-

partial succces

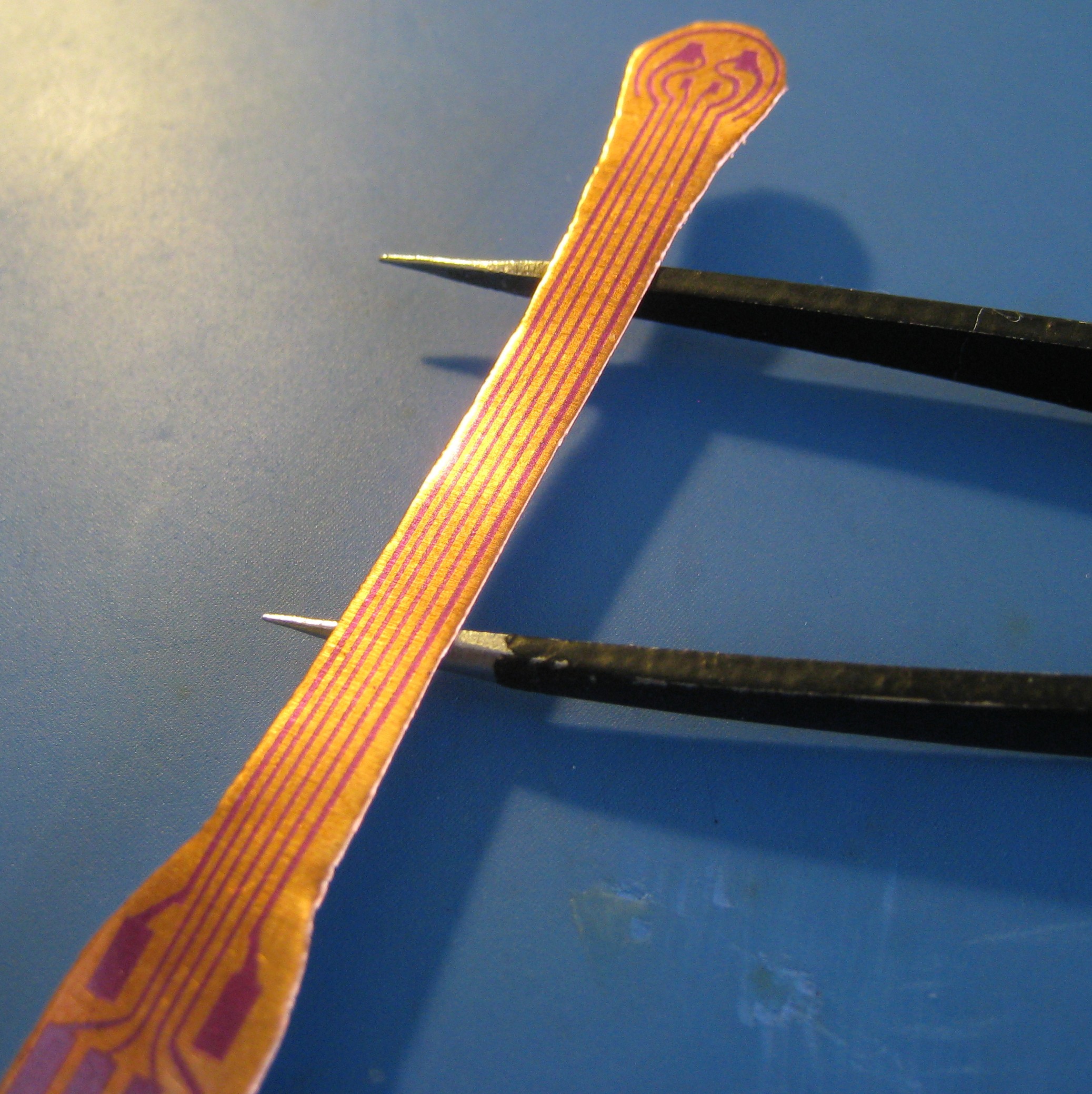

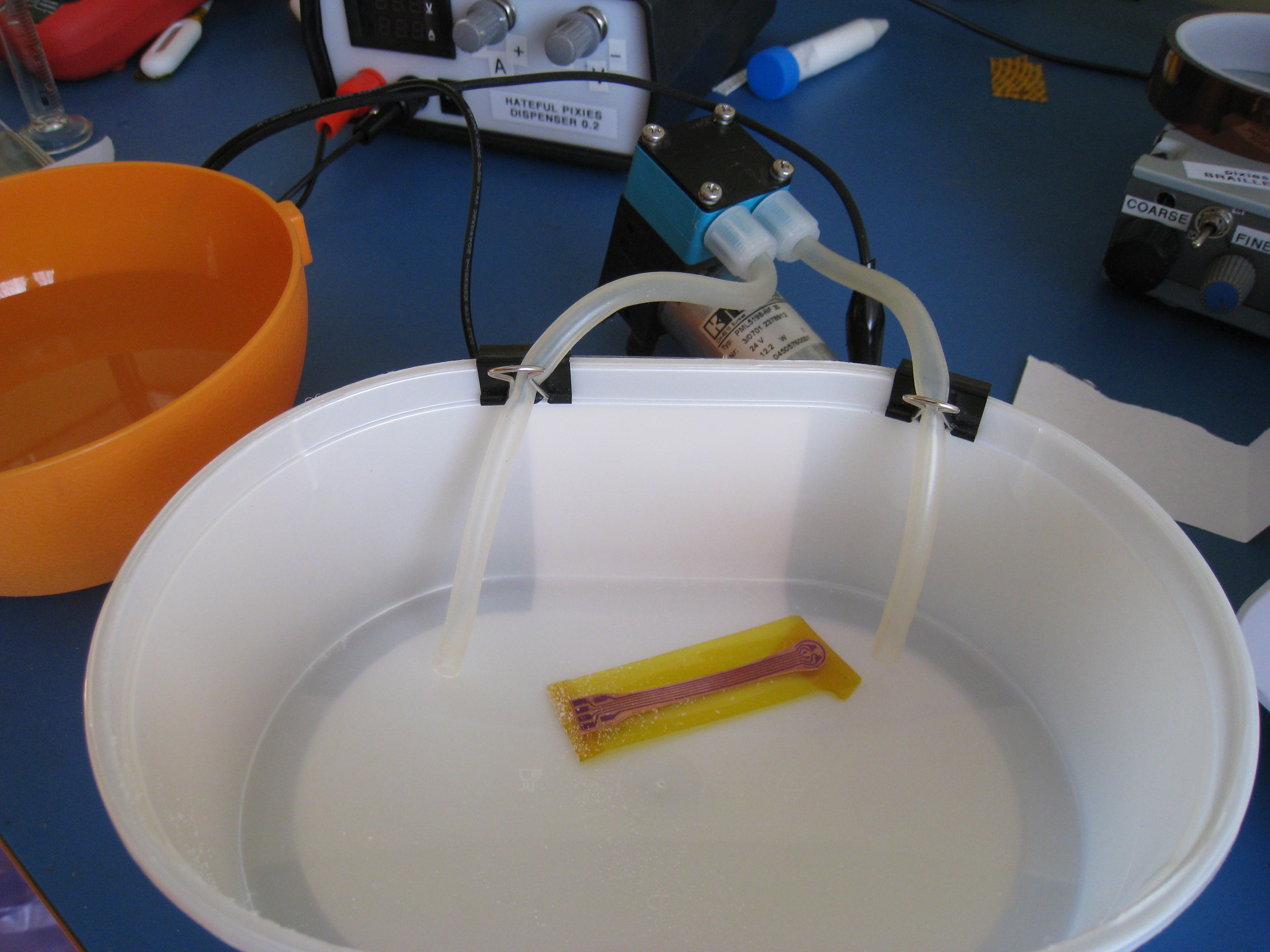

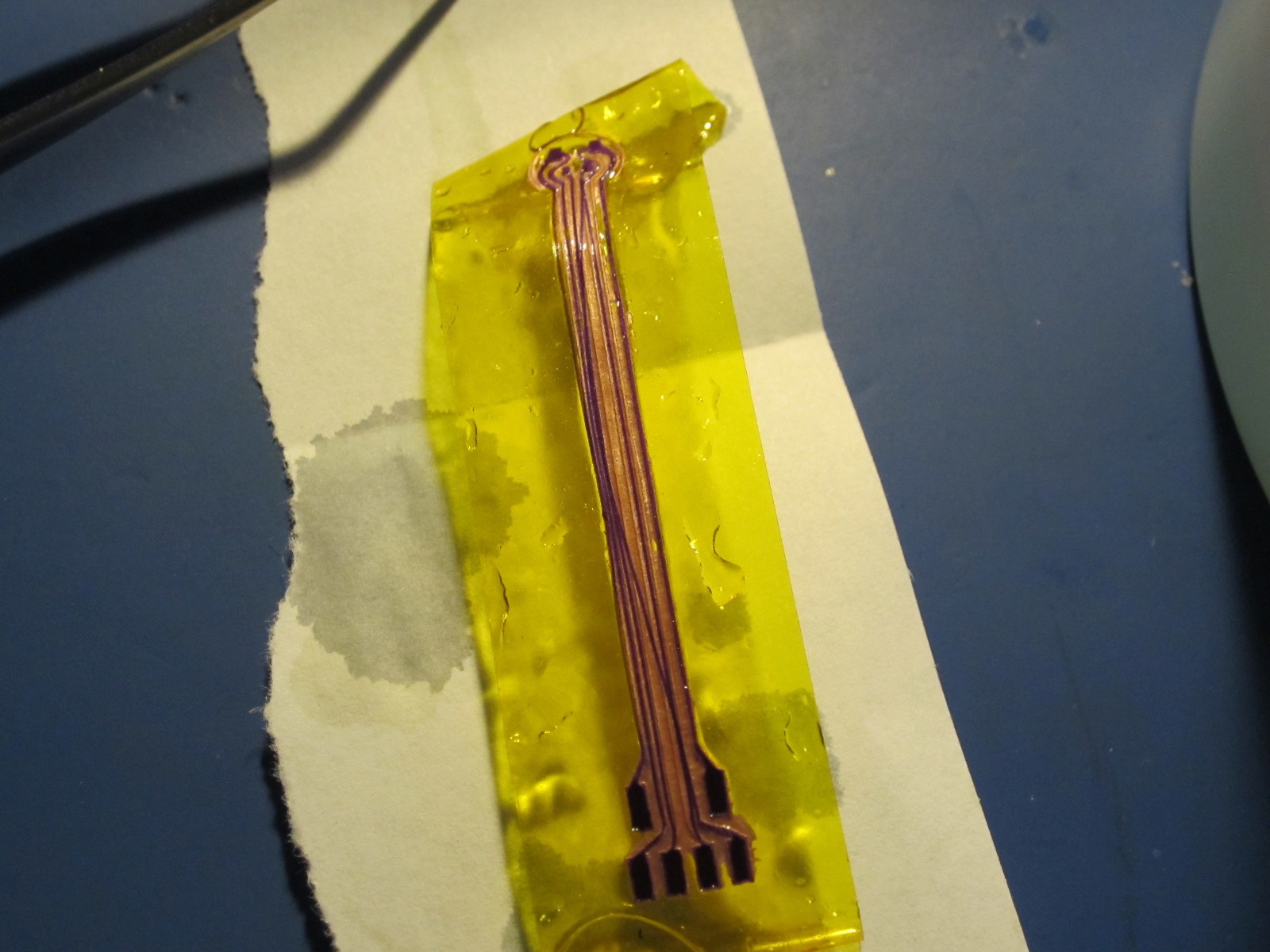

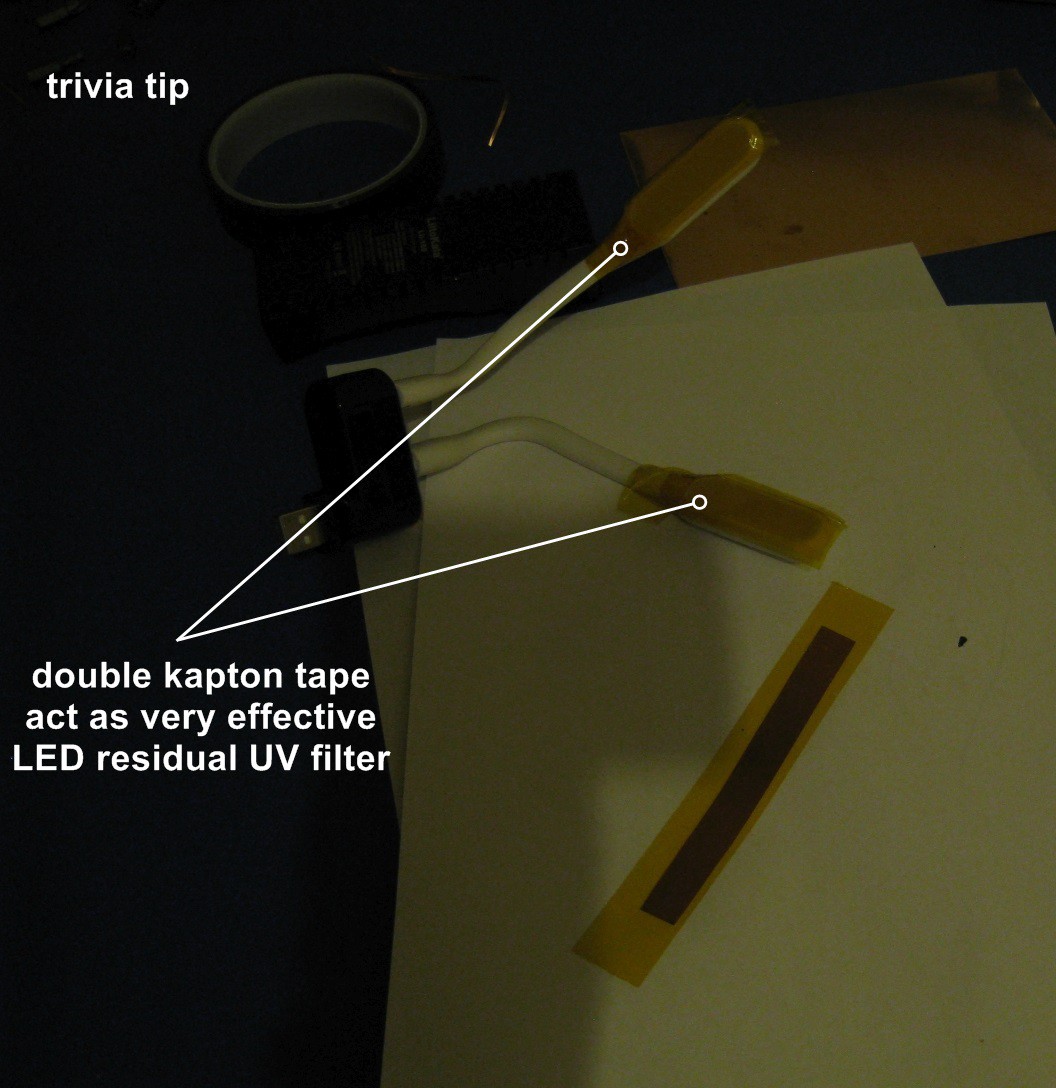

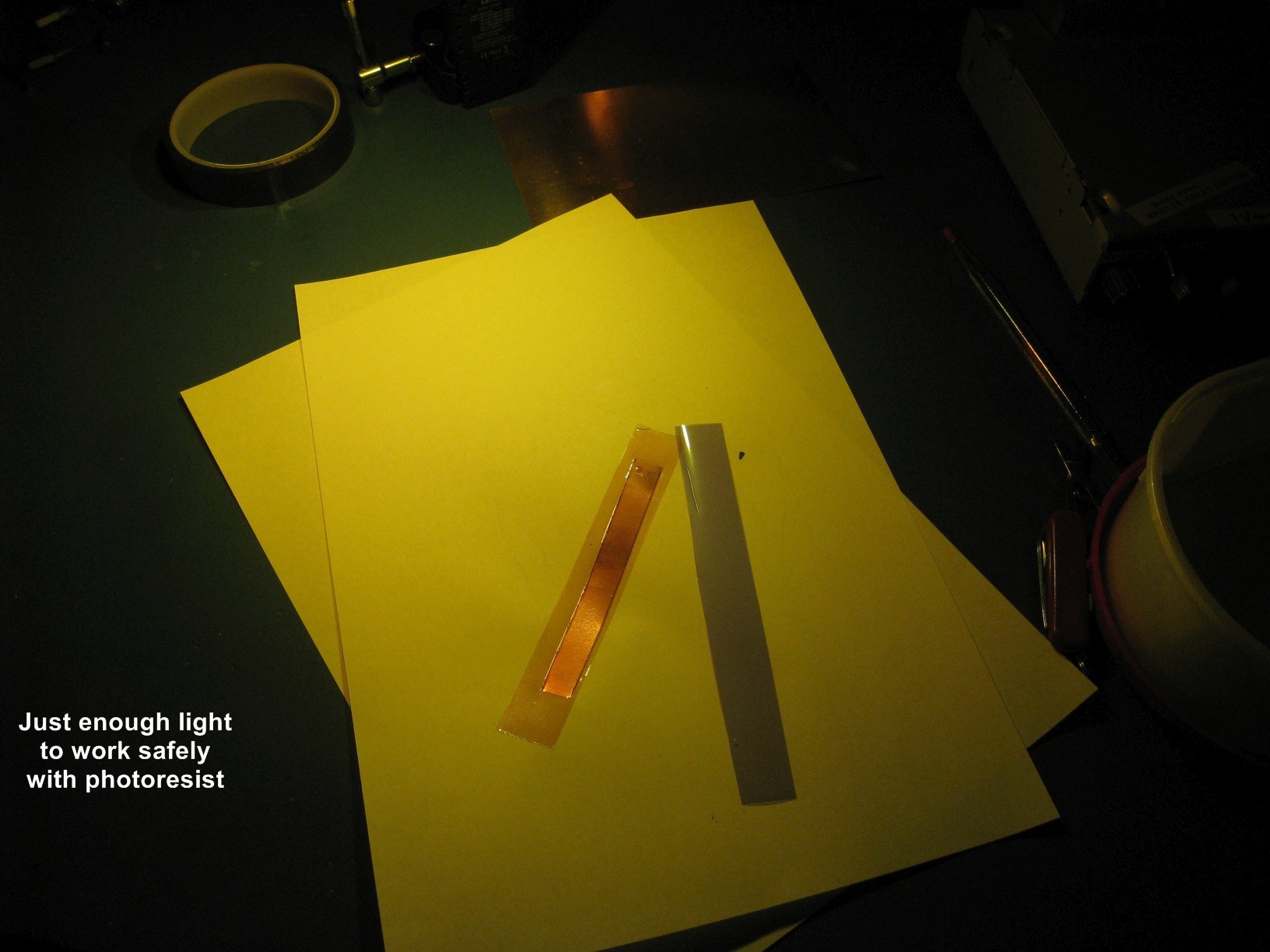

