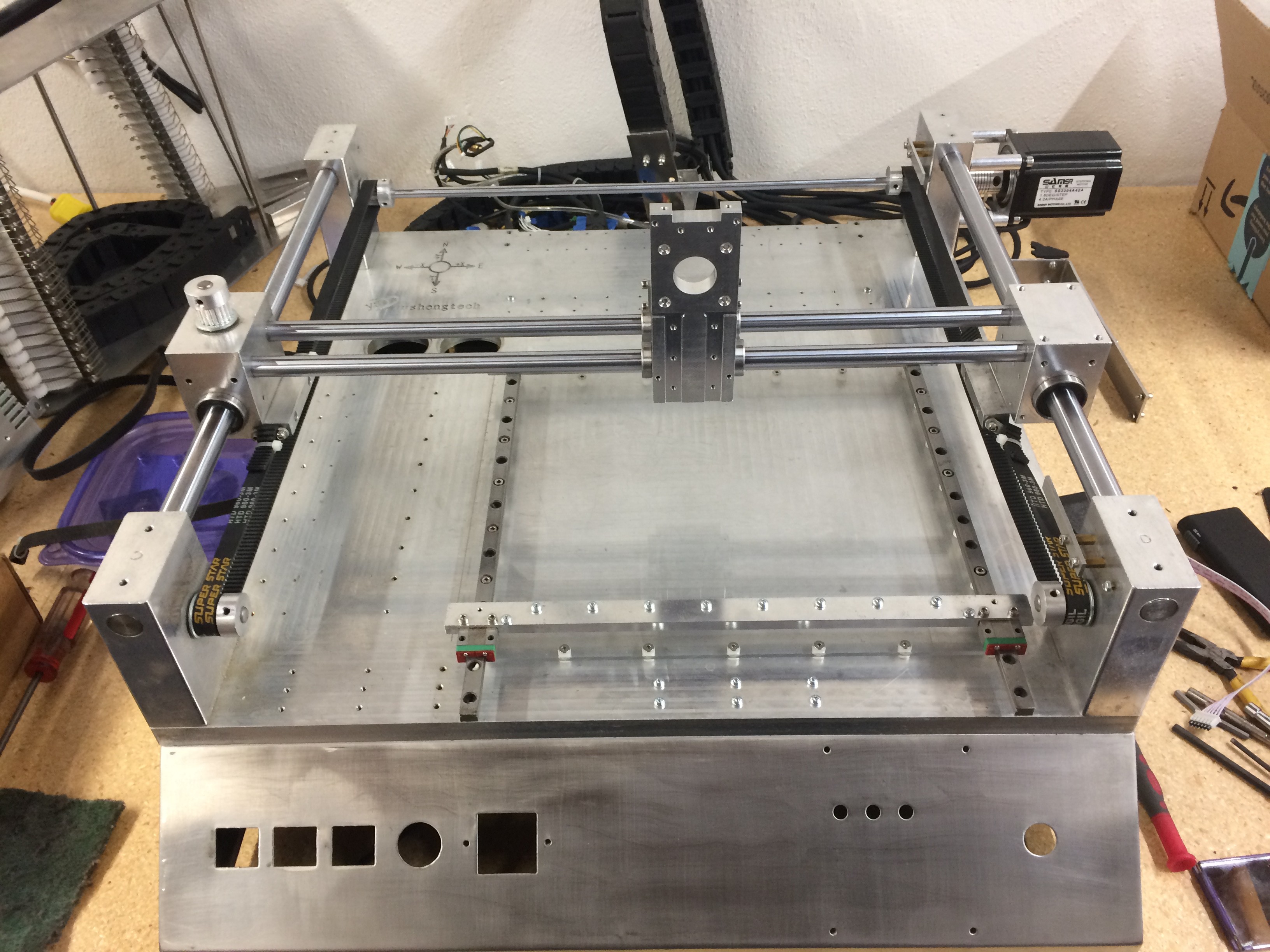

I "stripped" the machine down to the basic mechanical structure, leaving the 4 corner towers, slide rods, carriages. and pulleys. I carefully labeled the OEM cabling, but probably won't be able to reuse it, since it was cut to length with no service loops, and mummified in tons of shink tubing and tie wraps.

It was a pain to have to flip up the machine on its side to work on the underside. Putting the electronics and pneumatics to the right of the machine makes more sense to me. Meanwhile, I'll just lay out everything on the bench and connect using loose wires.

Darryl.N

Darryl.N

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.