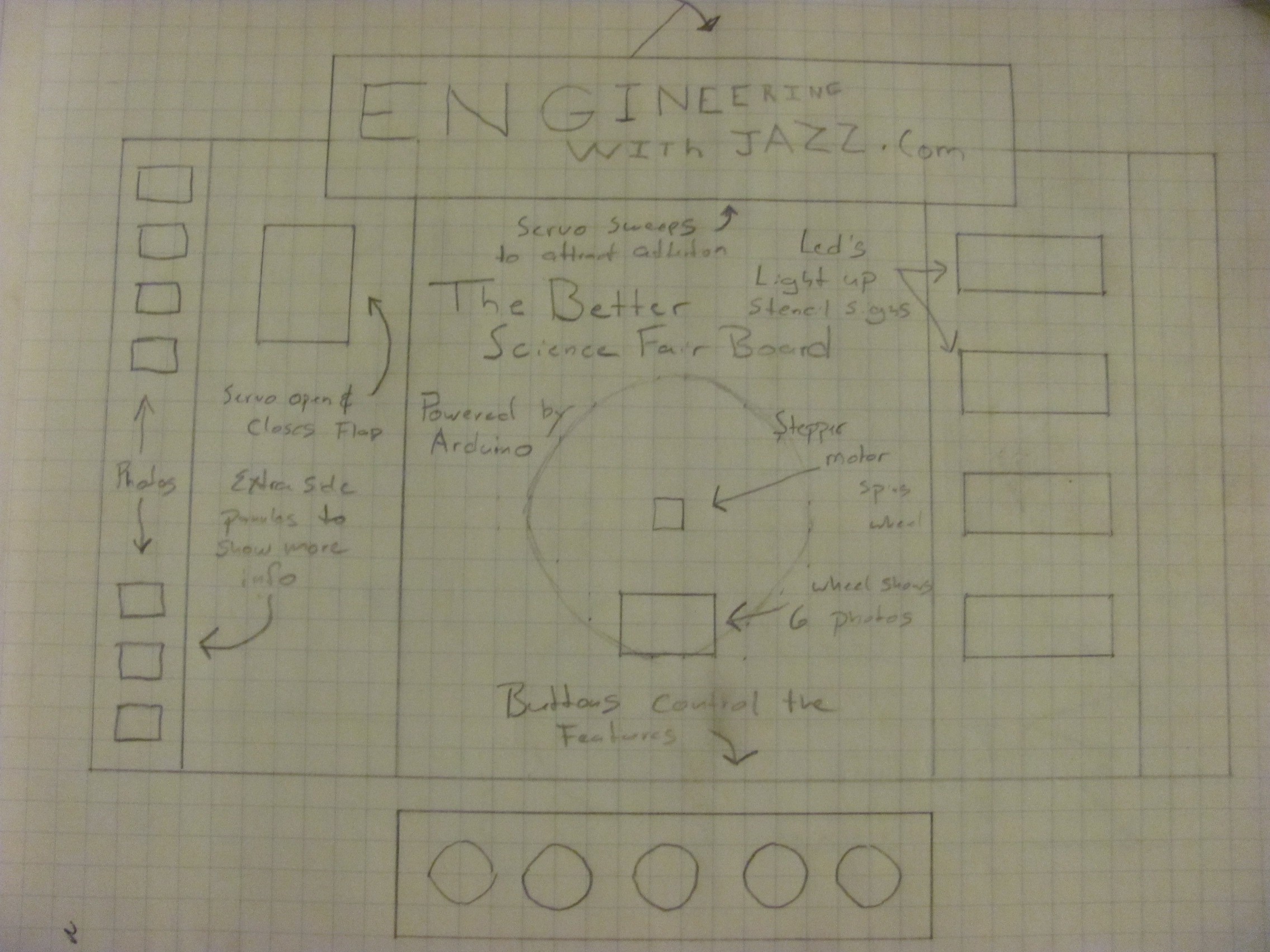

- Sketch look and feel

I used graph paper to sketch out my design and referred to this sketch many times during the build. The sketch prevented me from getting carried away with new ideas that could of interfered with my design. I recommend you always start with a sketch if for no other reason just to have something to inspire to when the build gets tough.

