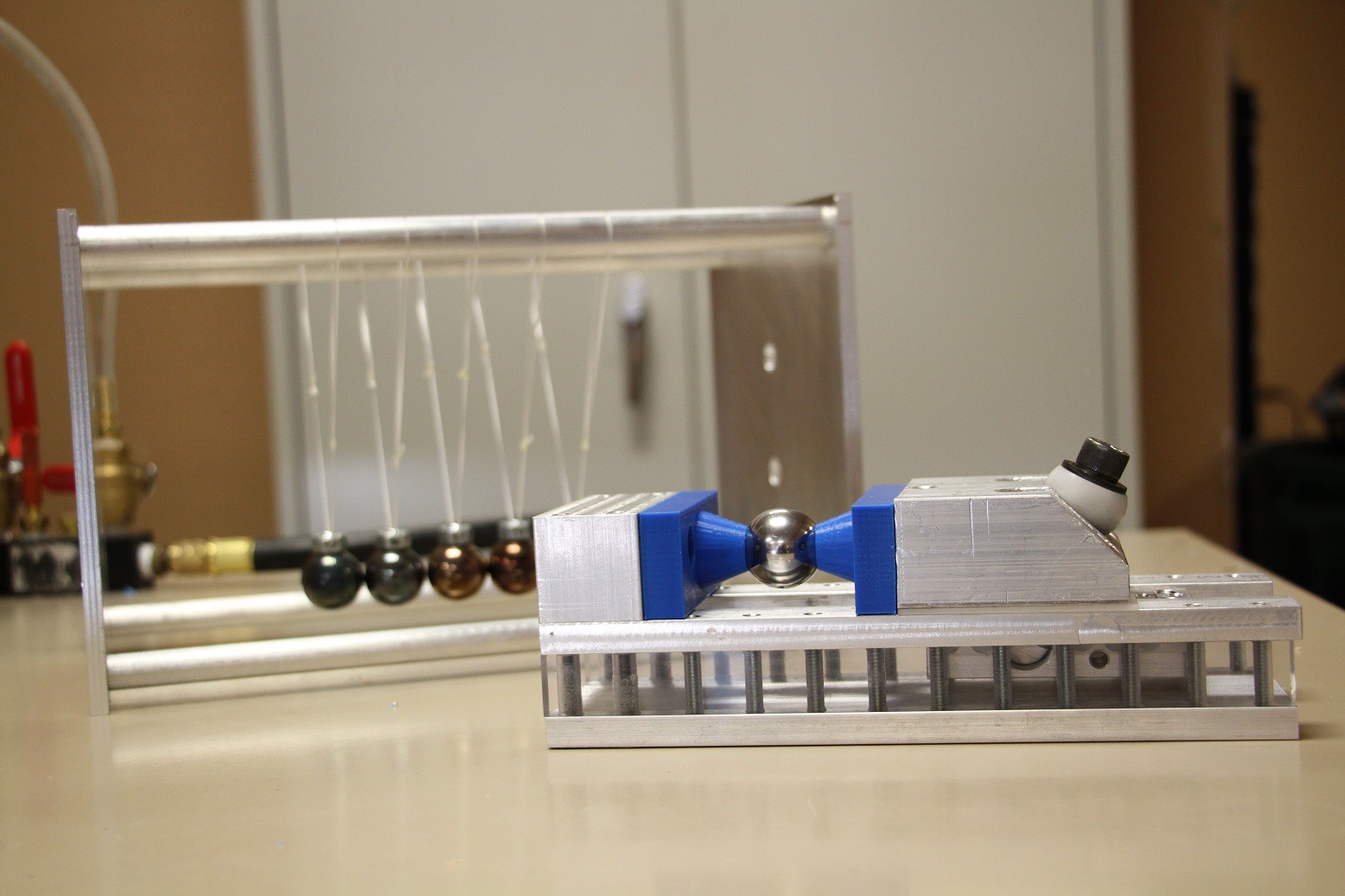

3rd Newton's cradle. Steel balls, attached by epoxied on nuts.

The balls were colorized by heating with propane torch. Not to red hot, this would leave an ugly scale. With heat they first turn a straw light brown, then finally blue black. I tried to get a range of colors. I first realized I could color polished steel like this while annealing bearings so they could be drilled. They're beautiful in the sunlight. The blueish black is actually from a thin layer of ferrite, an oxide that forms at higher temperature conditions than normal rust.

I made a rod+plate frame for this, possibly a quite useful thing for other people's projects. If you have a lathe and can face rod perpendicular to axis, then drill and tap axially t's very easy to make strong, well aligned frames.

In fact you can also do this with regular pipe or tube and allthread. We've used sched 40 PVC + allthread and plywood to make nice cable dispensers.

alex

alex

Michael Barton-Sweeney

Michael Barton-Sweeney

Michael Perrone

Michael Perrone

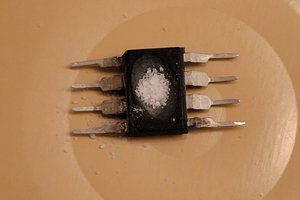

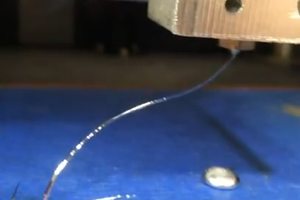

Ah.. Yesterday I used the induction rig to soft solder steel balls to a brass tube. Old roll of "Oatey" Safe-flo 29024 plumbing solder and H-2095 paste flux.. Tin-copper-bismuth-silver (I'm sure very little silver) from what I could gather off the net. Balls colored pretty deeply before I got the solder to flow. I had not previously known that one could soft solder to steel!!! One interesting effect to observe was the flux on the blued surface.. the hot flux knocks the blue off wherever it hits, as it is supposed to.

I'm going to try to turn that fat plumbing solder wire into sheet preforms for this at some point.

Why? Because I don't like the epoxy for permanent attachment or as part of a kit if it becomes that.