-

Break. Again?

04/23/2018 at 22:11 • 0 commentsThe deck is done! However, I did a bit of analysis of my progress on this project and the hardware aspects are hitting a bit of a wall; I am spending more and more time manufacturing while less and less is spend on actually learning and acquiring new skills.

Thus; I am panning on debugging the rest of the electronics, and writing code for the batter management system, but put a hold on the rest of the project until I make enough money to pay someone else to manufacture for me, or if I decide this can make a viable business.

In conclusion, ill leave it as something to work on whenever i'm bored. For now I got a few business ventures I want to take a look at ;)

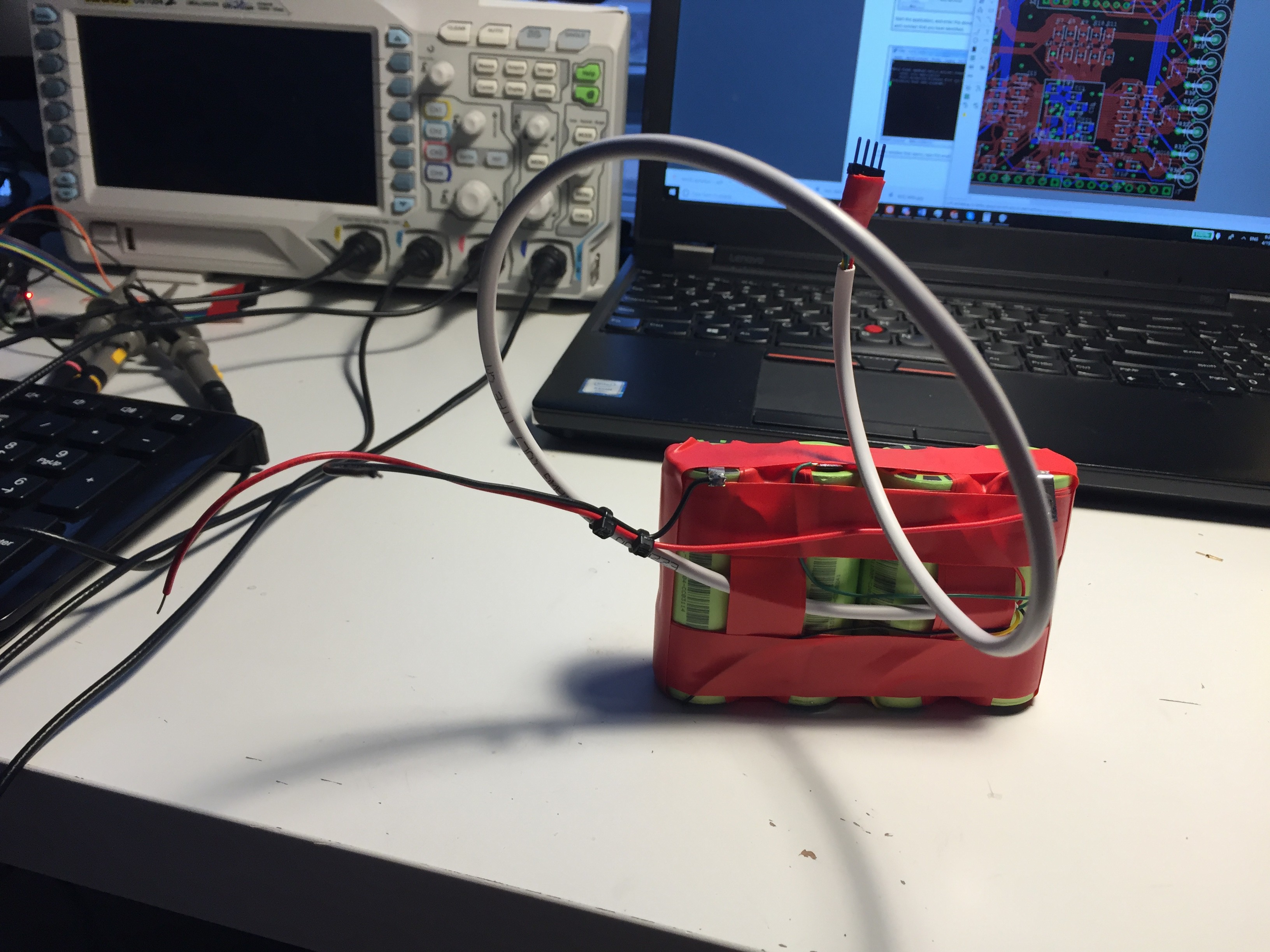

Test battery pack, tab welded with Keen Lab's kWelder unit (seriously high quality product for only ~200$) https://www.keenlab.de/index.php/shop/

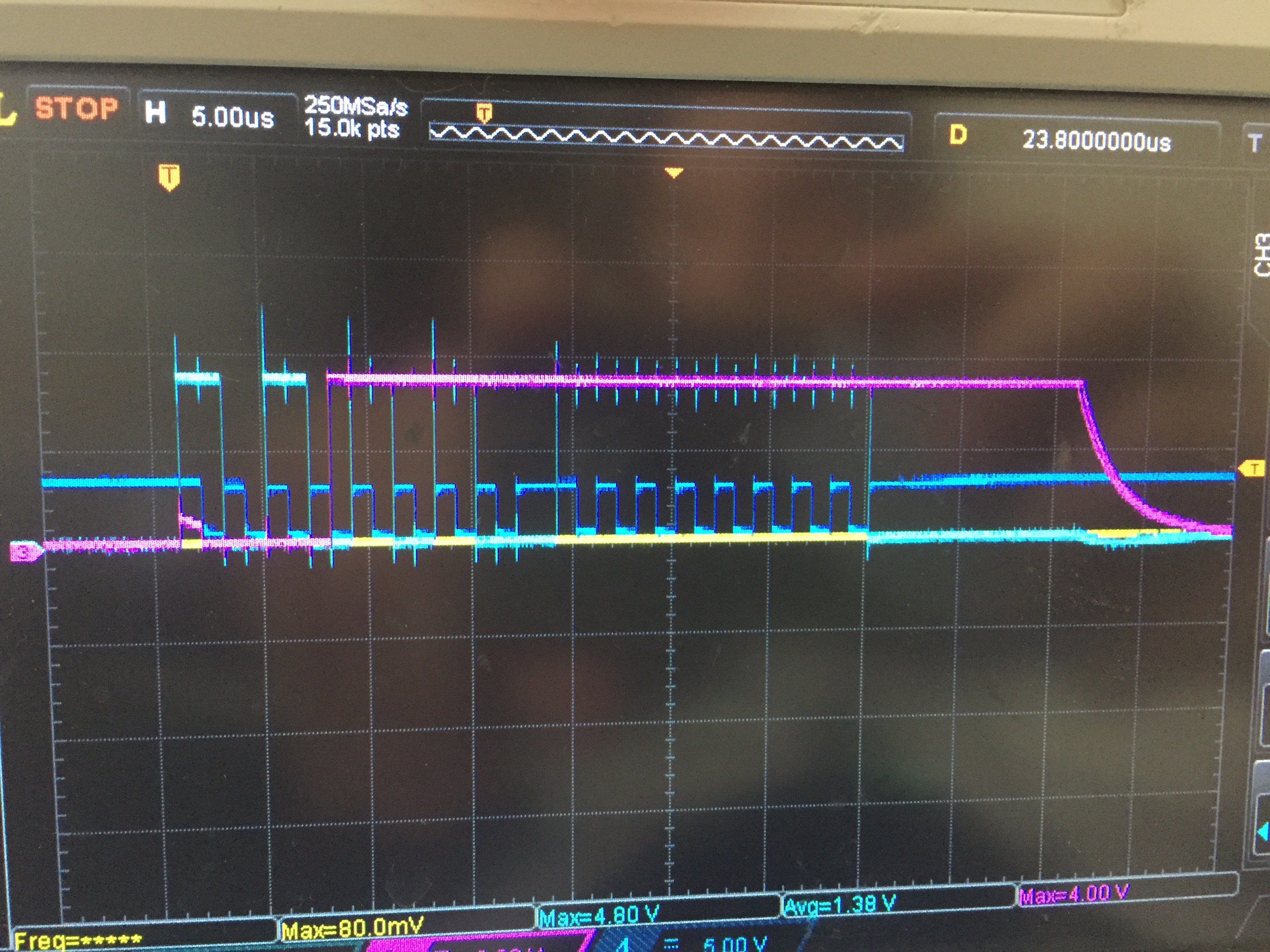

It seems I might have a little too much noise coming in from the digital side of circuit, so I'll see what i can do to mitigate that. Might have to order new PCB's...

