Picture yourself seated at the controls of a very large crawler crane. You've got a 4,000 lb. steel beam rigged and ready to lift. With your many years of experience, this should be no problem -- right? Wrong!

As you lift the beam and begin to swing toward its intended resting place, your entire view of the scene is obstructed by the walls you erected yesterday. You are now "flying in the blind". Rather than relying on your own sight to help steer your load, you now must rely on a flagman on the ground to give crane signals via two way radio.

Even with the most experienced flagman on the job, there are always communication issues when using two way radios rather than hand signals. It may be too loud for the operator or flagman to hear the other clearly (it is a construction site after all) or the quality of the radios could be poor among other things. Put an unskilled flagman on the radio or a flagman who doesn't speak the signals clearly in the operator's language and you've made a difficult situation that much harder.

With HoistInsight, the crane operator will always be aware of the position and movement of his load, even when flying in the blind!

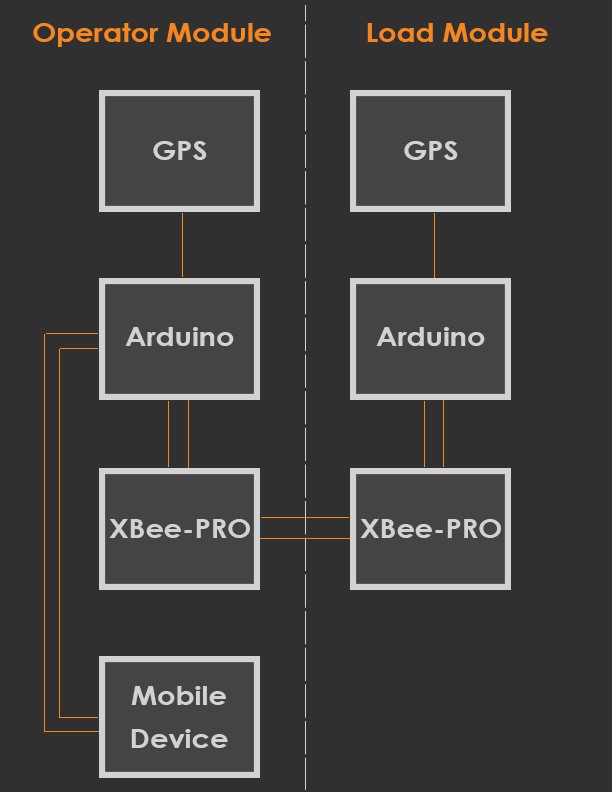

With a mobile device in the crane cab paired to the 'Operator' module (more details to come), and the 'Load' module installed above the lifting hook, the operator can use the 'Hoist Manager' software (more details to come) to help plan and execute a lift. He can see the location of his crane and the location of the hook (X, Y and Z), as well as the location of the target (more on this below).

Knowing where the load is and where it needs to go, the operator can now make more sense of the flagman's signals. Also, utilizing an optional wearable 'Flagman' module (essentially a 'Load' module repackaged in wearable form), the crane operator can see the flagman's position and finally make sense of "come towards me 40'".

Using the job's drawing files, the operator can calibrate (details on this later) the drawing with the crane, so when pictured the drawing is scaled and rotated to match the real world (relative to the crane). Now the operator can choose an item from the drawing to set as the target. The software accurately places the target indicator based on the crane's coordinates and the offsets and orientation of the scaled drawing.

When an acceptable drawing file is not available, a member of the ground crew can use the optional 'Flagman' module to manually set the target location. They accomplish this simply by placing the module near the center of the target and pressing the appropriate button on the outside of the module. With these coordinates automatically relayed to the 'Operator' module, the lift can then proceed smoothly.

Jan Gromeš

Jan Gromeš

Nick

Nick

Cristian Dobre

Cristian Dobre

David Troetschel

David Troetschel