In my previous blog I told about the weak construction of the Axle between Art1body and Art2BodyB. I also had to find a way to fix the Axle in Art1 because of the rotation sensors in Art2BodyB.

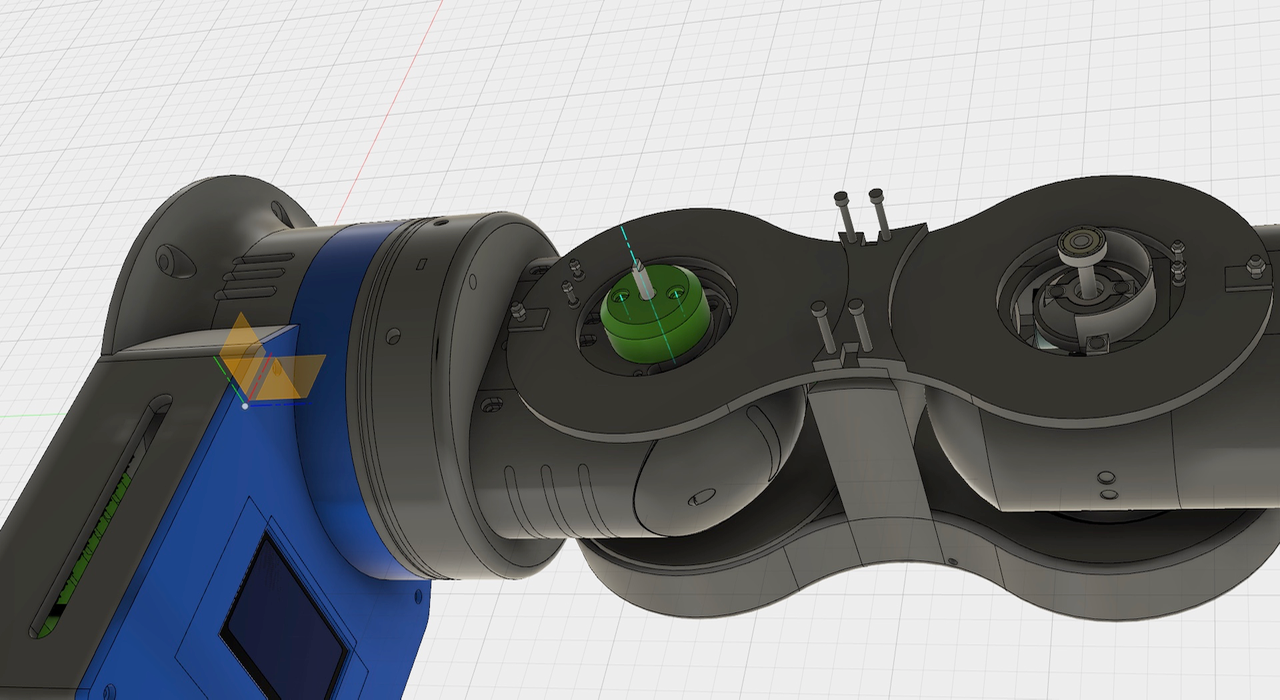

So I decided to design a custom part. The green AxleHolder part in the photo below is the solution for both problems. It replaces the bearing and the bearing ring holder. The same Axle holder can be used for the axle on the right side. (Note: There isn't room for the Art23OptoDisk anymore. Danny's design doesn't need one).

The new parts and the place it will fit on.

