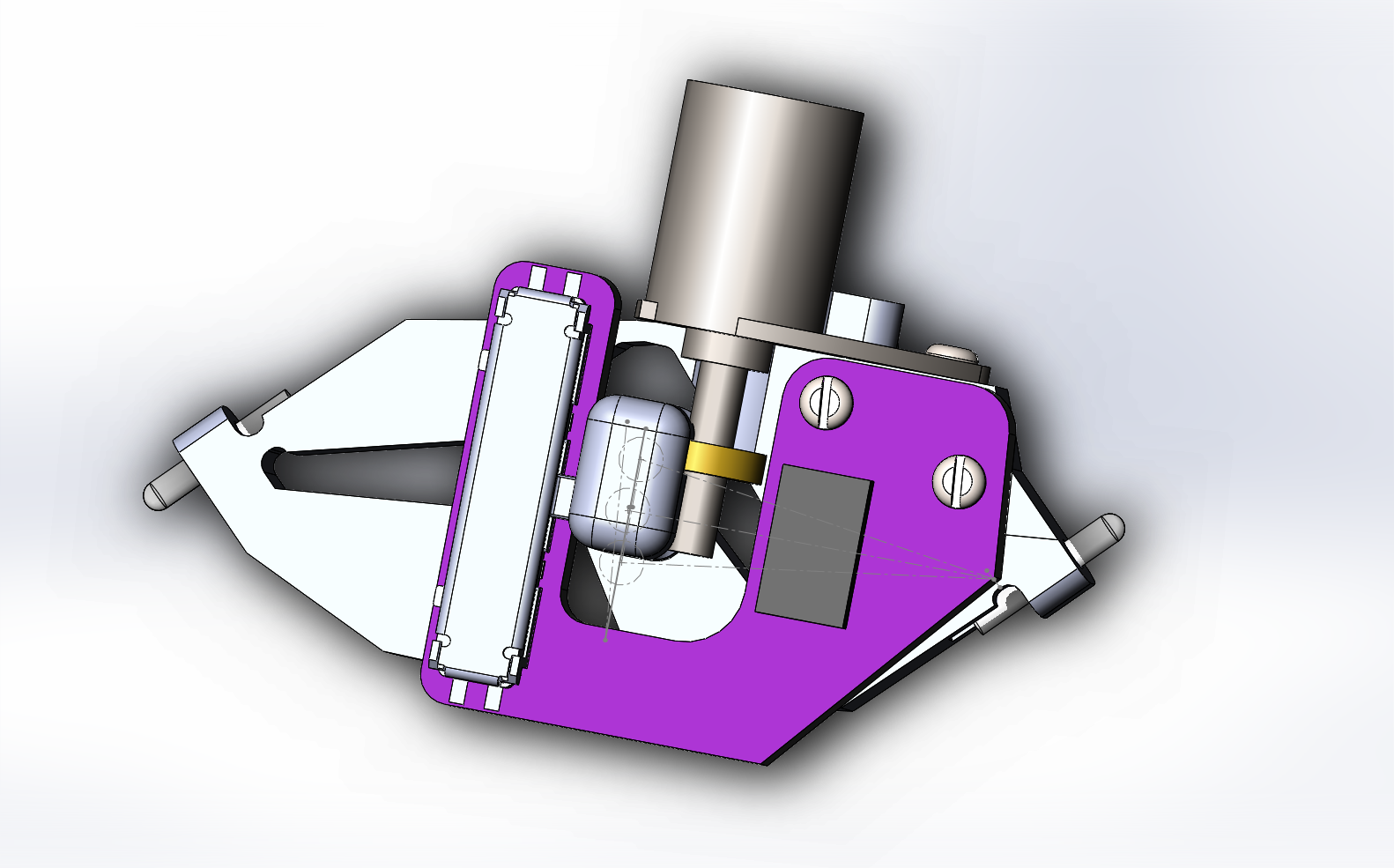

The alternative motors arrived, so i've been updating the design to use one of the types. The originally ordered ones arrived, but need a separate tooth part to run against the screw, so they are a no-go for this application.

