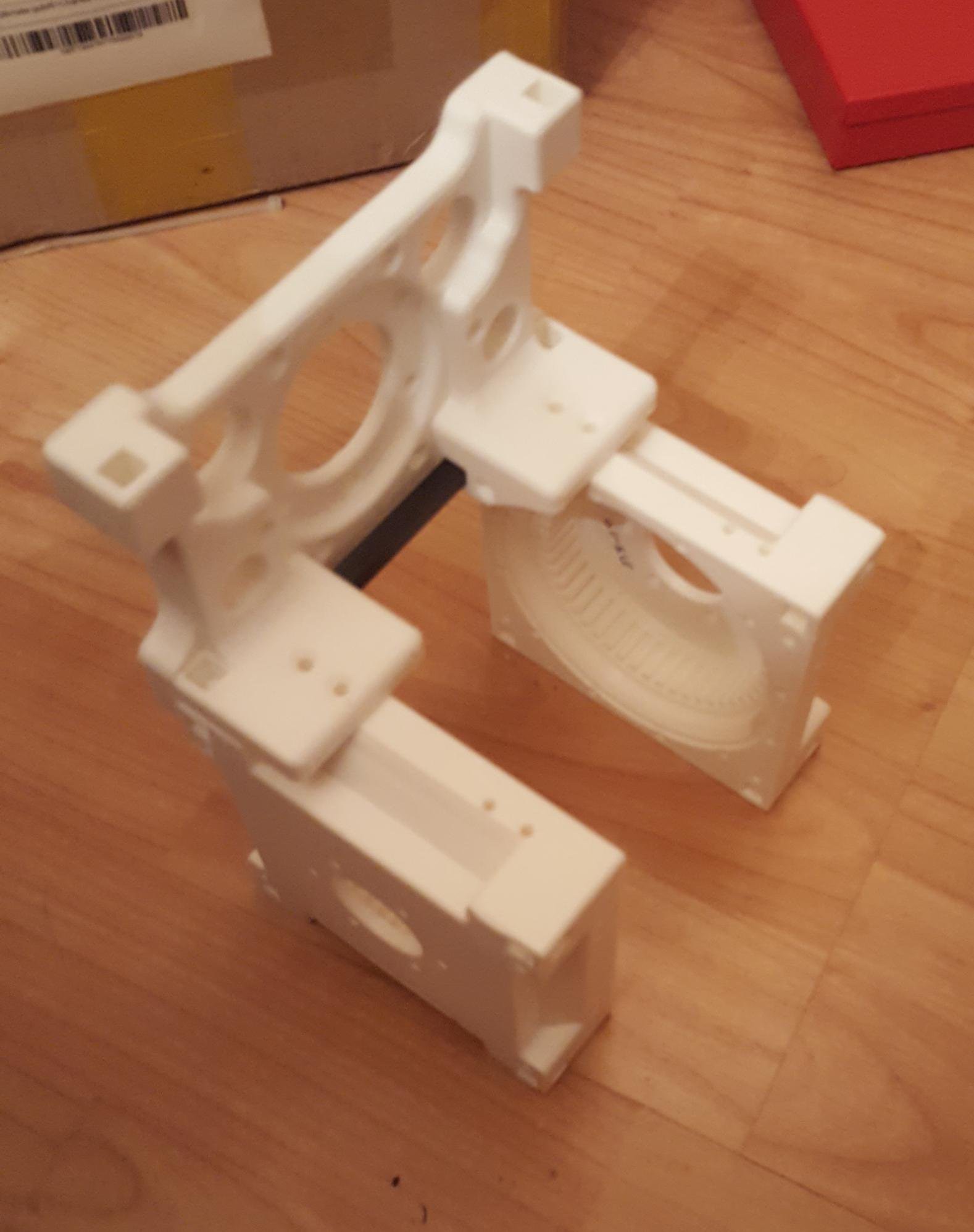

Originally the design had the two motors controlling the upper and lower leg position in line with the hip motor. This design was compact, but had the problem that it severely limited the range of motion of the upper leg. To allow the upper legs a full range of movement back and forward it was necessary to lower the motors, allowing the upper leg a full 180 degrees of motion.

