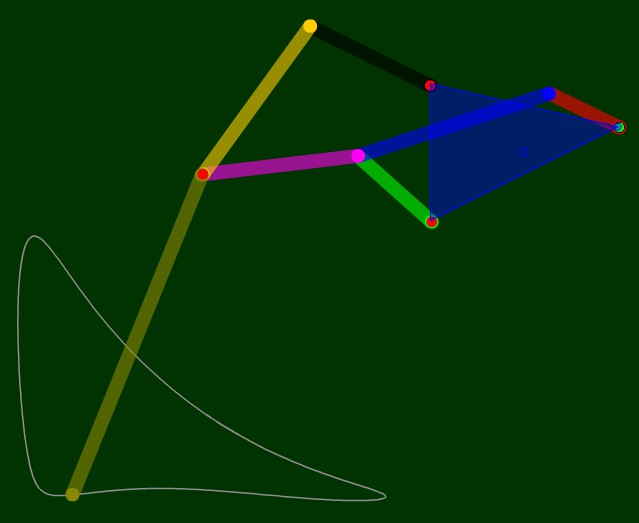

A few years ago i built a little walking mechanism based on the Klann linkage. It worked well enough as a proof of concept, but wasn't useful for anything else.

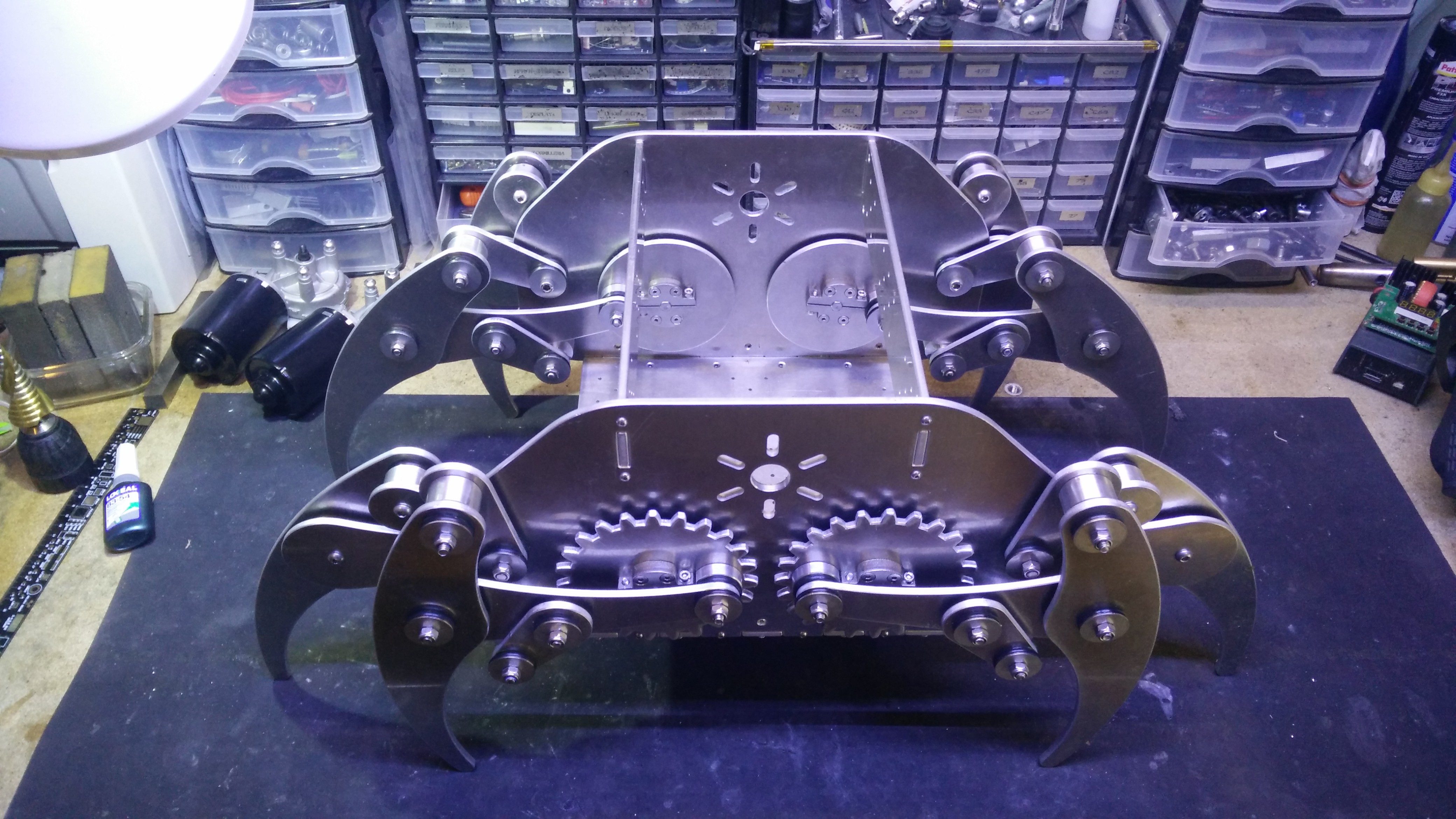

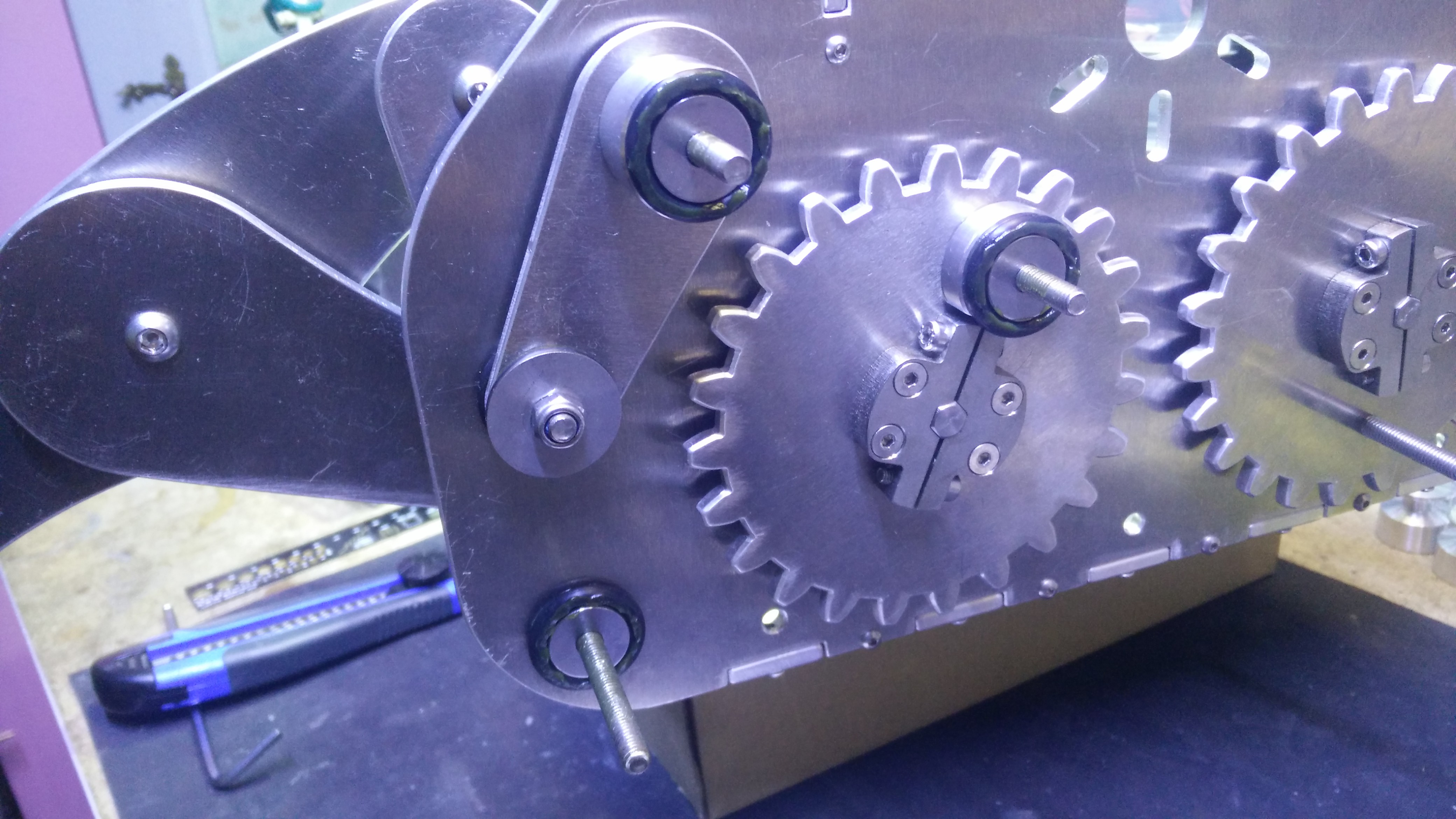

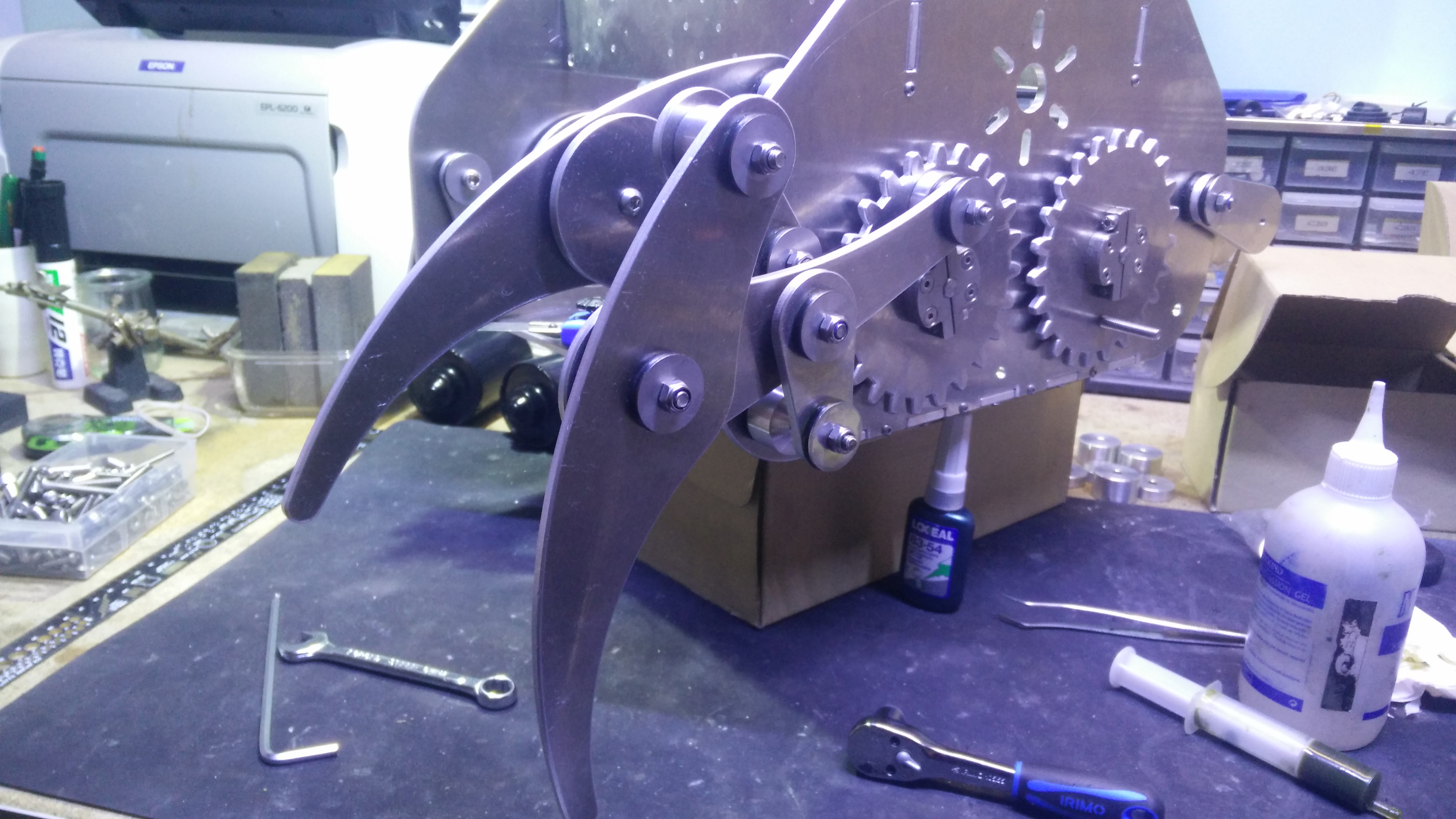

Now i'm building another one, but harder, better, faster, stronger.

