Autonomous driving, self-propelled drones, 3D mapping. All of them using fast and precise sensors to sense the surrounding space. It can be ultrasonic or optical or even radar.

One of the most advanced and widely used sensor type nowadays is the LIDAR, which is using a laser beam to measure distance continuously.

Not the topics which first comes to your mind when you look at your old dusty VHS player on your shelf or a VCR camcorder not used since the 90’s.

But as you already know from the title one thing is common between the two devices.

LIDAR has two main part, one is the laser and sensor module, and the other is a rotating base with position feedback.

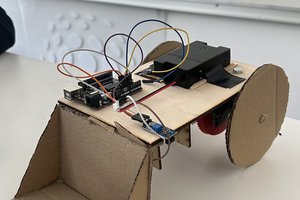

In the era of the 3D printing it is very easy to make the rotating base, (or even brushless motor), and cheap but precise Time-of-Flight (ToF) sensors can be bought, like the VL53L0X which is also used in this project.

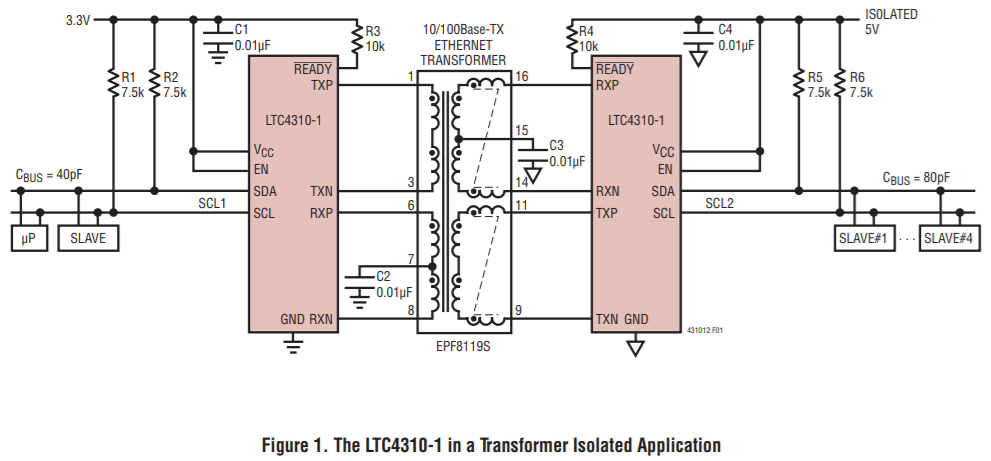

The tricky part is how to transfer data between the rotating head and the stationary base. You can scan the space back and forth, but it is not 360° than, or use slip rings, but it has limited rotational speed and not maintenance free because of the mechanical construction.

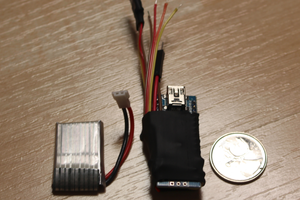

This the point where the VCR drum motor comes handy. It has two sections, a brushless motor with position feedback, and a rotating head with rotary transformer to transfer data without physical contact. All what is needed for the LIDAR, it just has to be controlled.

Roland Varga

Roland Varga

vcazan

vcazan

minifig404

minifig404

deepankar

deepankar