*******************************************************************************

*** Update 02/21/2019***

Due to low turnout I quit updating this project on Hackaday a long time ago - as this is written the http://cubespawn.com website is receiving a major face-lift

http://patreon.com/CubeSpawn is much more up to date, and most day to day updates are on FB

https://www.facebook.com/CubeSpawn

Pardon the lack of updates, but life is a busy place!

*******************************************************************************

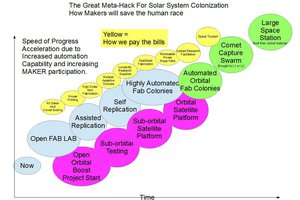

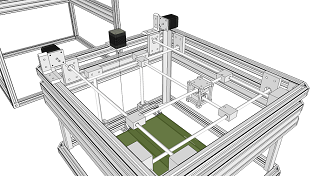

CubeSpawn has been evolving as a concept since 2006. In 2009 the RepRap project started spreading on the 'net and I decided to start building the first cube, I chose a 1 meter size and ordered the parts. 1 meter turned out to be an awkward size: too big for small stuff, too small for big stuff, and as a citizen of the last country on earth using feet and inches, a meter is odd sized for our supply chain. Yet I wanted the concept to work for anyone on earth, so I borrowed from smarter people and used the "British Metric Foot" a 300mm unit that is really close to one foot, yet works well with "Modular coordination" a concept relating to easy additive dimensions and easy sub-divisibility.