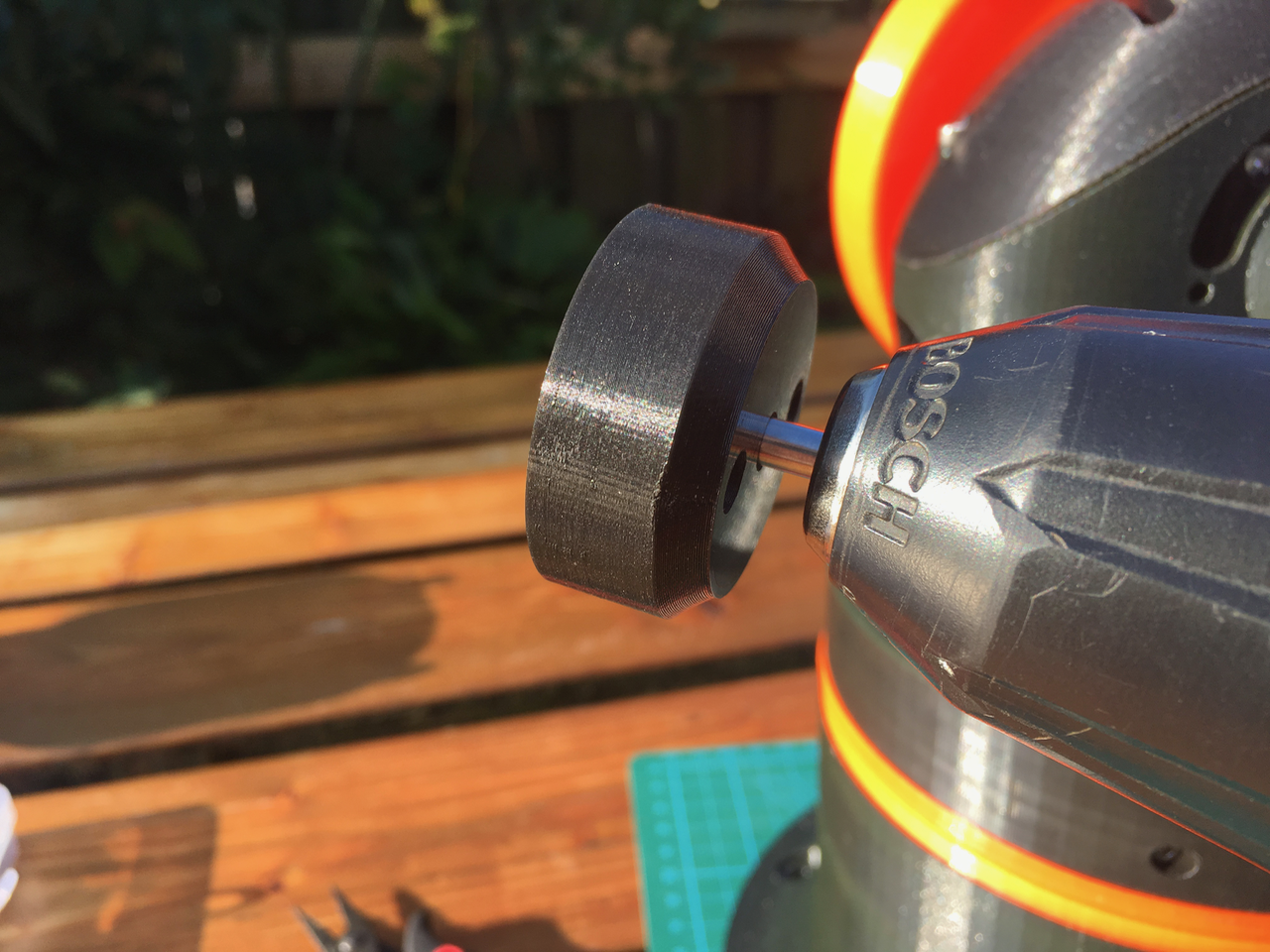

The hole for the Axle is very tight. I did put the Axle in a electrical screwdriver and used it to "screw" it into it's place. Because of the friction the plastic melts a little bit and that keeps the Axle in it's place.

The other side.

Both axle holders are mounted. You need 20mm screws.

After putting everything back together it feels much sturdier. No wobbling axis anymore.

The AxleHolder part is available for download: AxleHolder.stl

Sepio

Sepio

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Are you still using PETG for all of this?

Is this PETG strong enough?

Are you sure? yes | no

I printed most of the parts with PLA. That’s why I added fans on all places with motors. PLA an PETG are both strong enough.

Are you sure? yes | no

Sepio, is the AxleHolder the thing that keeps the long axle in Art3 from rotating freely in Art3Body_02? Does it also keep the body from shifting back and forth on the axle?

Are you sure? yes | no

Yes and yes. One of the sides (with the new holder) stays fixed. Because of the longer length its much sturdier. It doesn't wobble anymore.

Are you sure? yes | no

Thanks. I just added a set screw to the axle holder so I can adjust the orientation of the flat on the axel to the body and also set the position of the body along the axle without worrying about a press fit.

Are you sure? yes | no