RPM9001 - Rapid Prototyping Machine

CNC machine with swapable tool heads for rapid prototyping, built as inexpensive as possible.

CNC machine with swapable tool heads for rapid prototyping, built as inexpensive as possible.

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

CoreXY_V2.123dxVersion 2 of the design, work in progress- 506.58 kB - 01/11/2018 at 16:03 |

|

|

CoreXY Frame.123dx3d model of the design- 535.52 kB - 09/20/2017 at 10:20 |

|

|

CoreXY Frame Printed Parts.stlall printed parts arranged in the optimal orientation for 3d printing- 5.46 MB - 09/20/2017 at 10:20 |

|

|

CoreXY Frame Printed Parts.123dxall printed parts arranged in the optimal orientation for 3d printing- 424.52 kB - 09/20/2017 at 10:20 |

|

|

CoreXY Frame Baseplate.svgvector image of the baseplate for cutting on a cnc routersvg+xml - 43.45 kB - 09/20/2017 at 10:20 |

|

|

Just a quick one to show the result of the latest test.

This time I tried to engrave a simple design into wood. Here's the result:

Please keep in mind that this is basically my first time using a mill.

The feed was set way to high, but I'm impressed that it didn't lose any steps.

Another thing that gets more and more clear as this project advances is that it needs some sort of auto Z calibration. For a decorative design like this it's no big deal if one side is 0.5mm higher than the other, but for technical parts or milling PCBs this makes a huge difference.

I know that Marlin has this feature, but it's used to calibrate on the entire working area, not just on the actual work pice. Estlcam would have this feature, but it's not working with CoreXY designs.

If anyone knows a solution for this please let me know :)

Just a quick update, I did a small test with the milling head this weekend.

Sadly I only had the time to do a quick test with styrofoam, because I had to reprint a part that took 11 hours.

This is the result of the test:

The cuts look pretty good and the mill ran very quiet, I hope it works as well with wood and other materials...

There's not much to say other than RPM9001 is up and running! :D

And here you can see it in action:

There's still a huge amount of work to be done, for example this is what the electronics look like right now:

I'm so happy that it's working so good so far :)

Next log should be about the first tests with the milling head and cleaning everything up.

This weekend did not go as planned, there were a bunch of setbacks...

First of all, I'm still waiting on the Z-axis stepper motor, but that should goefully arrive this week.

What should have just a quick test of the firmware and the X- and Y-axis turned into a 6 hour long bughunt. I first tried GRBL, but it turns out that nobody got GRBL running on an Arduino Mega 2560 with a CoreXY configuration. You can choose 2 of those 3 things and have it running in a couple of minutes, but for some reason all 3 is impossible...

After about two hours I gave up with GRBL and instead installed Marlin, which worked on the first try, but seems to have less smooth motor movements. And for the next 2 hours I was trying to figure out why only one of my steppers was turning.