Figure: Updated actuator for alternative motor

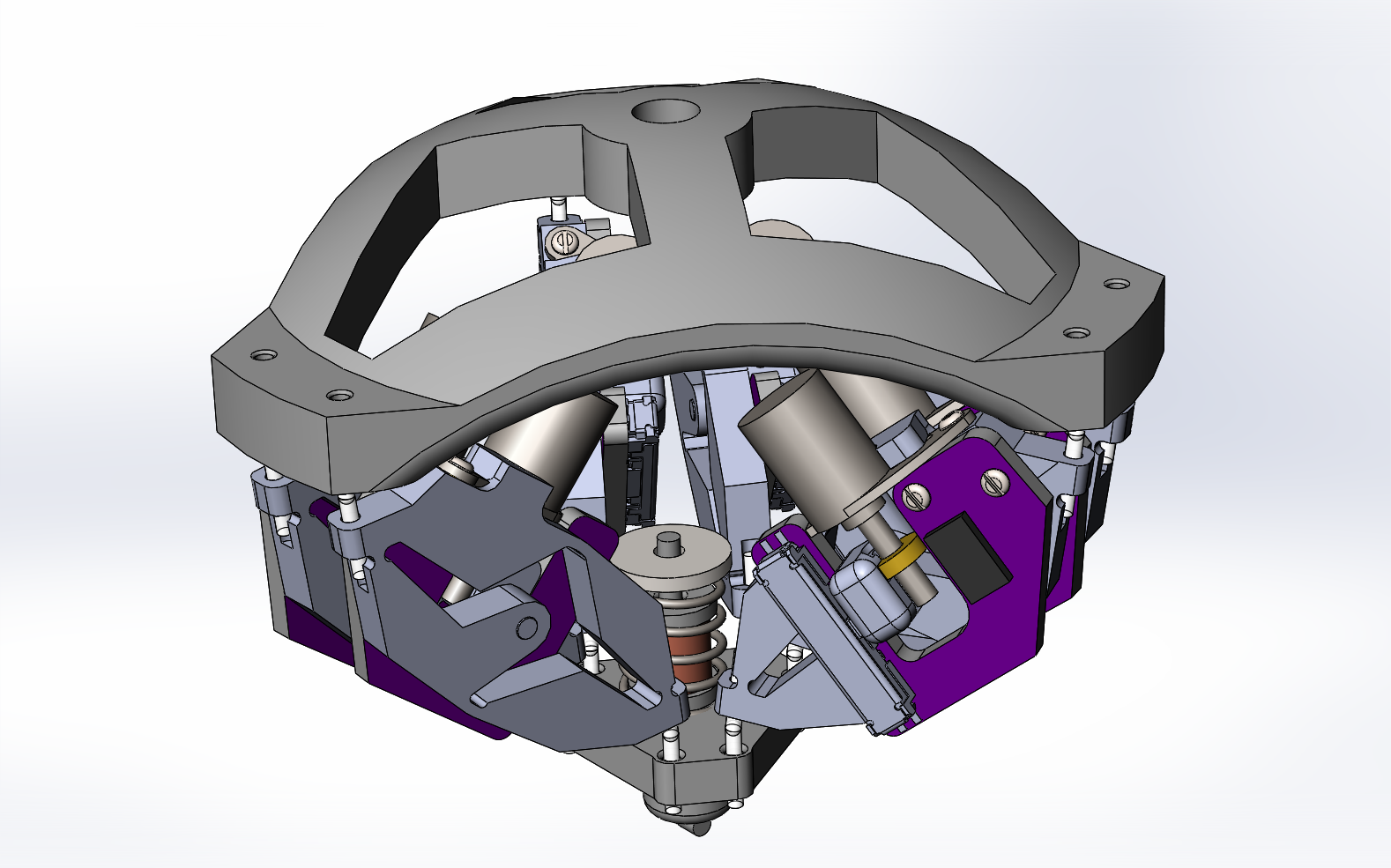

The new motors stick out one of the sides, this required a re-design for the main frame to give them space to move, without clashing. The next step is to run some simulations of the actuator bodies to get an idea of their longevity and the forces the motor will need to apply. If too high then they will need a re-design by thinning the hinges.

This could be done manually as there are size limits for getting the parts printed using nylon powder fusing method. The thinnest part of the joints is 0.7mm thick at the moment.

Figure: Main frame updated for new actuators

I've also identified the optical fiber i will be using which has a core diameter of 105um with an outer coating diameter of 250um, so the end effector needs to be able to securly grip this diameter without damaging it.

David Brown

David Brown

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.