-

CubeSpawn is the Borg of Open Source Hardware

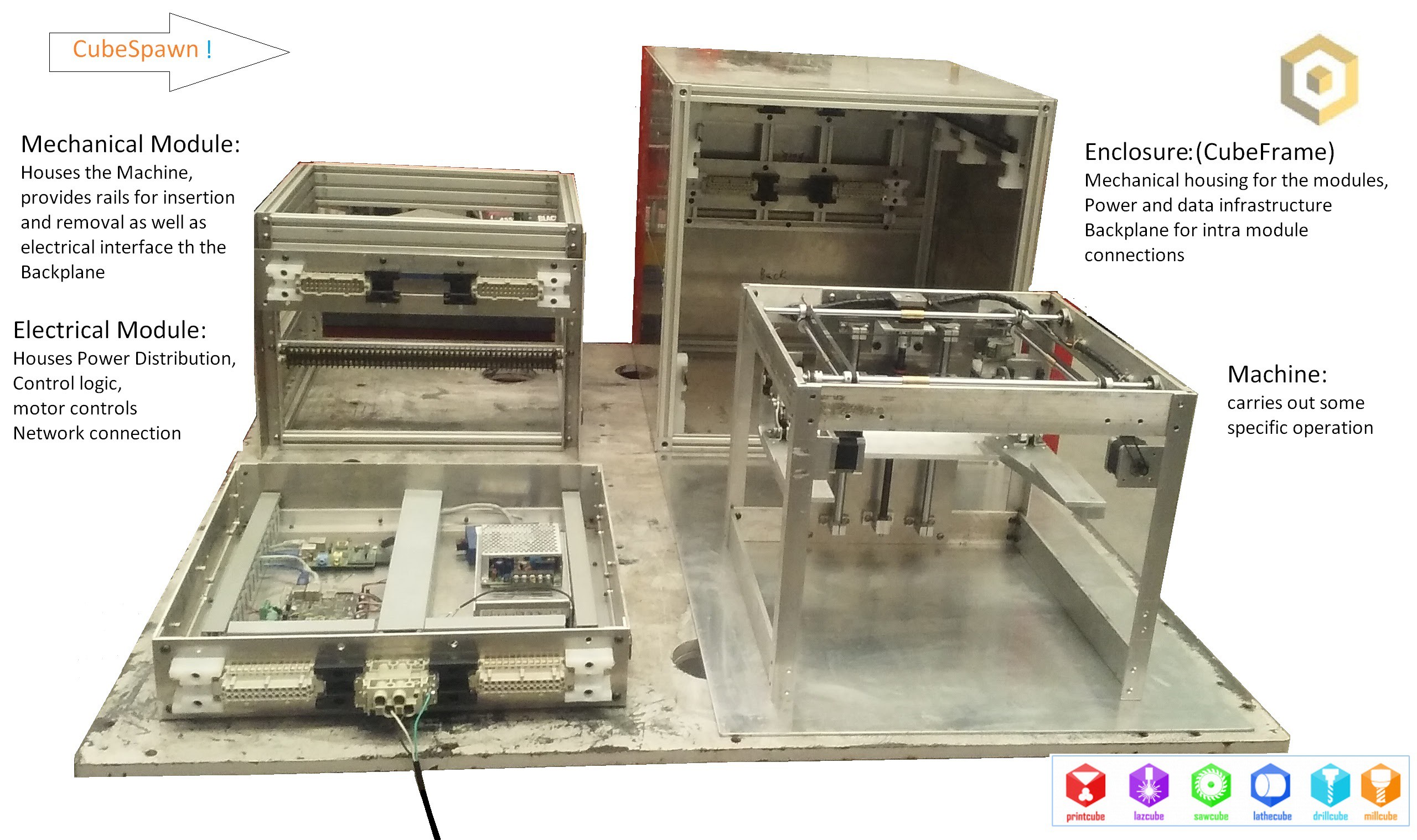

10/06/2015 at 20:06 • 0 commentsHere are the Elements of the CubeSpawn System as the stand today:

https://picasaweb.google.com/103828779781480193226/DougsShopPhase2#6202620107616244994 -