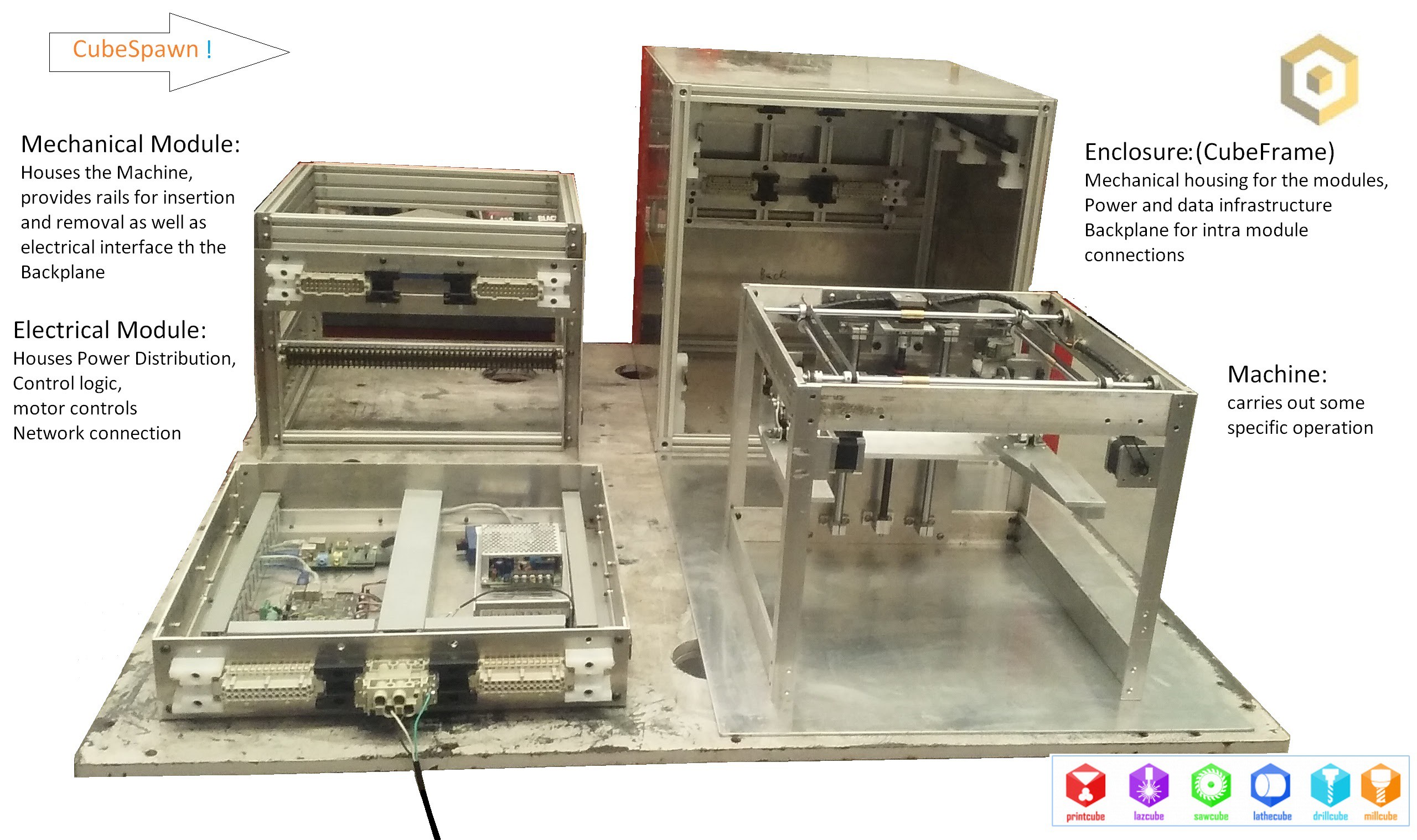

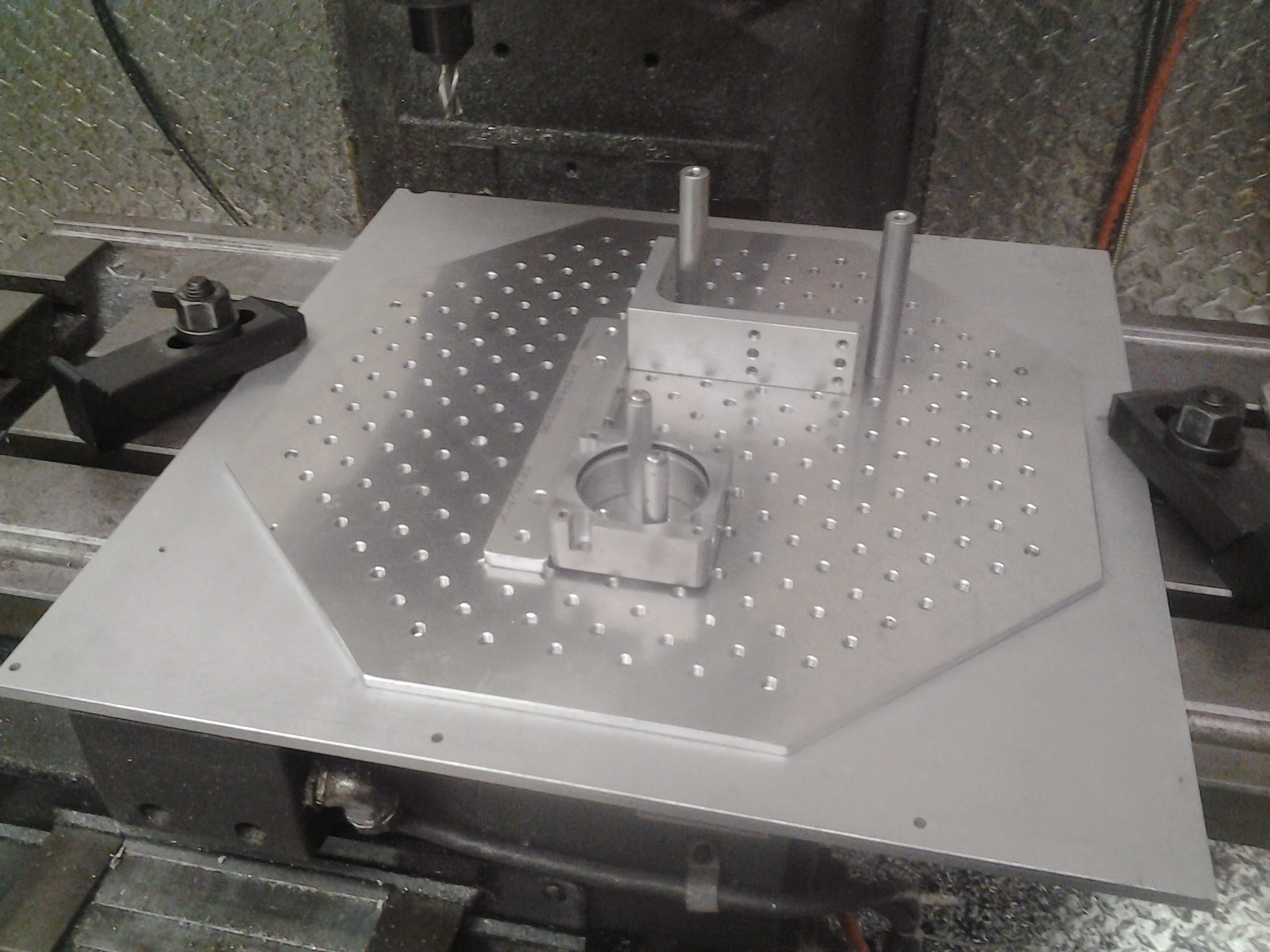

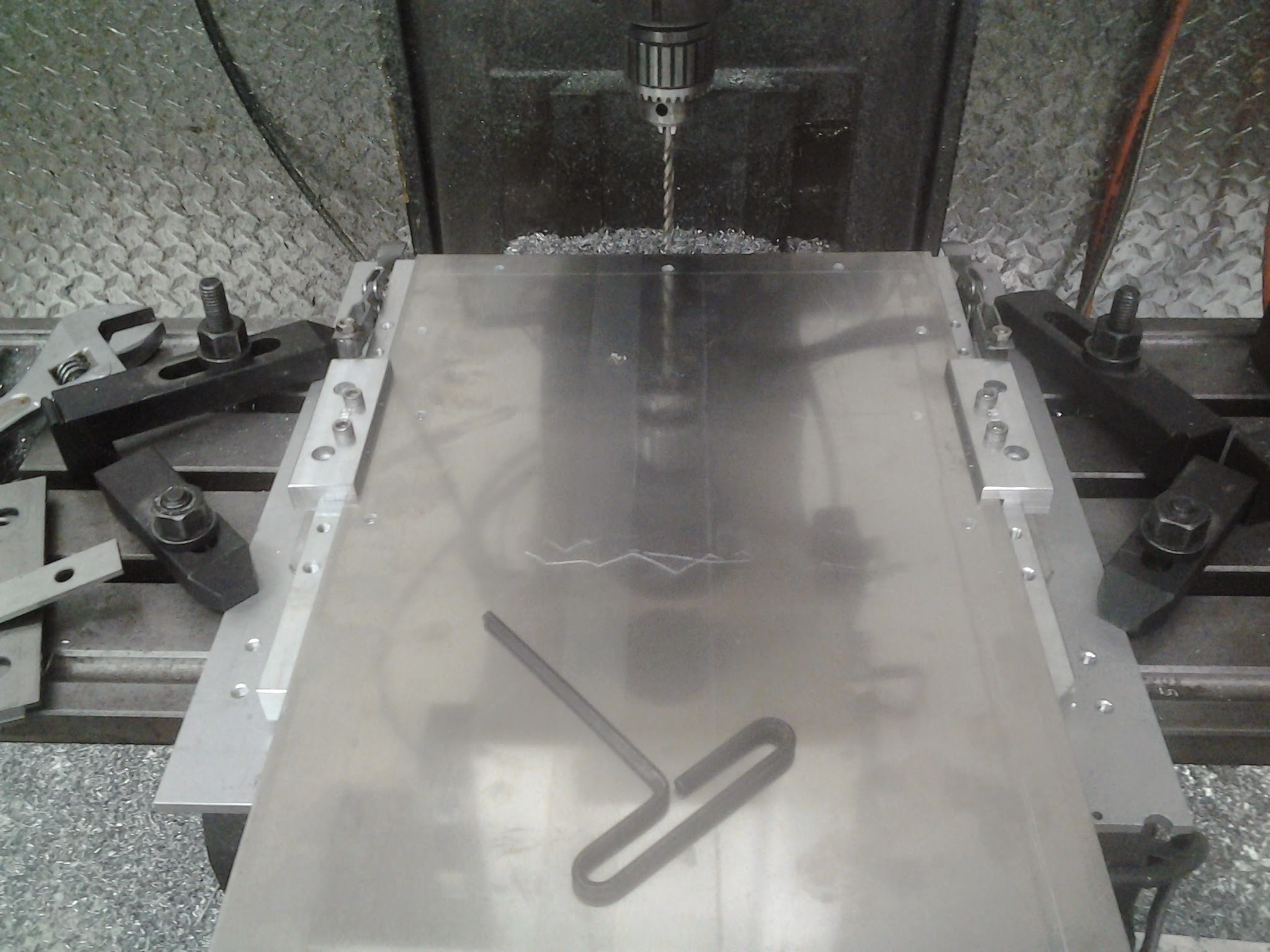

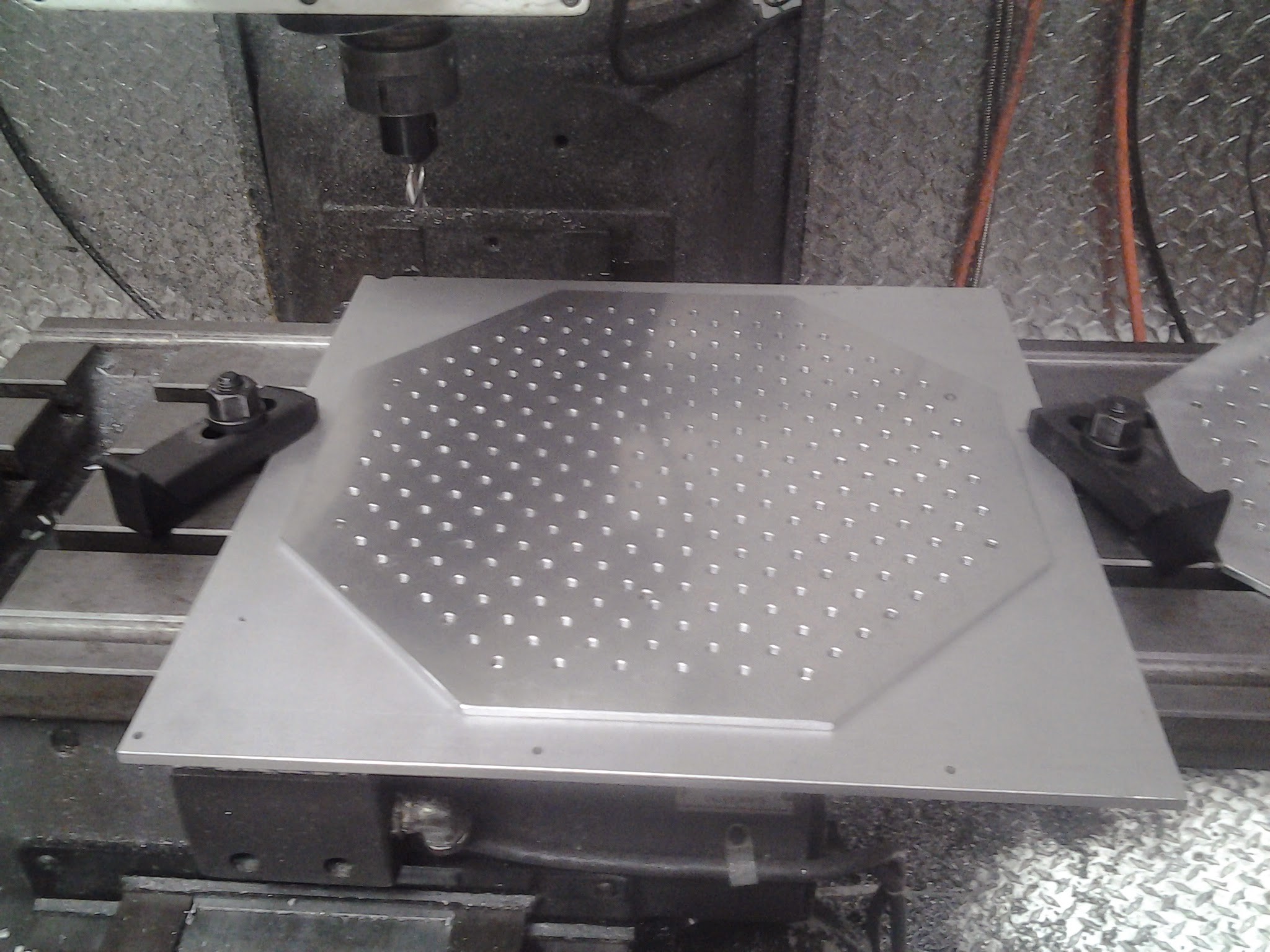

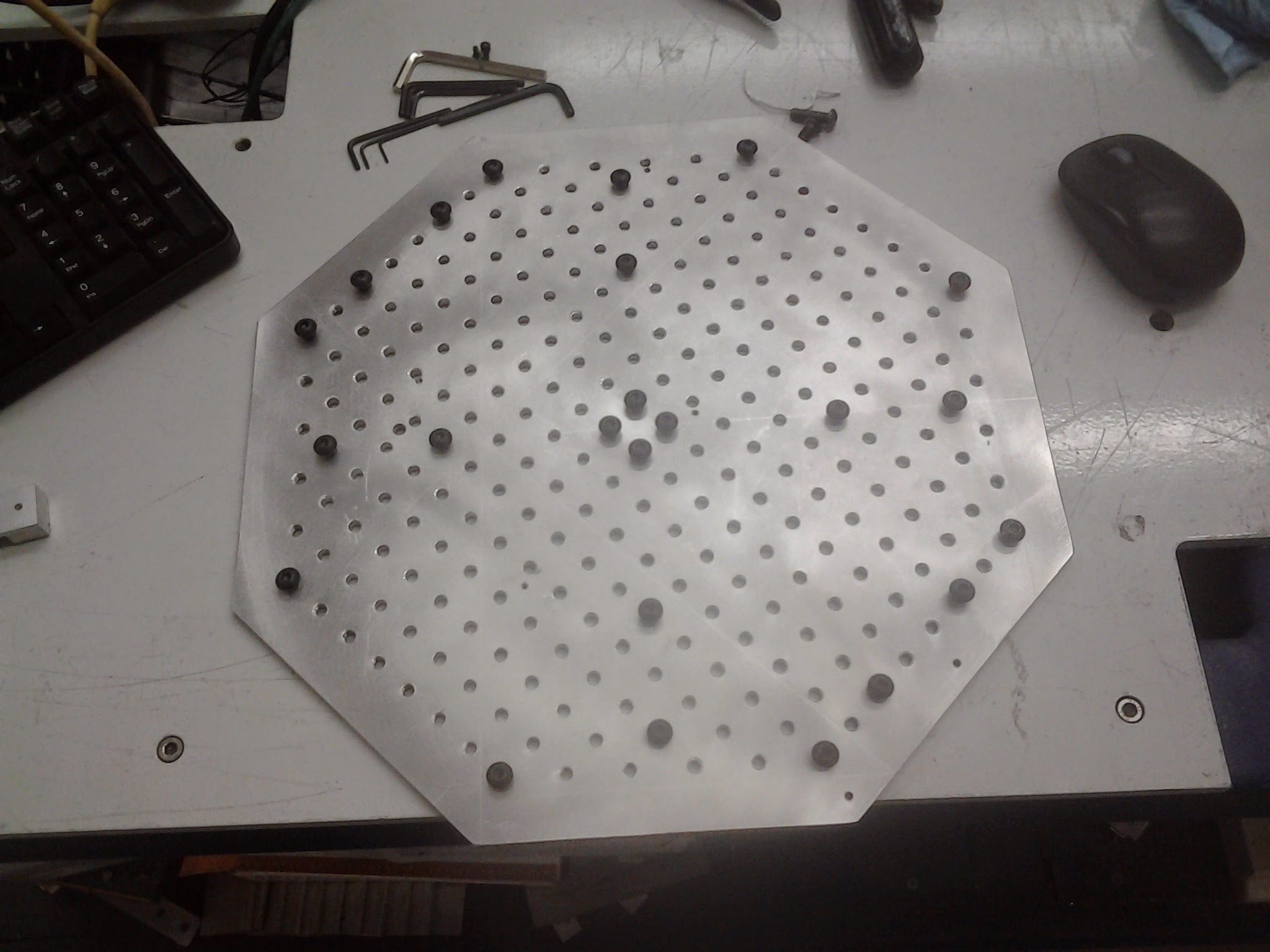

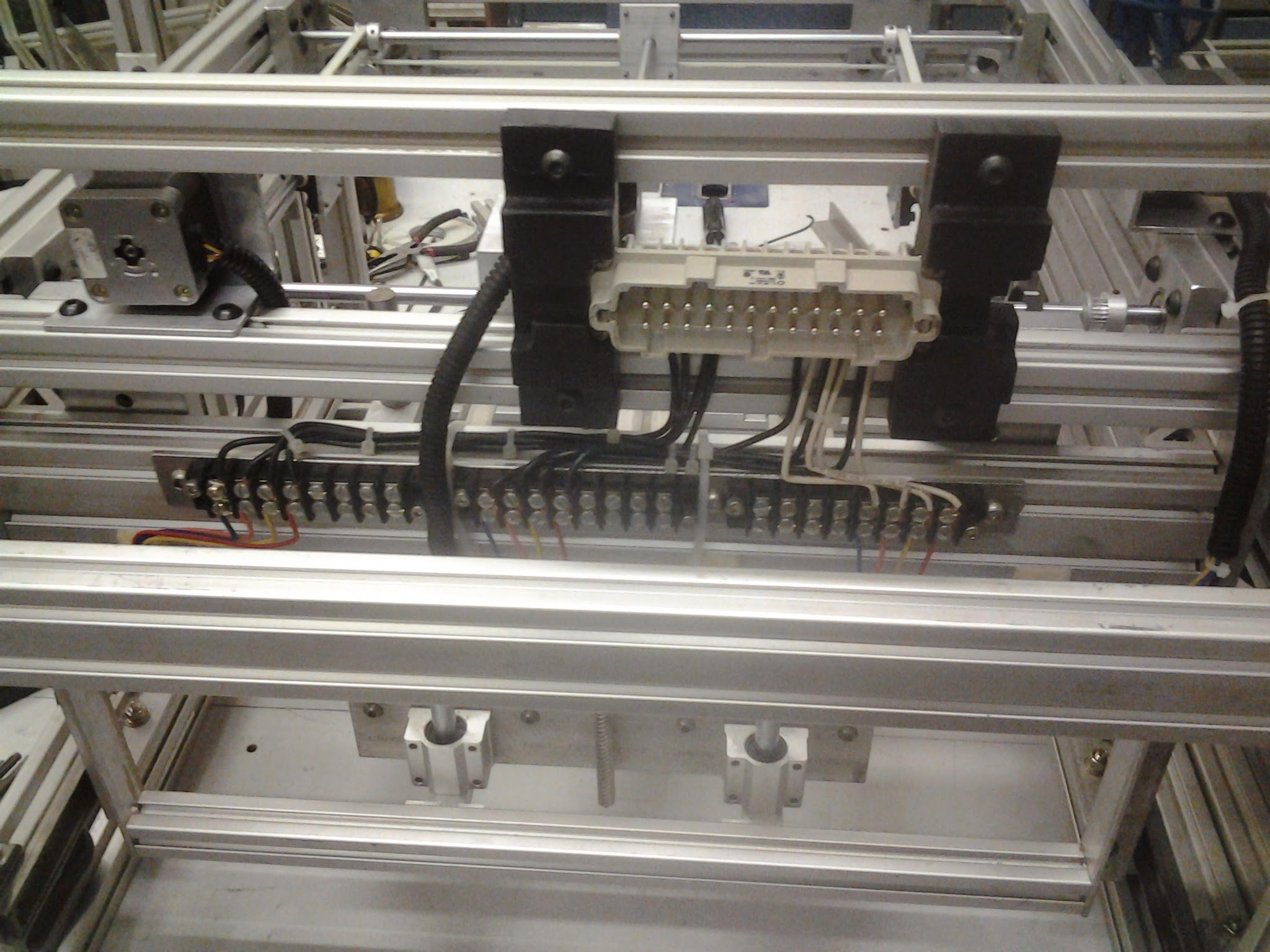

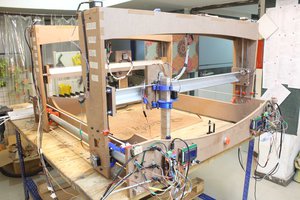

Dimensional issues resolved, the project searched for a design that would allow for modular CNC machines of many different types to work together in a