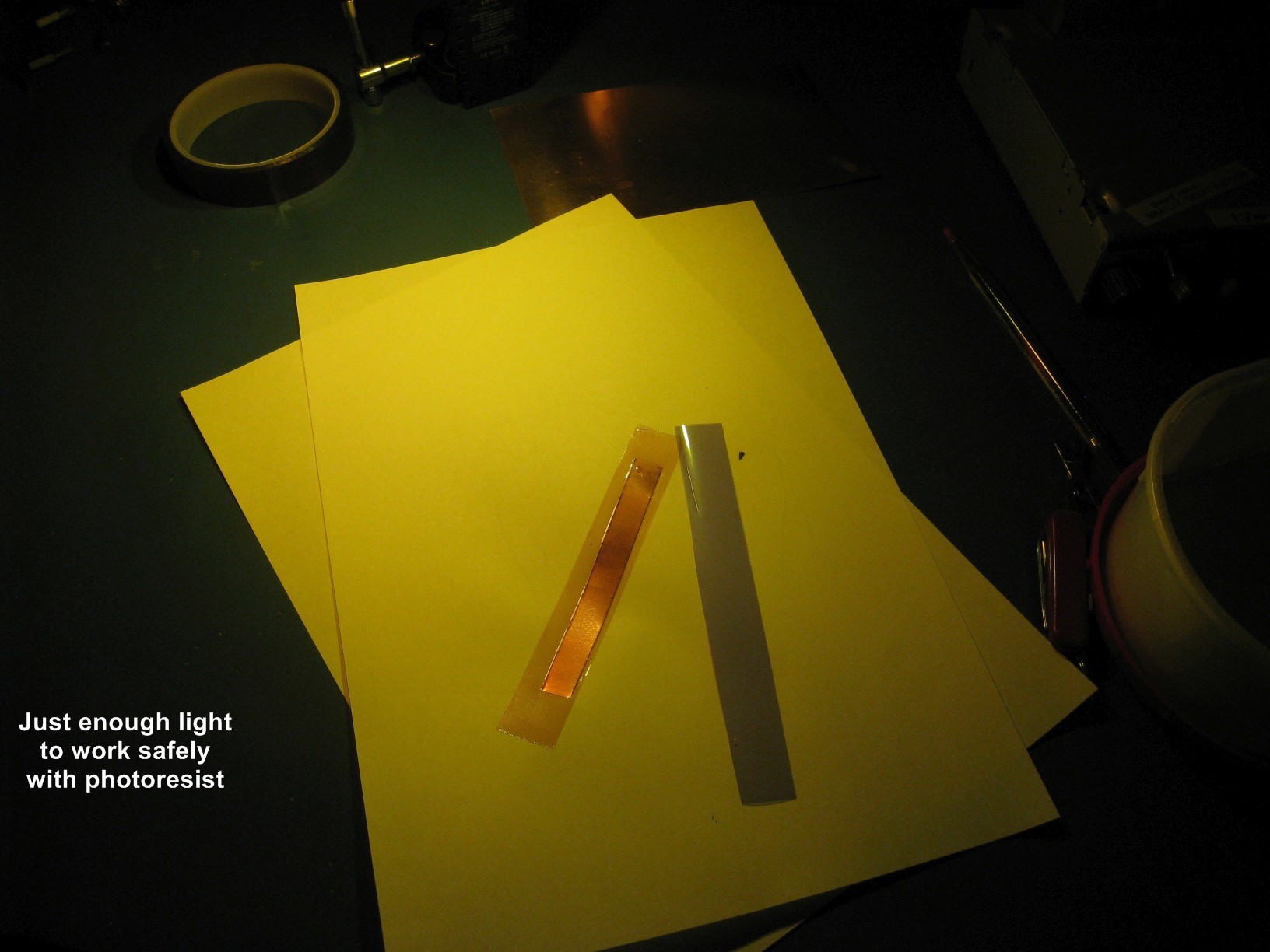

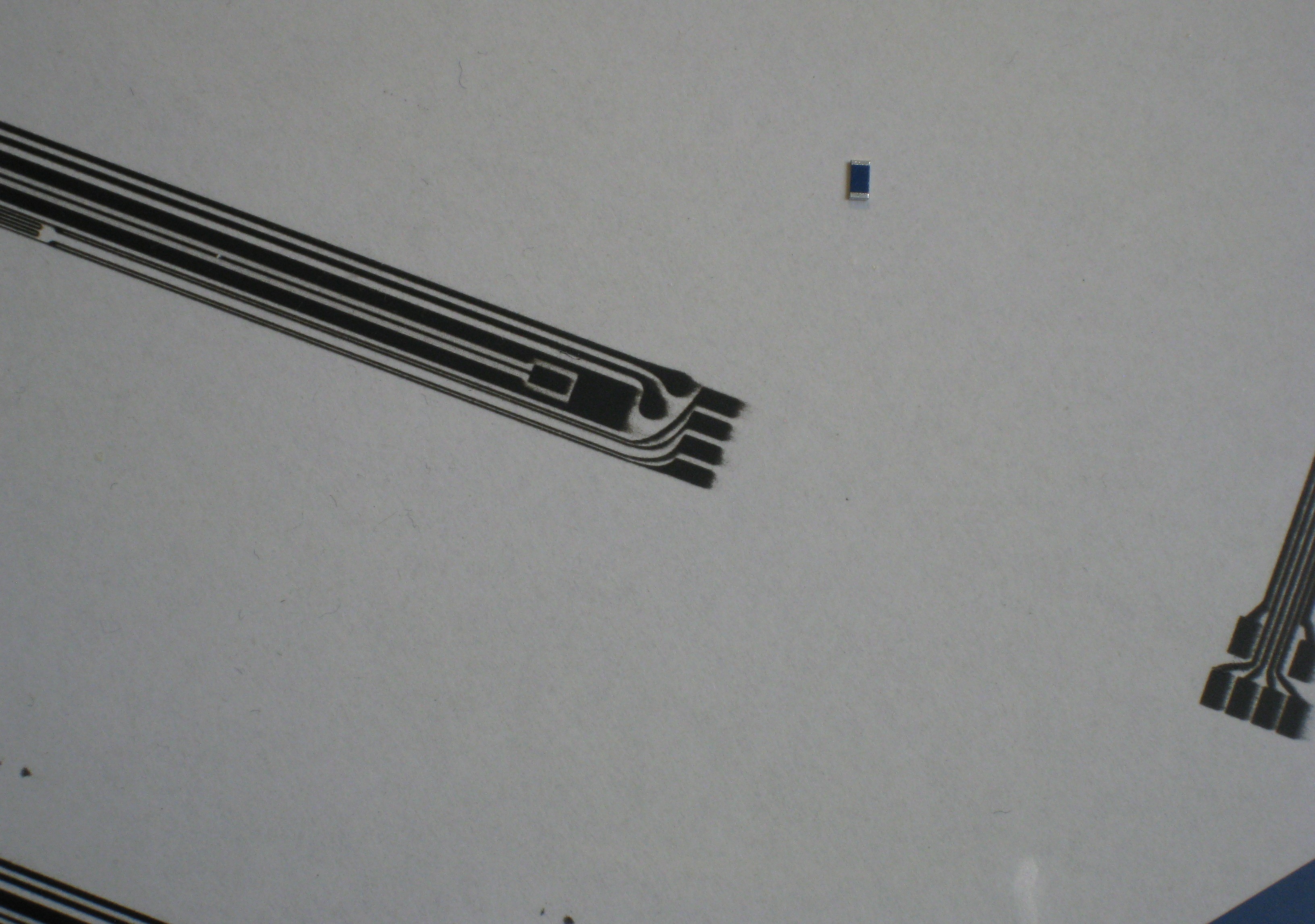

09/08/2017 at 17:04 • 3 commentsPartial succes! ;) I found 2 ways how NOT to do sensor etching.

The coper foil can't be too thick. 