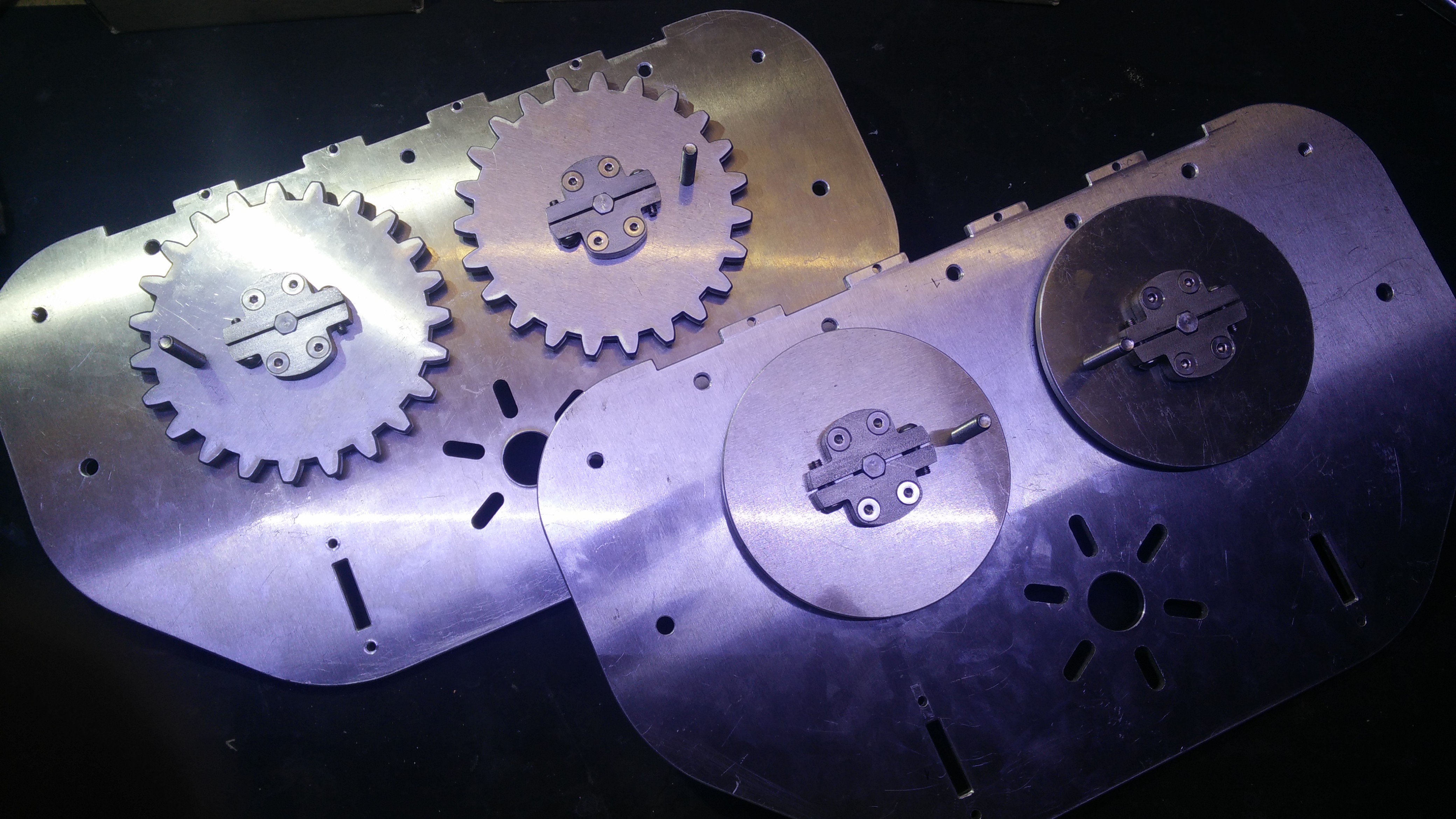

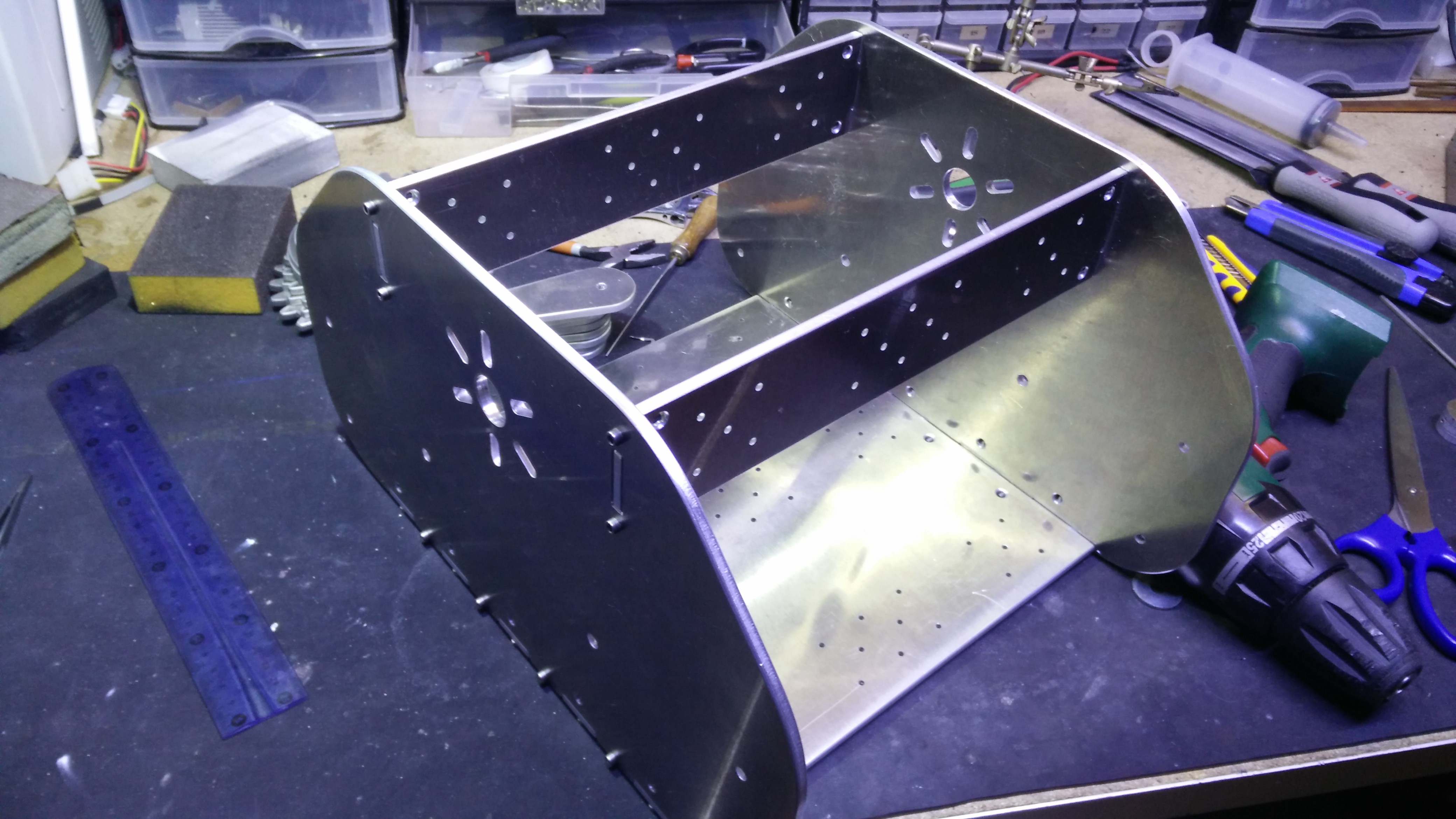

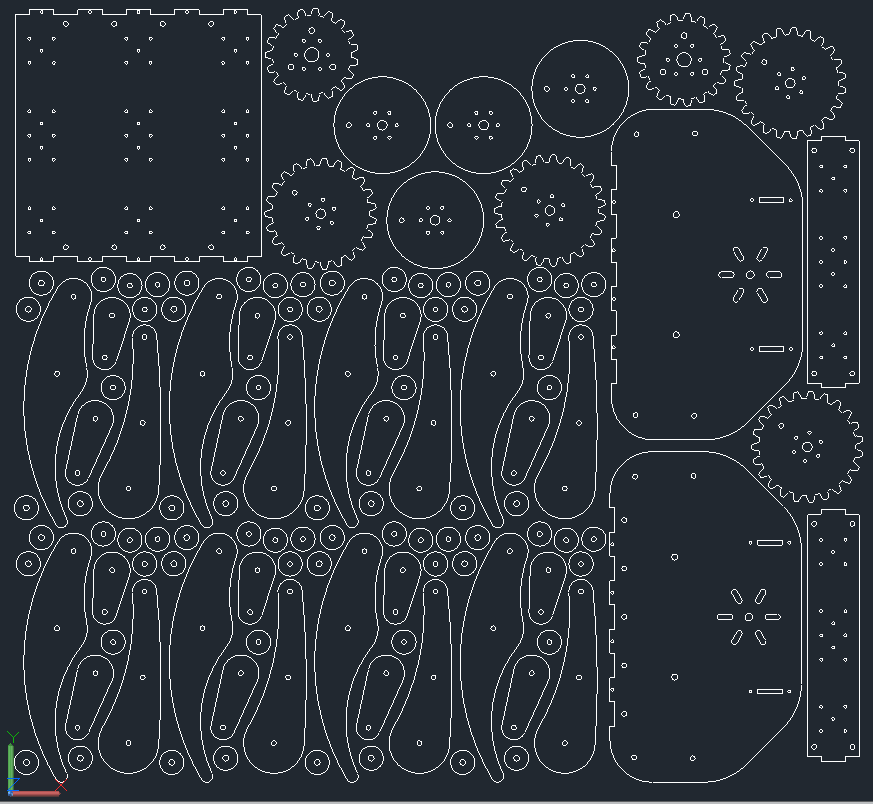

Intead of making it out of brass and small enough to fit on a hand, the new one will be made out of aluminium and stainless, and big and strong enough to carry tools, actuators or a payload.

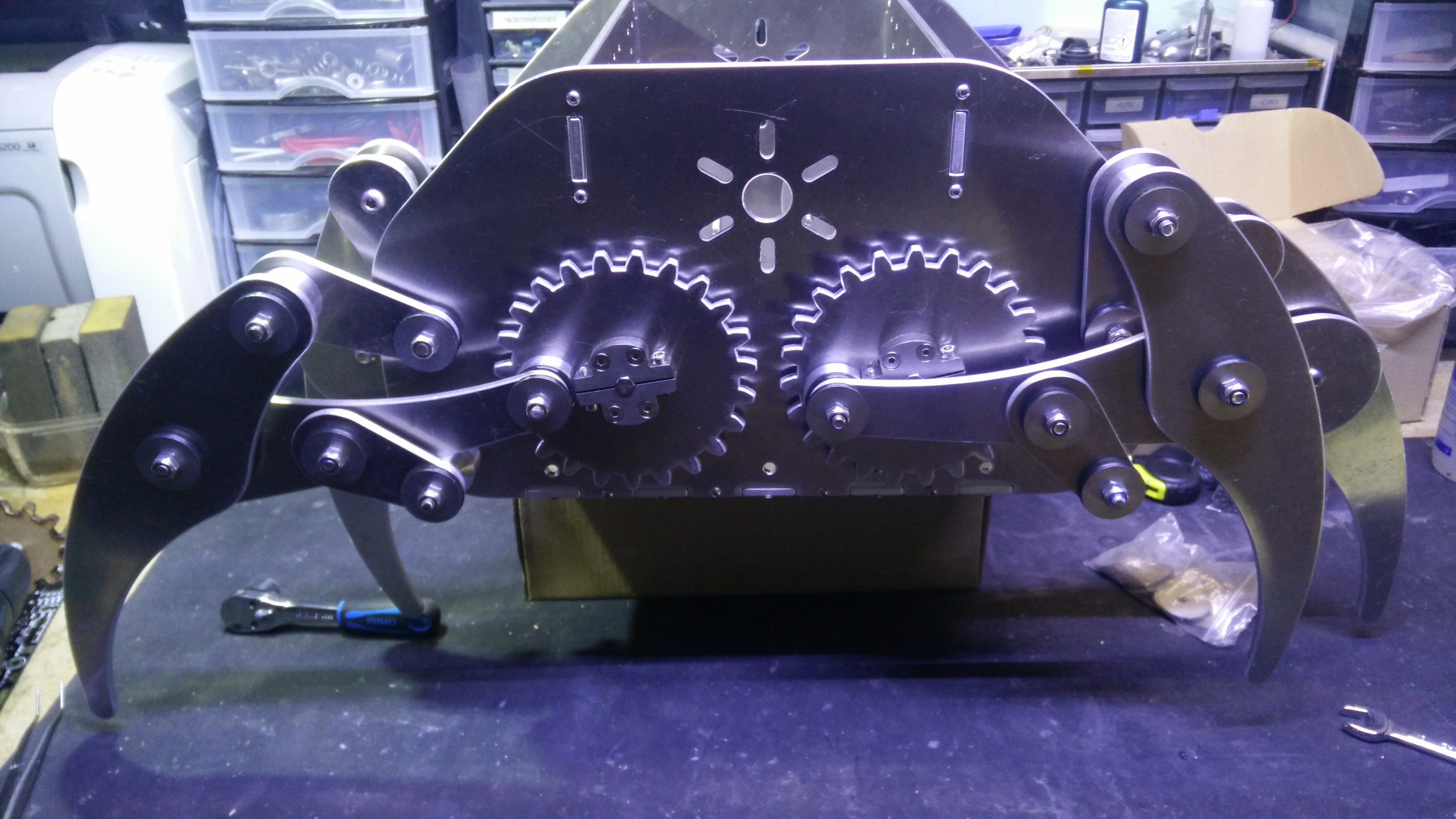

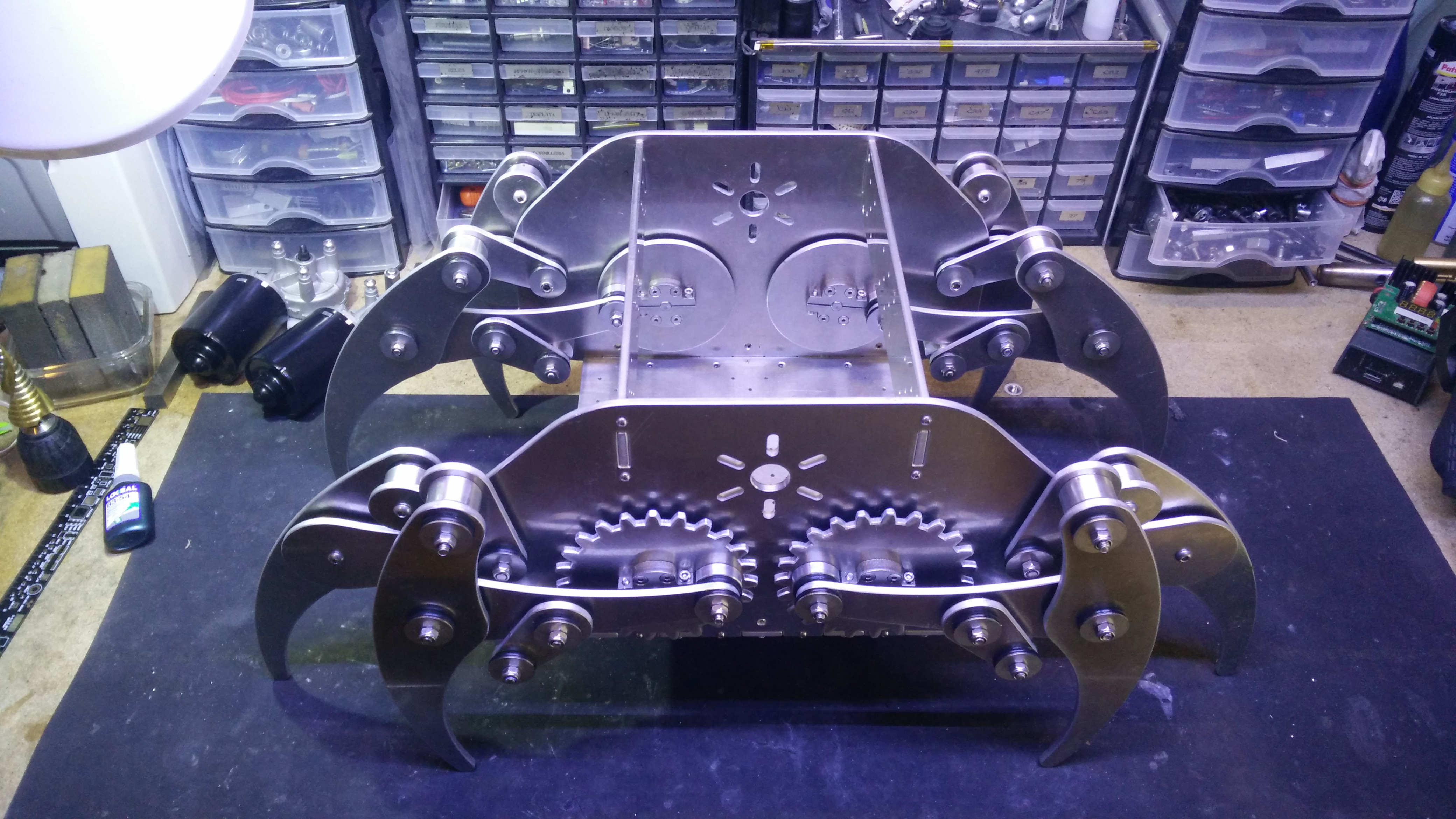

I'm almost done with the mechanism itself, and it looks very promising.