Inadvertent progress

05/10/2015 at 17:01 • 0 commentsDaily progress seems slow, but the cumulative progress is beginning to become significant:

the CubeSpawn system consists of 5 basic sub-systems:

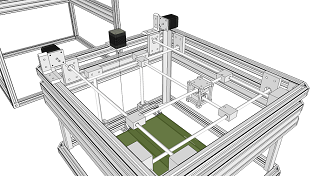

1. The cubical enclosures, (Frame)

2. A removable Mechanical Module

3. A removable Electr(ical/onics) Module (the control software runs in here)

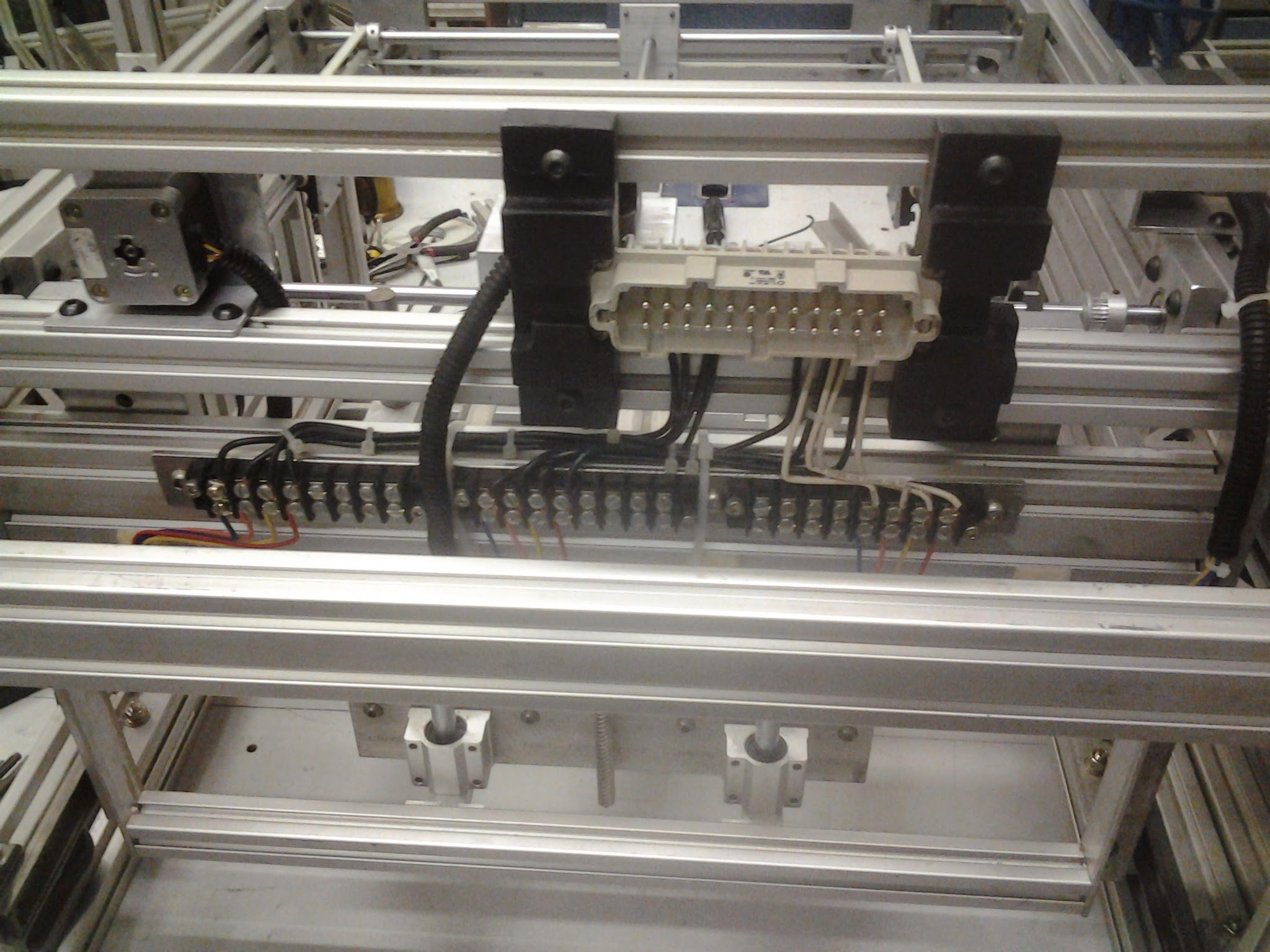

4. A backplane to connect the two modules to each other and the frames sensors

5. The mechanical/electrical and electronic connectors to tie the machines together.

These are all in some fairly advanced functioning state, and in building them I have discovered a significant number of improvements that could be implemented (leading to a "two steps forward, one step back" cycle of design improvements.)

This, in turn, has made everything take months where I thought it would take weeks, but I think the payoff is getting pretty close.

While waiting for some parts to come in I have worked on a modular fixture solution for the Milling Machine Cube. Due to the overwhelming engineering task involved in creating a whole flock of machine designs, I will be adapting existing open source machines to the mechanical modules rather than rolling my own machines, since this, after all is why we open source!

From a practical standpoint, this means finishing out the circuit mill/router/milling machine design is going quickly, The 3D printer is done, all but a few details...

Since I'm using existing open source designs, appropriately adapted to the modules constraints, this also applies to a Laser Cutter, a Vacuum Former, a Surface Grinder and several others.