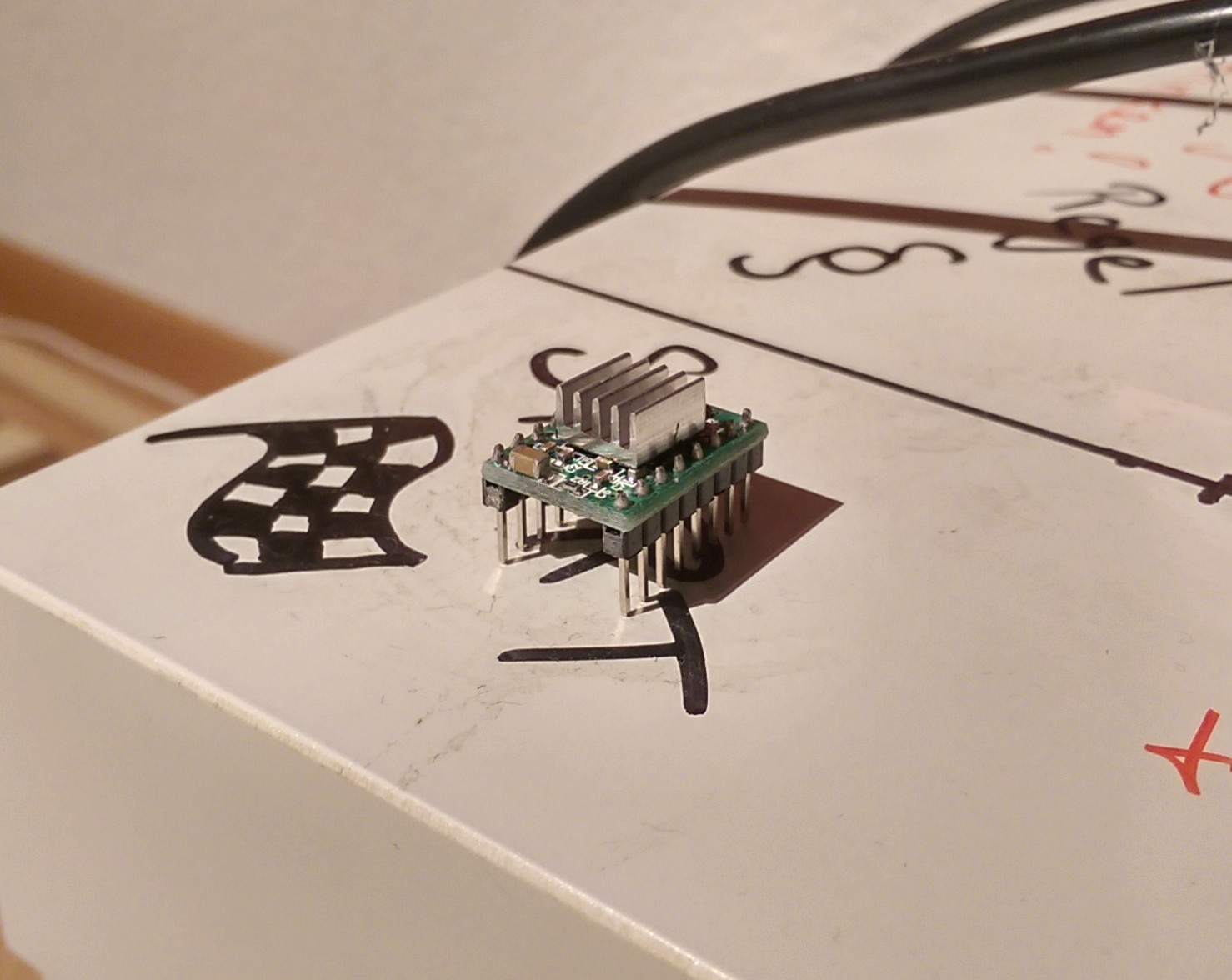

And this was the cause:

One of my stepper drivers was dead on arrival!

One of my stepper drivers was dead on arrival!

At this point I was ready to throw the electronics against a wall and felt extremely stupid that it took me this long to find the problem, but I wasn't done yet. With both motors now running I realised that they were stuttering and seemed to move too much. After quadruple checking my calculations for the steps/mm settings and everything else I gave up and went over to my girlfriend.

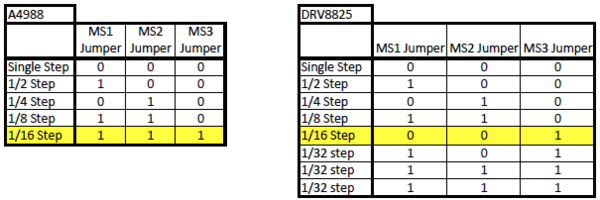

We talked it over and came to the conclusion that my calculations were correct, and she had the idea that the microstepping jumpers were set wrong. I wasn't convinced about this but said "sure, why not, I'm gonna test that tomorrow...".

Turns out she was right.

When I looked up the jumpers on a Ramps 1.4 board I found the table on the right, without the "DRV8825" label and assumed this was correct for all stepper drivers. Moral of this lection? Don't assume stuff and double check your sources...

When I looked up the jumpers on a Ramps 1.4 board I found the table on the right, without the "DRV8825" label and assumed this was correct for all stepper drivers. Moral of this lection? Don't assume stuff and double check your sources...

Lastly I couldn't make the baseplate to mount everything to because of all the lost time. My local makerspace is only open on wednesday and saturday, so I hope I can go there today or next saturday...

Now to the good news:

All the parts that I had to reprint are printed, and the quick swap system works fine and seems to be very riggid!

The "universal toolholder" with a pen.

And the part that I'm most proud of so far:

I couldn't find a solid 5mm to 8mm coupler, so I made one myself :D

The last time I worked on a lathe was about 8 years ago, so I think it turned out pretty decent :)

A flexible coupler would have been too weak for my design, but this should do the trick.

That's it for this update, if anyone knows how to get GRBL working with a Arduino Mega + Ramps + CoreXY, or how to get smoother movement out of Marlin, please let me know.