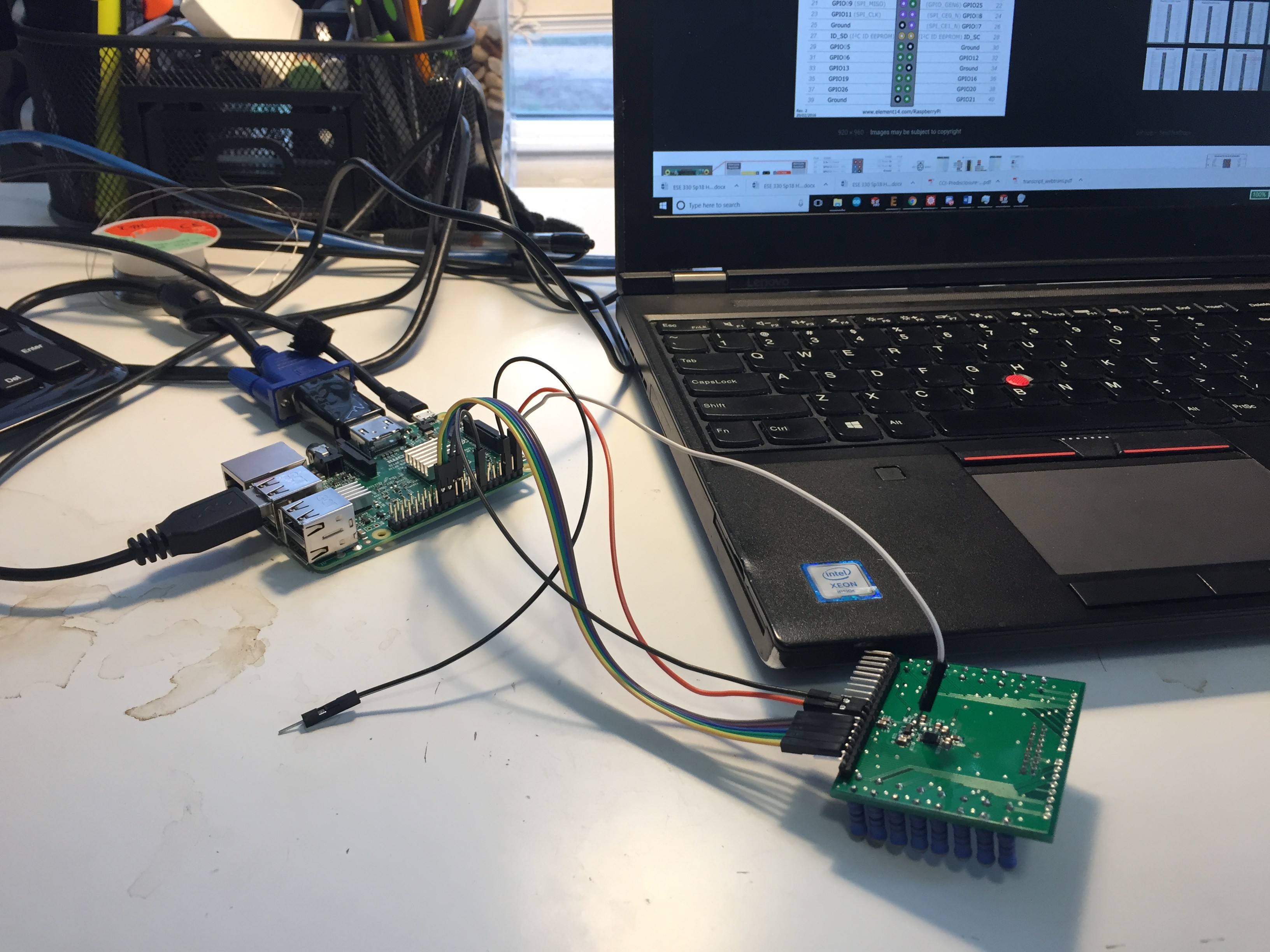

Finished debugging the SPI, time to start pumping out code...

Down the software rabbit-hole we go!

-

Caveman

03/26/2018 at 16:20 • 0 comments -

Min-Max

03/01/2018 at 17:22 • 2 commentsI am taking 9 courses this semester, so I am in the midst of an optimization problem...

Looks like whatever built-in neural net has figured it out. Back at about 20hours/week on the board.