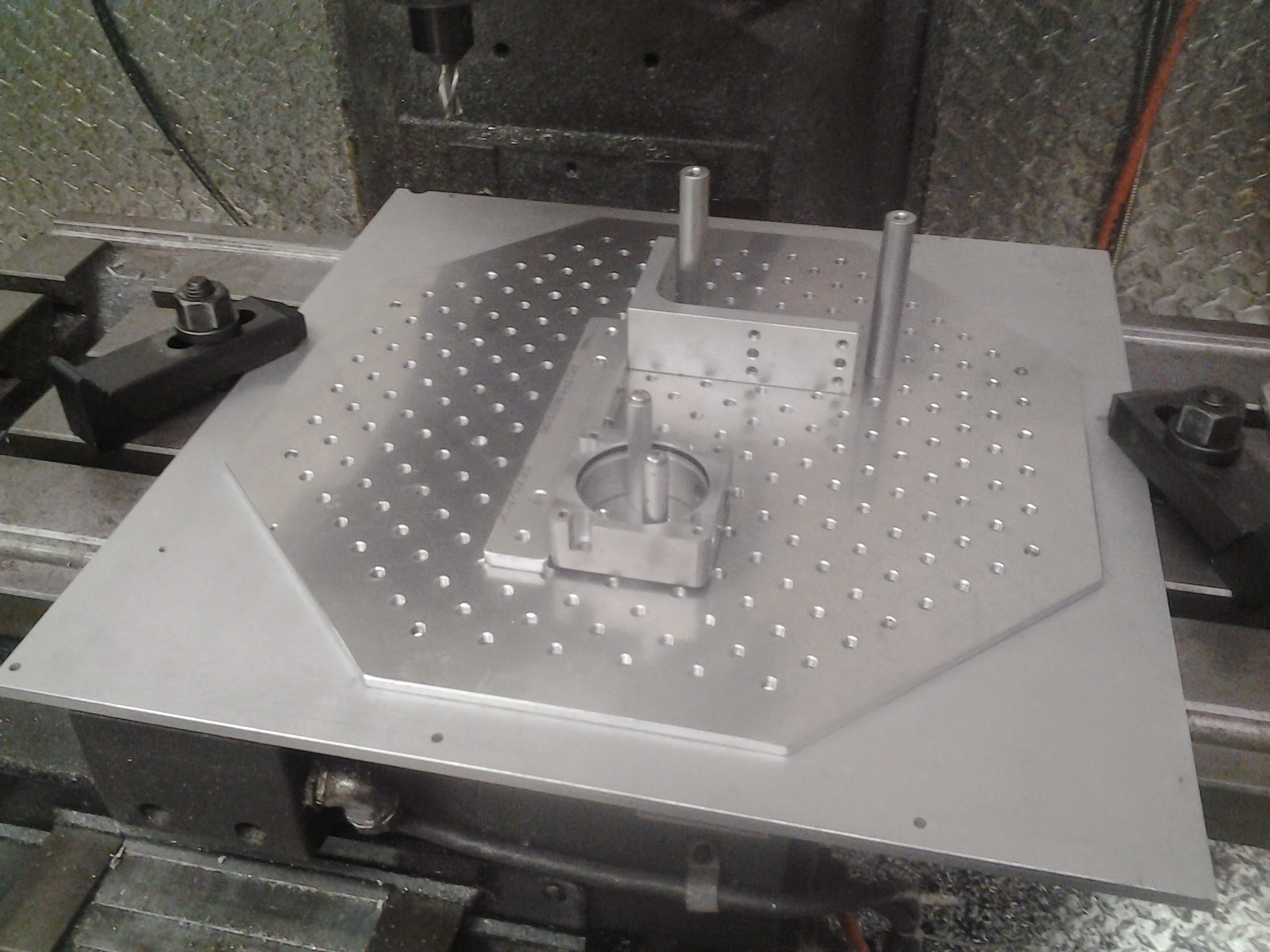

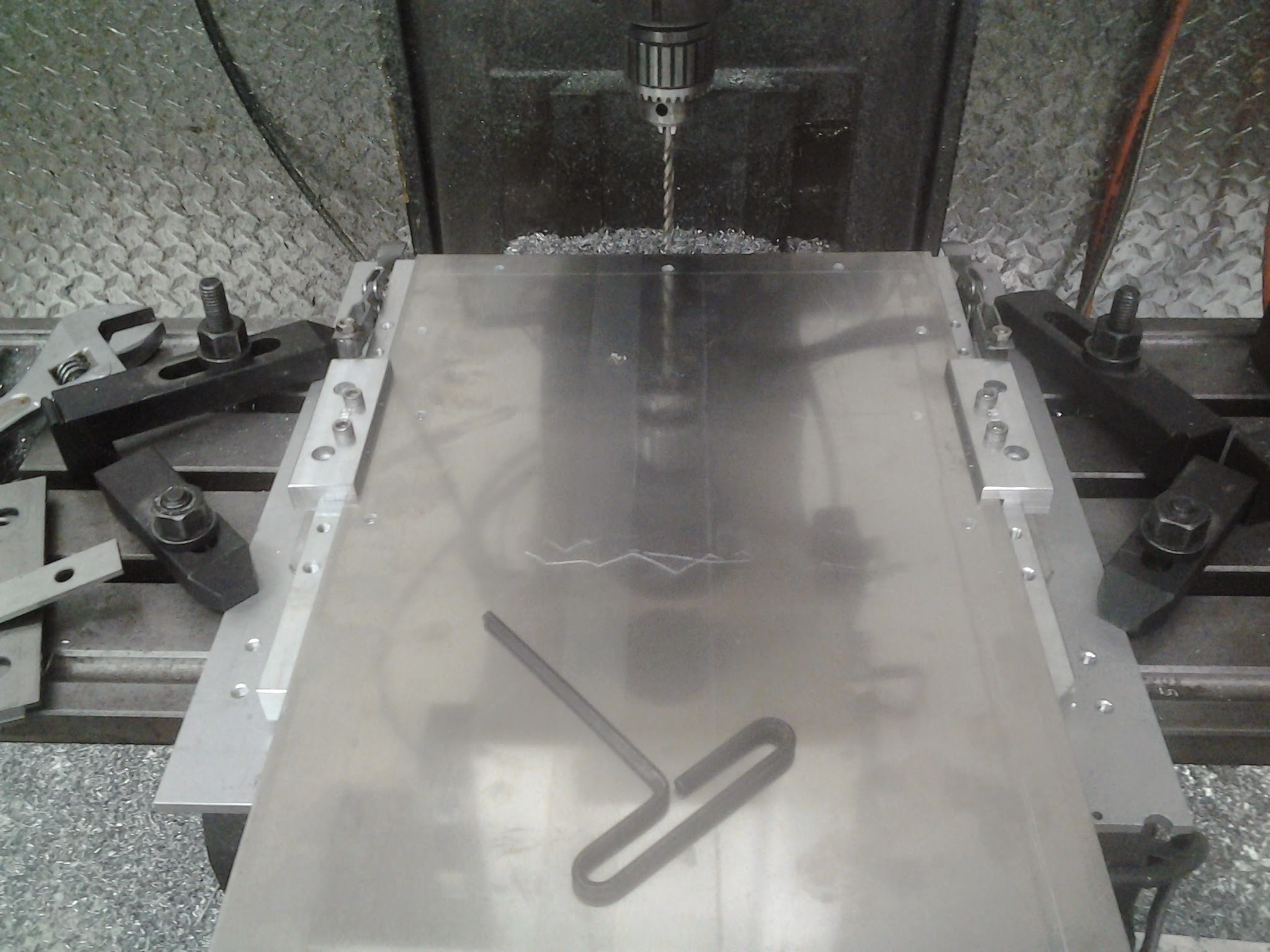

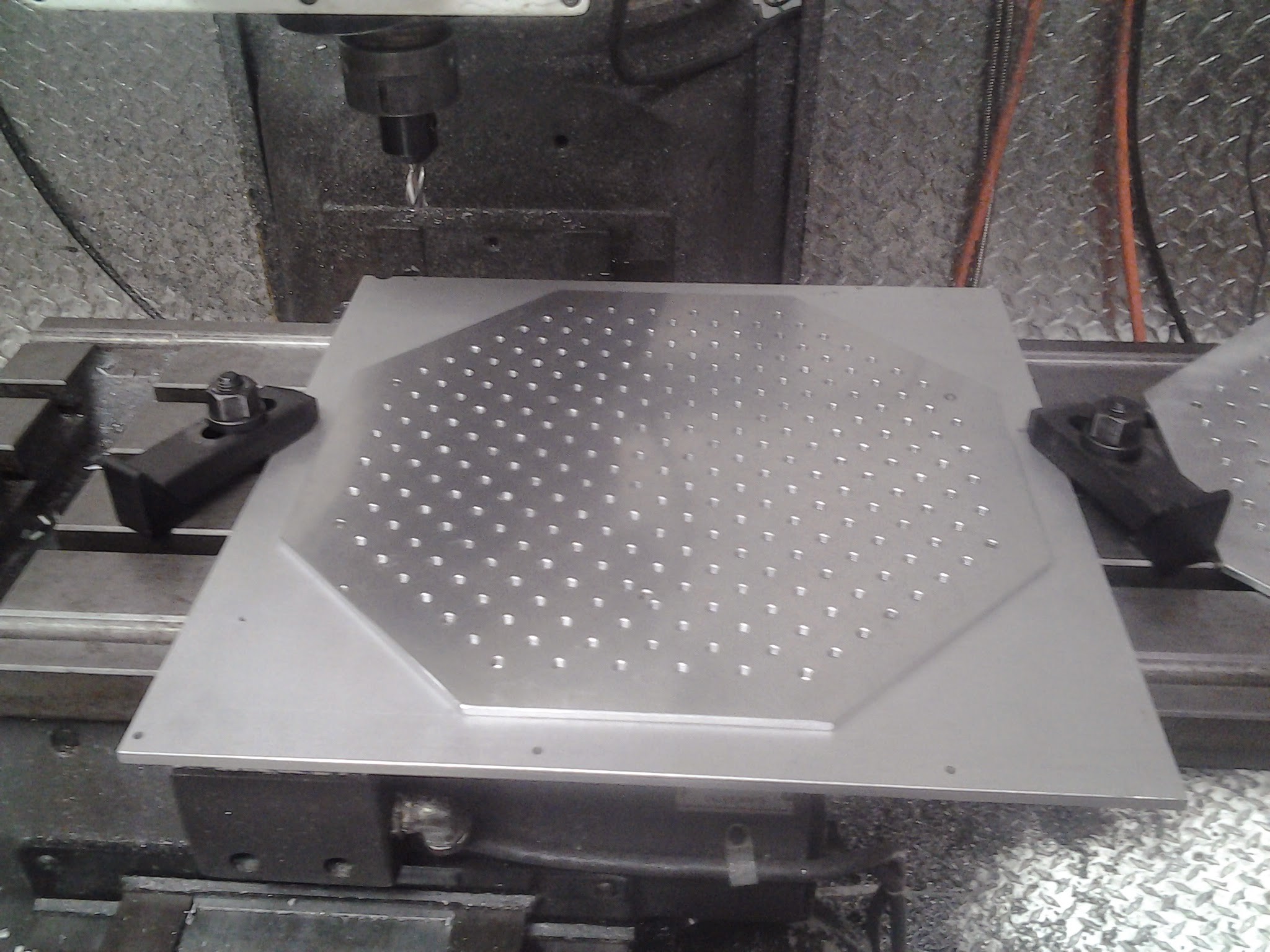

Additionally, I have part of a Cube mounted on a CNC milling machine to test out and expand the modular fixture setup, and I am using the fixture to make cube parts and plan sequencing for said parts (some require multiple setups, g-code, and tools.

I feel that this only the tiniest of preliminary steps, since there is an open field for application, since many of the projects I see on Hackaday could be made into automation templates and created semi-automatically on a CubeSpawn array.