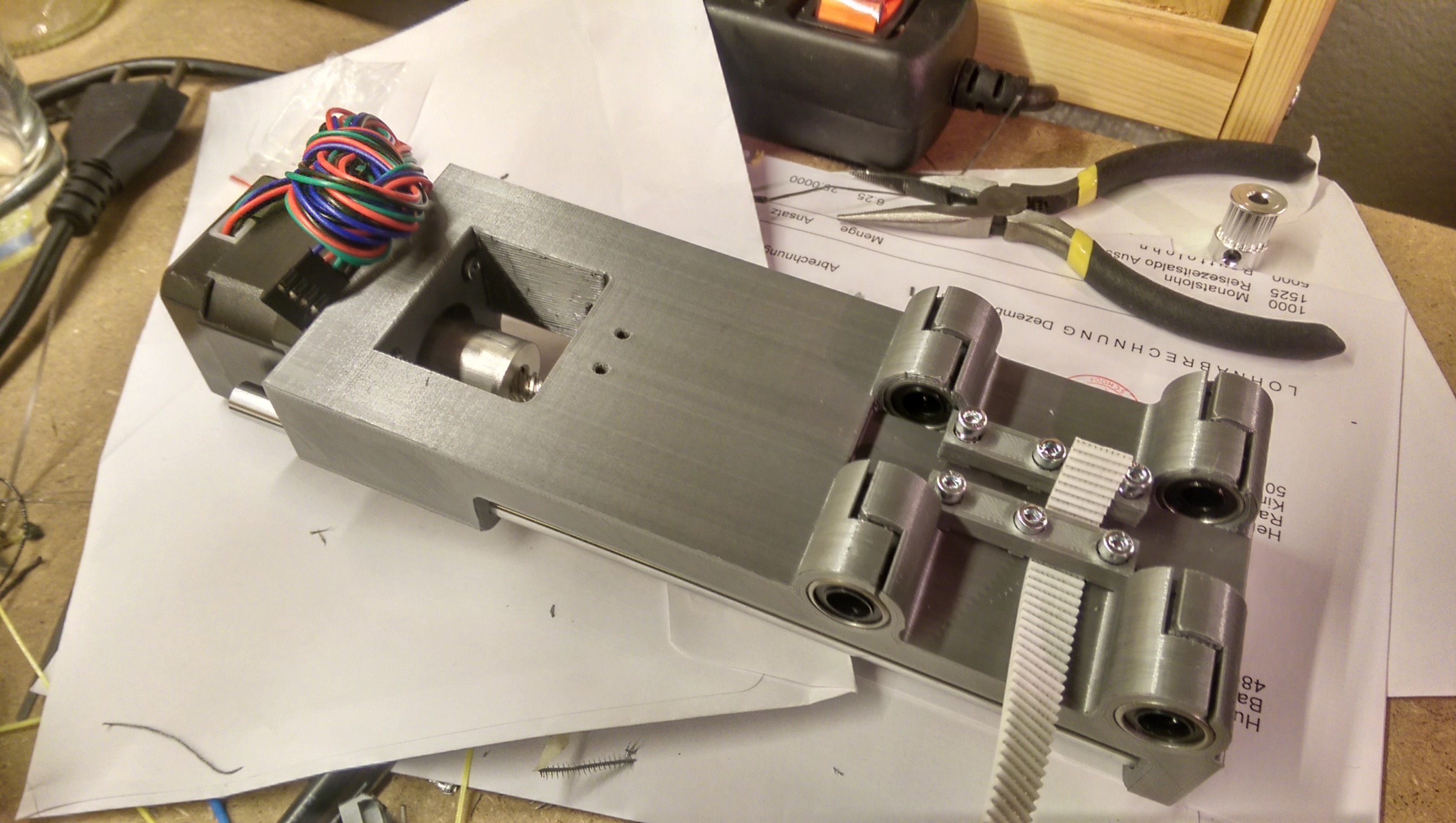

Most of the parts that I ordered from aliexpress have arrived (still waiting for some Z-axis parts) and I printed about 50% of the 3d printed parts, so I thought it's time for a test assembly.

Here are the results:

X-Carriage turned out great, except for the Z endstop, which would get in the way of the nut... I have to find another place to mount it.

Back of the X-Carriage, clamping mechanism for the belts works great!

Everything that I can put together so far. I found some small changes that I need to make, which hopefully won't result in me having to reprint almost everything. It seems to have only a small amount of flex which stems from the long smooth rods and not the 3d printed parts.

Overall I'm happy so far and hope to have all the parts ready to assemble this weekend :)

Create an account to leave a comment. Already have an account? Log In.

Become a member to follow this project and never miss any updates