- Will it fit?

There are many different moving parts on this board and I had to get creative to get them all to fit. This is where the sketch came in the most handy. The last thing you want is for two moving parts to collide and break during the fair. The other thing to consider is you schools rules on how big the science fair board is allowed to be.

- Paper or Plastic

The moving parts had to be built out of something and what material to use was a big question. Due to cost, weight, and availability I chose to build as much as possible out of foam core. Some other parts were to be out of plastic or metal coat hanger wire. Depending on the use and durability requirements (will it work all day?) is how I chose where to use what material.

-

5Step 5

Parts and Equipment

- Part list

Create a parts list of what you have on hand and what you need to buy. Try to be as through as possible. It will surprise you of all the little things that will add up. Some will be forgotten if you don't write them down when you are thinking about them. This will help prevent last minuet trips to the hardware store and extra shipping costs for forgotten items.

- Make budget

Try to figure out how much each feature will cost and compare that to your budget. If you cannot afford a feature it may be better to leave it off rather than to give up or get stuck on your project. Some features are connected to each other because of a part they use. In this case try to make sure you have the room in the budget to get the most bang for your buck.

- Place order

Try to place your order with as few vendors as possible because of shipping costs. Keep a eye out for free shipping deals. This is where your parts list comes in real handy. Try to resist the impulse items and stick to what you need for your project. If you do require any tools think about how often you will use them to help determine if you get the cheap or name brand version. Tools will far outlast any project so if you will use them on more than one project get the best tool you can afford. You will thank yourself latter.

-

6Step 6

Research the More the Merrier

- What I know

Read about each component you are using to learn how it works and how it dose not work. This will prevent you from getting stuck in the late stages of the project. I knew that any one of the features I hoped to build could be done by itself. This is important to give you the confidence to get through the next step. But would they work together?

- What I don't know

With any big project what you don't know is what will stop progress faster than anything. As you start to combine parts and Arduino code unexpected things may happen. Additional research when you hit these problems will help and if you get truly stuck ask on the forums. I had a problem with servos and neopixels not playing nice. Thanks to the adafruit neopixel uber guide I was able to find a different library for the servos that did play nice and get back to work. This was a couple day delay because I had failed to do my research before I started. Learn form my mistakes or don't you may learn more that way.