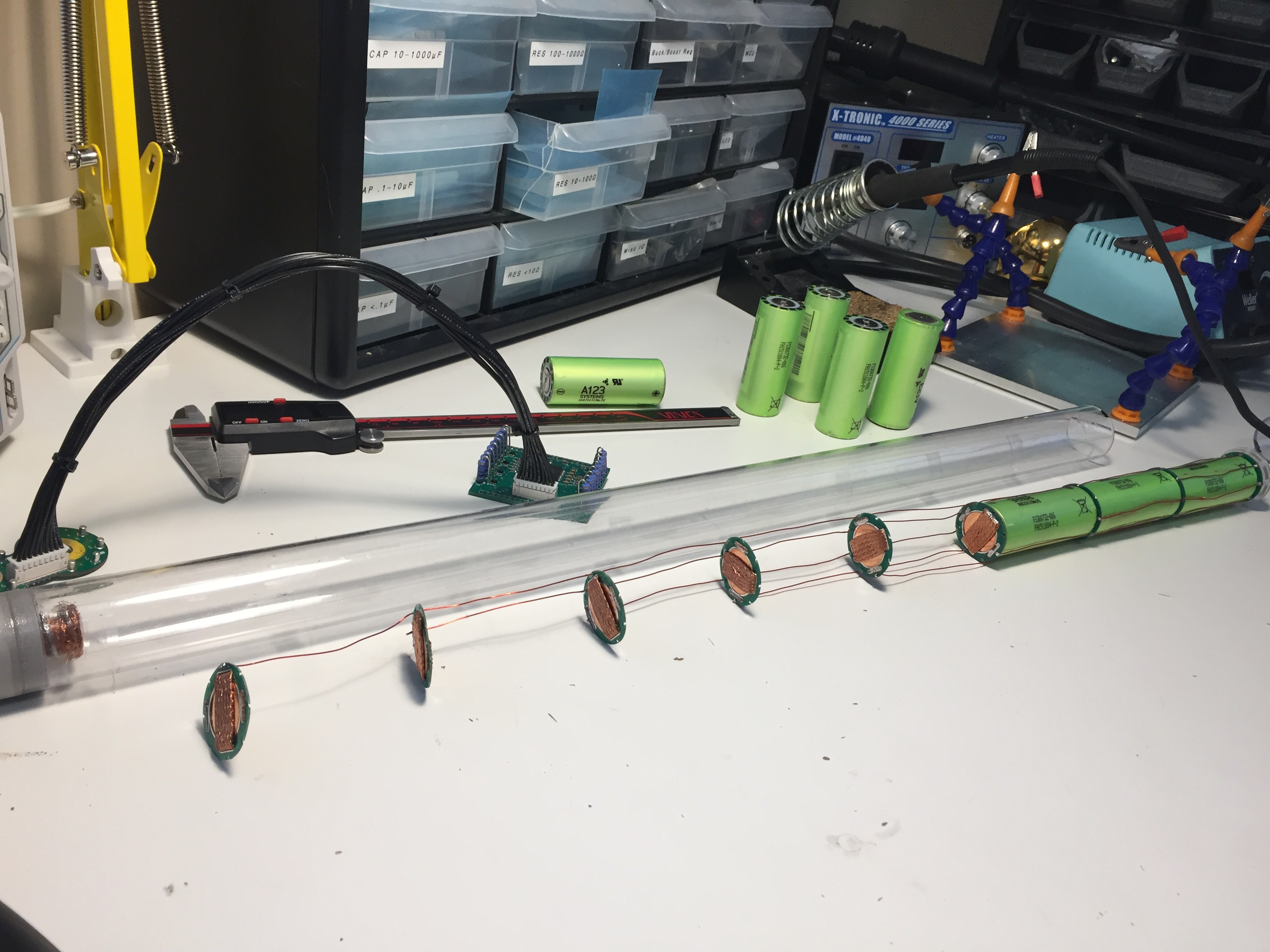

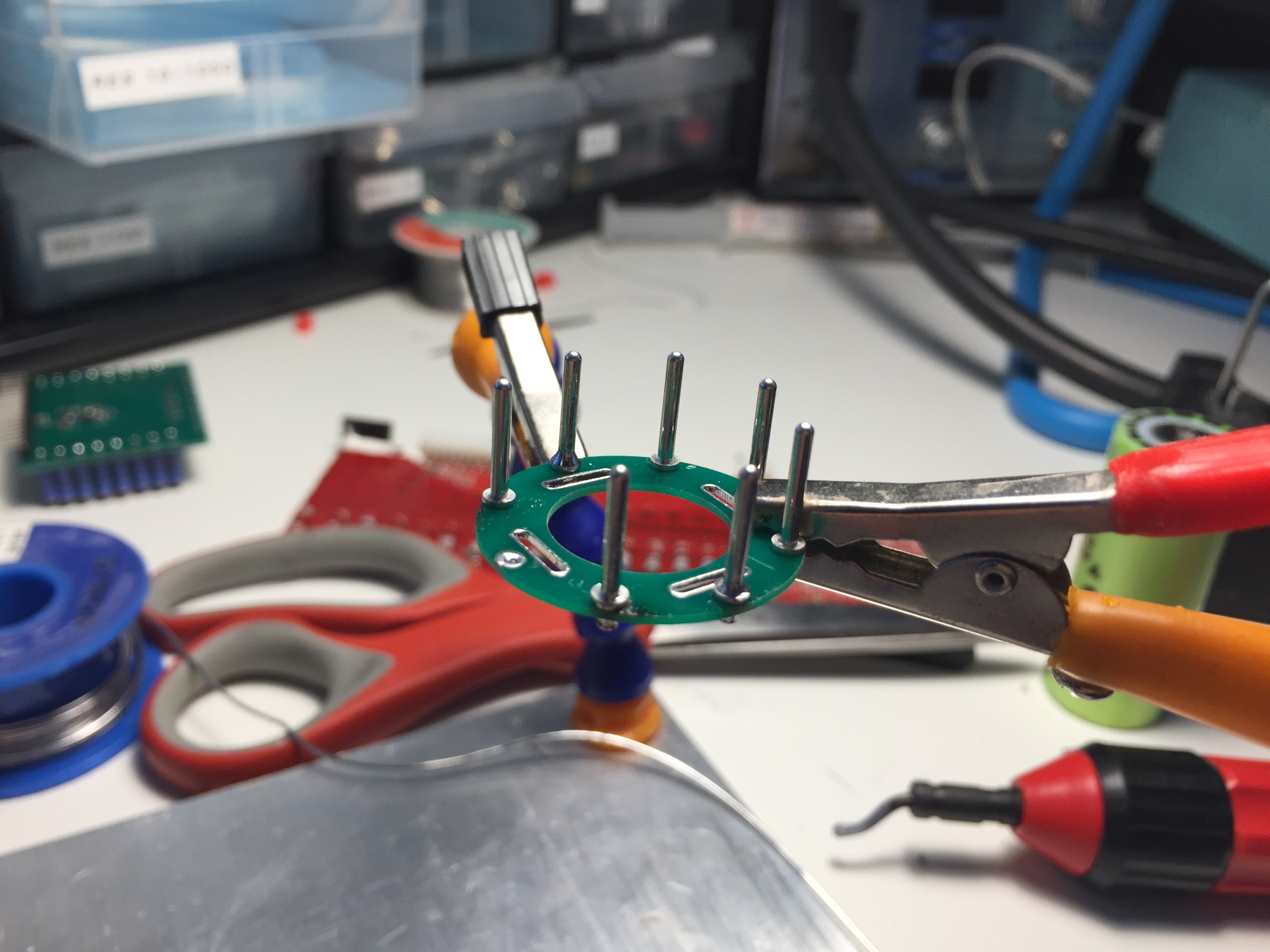

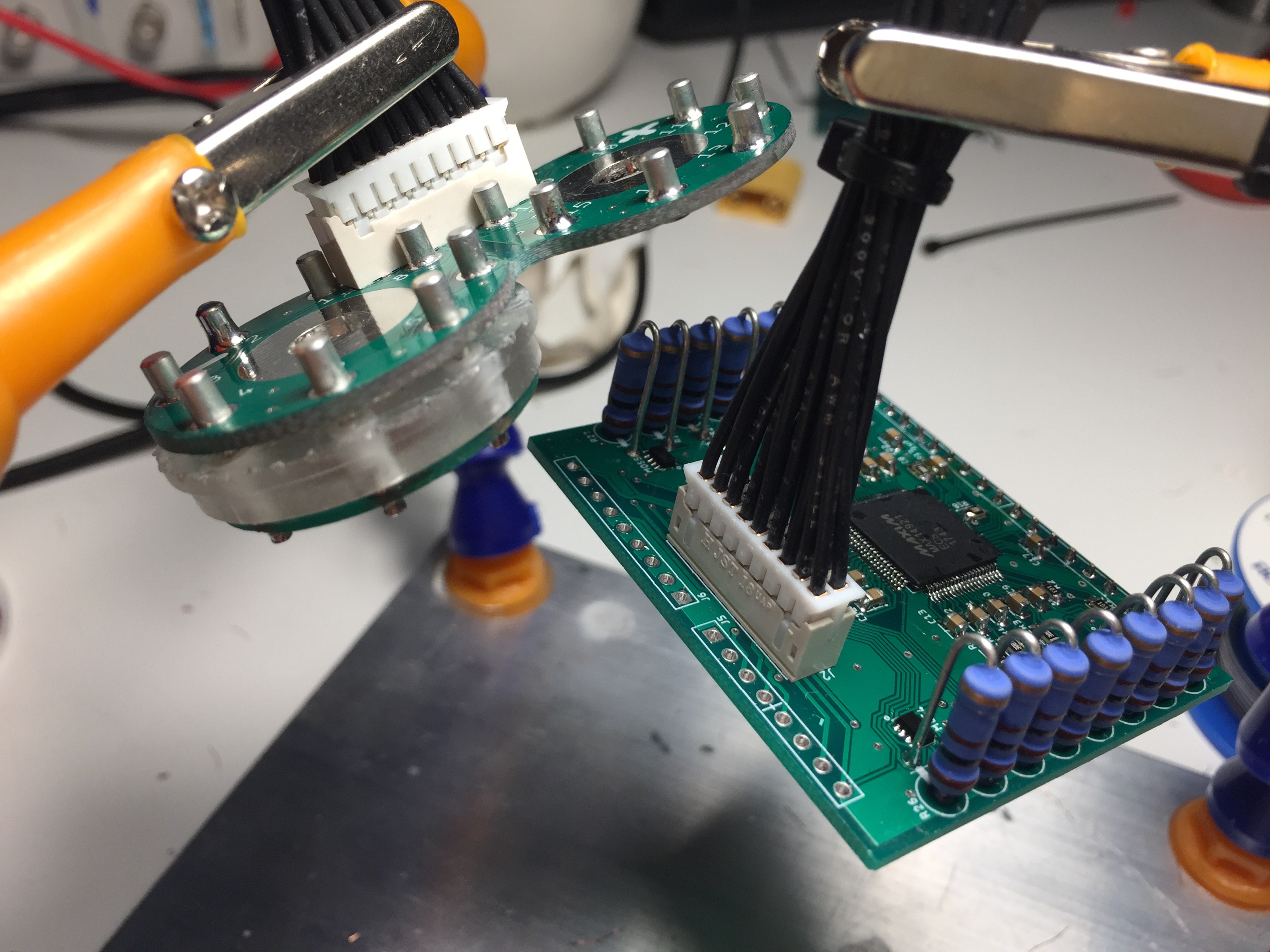

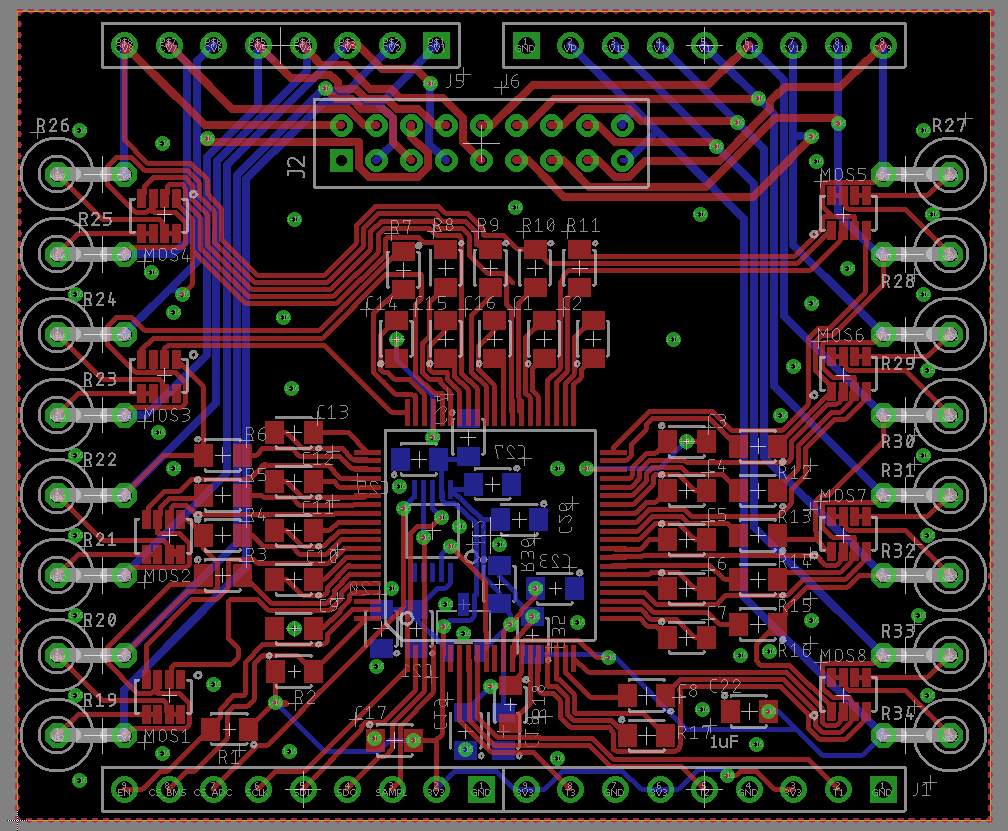

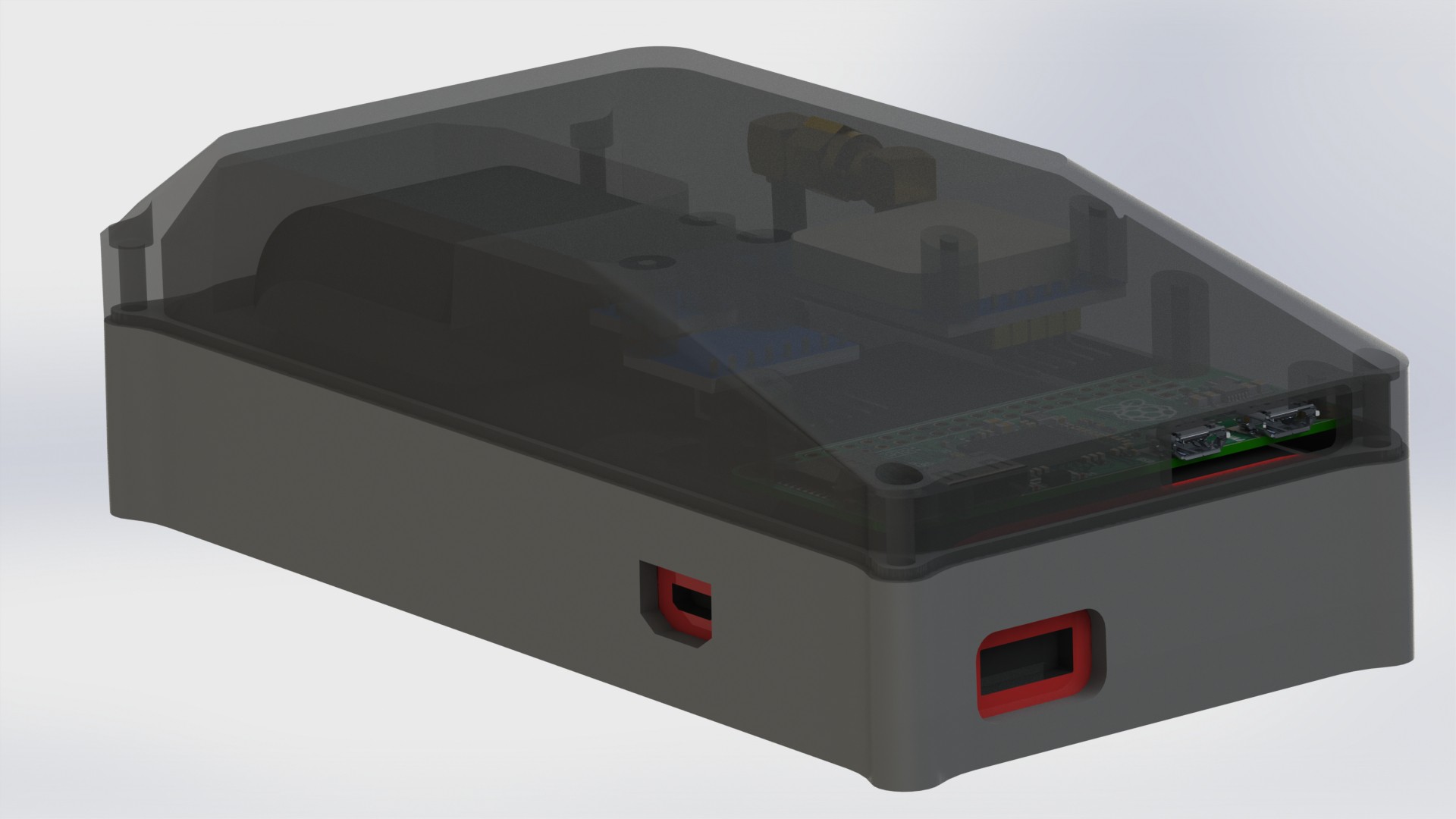

After much deliberation last semester, I decided to build the battery management system around the Max14921. I made a breakout board for it, and I will be controlling it using a STM32F01 Discovery board (later integrating the chip directly).

