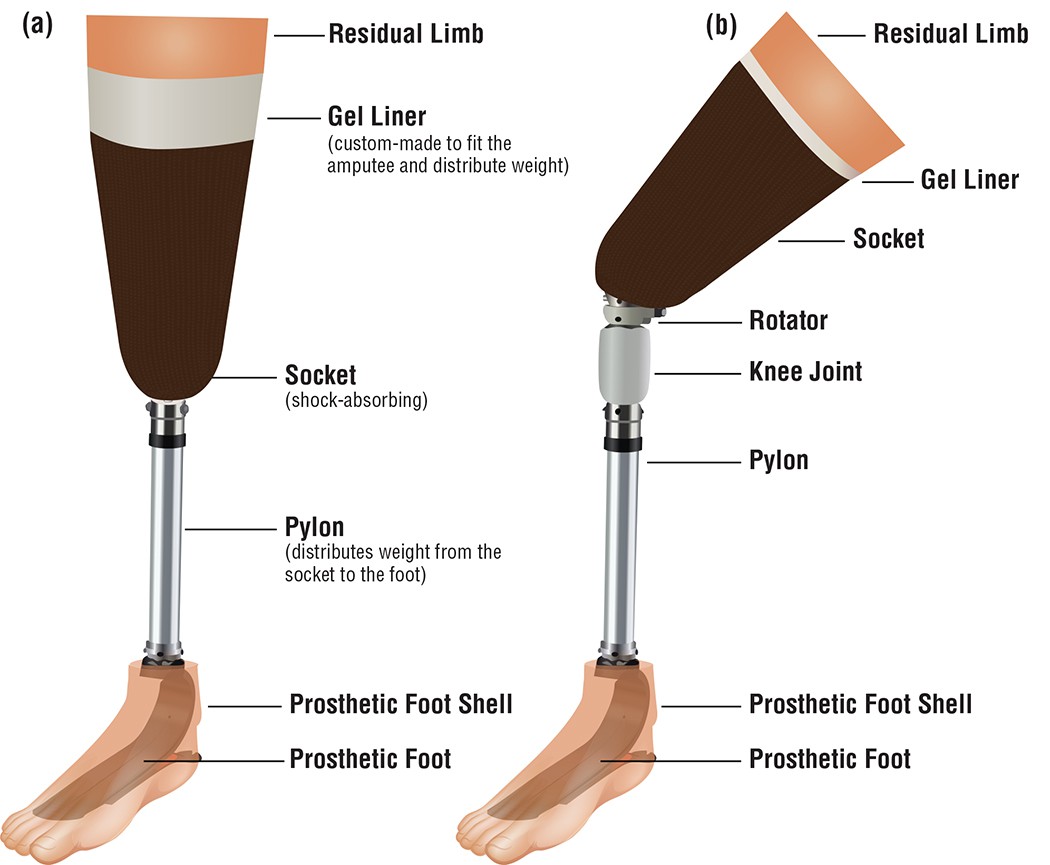

In the previous log I had mentioned about the design of the mold for housing the amputated knee region. This mold has to be connected to the foot by some means. There are several parts available in the market which can perform this function. But one thing to be focused is that it should be strong enough to balance the whole weight of the body without any deformity. It should also be light in weight such that the athlete should not feel any kind of stress during action i.e: It should be a mirror image of the other leg with similar weight and must function with ease.

Why Stainless Steel? Why not Carbon Fibre?

Of course carbon fibre is comparatively better material than stainless steel.

- Carbon fiber is approximately 5 times lighter than typical stainless steel material 1.5 times .

- Carbon fiber is approximately 3 times stronger than typical stainless steel material.

- Carbon fiber is nearly 15 times greater than the cost of stainless steel.

By using the carbon fiber one may reduce the weight of whole structure but will fail in giving balance to the body having right weight proportion as the same weight of tibia.

Aluminium may be considered as it is 3 times lighter than stainless steel but it is not strong enough as in case of stainless steel.