-

7Step 7

3d Printed Part Design

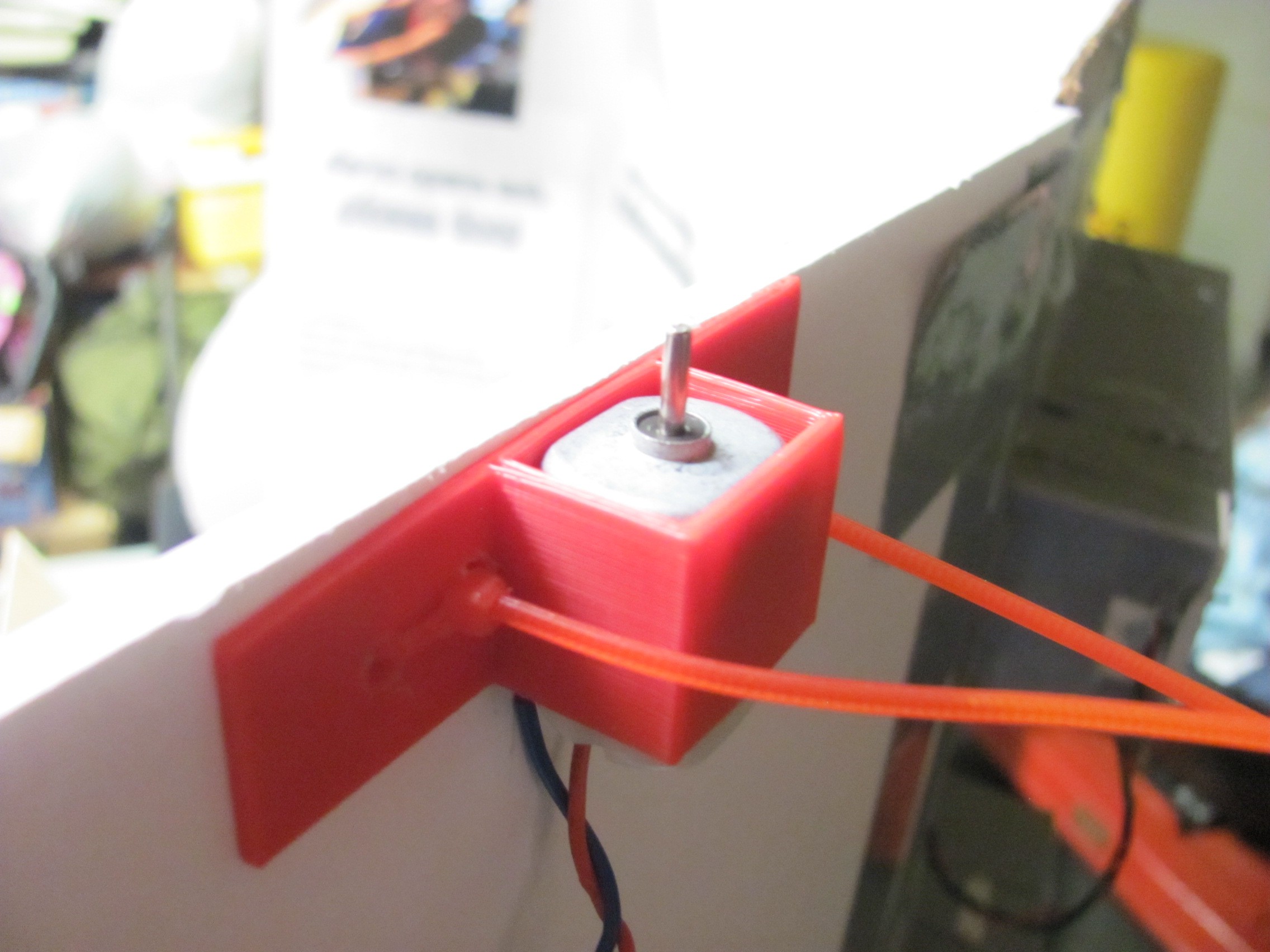

- Design in sketch up

I knew before I started that I would use some 3d printed parts. You do not need to but a 3d printer but they make creating new things so easy. With this in mind I started thinking about where 3d printed parts would help out. Attaching things to motor shafts, strengthening the foam core parts, and prototyping gear ratios is where I used it the most.

I use sketch up to draw the parts for my printer. I like sketch up because it is free and easy to use. There are many good alternatives like 123d, tinkercad, and others. Use what you feel the most comfortable with or download the parts I made from thingiverse.com/Jazzmyn and print them.

- 3d Print

Print early and often. Many times the first print dose not work. The size may be wrong or the shape could be improved. Just save time for reprinting when things do not go to plan. It is called rapid prototyping but when you are in a time crunch it dose not feel rapid at all.