P.S. the pitch on the Max chip is .5mm not .025in like in other TQFP packages of similar pin number (the data-sheet said NOTHING) So the next batch of pcbs will be here next week.

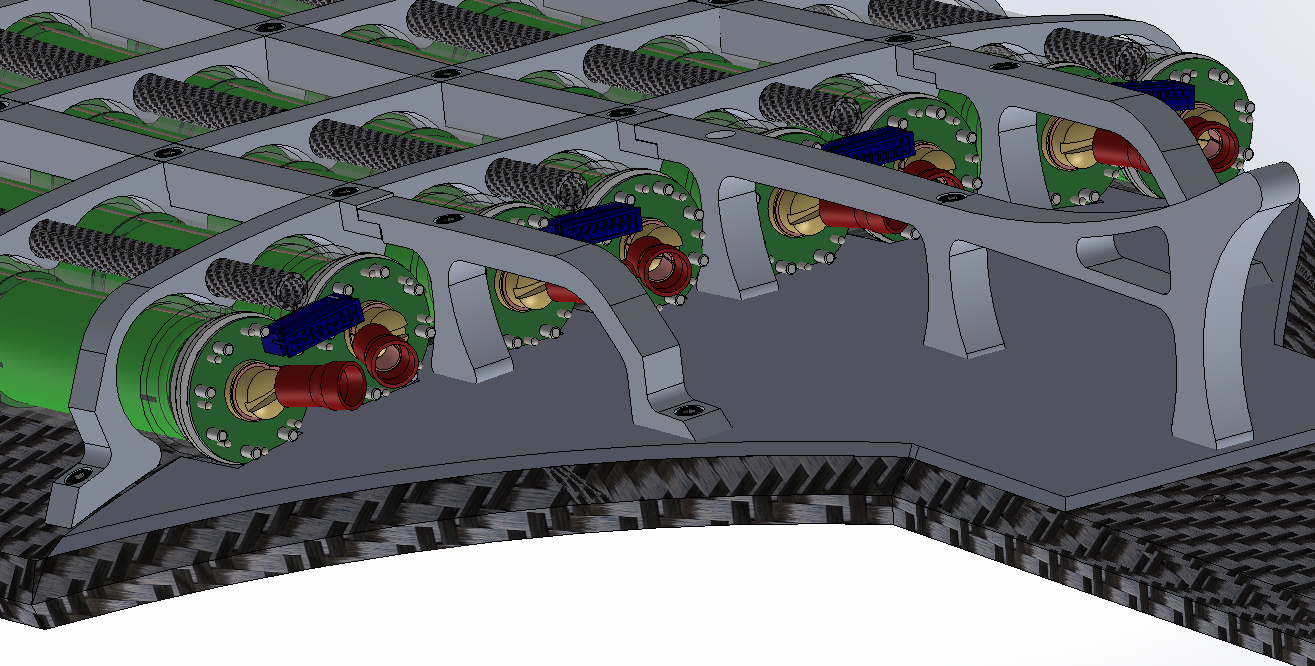

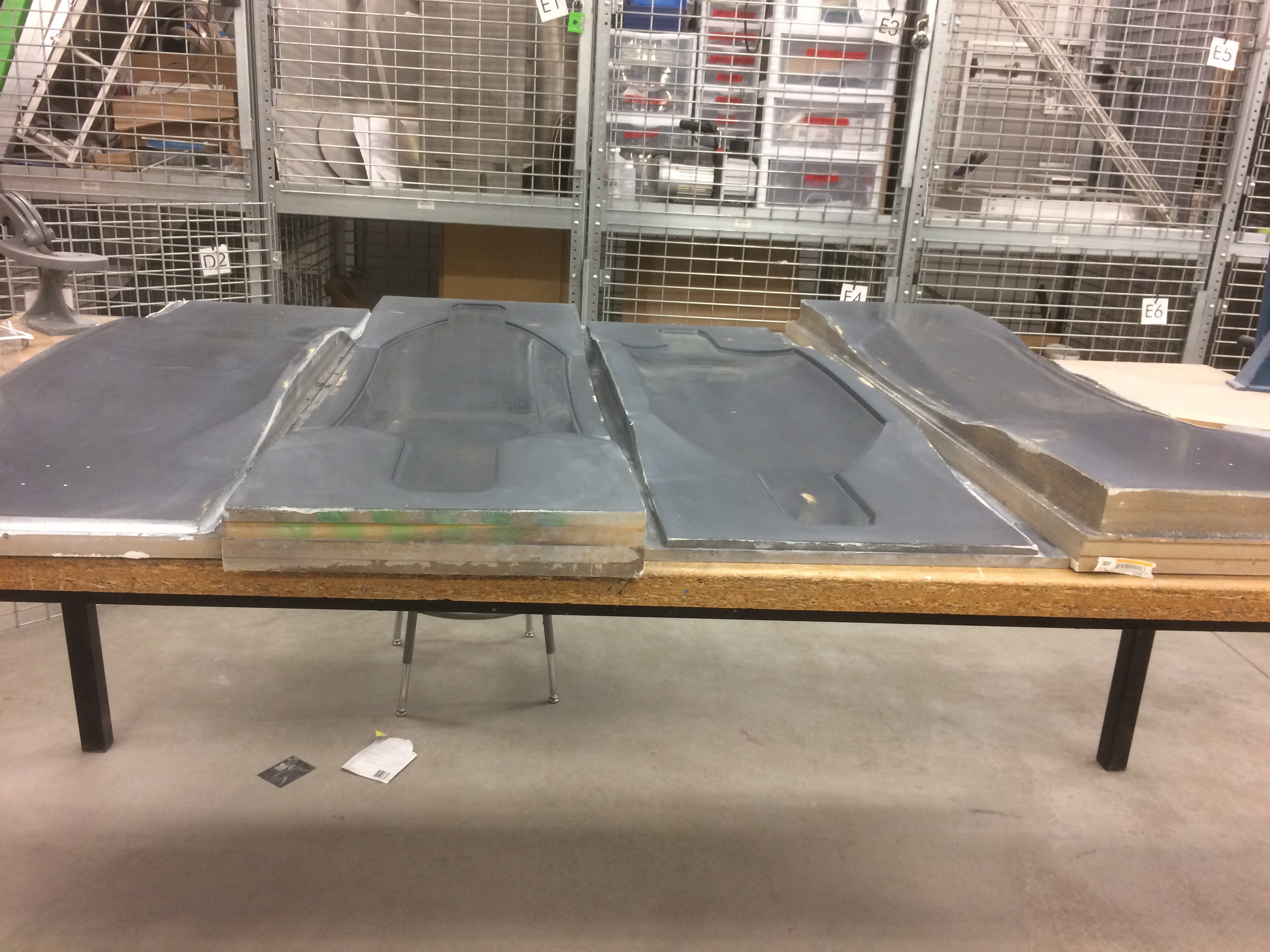

As you can see I have a foam core (actually Ill have two of them) and plain flat carbon fiber plates at the front and back so that the mounting points for the trucks are extra secure.

I am slowly building up the layers of carbon fiber (they are .03in thick and takes me about 2hours for each layer) Half way done though!