standards based framework, and from that effort a module holding the mechanical workings of a machine in the lower 2/3rds and the electrical/electronics in the upper 1/3rd. is the best solution so far.

The last issue was what software to control all the potentially diverse processes spread across the system, the answer turned out to be the Robot Operating System (ROS) and more particularly its variant for manufacturing (ROS-i) for the prototypes, this runs on top of a Raspberry Pi (although any Linux based SBC should work) running Raspian and ROS this then drives a SmoothieBoard for stepper control, additional solutions will be researched in the future.

Latest Pictures

https://picasaweb.google.com/103828779781480193226/DougsShopPhase2?noredirect=1

Ethereum Discussion

Dimensional issues resolved, the project searched for a design that would allow for modular CNC machines of many different types to work together in a standards based framework, and from that effort a module holding the mechanical workings of a machine in the lower 2/3rds and the electrical/electronics in the upper 1/3rd. is the best solution so far.

The last issue was what software to control all the potentially diverse processes spread across the system, the answer turned out to be the Robot Operating System (ROS) and more particularly its variant for manufacturing (ROS-i) for the prototypes, this runs on top of a Raspberry Pi (although any Linux based SBC should work) running Raspian and ROS this then drives a SmoothieBoard for stepper control, additional solutions will be researched in the future.

Latest Pictures

https://picasaweb.google.com/103828779781480193226/DougsShopPhase2?noredirect=1

Ethereum Discussion

CubeSpawn

CubeSpawn

Nishant Agarwal

Nishant Agarwal

Andy Lee

Andy Lee