-

8Step 8

Build It Small First

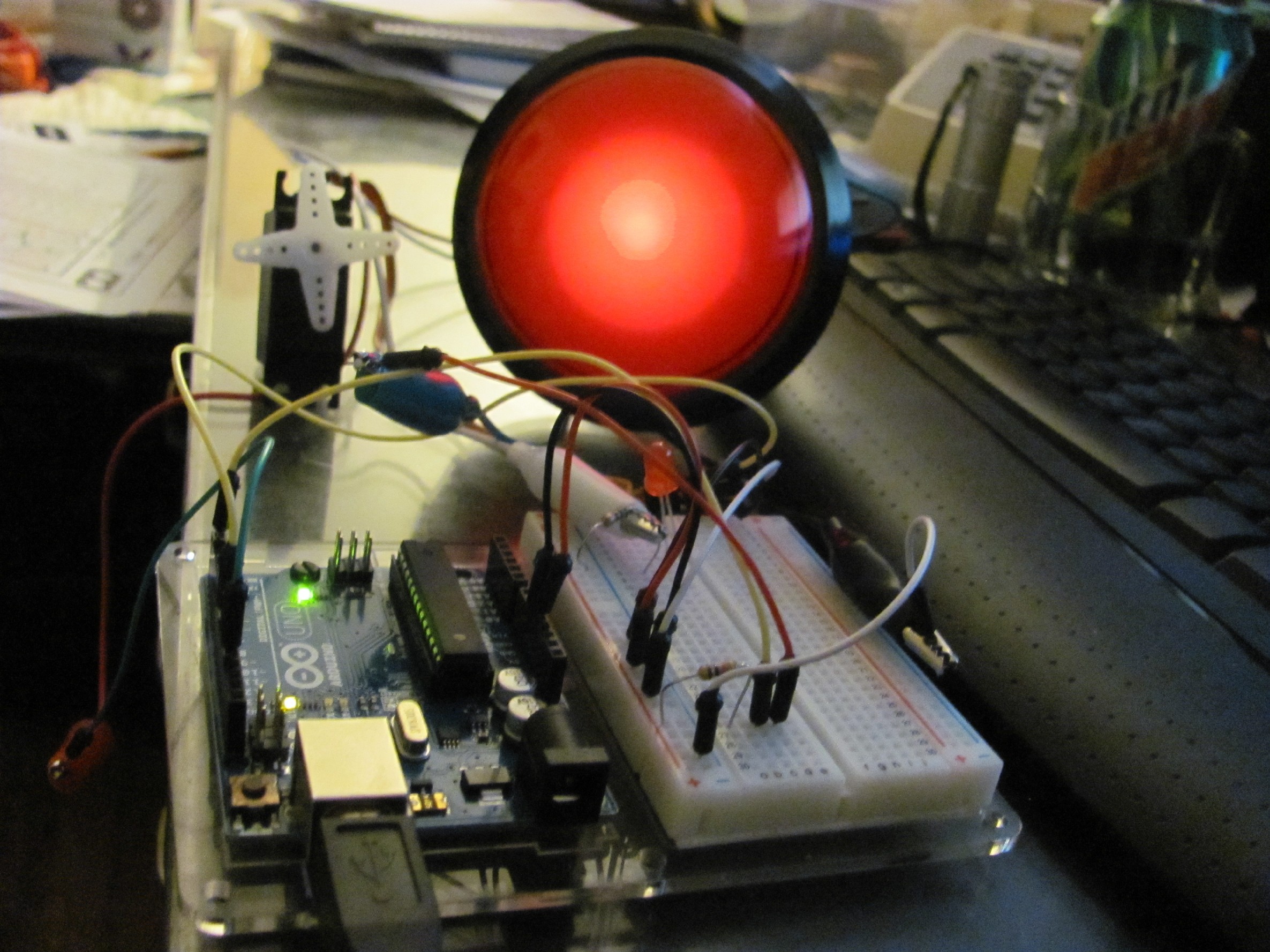

- Prototype circuit and code

I had tested all the parts separately but now it is time to put the together. This is where many small problems creep up. It is best to start on a bread board instead of just jumping in with the soldering iron. I used small cheap components to test like small push buttons and micro servos. Jumper wires and alligator clips are your friends at this stage. With the prototype I made sure each feature was working like I planned when they were all combined together. Small adjustments to servo travel distance and delay lengths were tested. Did I mention to save your work! I forgot to save my work one night and when I came back home from school windows update had restarted the computer and I lost all the settings I had worked on the night before. Just hit the save button every time you upload, take a break, or take a drink of your favorite soda.