I have also figured out all the PCB placement and solved the issue with high current print contacts! (more on this later)

-

Back in Black

01/26/2018 at 23:52 • 0 comments -

Adjust

11/20/2017 at 15:10 • 1 commentSad news this week. The Techshop has closed. However, I am glad that most of my hardware requiring heavy CNC machinery is finished.

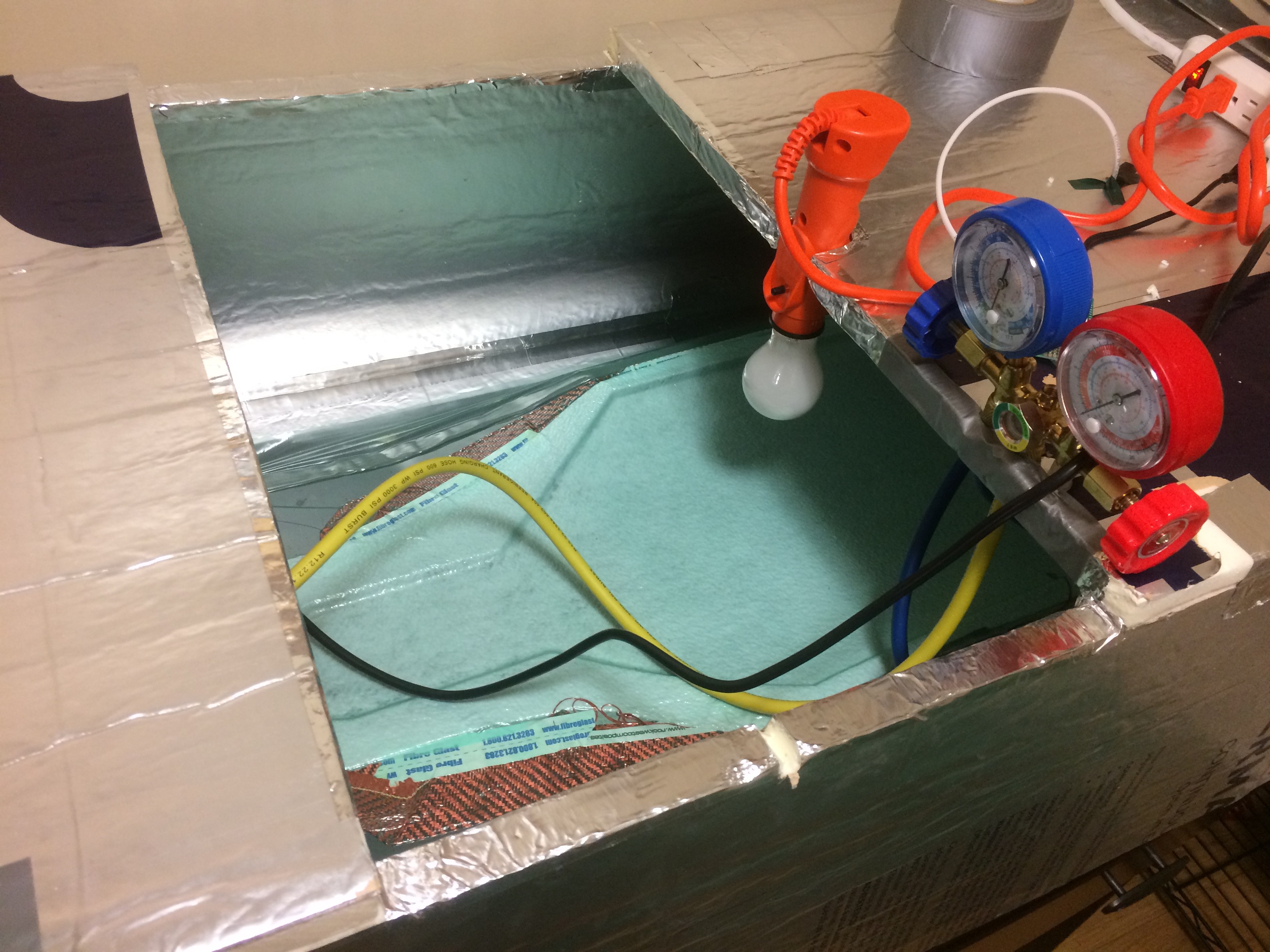

I have already started to recreate some of the capabilities of the techshop. One such adjustment is a epoxy curing, vaccum press oven in my living room.

This is the single layer outer shell, its a bit rough around the edges and I am going to redo the layup.

Roomates have agreed... as long as I keep it clean.

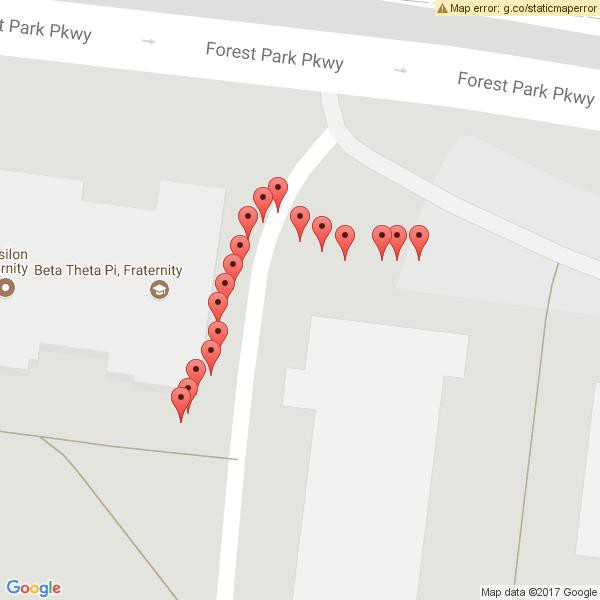

In other news. The GPS tracking works! the sensor board is outputting gps, and using the google maps api I can overlay my location onto a proper map!

Lastly:

I am going to be doing some redesign and try to remove the rest of the hardware manufacture. Since I no longer have access to CNC and metalworking machinery I will have to impovise...

-

The Molds are Done!

11/15/2017 at 03:20 • 0 comments -

Molds and Models

11/05/2017 at 23:05 • 0 commentsA week off of the project due to midterms, and now im back!

Got a lot of good stuff since the last project log.

Sensor module is reading in data. The next step is to take the Accelerations,position, velocity and have it plot on a neat interface