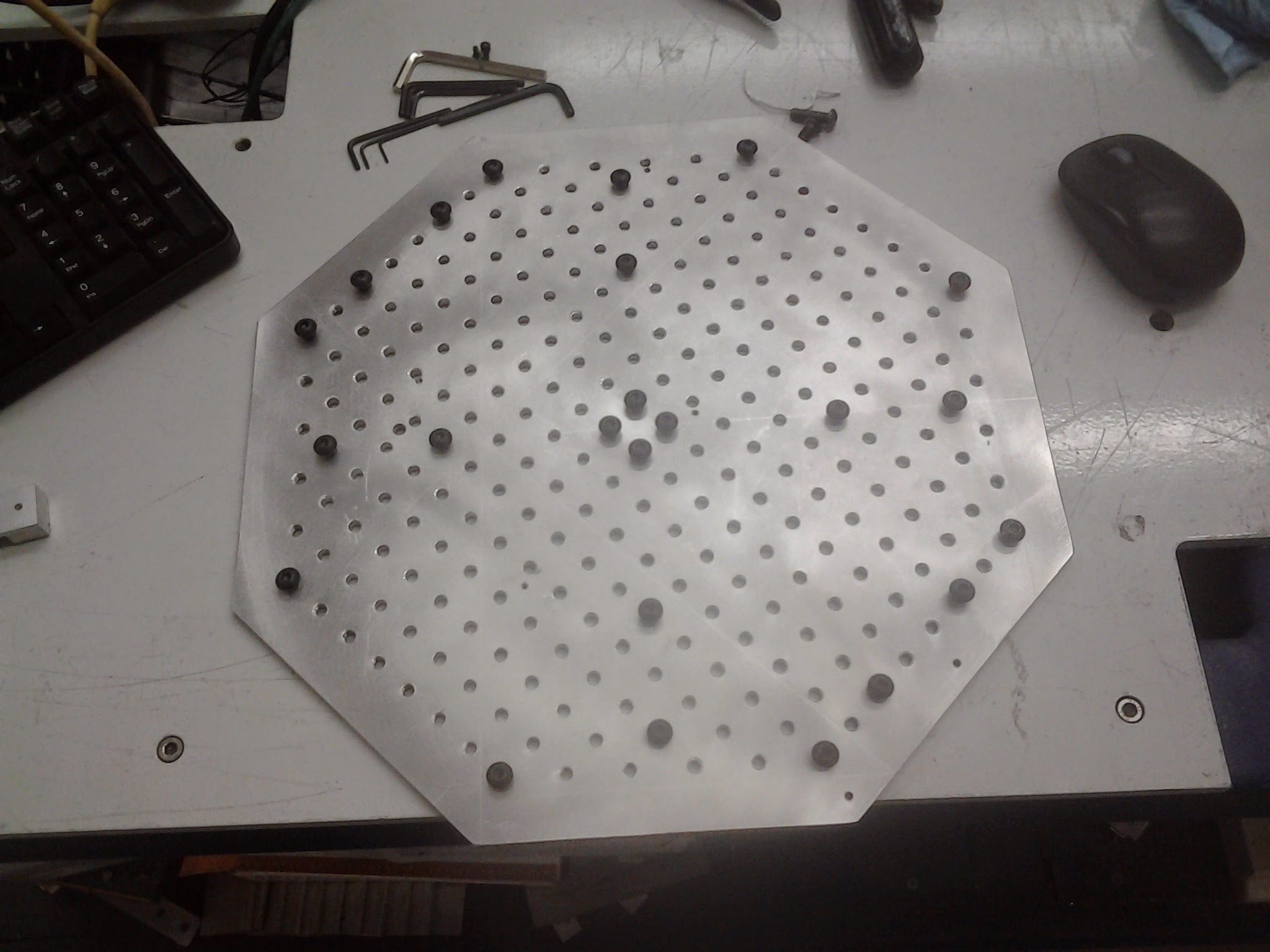

Some fixture parts

Making Cube side panels on the modular fixturing

-

Modular Fixturing Progress

04/21/2015 at 17:50 • 0 commentsWhile the main Focus has been on the 3D printers Hot-End, while waiting for parts I put together a few more pieces of the Modular Fixture for the Milling Cube:

the 350mm Pallet, indexed on 4 pins to a 400mm Base-plate, I'll mount the clamps next to be able to swap plates out for multiple operation machining and 3D printing fixtures.

An automatic fixturing cube is partially designed to robotically set-up fixturing to turn stock into parts.

In the Cube mill, the Base-plate will be a part of the machine more pix here:

https://picasaweb.google.com/103828779781480193226/DougsShopPhase2?noredirect=1#6140248481839799042

Feedback appreciated!

-

Slow but steady

04/17/2015 at 02:10 • 0 comments -

Much Progress, few updates

03/18/2015 at 14:24 • 0 commentsI have been trying to ping all the relevant components to the central idea:

So I added a post to the Ethereum discussion:

And the latest pics are here:

https://picasaweb.google.com/103828779781480193226/DougsShopPhase2?noredirect=1#

Couple of short video's to the Youtube channel also

https://www.youtube.com/channel/UC_pD1fekqXGpVXcshxrsQRQ

N Joy!

feedback appreciated!, help, even more so.

-

Belated updates

02/06/2015 at 17:02 • 0 commentsI have not invested much time in updates, instead choosing to focus on getting some hardware up and running, a sponsor has given me the run of a fairly complete machine shop, but its about 3 hours away from home, so it requires some planning...

--> the latest is to get the 3D printer module running and implement a working backplane:

Getting close to a generally usable design for the light milling machine, a "heavy" mill and a lathe... stay tuned

-

Where the Action is...

08/22/2014 at 00:30 • 0 commentsI will be putting a lot of the documentation here: goo.gl/MO0sta

CubeSpawn Ultimaker 3D Printer Module

and here: goo.gl/7BaBIh

CubeSpawn 3 Axis Mill Module

CubeSpawn

Open Source, Modular, Flexible Manufacturing System "We are to Manufacturing, What the PC was to Mainframes"

CubeSpawn

CubeSpawn