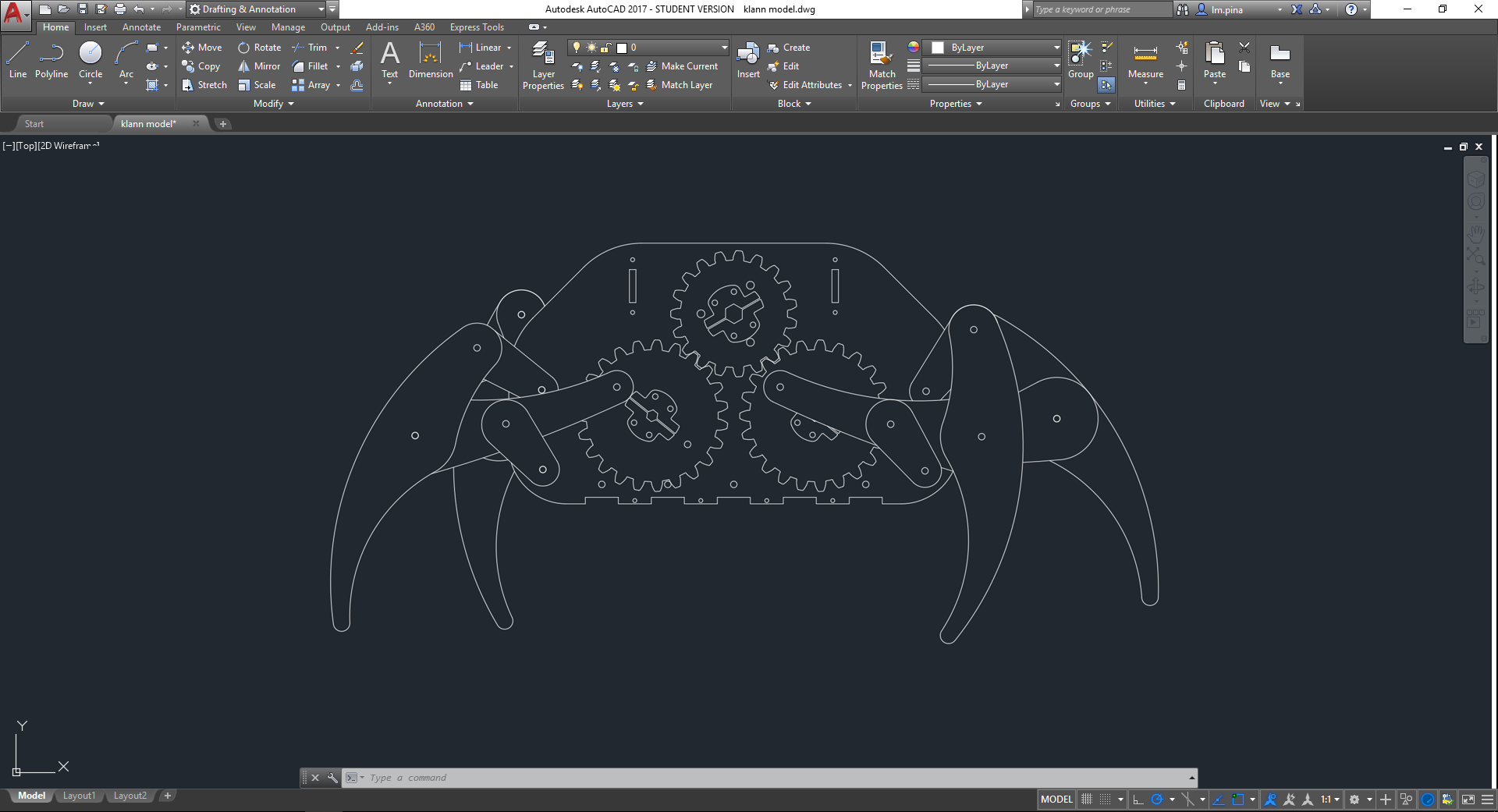

this is how it looks loke so far:

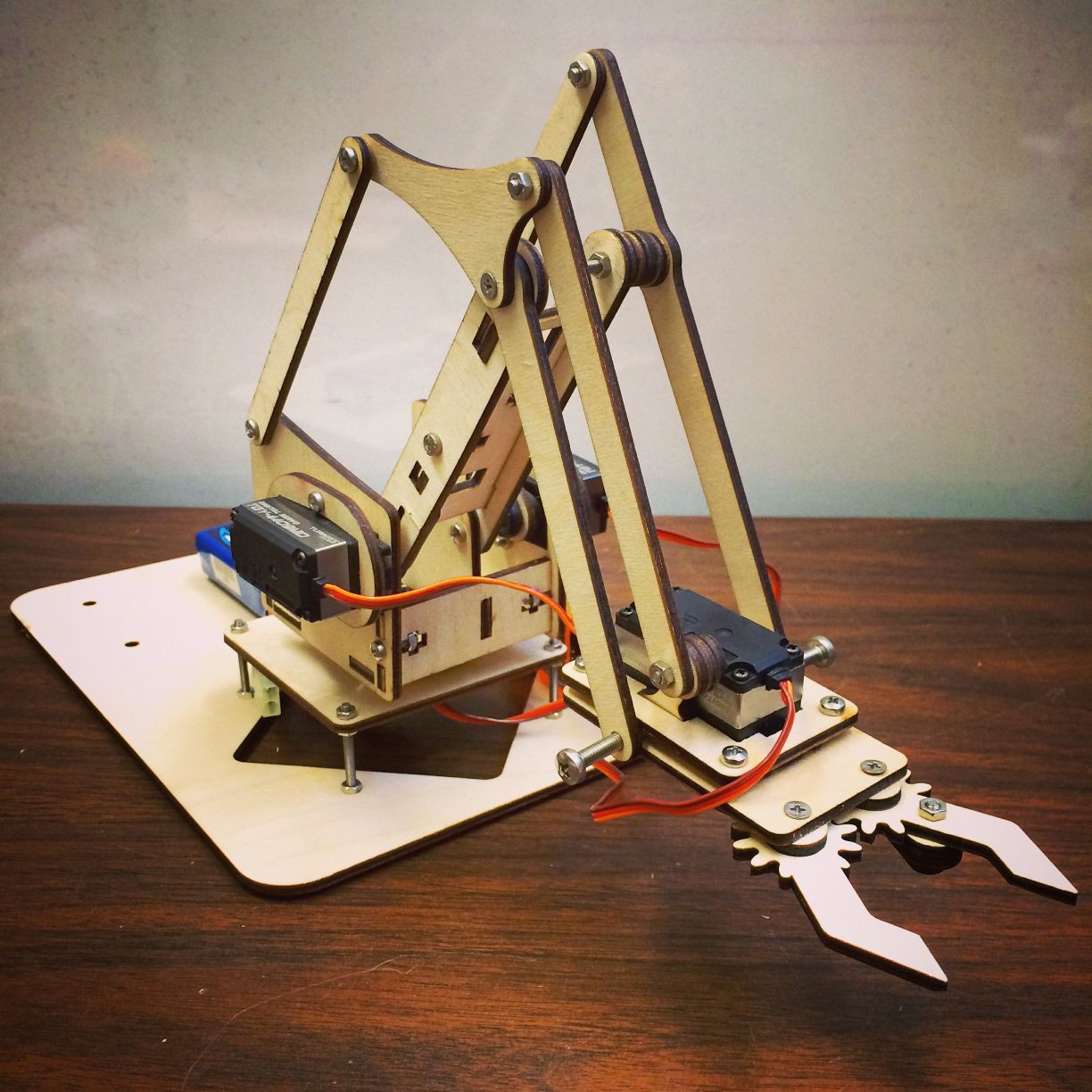

Compared to the brass prototype:

Pinomelean

Pinomelean

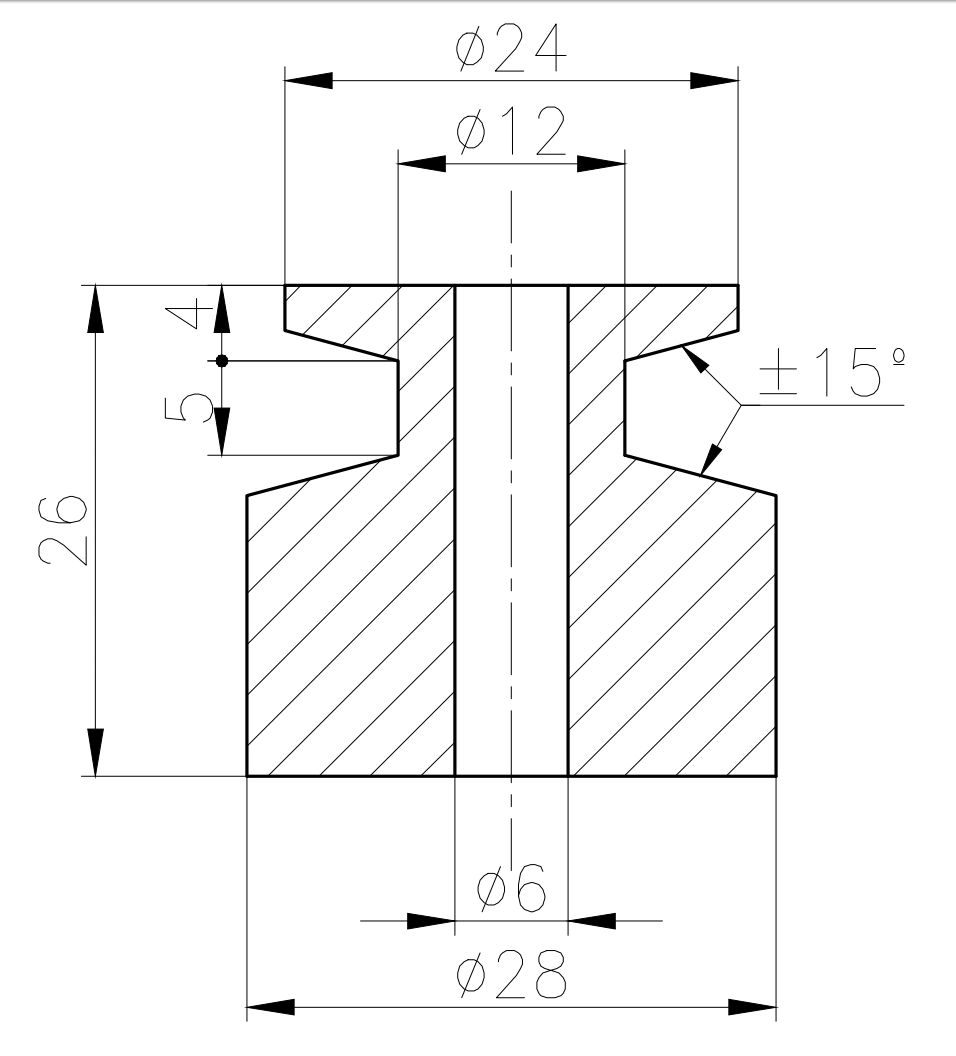

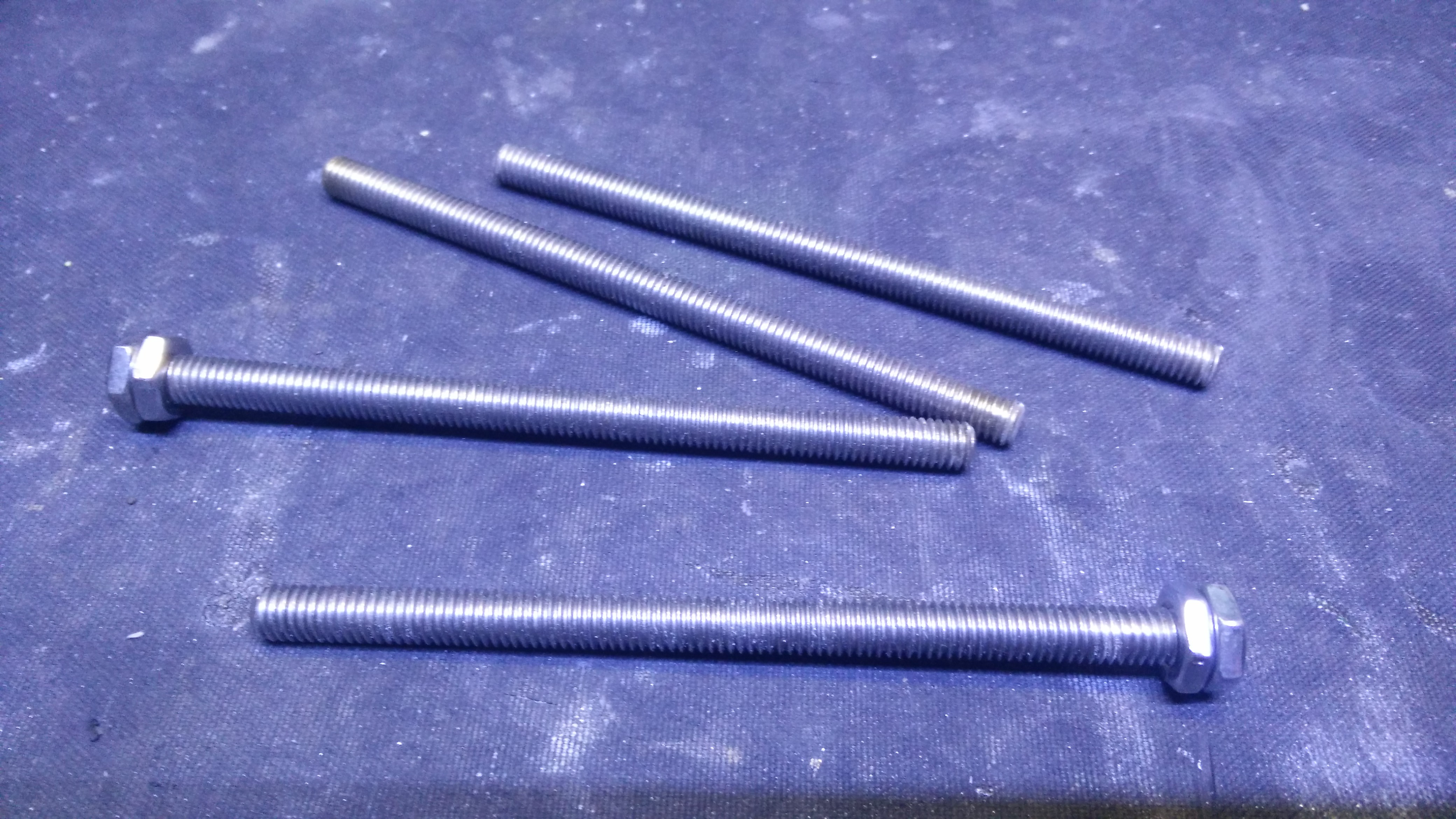

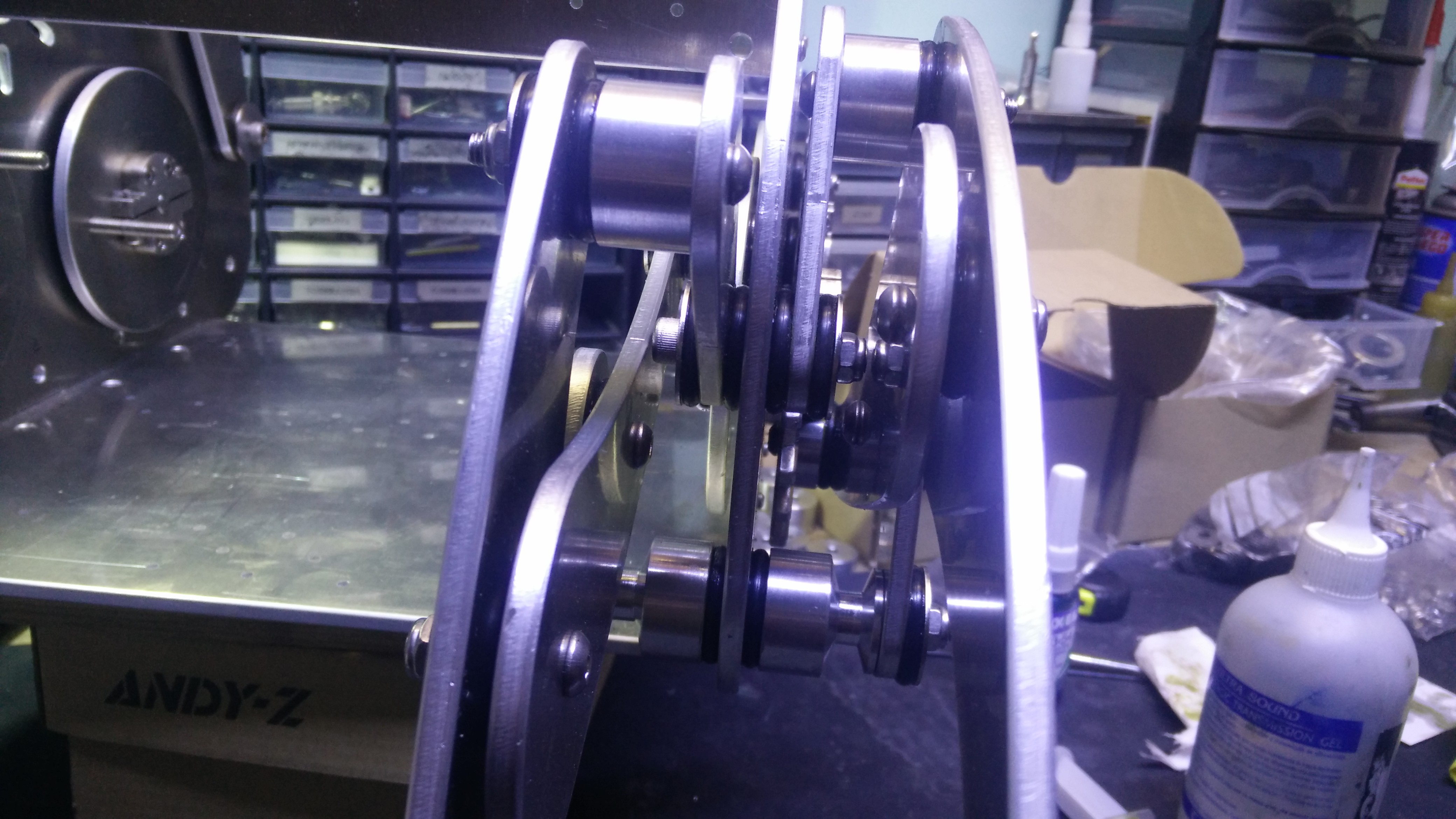

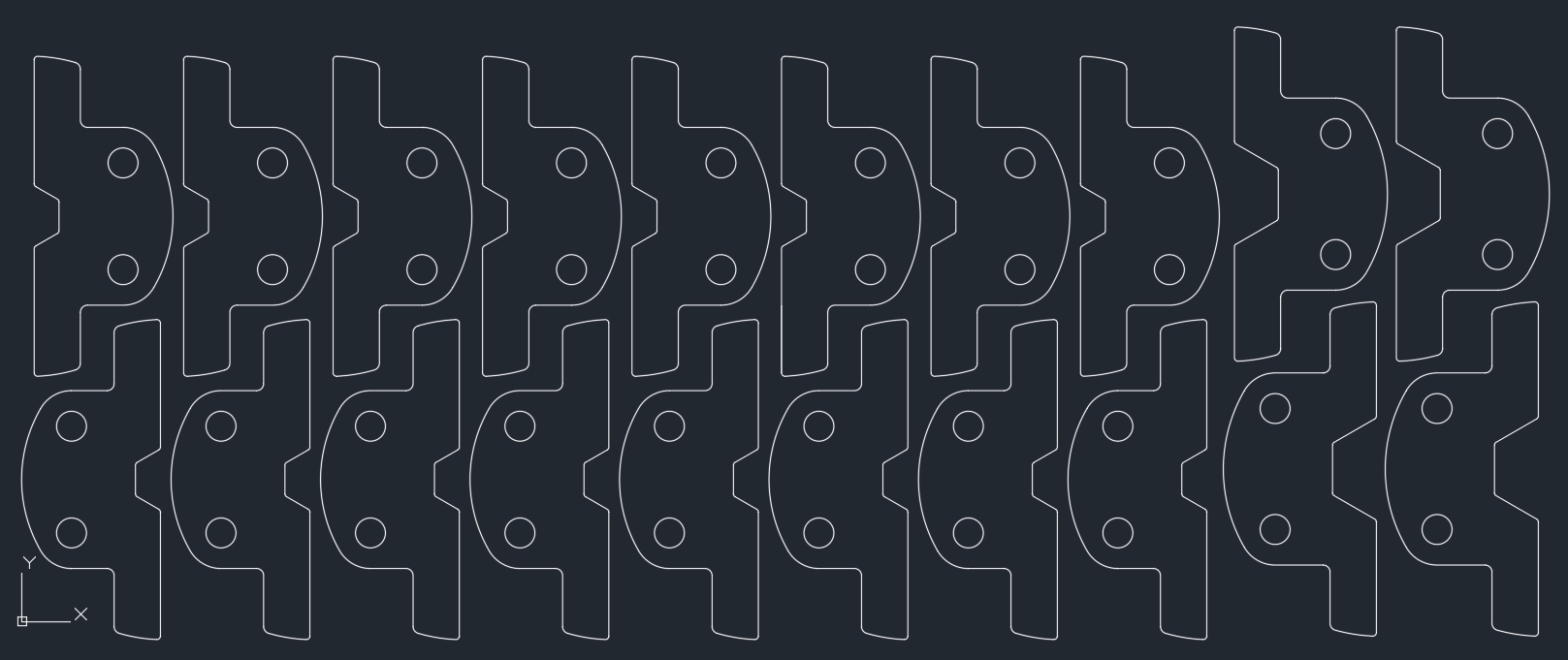

All the spacers have a 6mm hole in the center for the axles to pass through. The following are the ones i used (eight of each one):

All the spacers have a 6mm hole in the center for the axles to pass through. The following are the ones i used (eight of each one):