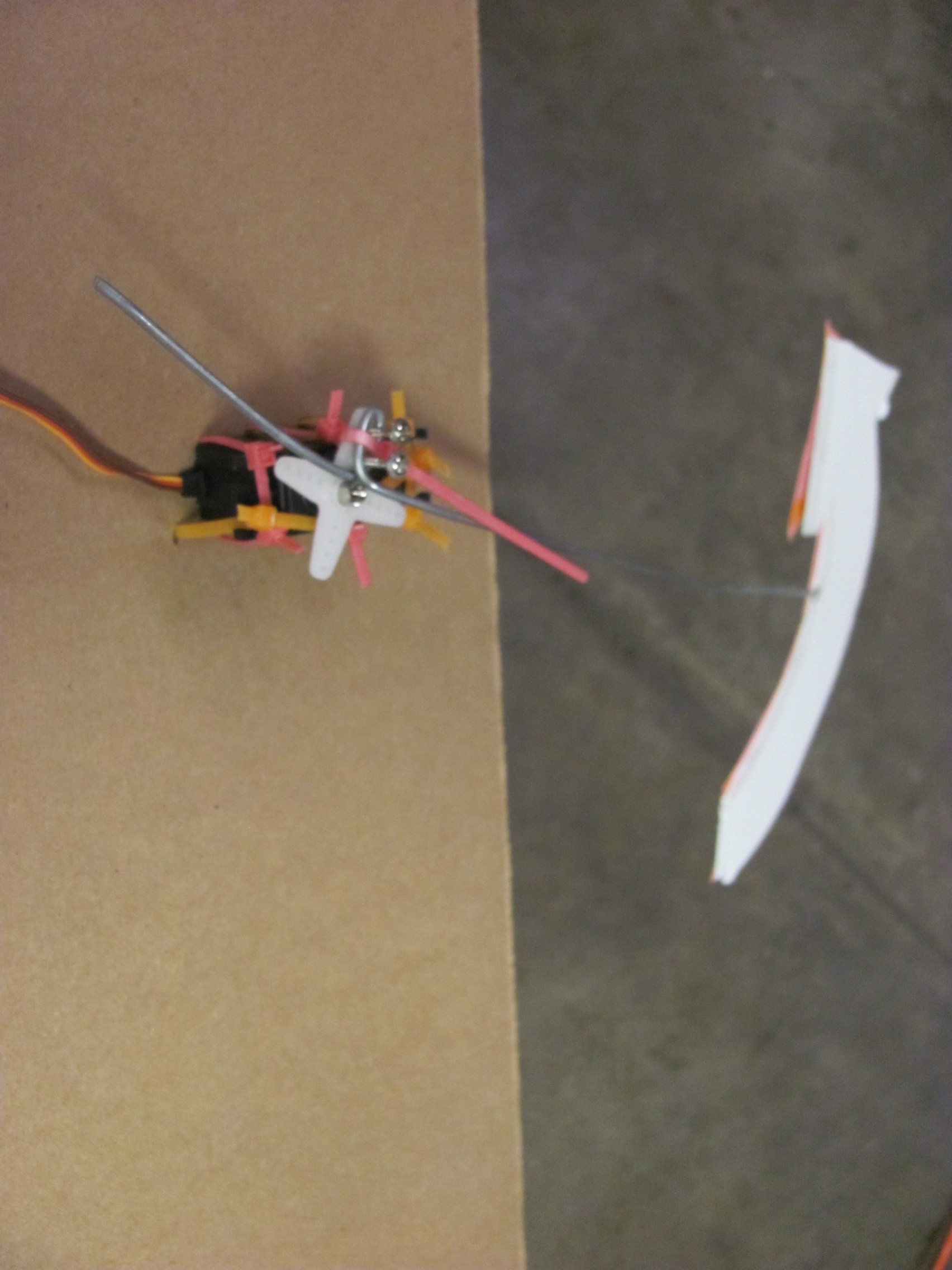

- Scale up

When every thing is working the way you want it to then scale up to your more expensive parts. This is where I tested the big push buttons and full size servos. I also realized I could get away with a micro servo for the flip up door. So sometimes when you scale up you learn that you can scale back down and reduce cost. After all the bugs are worked out and the final components are working it is time to start the main build.