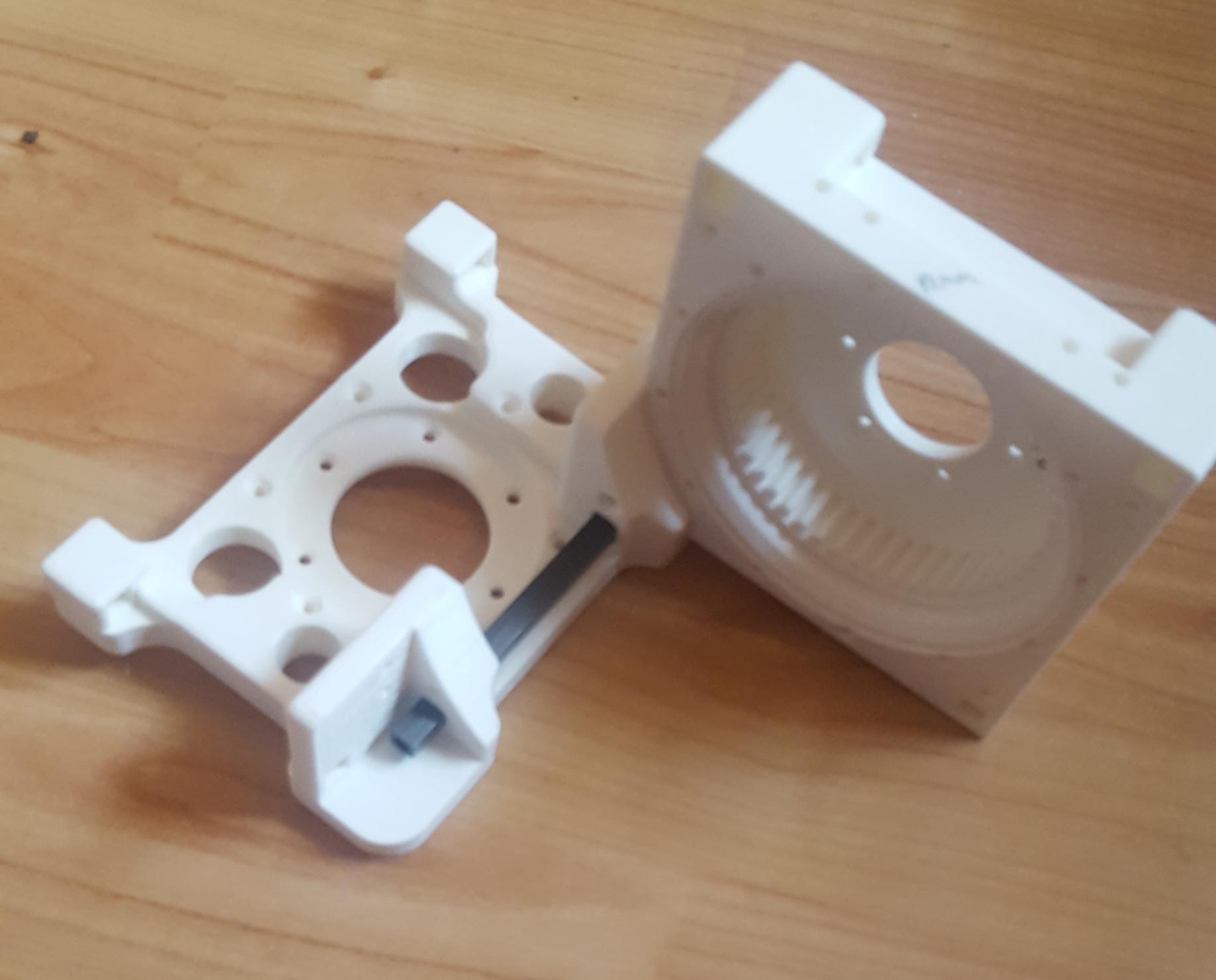

The hip joints are of a composite design using carbon fibre rods to reinforce the 3d printed plastic parts. How well this works we’ll see when the robot starts walking.

In the following picture you can see how the carbon links the two parts. When fully assembled there is also a rod threaded vertically.

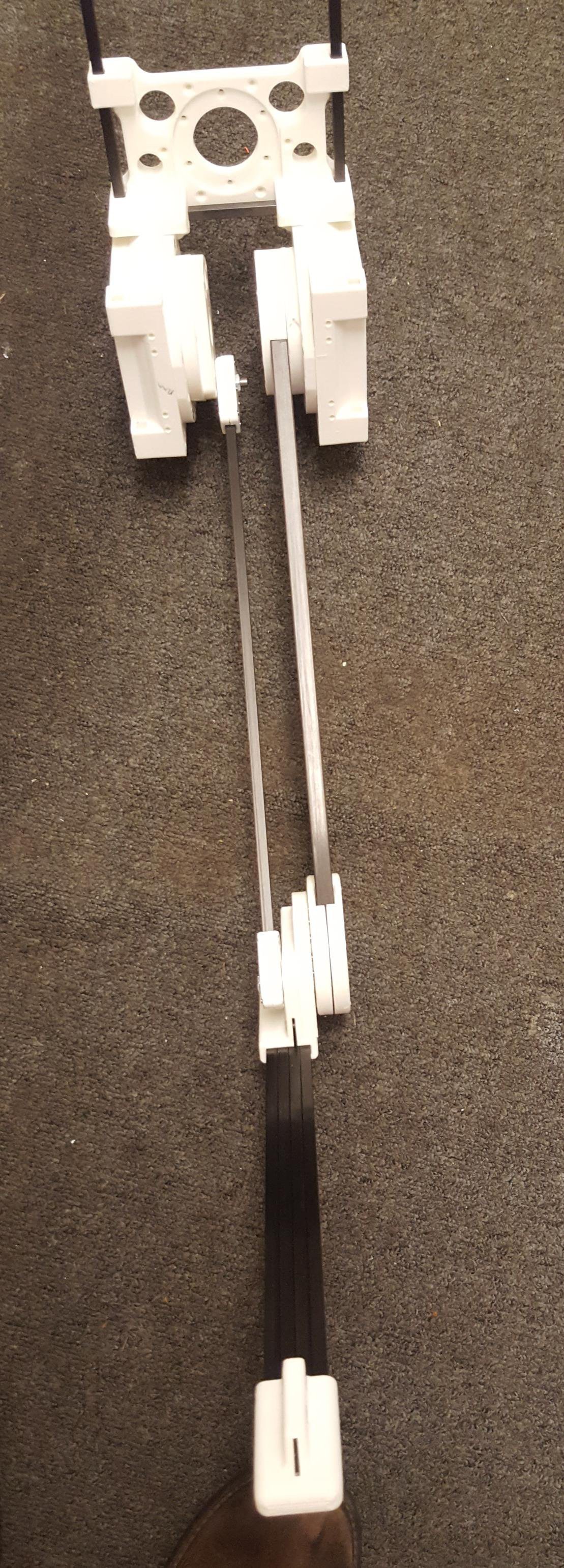

Side view of the assembled leg, the vertical rods haven't been trimmed to size yet.

Front view of the assembled leg

Charles Galambos

Charles Galambos

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.