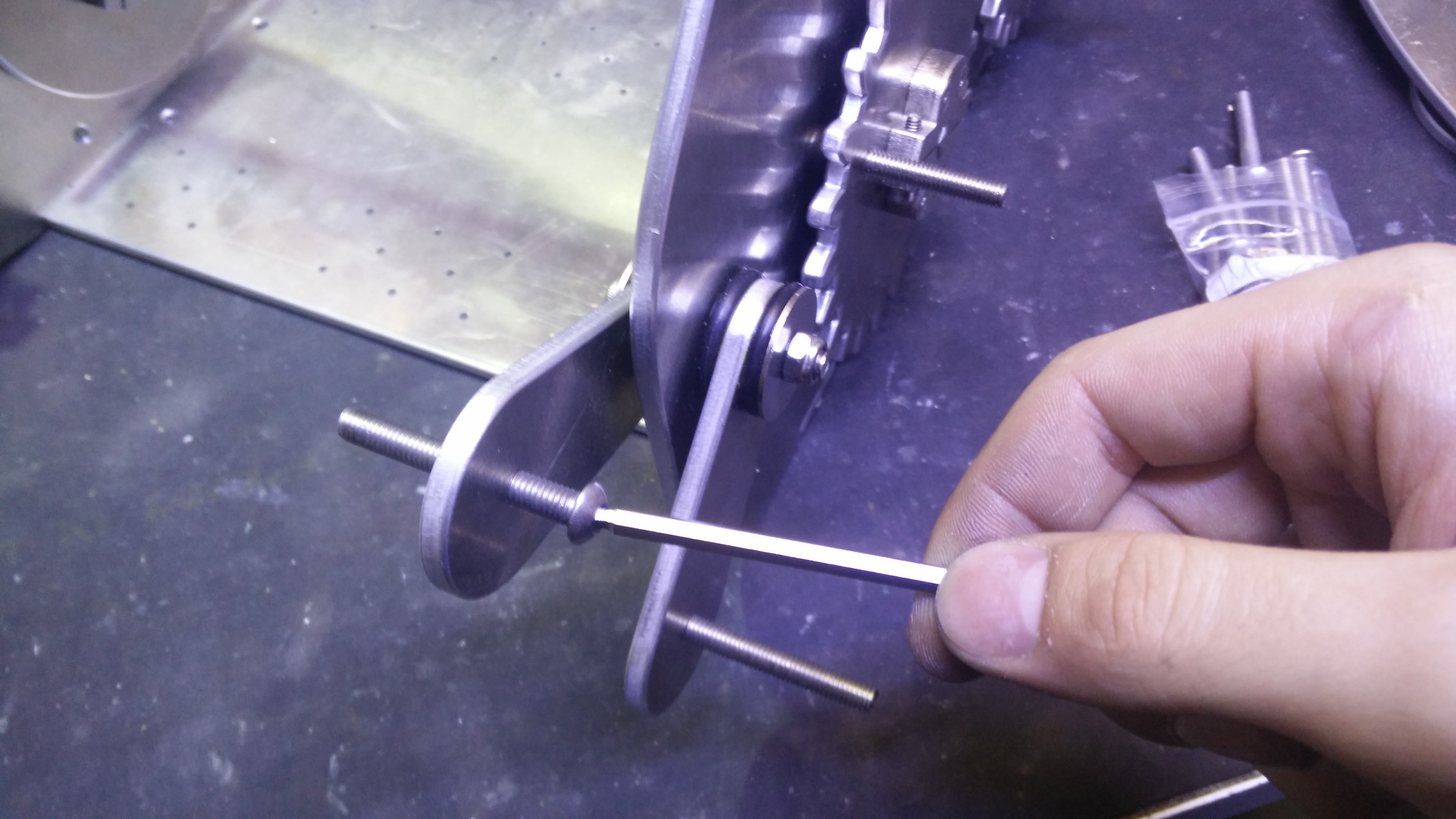

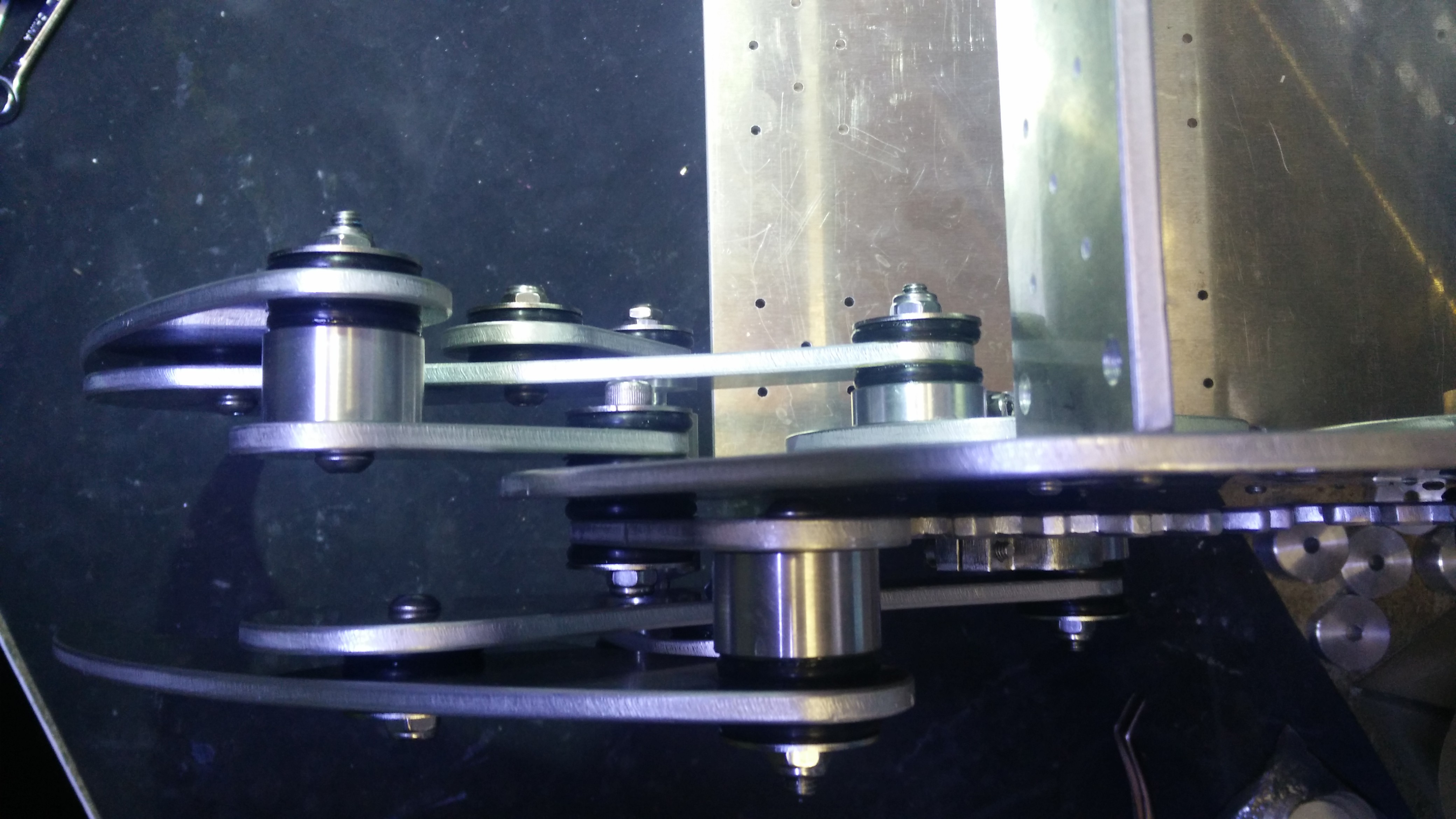

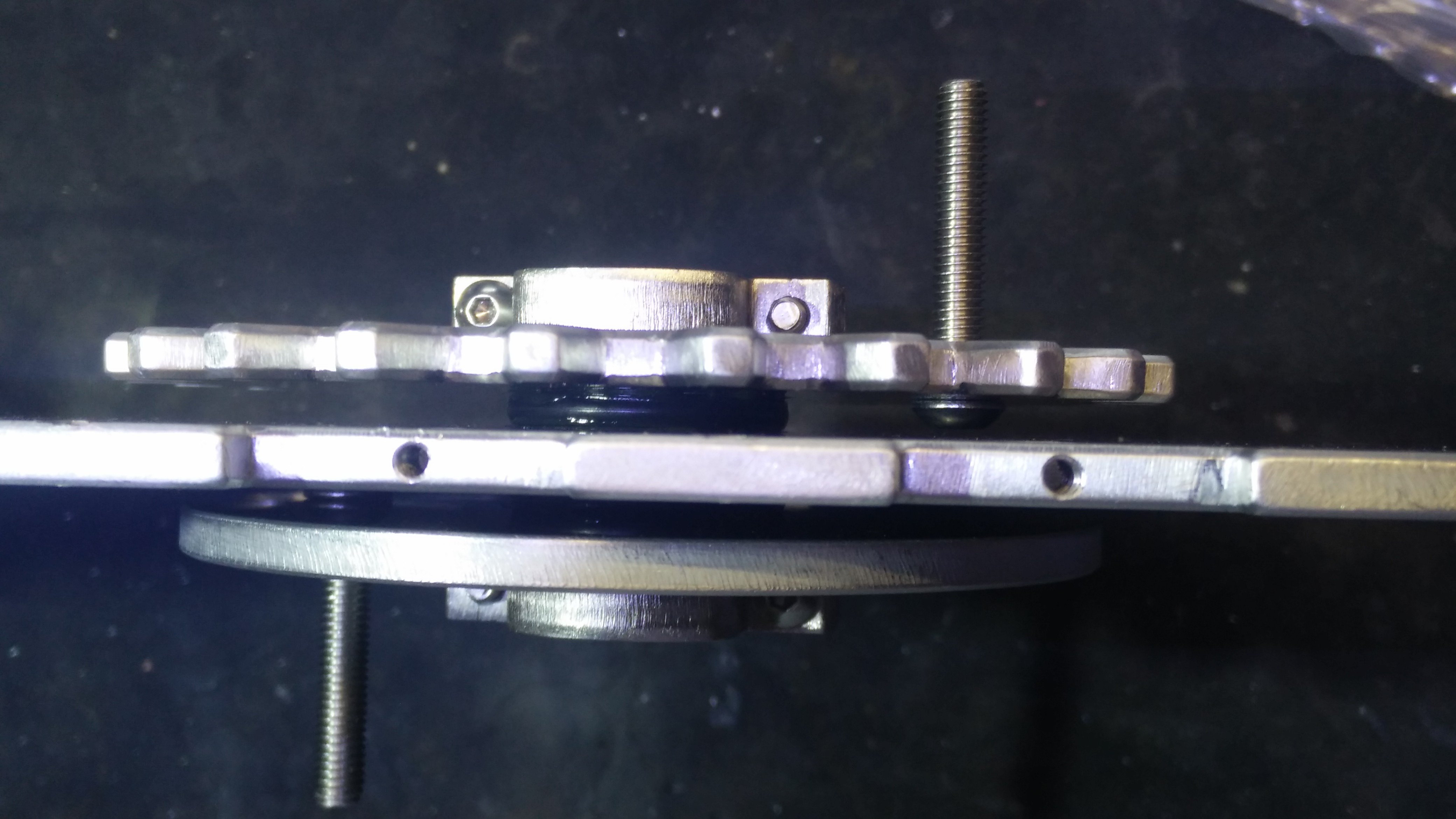

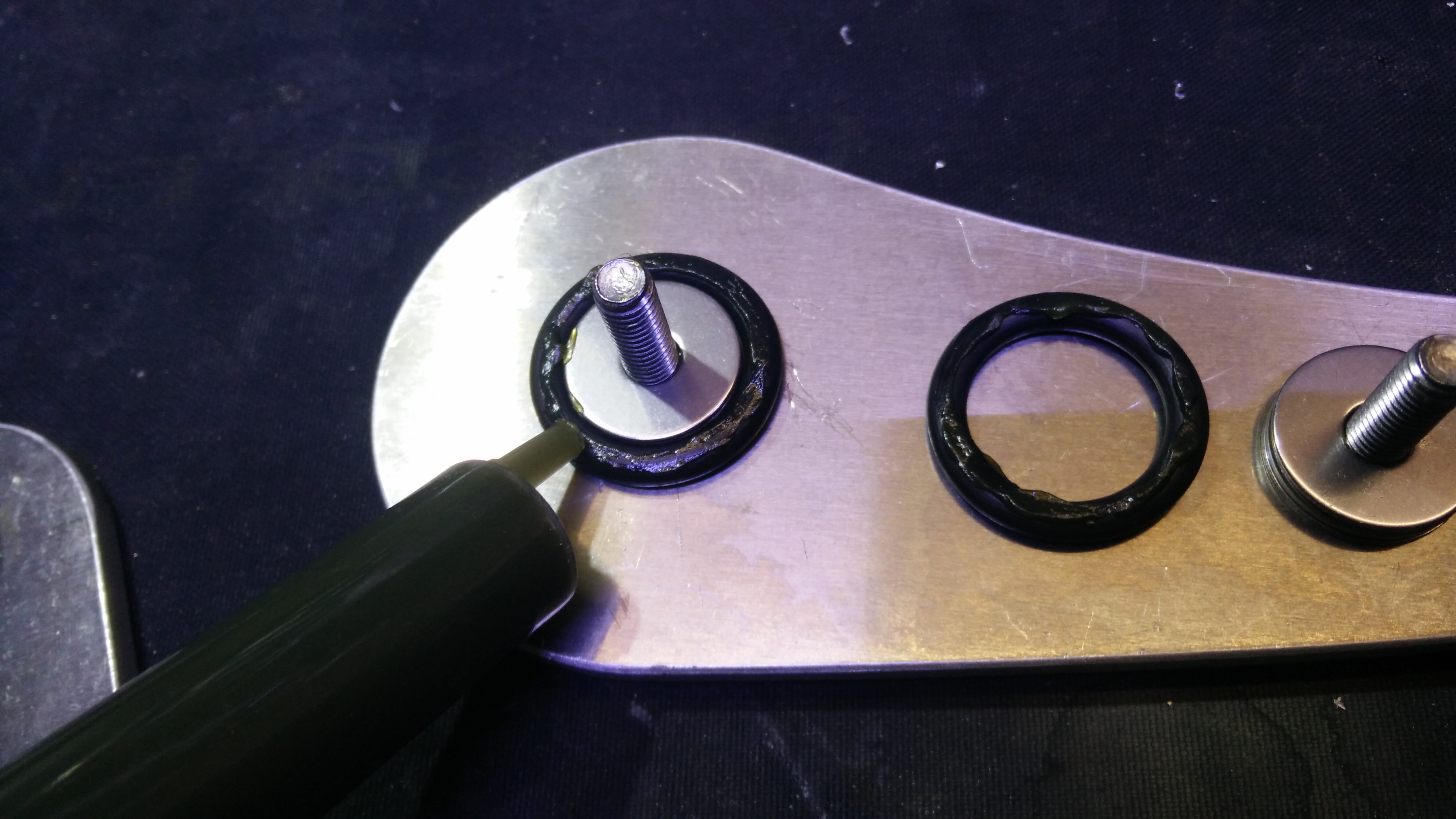

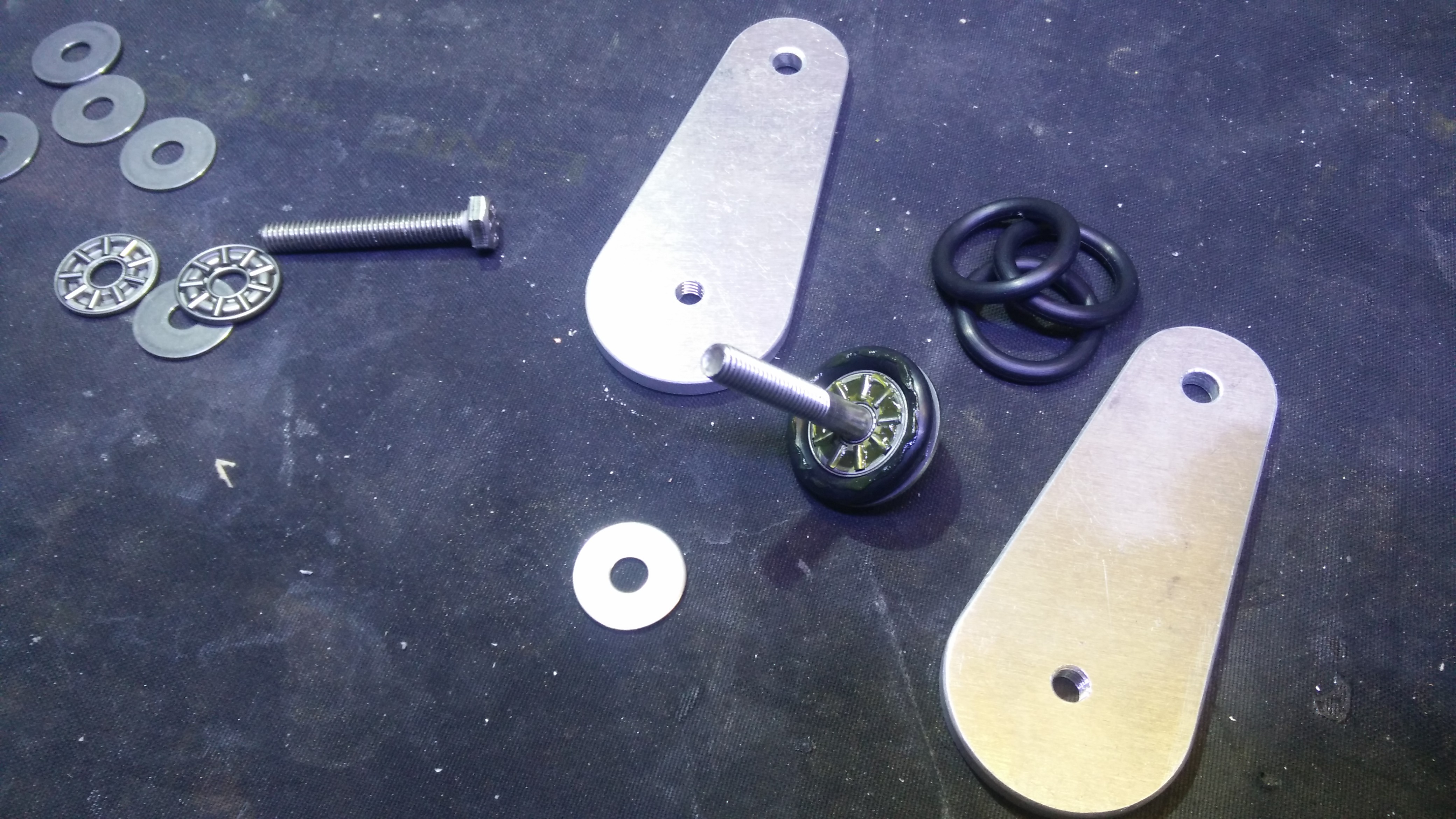

Greased thrust bearings (AXK 0619) and o-rings are placed on both spacers.

Greased thrust bearings (AXK 0619) and o-rings are placed on both spacers.