0.11mm can seem to be pretty thin, but not for this application.

And Riston photo-resist don't get along with ammonium peroxydisulfate. 1 hour is maximum time within this two can tolerate each other.Just like my...

The solution was in ballpark of 220g/L and room temp for slow copper bite.

I might take this from wrong side, i will try with thin wire instead just to speed up things, while I wait for thinner copper foil.

![]()

![]()

![]()

![]()

![]()

![]()

-

printer setback

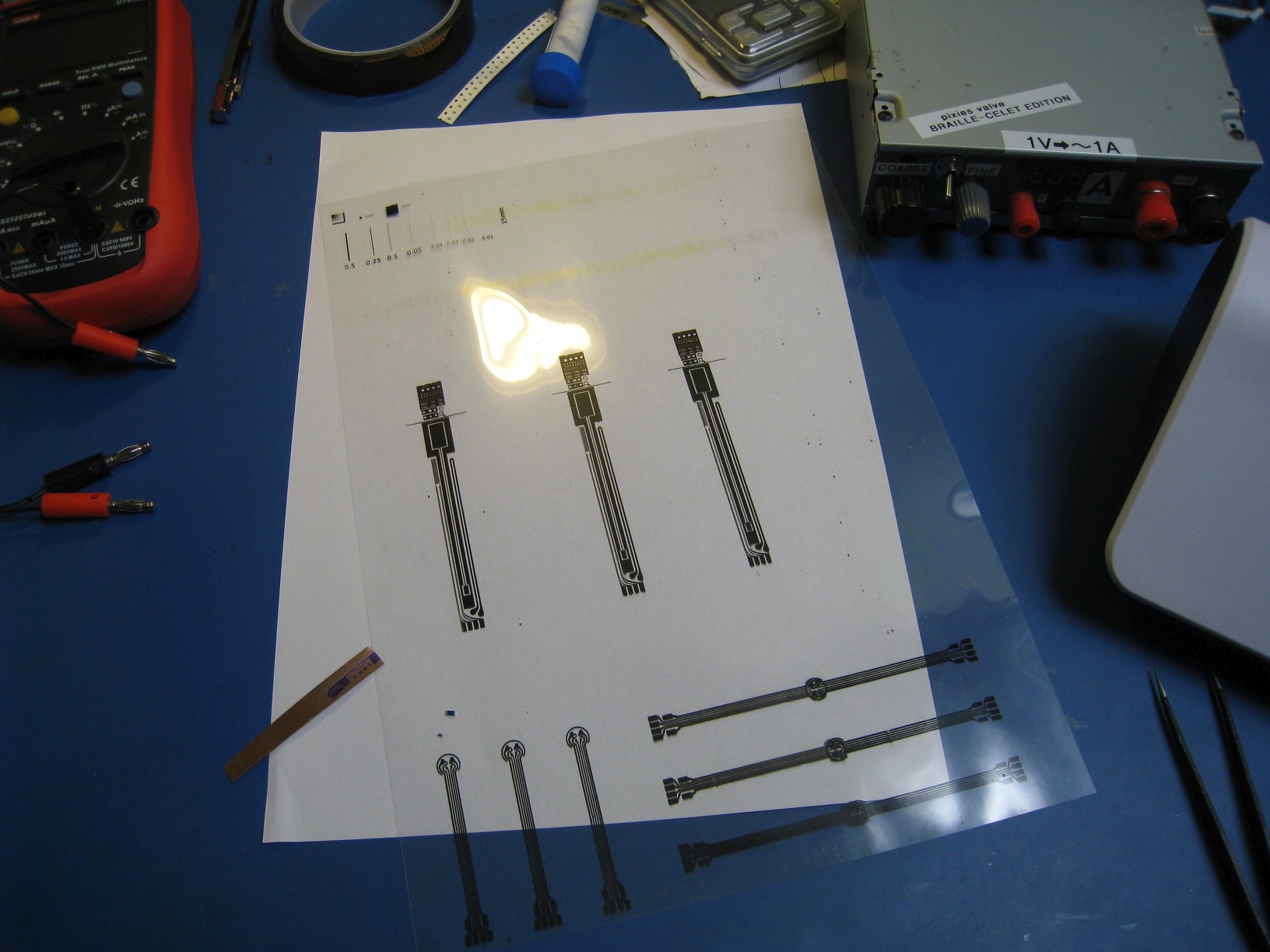

09/06/2017 at 17:58 • 0 commentsYour Honor, I would like to quote another anecdotal evidence supporting the thesis that printers can and do smell fear and when you are in a hurry.