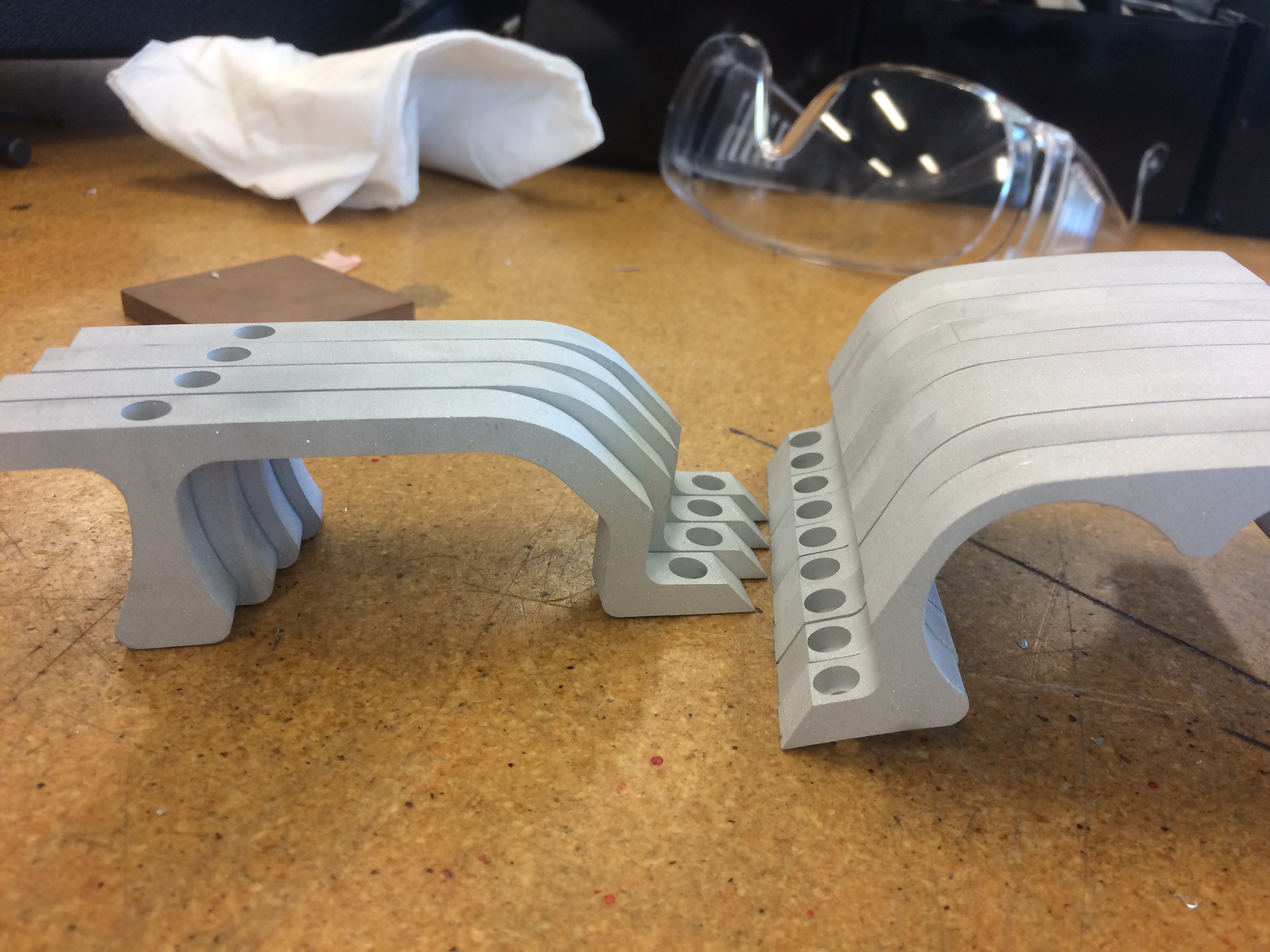

Got the Molds painted, just need to sand, and buff them. Should be ready to do the CF lamination next weekend.