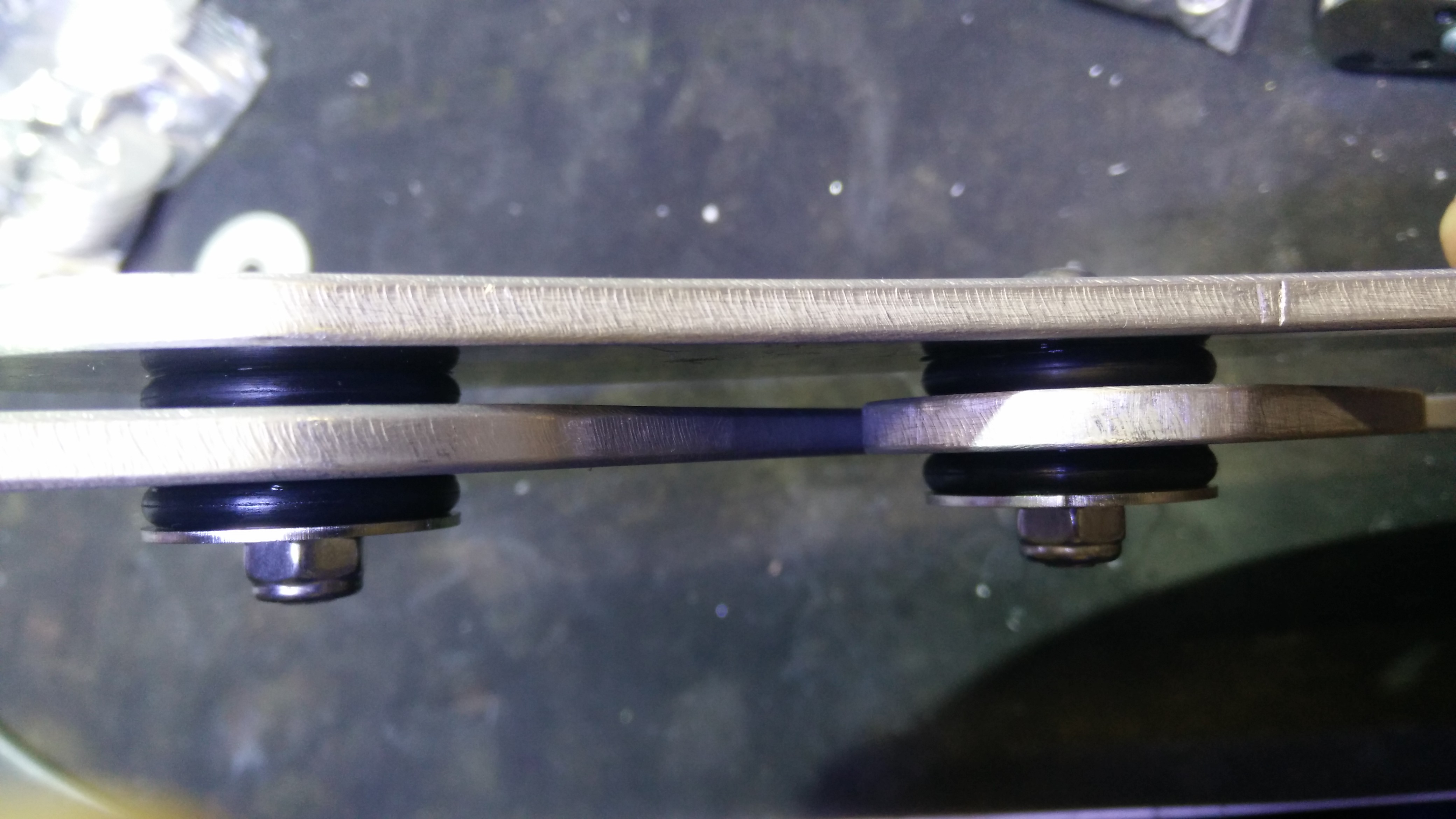

Followed by a covering washer and a nylon-insert lock nut.

Followed by a covering washer and a nylon-insert lock nut. Once the inner leg is done, similar steps are followed for the outer leg.

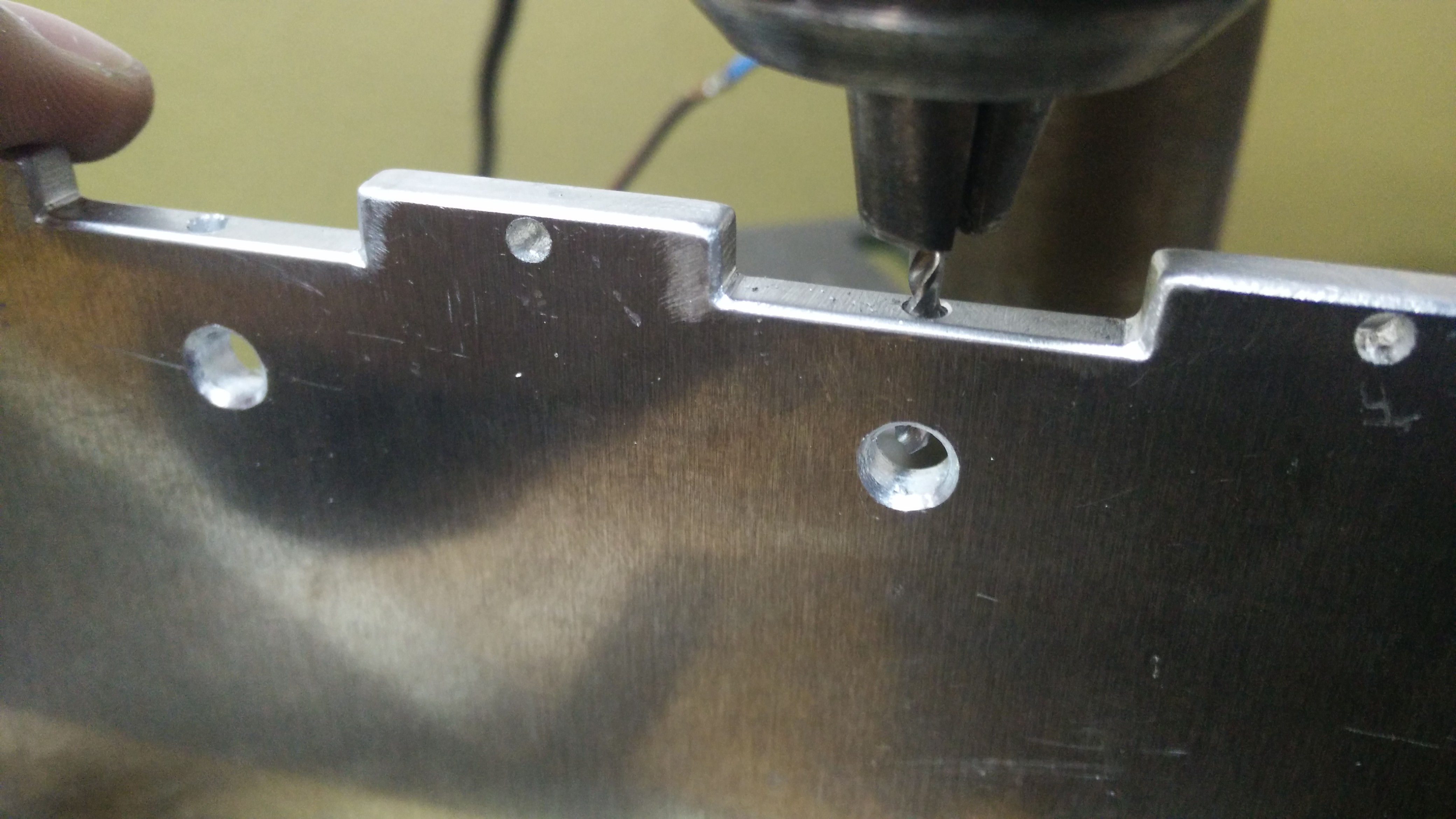

Once the inner leg is done, similar steps are followed for the outer leg. The 26mm spacer is placed on the bearing for the lower pivot.

The 26mm spacer is placed on the bearing for the lower pivot. The outer leg is slided onto the three axles (which have been greased beforehand).

The outer leg is slided onto the three axles (which have been greased beforehand). As with the inner legs, bearings and o-ring are placed on each bolt, and a washer and nylon-insert lock nut are used to finish the joints.

As with the inner legs, bearings and o-ring are placed on each bolt, and a washer and nylon-insert lock nut are used to finish the joints.

I can't wait to get this...

I can't wait to get this...