My otherwise trustworthy Epson Acculaser found today my weakness ad decided to rebel and manifest it with that results.I'm currently negotiating the therms of piece, mainly calling it piece of junk.On the bright side, highly certified medical device intended to test first prototype, seen on the last picture, works flawlessly.(nah, just lm328 with mosfet in linear region, in dvd case). As soon as I deal with fractious printer I will present working prototype...stay tuned!![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

-

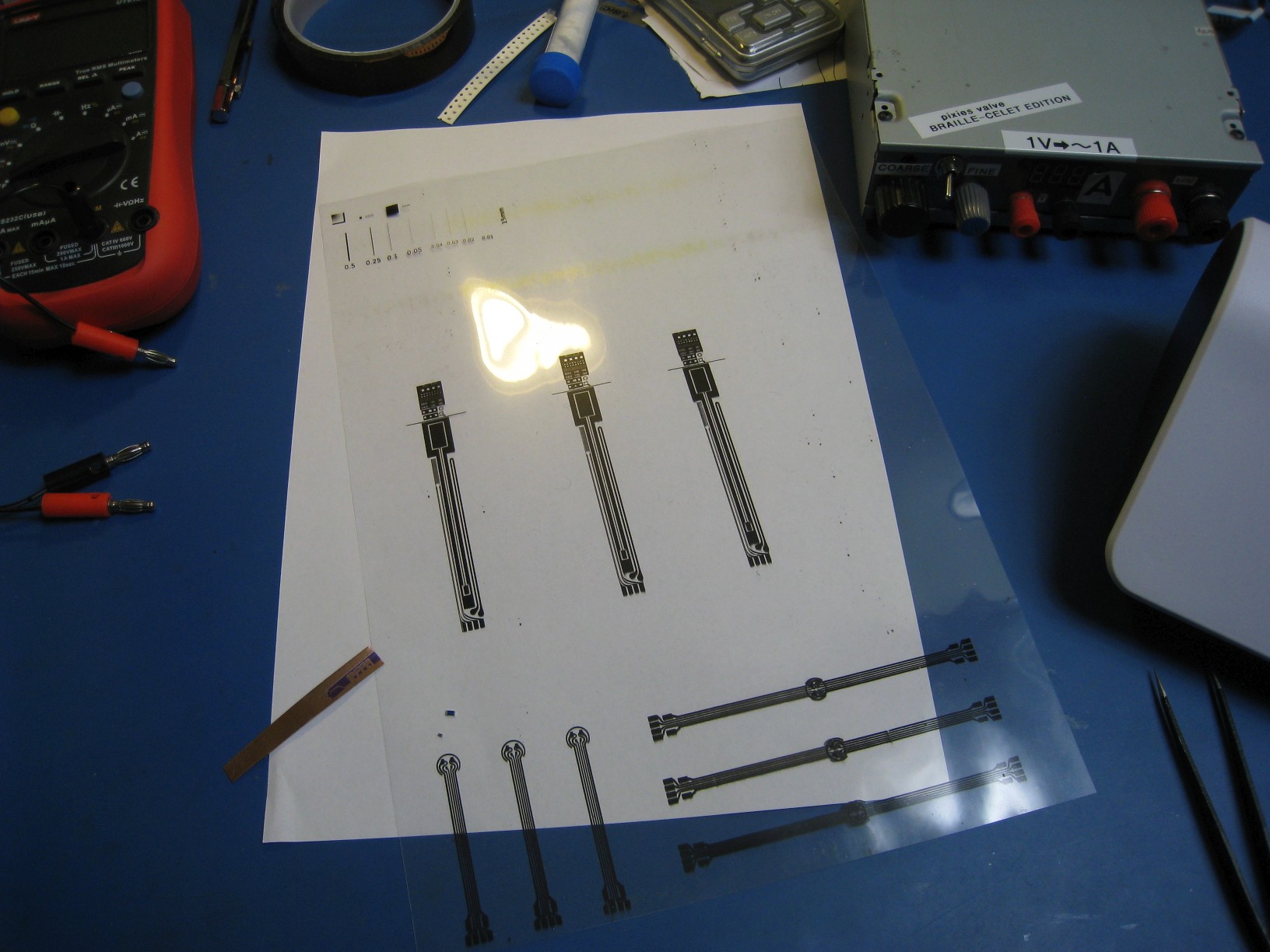

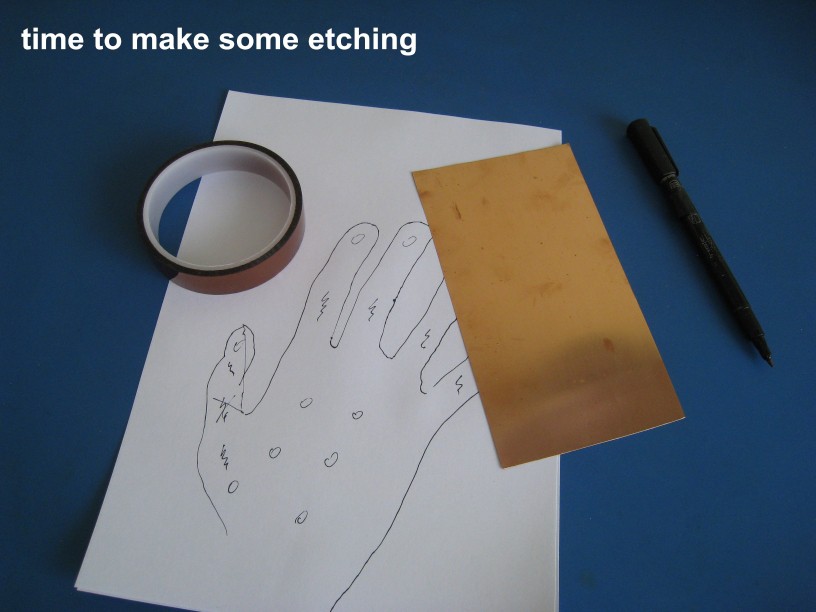

sensors design

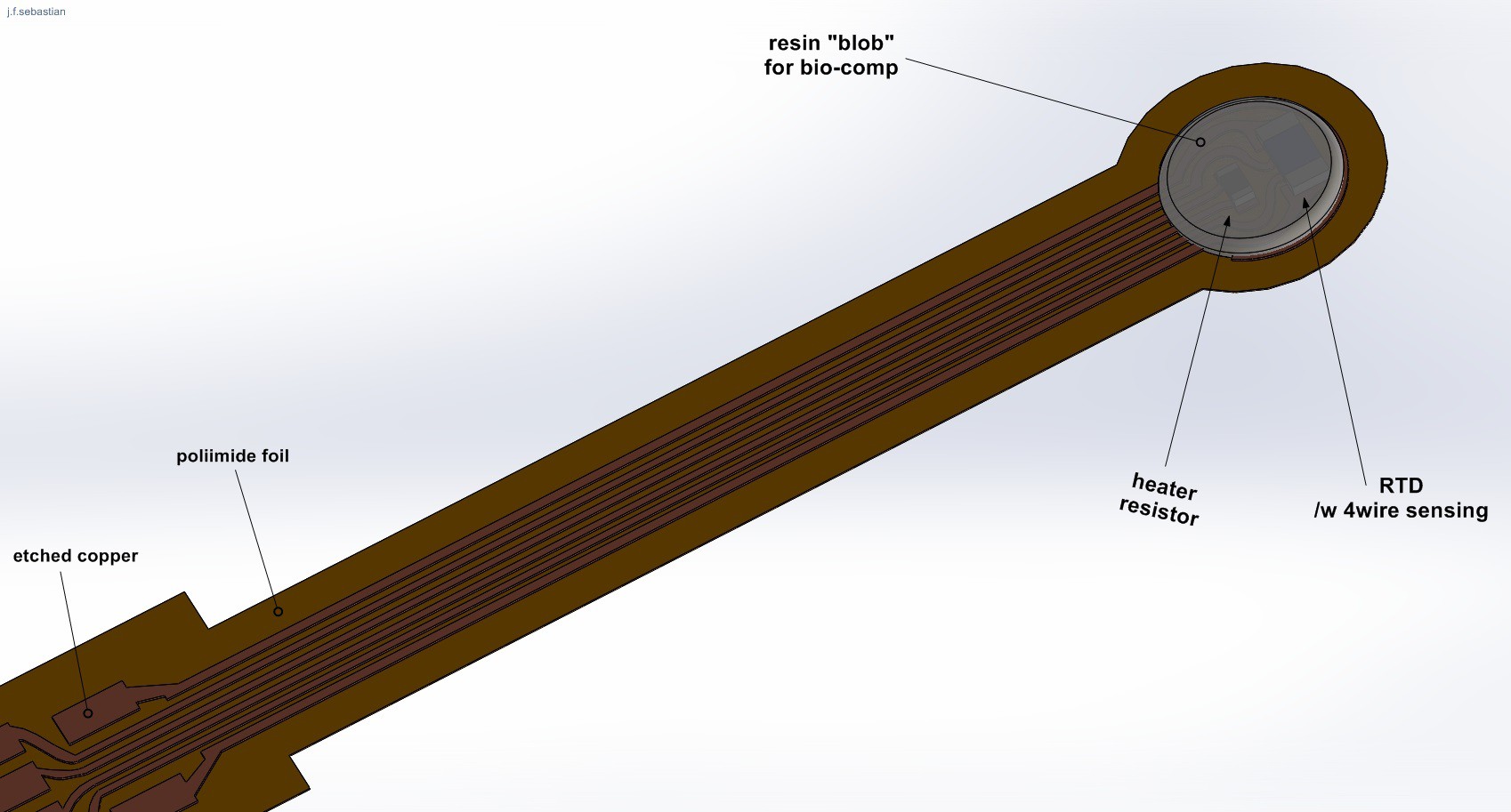

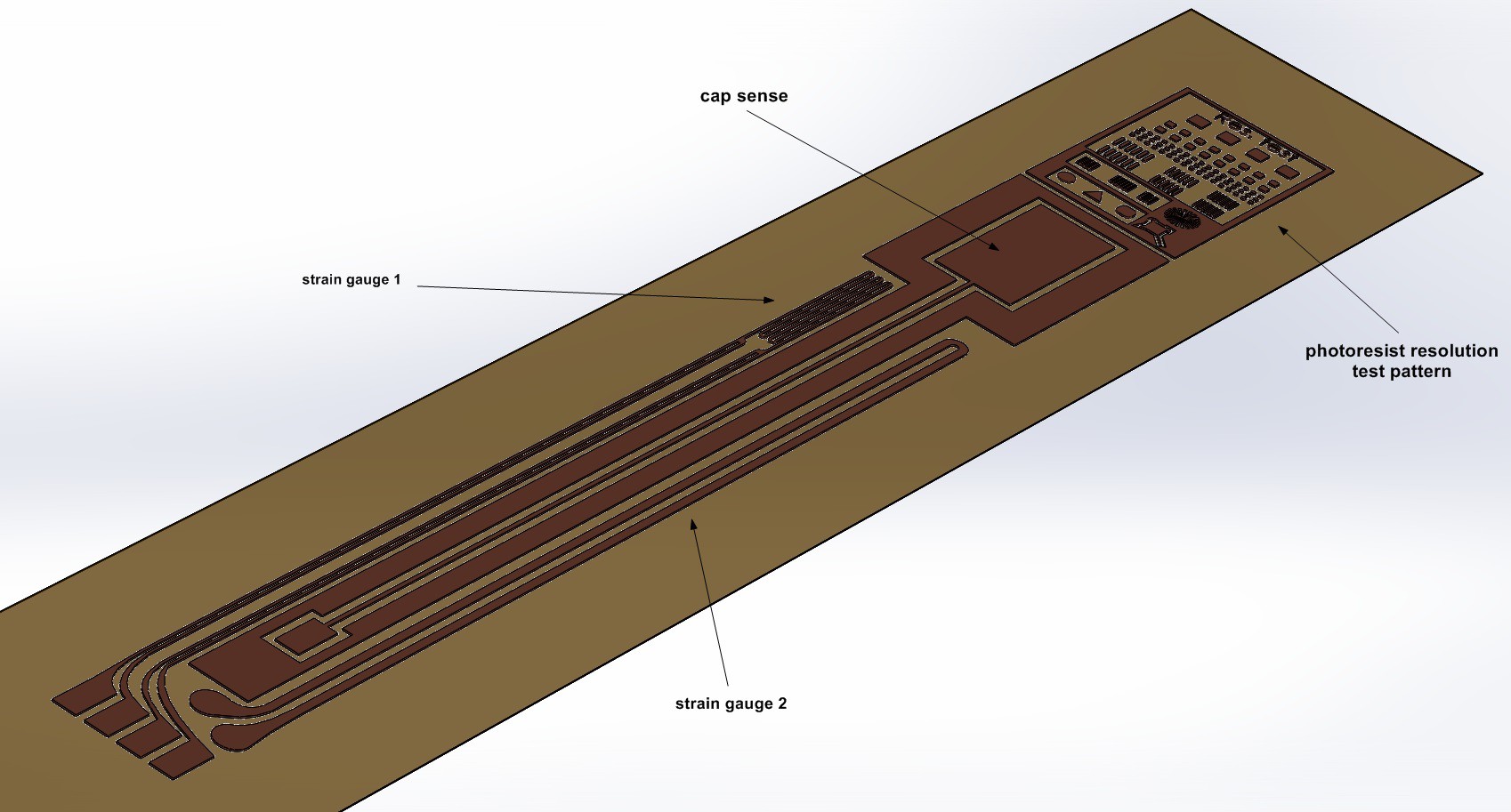

09/05/2017 at 22:52 • 0 commentsdot and move sensor to asses tape and copper foil flexibility, dot resin for skin protection

![]()

![]()

tomorow - etching and load testing with ultra precise diy machine - stay tuned mom!