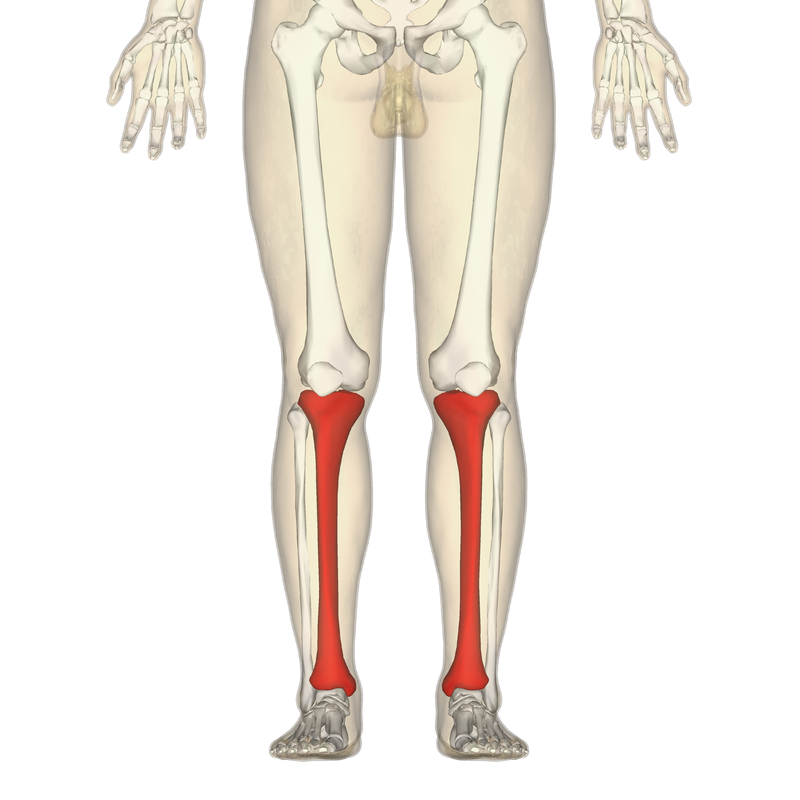

Since the main aim of developing a bionic/prosthetic replacement for the amputated part we must consider the fact it is going to replace the lower leg or Tibia and Fibula portions in the body. Of these, Tibia is the weight bearing portion. Fibula is also an equally important portion (lighter in weight) that gives support to the tibia and provides support especially in the foot region. But mimicking the tibia would alone be enough along with some couplers to design the supporting portion.

Design and Implementation

Keeping the above stated factors in mind we considered that physical features of 20 year old disabled athlete of weight 65 kg and height 180 cm. Based on the height and weight features we have designed a custom steel rod.

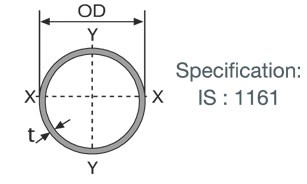

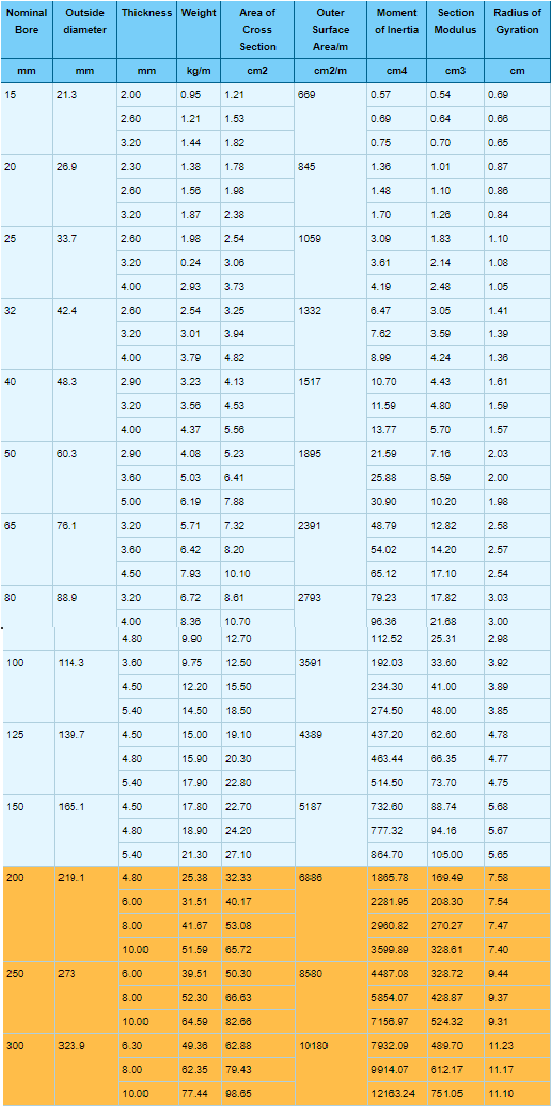

We have used the below mentioned industrial grade hollow steel section for greater efficiency and enhanced properties.

Some of the commonly used hollow steel section produced in industries and their properties are listed below.