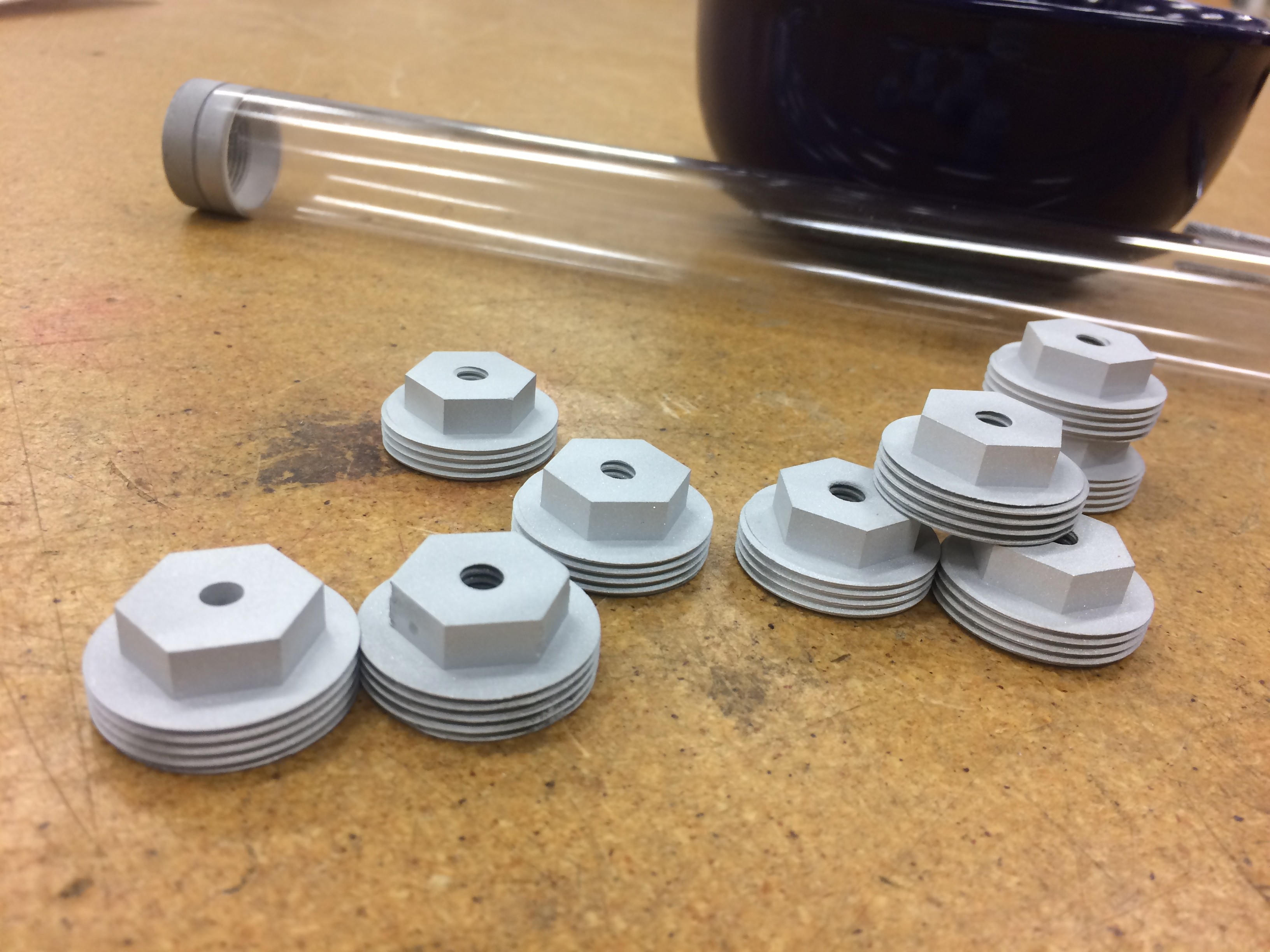

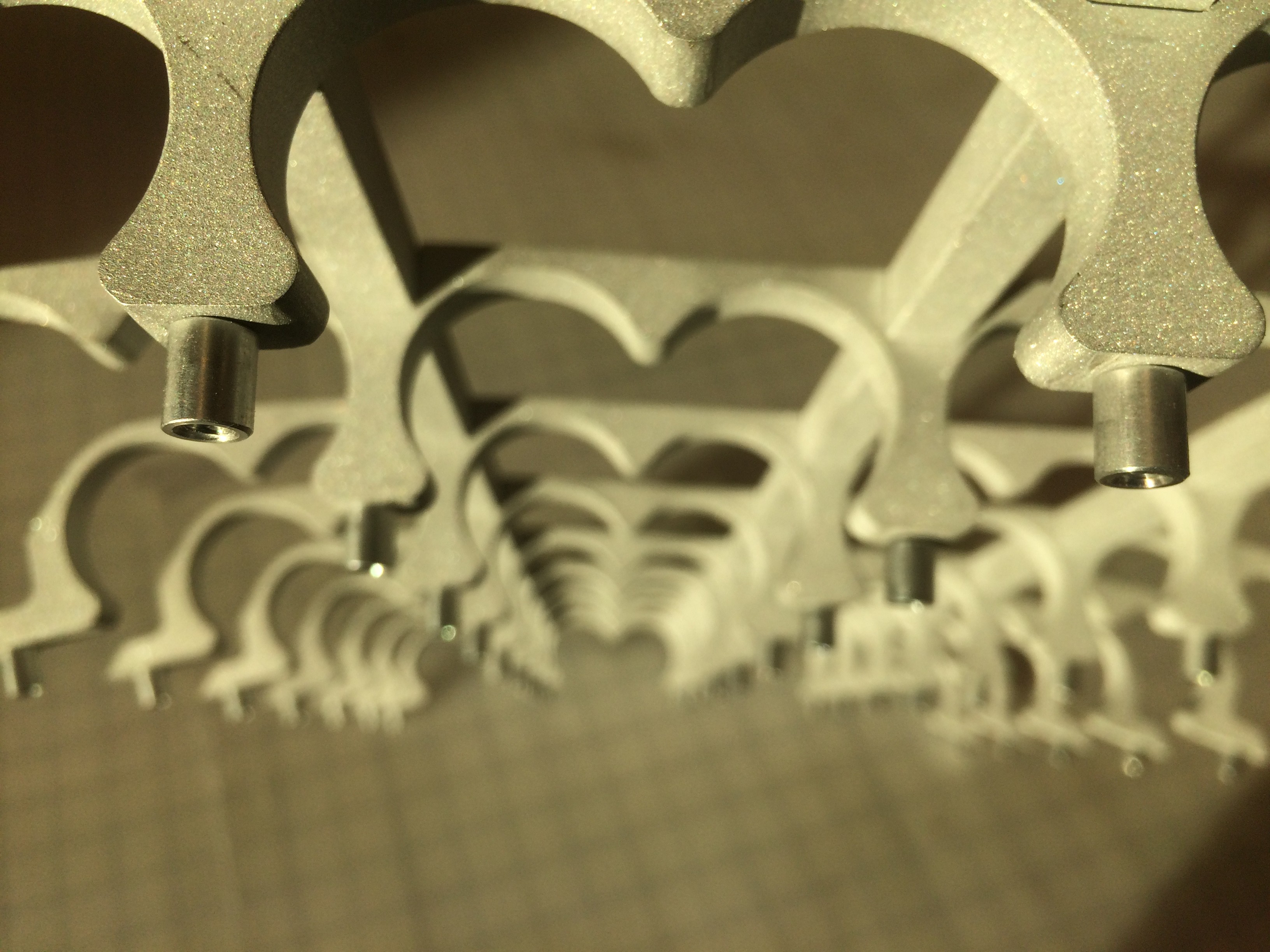

A decent amount of time went into a side venture. I have a friend who sells finger boards, I made him some molds to speed up the process :)

I hurt my foot (bruised a metatarsal) So i slapped V1.5 together so I dont have to push when getting to/fro class.

-

4 Day Weekend

10/16/2017 at 21:46 • 0 commentsFall break! you know what that means! just clocked in 50 hours at the techshop in 4 days.

- Bought Carbon fiber vacuuming stuff

"hhhnnnnnngggg" - My wallet

-CNCed the last two molds out of the MDF that I prepped last weekend.

(All me!)

-Almost finished the battery pack hardware

Dat sand blaster tho

Yea, yea, I know. Steel on aluminum ill figure it out.

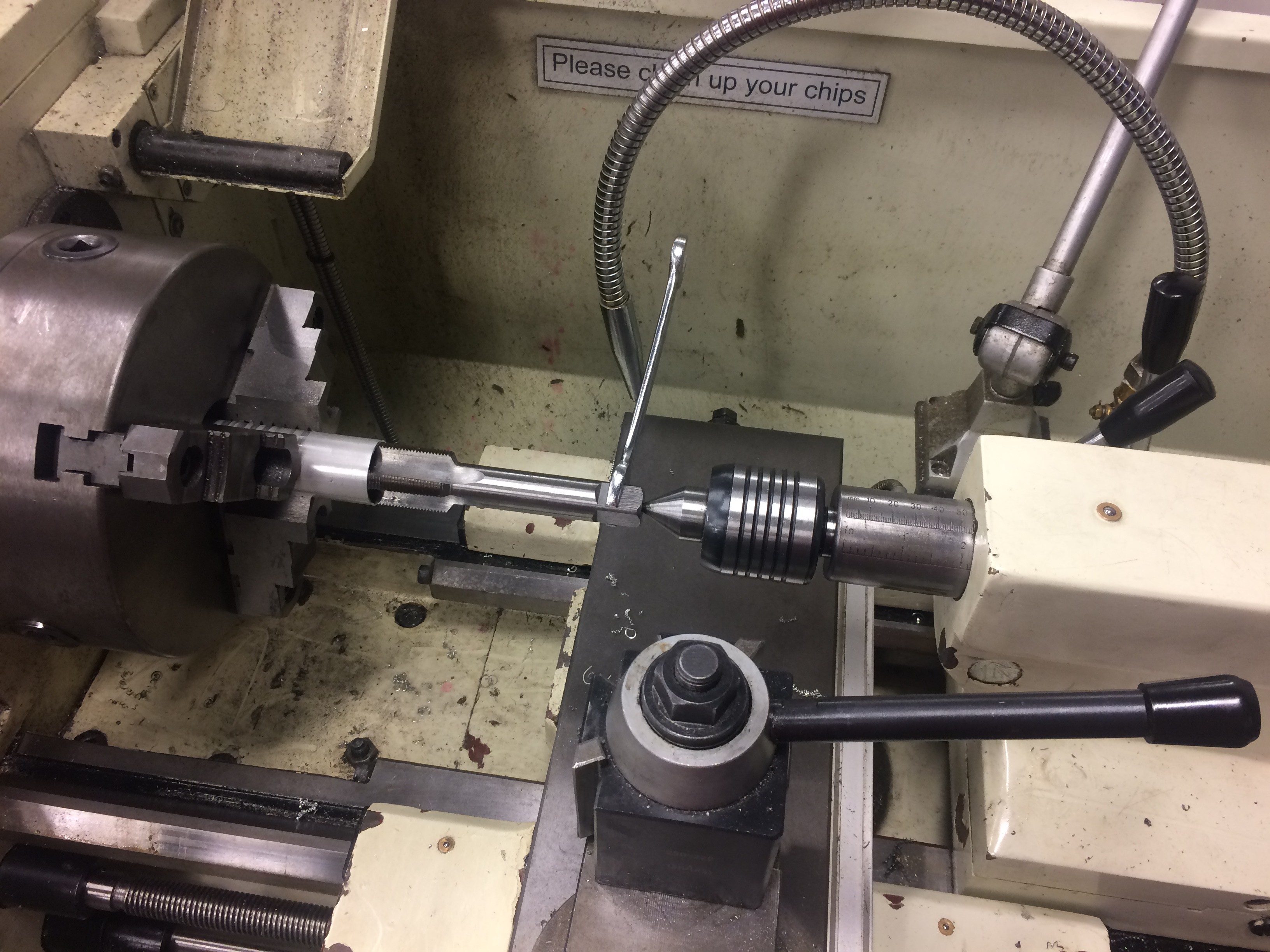

"What exercise equipment do you use?" - "Oh just the BDB 1340A Jet Lathe"

-Started on the GPS, Accelerometer, Raspi module!

-

Check your CNC specs!

10/08/2017 at 22:21 • 0 commentsThe 3/4"D 6"L ball endmill does not fit the shopbot... The highest diameter that ER-25 collets go is 1/2"

Probably for the best since i got 3 exams this week and I gotta study instead of CNCing molds.

P.S. If you are ever spearing large amounts of glue: buy the non-waterproof version and the largest paint roller they have.

-

Battery Holder Skelton Done!

10/01/2017 at 16:28 • 1 comment

Danny Andreev

Danny Andreev