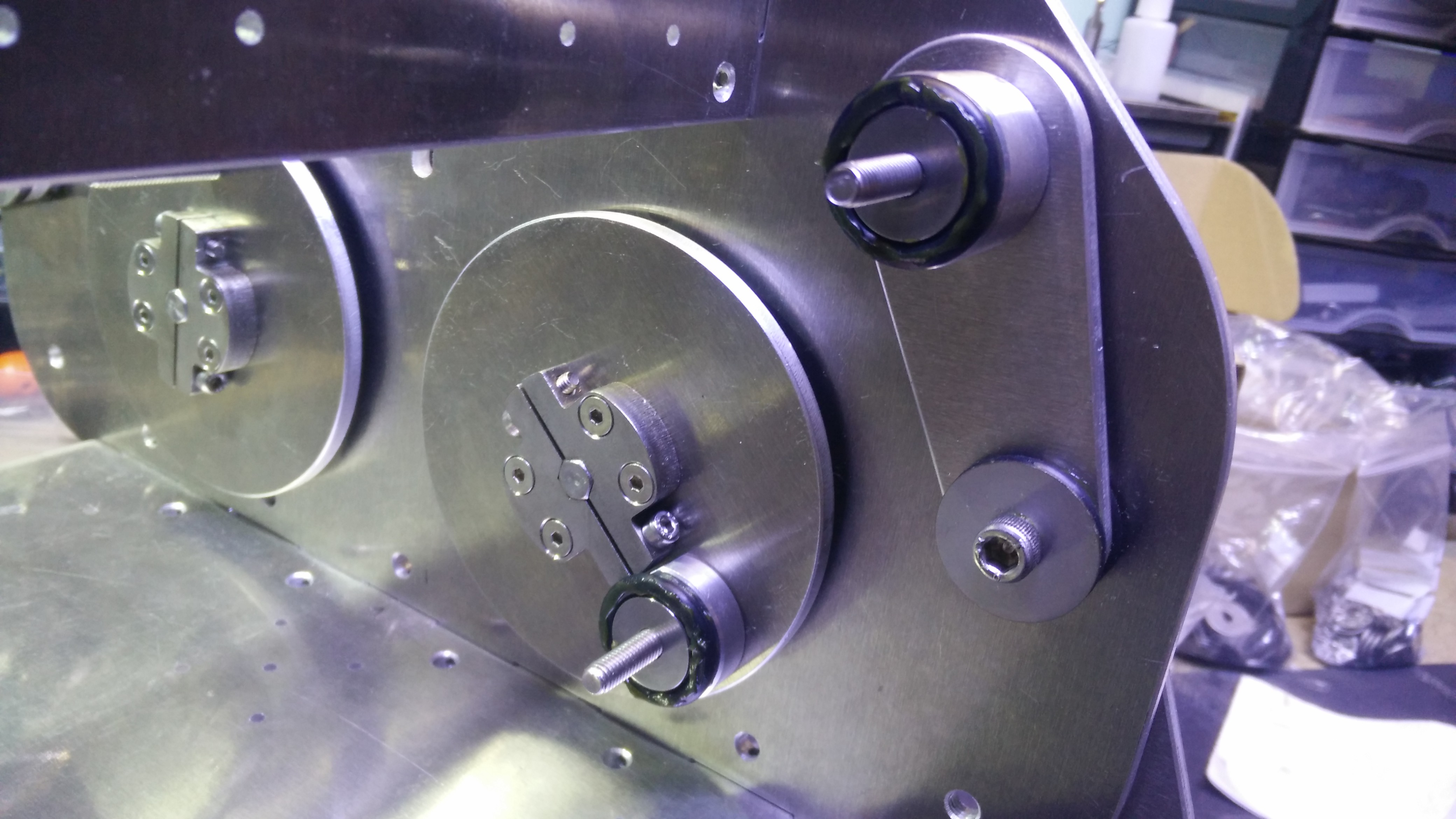

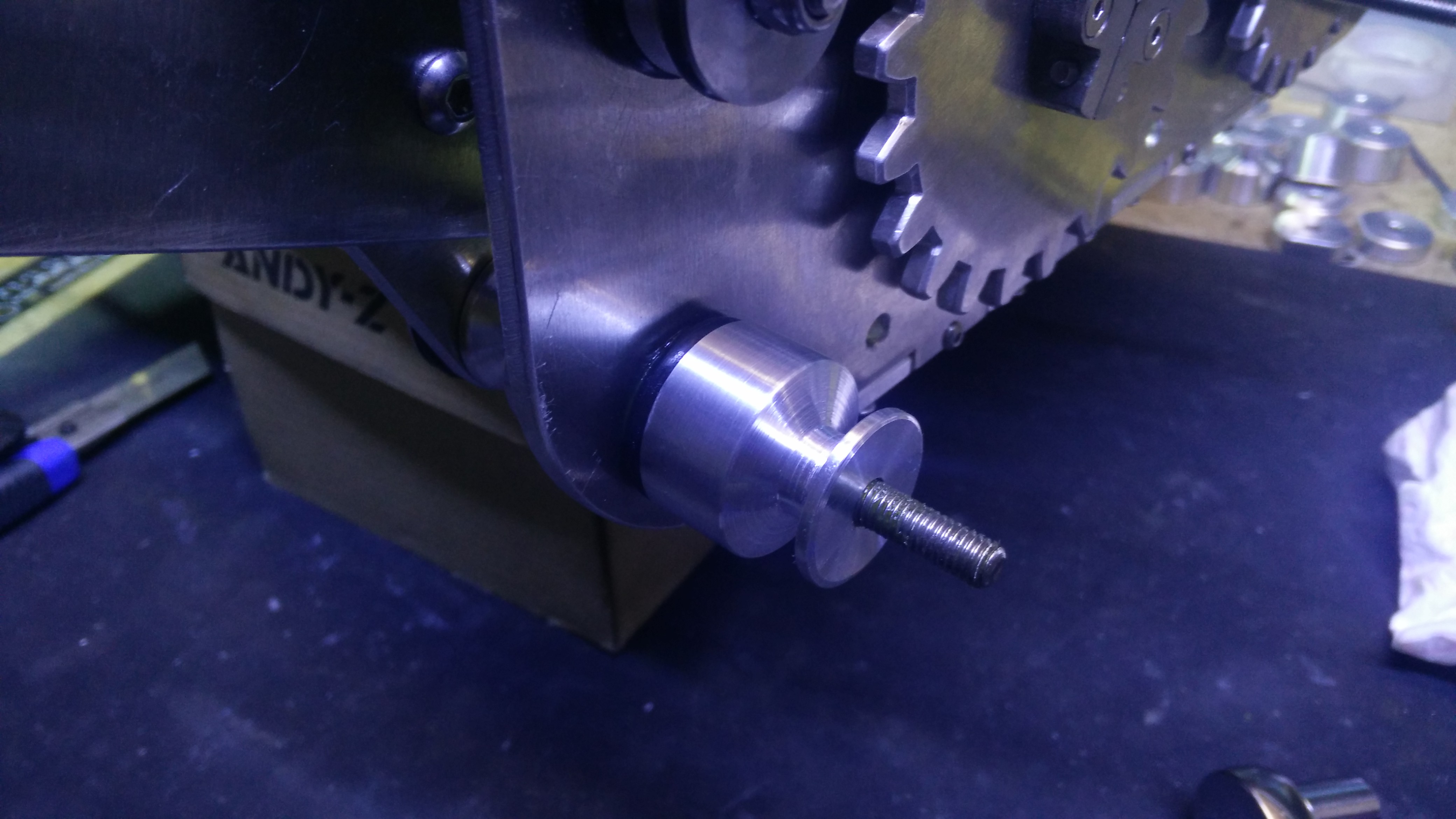

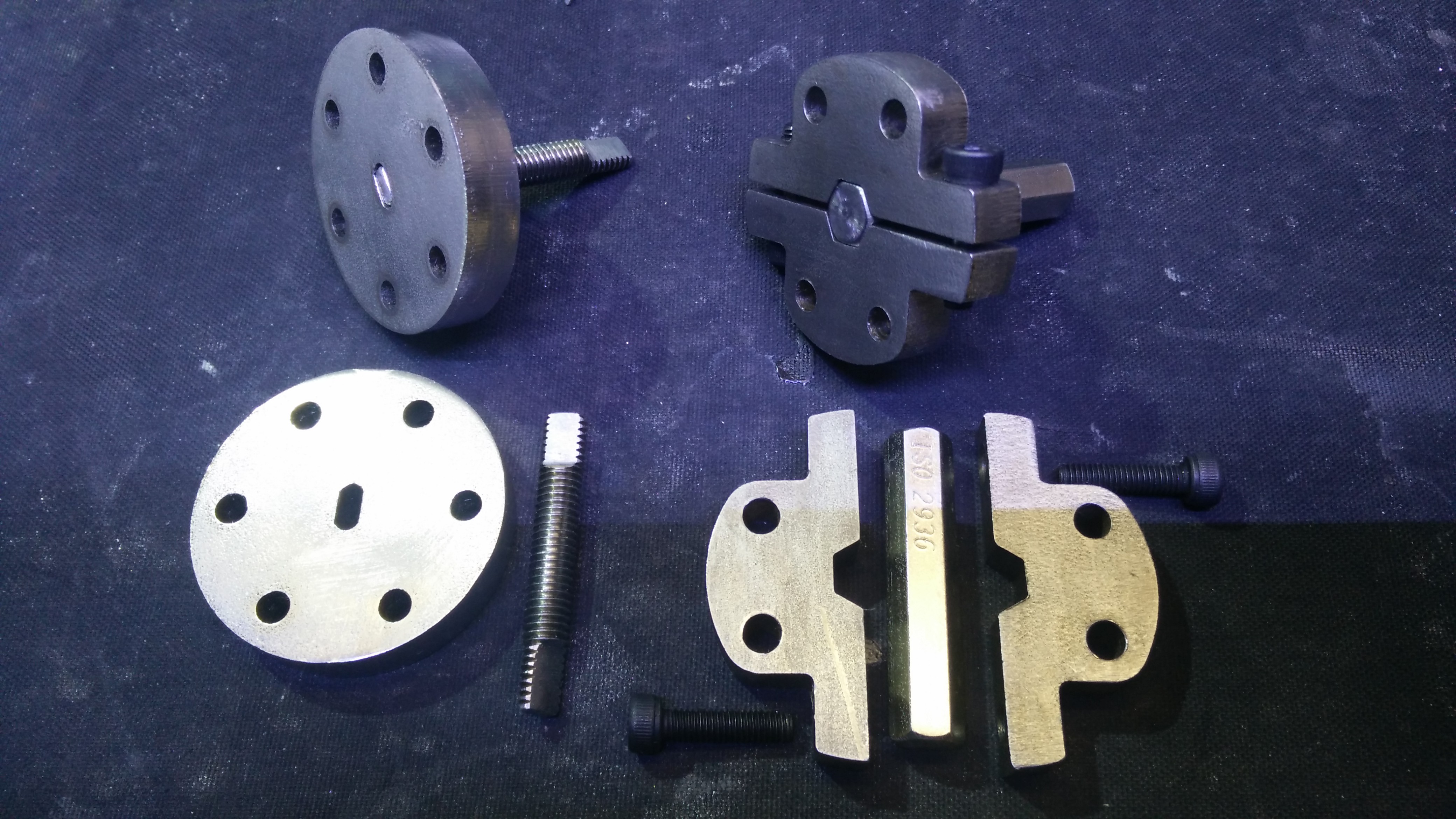

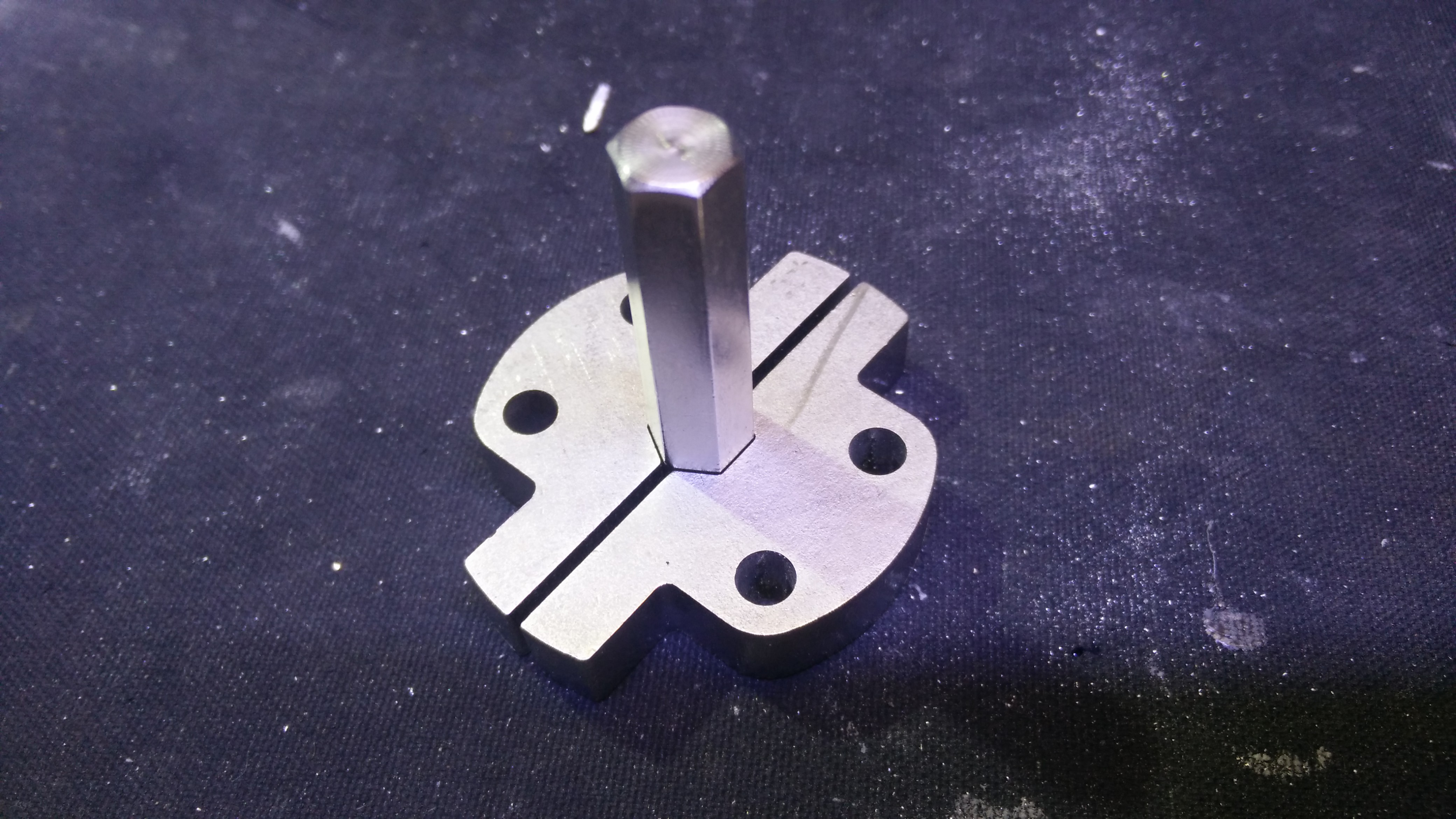

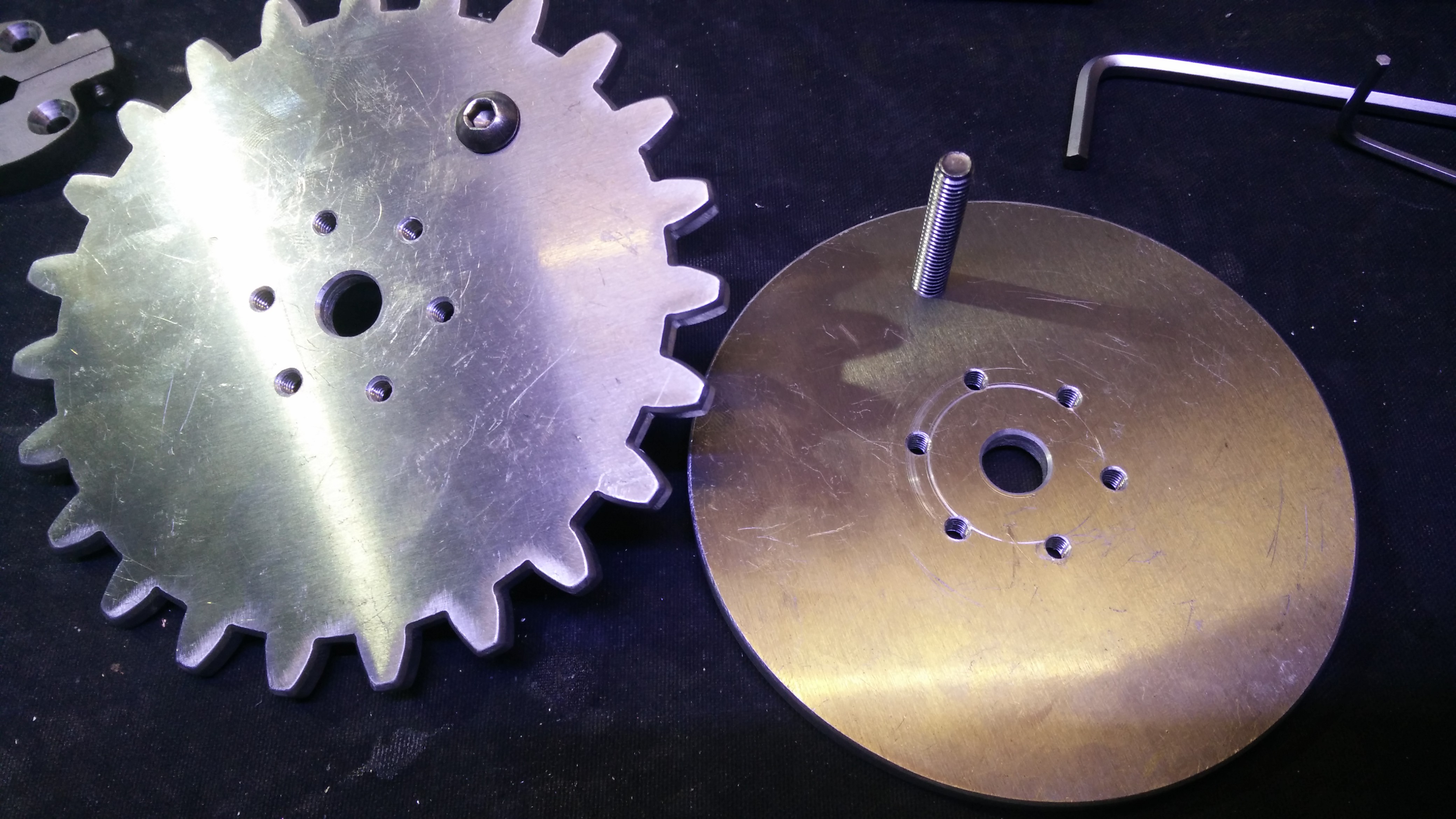

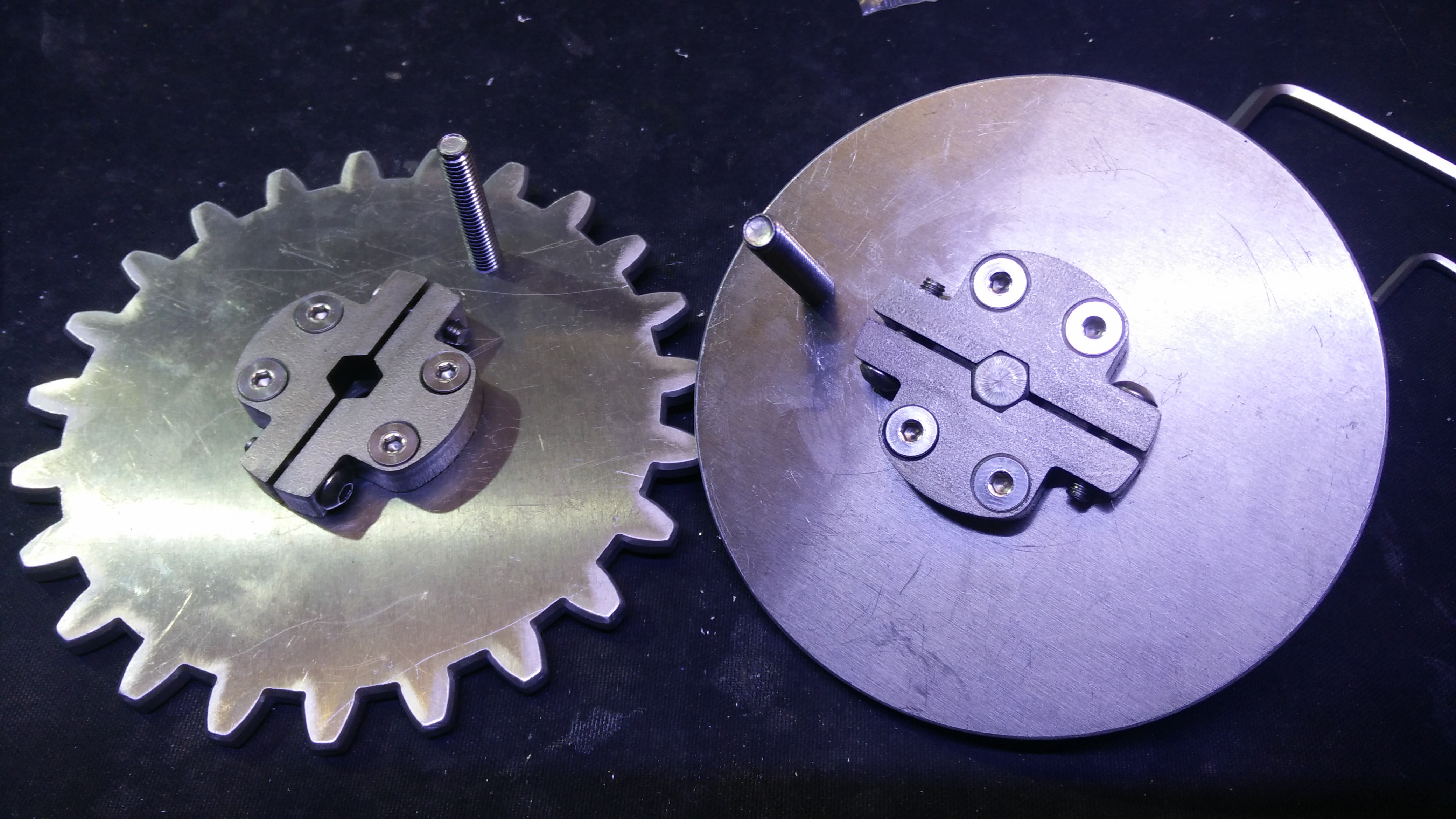

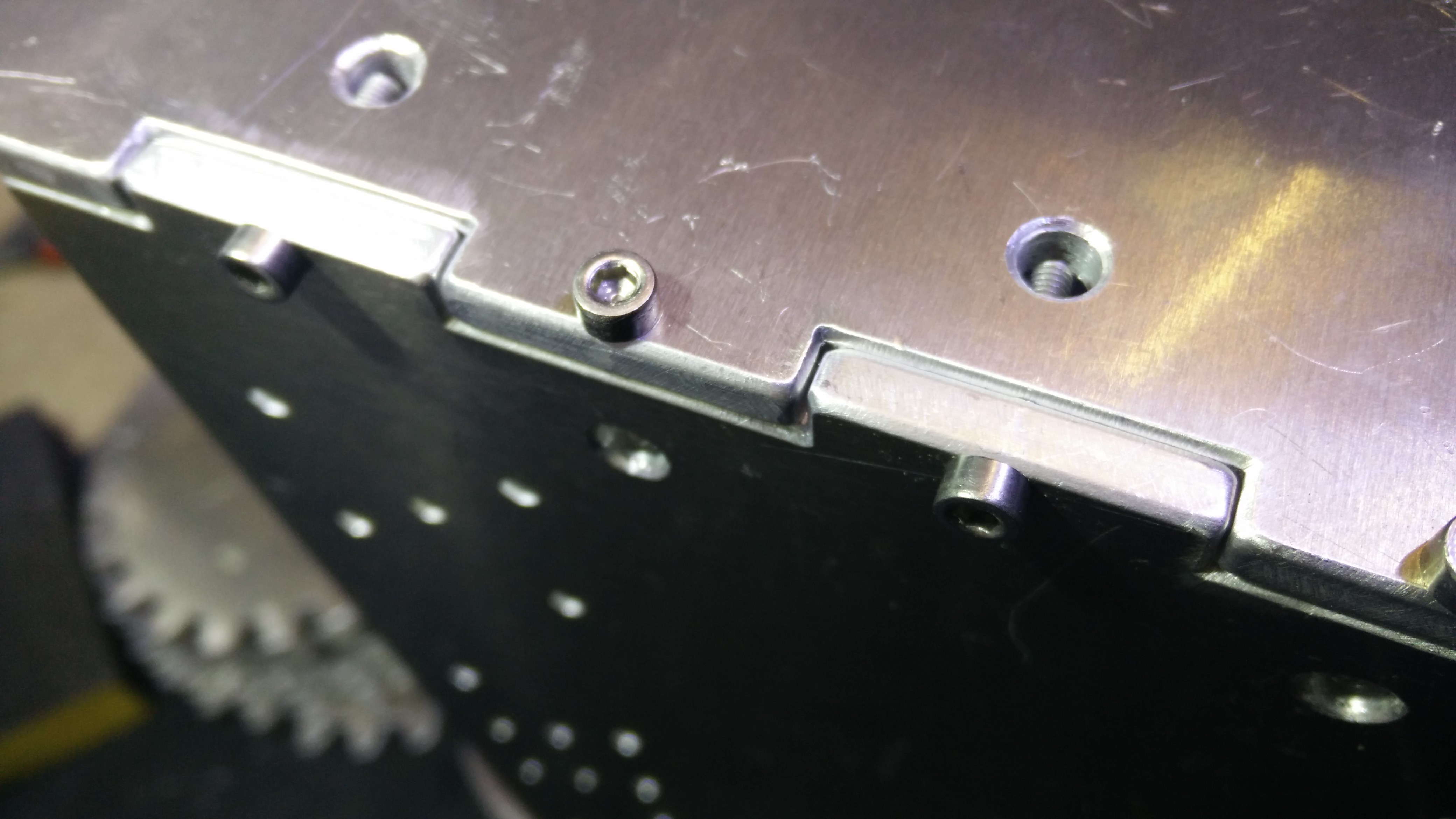

With M4 x 16mm screws the halves are clamped onto the hex shaft.

With M4 x 16mm screws the halves are clamped onto the hex shaft.

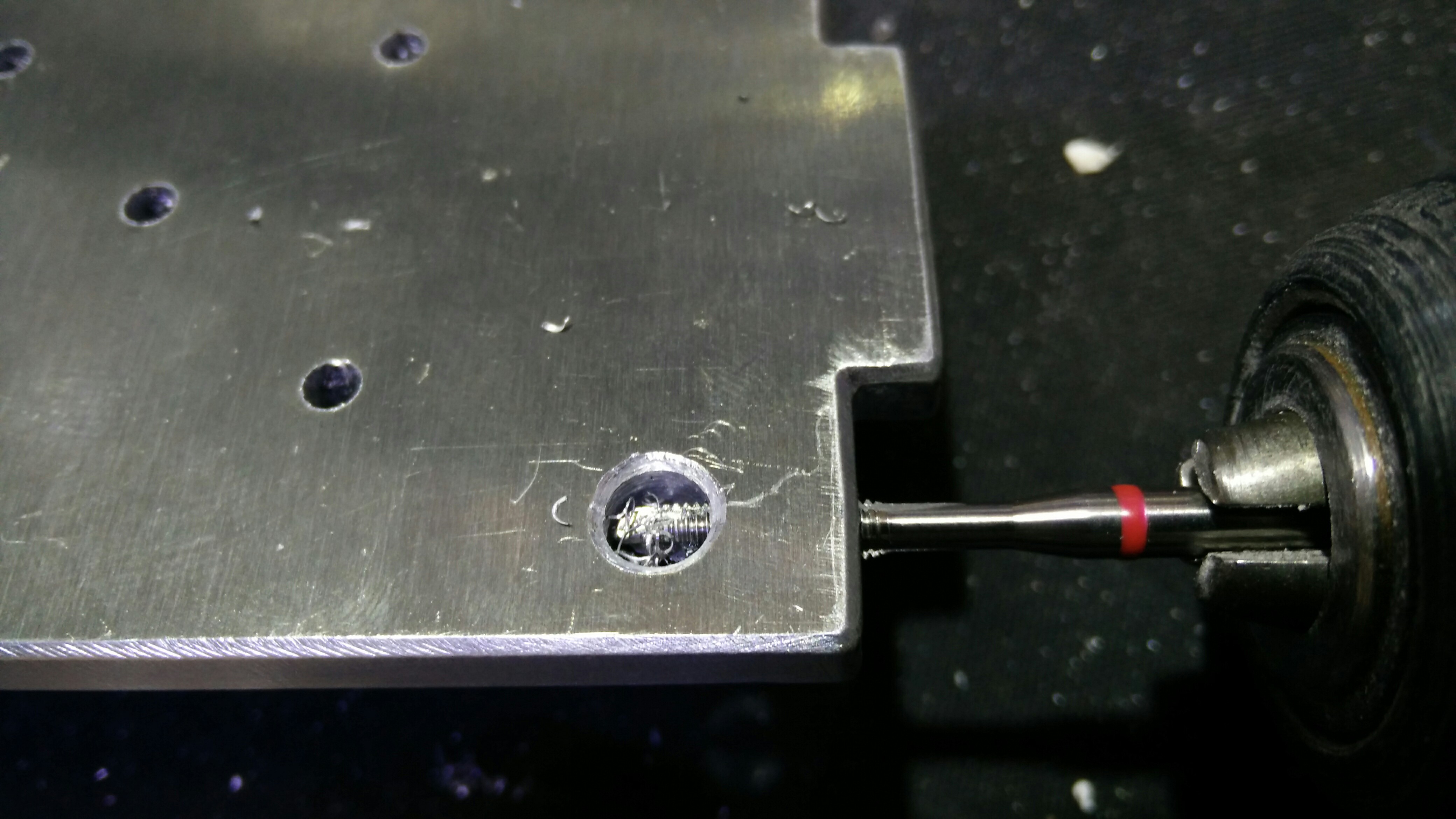

The assembled half is put though the 10mm hole in the frame after greasing the hex shaft, and another bearing and o-ring is placed on the other side.