- Code and code some more

I am looking for a place to post the code "Stay Tuned"

-

9Step 9

Button Board

- Layout

The layout of the button board had to be determined before I bought the wood. Measure the big buttons and add a little wiggle room. I chose a simple straight line of buttons but there are endless combinations you can consider. I bought a white bookshelf board from Lowe's hardware and covered it in blue tape to prevent scratches. Then I measured where all the buttons would go and drew there locations in pencil on the tape.

- Out to the work shop

I used a drill press to make the holes. This helped keep every thing nice and straight. You could use a hand drill if that is what you have. First I drilled a small hole with a regular drill bit. Then I used that hole to center the 1" spade drill to cut the hole to size. You could use a hole saw if you do not have a spade drill. I then cut some scrap wood into triangles to use for legs. This held the board at a angle and made for a inviting display of buttons. If you put the buttons in a different pattern remember that you will need room on the back side for wires.

-

10Step 10

Customize Tri-Fold Board Part 1

Foam core parts

- Picture wheel

The picture wheel will go in the middle section of the tri-fold board so I measured that and made the wheel as large as I could. To cut the wheel I used a small nail pushed through the middle of the circle and a string attached to it to set the length. First I tied a pencil to the other end of the string and made a outline. Then I replaced the pencil witha X-acto blade to make the cut. Go slow and make many passes until you cut all the way through the foam core board. It dose not have to be perfect.When it is mounted you wont be able to see the edge. Then use the nail, string and pencil to mark off even sections around the edge. Draw a line from the center to your mark on the edge. This will tell you how many photos will fit on your board. Taking a photo and moving it up in one of the sections until the top corners of the photo touch your lines will determine the location for the window you will cut in the tri-fold board latter.