Rotary Coupling

This plays a important role in the bionic leg movements. The fact is that it should be able to convert the impulses into work by moving the pylon(weight distribution part from mold to leg) in accordance with the amputated part. We are measuring the movements of the other leg by using sensors and using the same values the bionic leg would be used to train and one could adjust the nob according to their wish.

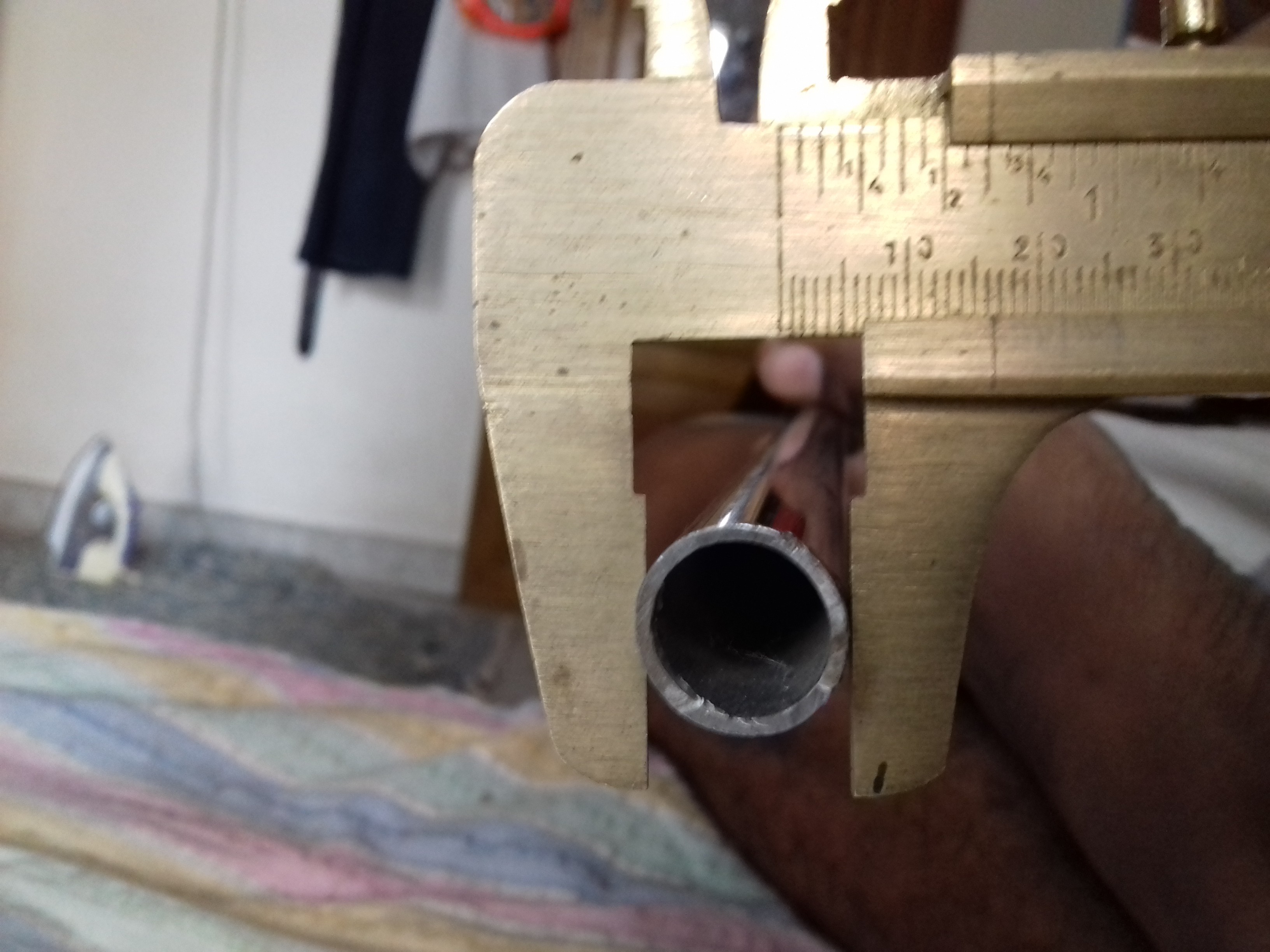

We used a vernier caliper to measure, so that it becomes precise. The hollow stainless steel section that we have ordered a steel section of

- Length 310 mm(31 cm)

- Thickness is about 1.5 mm

- Outer diameter - 16 mm.

- Area of cross section - 0.68 sq.cm

- Weight - 0.51 kg

- Maximum bearable weight - 500 kg

The other end could be connected to a prosthetic foot or shoe to complete the whole system.

G.Vignesh

G.Vignesh

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.