The assembled half is put though the 10mm hole in the frame after greasing the hex shaft, and another bearing and o-ring is placed on the other side.

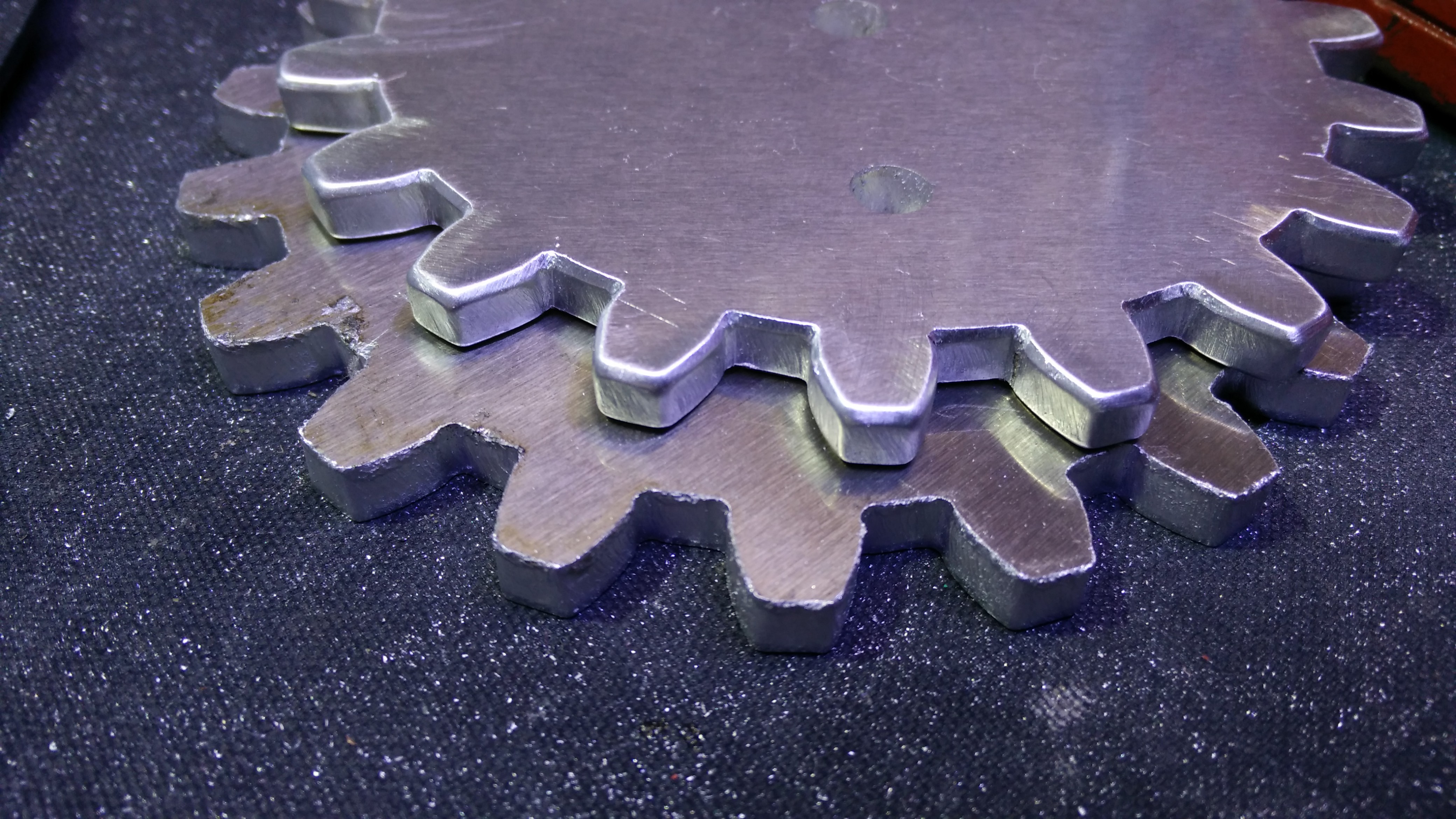

While the idea may have seemed good, the tolerances required to make this kind of "splined" joint work well are beyond what can be achieved in the home shop, even with laser cut parts.

While the idea may have seemed good, the tolerances required to make this kind of "splined" joint work well are beyond what can be achieved in the home shop, even with laser cut parts.

Øystein

Øystein

Timescale

Timescale

Kevin Harrington

Kevin Harrington