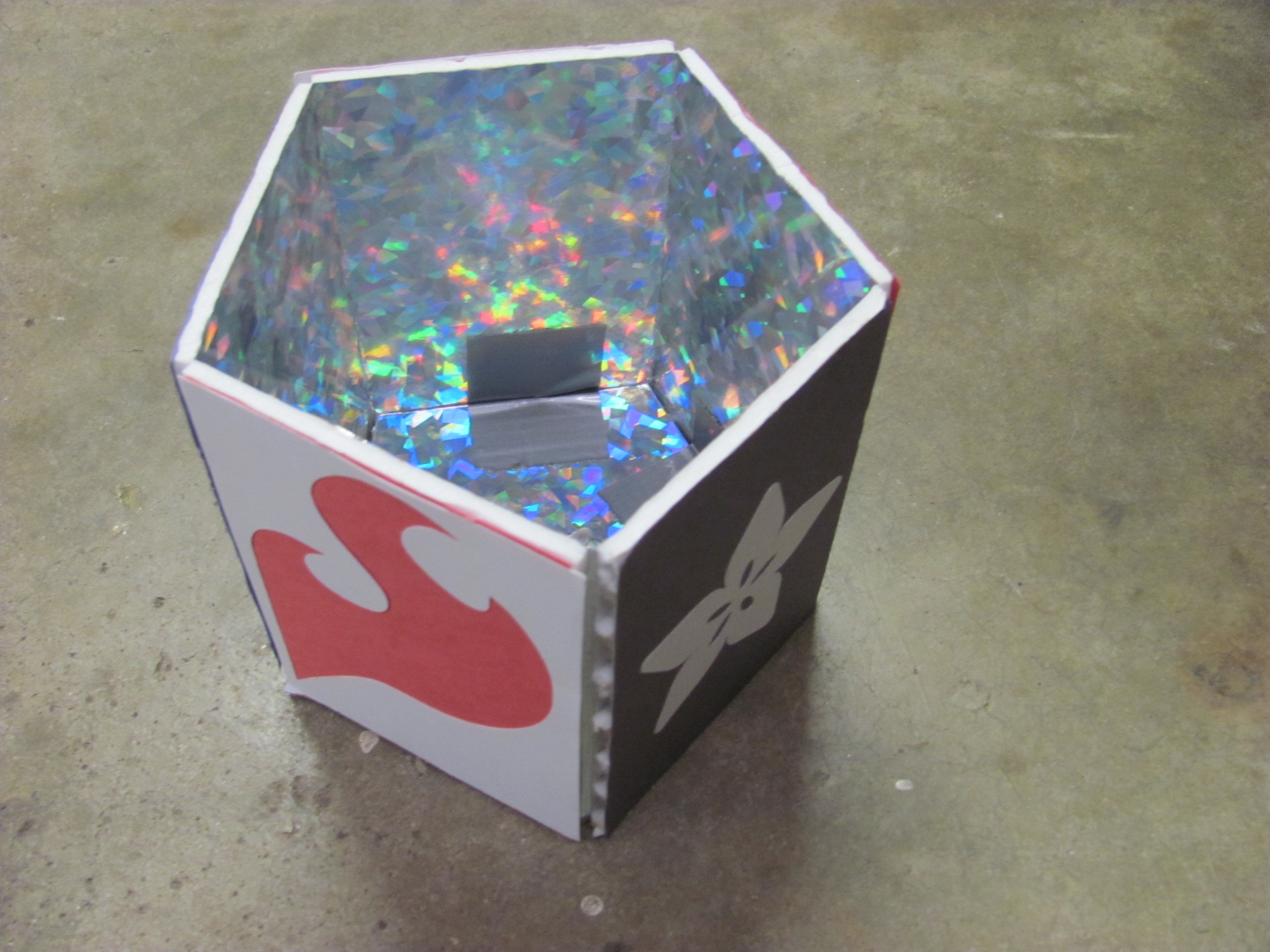

- Photo spinner

For the photo spinner I measured a photo then drew rectangles on a leftover piece of foam core.I was able to fit five photos. I then cut out the outside line to remove it from my piece of scrap. In-between where the photos would be I carefully cut threw the foam core leaving some material so it would bend into a pentagon shape. I then taped the ends together.With the shape solid I traced the inside of the pentagon onto another piece of foam core. This gave me the size I needed to cut out for the bottom. The part I traced moved a little so it was not perfect but with a little duck tape it all worked out in the end.

- Header board

I attached the full size servo to the header board using zip ties. I cut small holes in the header board and laced the zip ties threw it. This made raised bumps where the zip ties went threw. This made my title sign not lay flat. If I were to do it again I would of buy two header boards and glued the second on top of the first to hide the bumps.

- Flip Up Door

The flip up door was sized to fit two photos one above the other. This was also cut out of foam core. I used duck tape to act like a hinge on my board but a better solution would be to cut some thin cardboard to attach to the underside of the door and tri-fold board.

- Back-light Boxes

The light up stencil signs have light boxes attached to the back of the tri-fold board. They are also made of foam core but I selected a board that had a reflective sticker to help bounce the light out toward the stencils. I think white would work just fine if you can not find any reflective board. The light boxes are made with one open side that attaches to the tri-fold board. I sized the boxes to the stencil I was using and used a X-acto blade to cut out all the parts and attached them together using duck tape. I also cut small holes for the wires to pass threw.

- Side Panels

To fit all the features I needed more space on my tri-fold board so I cut two additional sides to the board the same size as the small sections of the tri-fold board. These were attached to the board using duck tape as well.

Bored No More

Interactive Science Fair Board Using Arduino, big buttons, servos, and motors create excitement while interacting with science.

Jazzmyn

Jazzmyn

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.