-

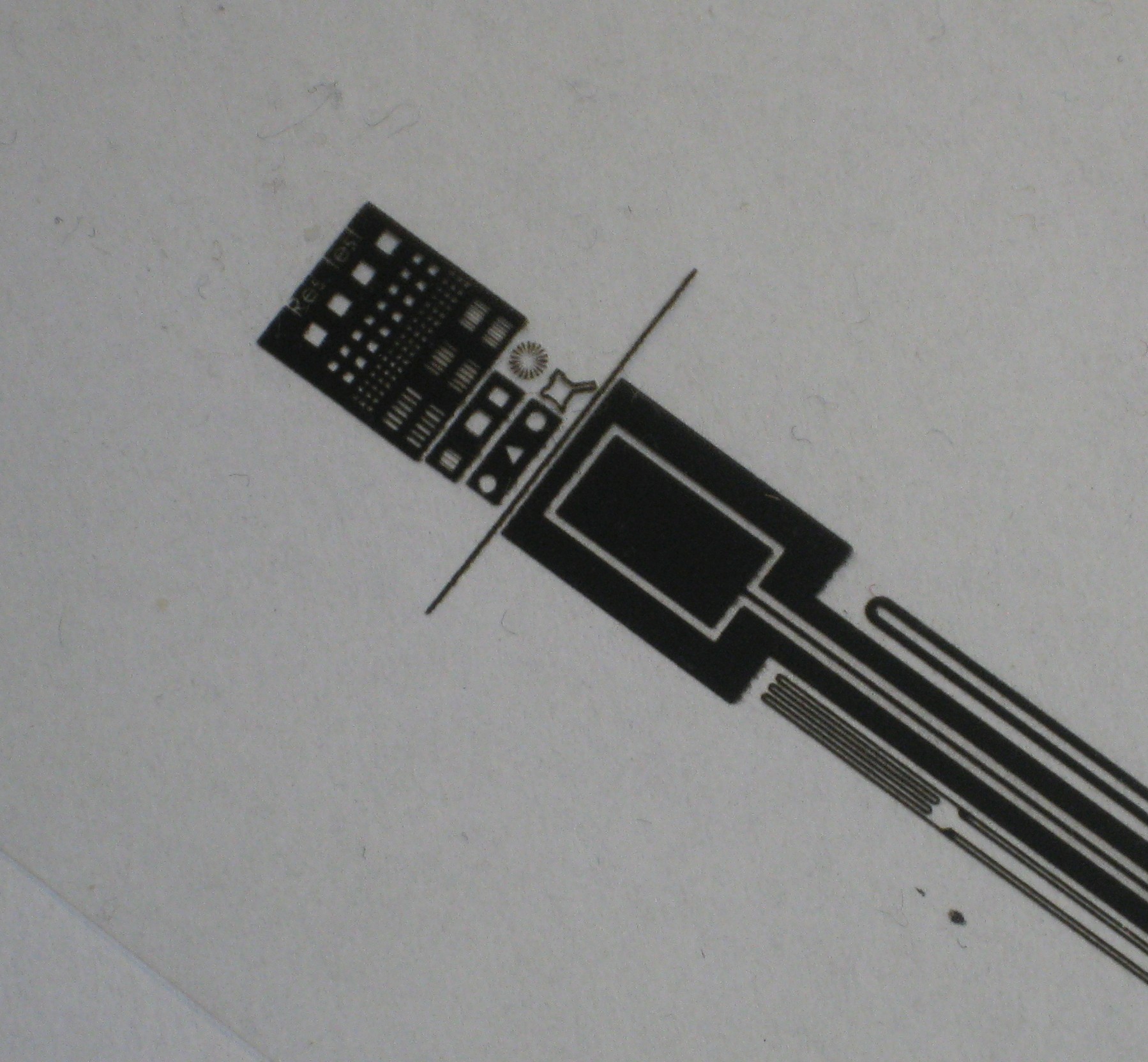

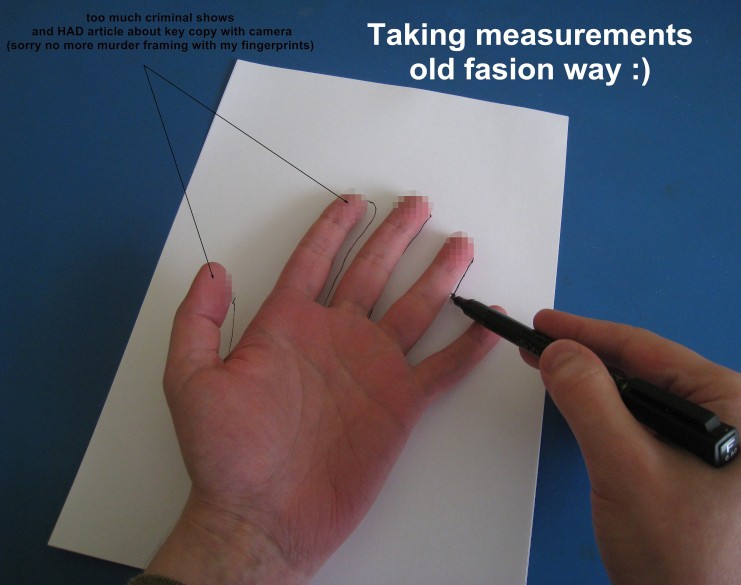

first attempt

09/04/2017 at 11:15 • 0 commentsThe process begins...

![]()

![]()

Braille-celet

Two way interface for Braille /discreet typing, with feedback, in form of sport bracelet.

j.f.sebastian

j.f.sebastian