-

log 5: Jerky and kumquats

01/05/2018 at 05:20 • 0 commentsI tried making jerky a couple times. It works great. I have to keep an eye on the drying times because I think I over dried it and it was way tough and not very flexible. Then again, it might be my recipe or the cut of meat that needs changing. I wish I could go to the store an buy a nice flank steak, but that is not the case in these lands.

I also dried a bunch of kumquats cut in half. I left them in for almost 15 hours and although the outside is completely desiccated to the point of being crisp, there is still lots of juice locked away in the deeper parts. I think they need to be prepared differently. I don't want to make slices because they are already so small to begin with, but I can't think of another way to expose the wet parts.

-

log 4: heater power comparison

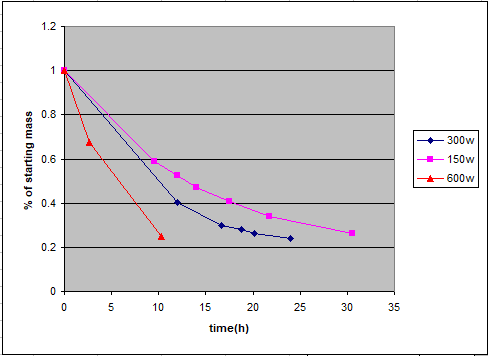

10/28/2017 at 09:08 • 1 commentData has arrived! The persimmons are ripening and the experiments are taking place. The first series of tests were using different heater power levels, 150W, 300W and 600W. Note that most commercial dehydrators of this size use around 1kw, but they also heat the food more than I would like, which kind of cooks it and changes the nature of it.

I will first apologize for my lack of scientific rigor. The amount of fruit was not kept consistent between tests because my supplies vary and it just takes so much time to do a batch. There were long periods of no measurements due to me being asleep. Also, I did not measure the temperature, which is an important parameter. Having said that, here is the result of the first three tests.

One cool thing to point out is that the 600W test was drying 999g of fruit. After just 2.7 hours it was down to 672g. That means I evaporated 327g of water in just 2.7 hours. That's almost a full can of beer. In total it evaporated 749g, or about 75% of the mass, in 10.3 hours. I suspect it got to a good level of dryness earlier, but I lack data points due to being asleep.

So how about energy use:

- 600W for 10.3h = 6.18kWh

- 300W for 25h = 7.5kWh

- 150W for 36h = 5.4kWh (It looks like it would take about 36 hours to get to the same dryness)

Considering time required, the clear winner is the 600W version.

-

log 3: Second test - more power, more flow

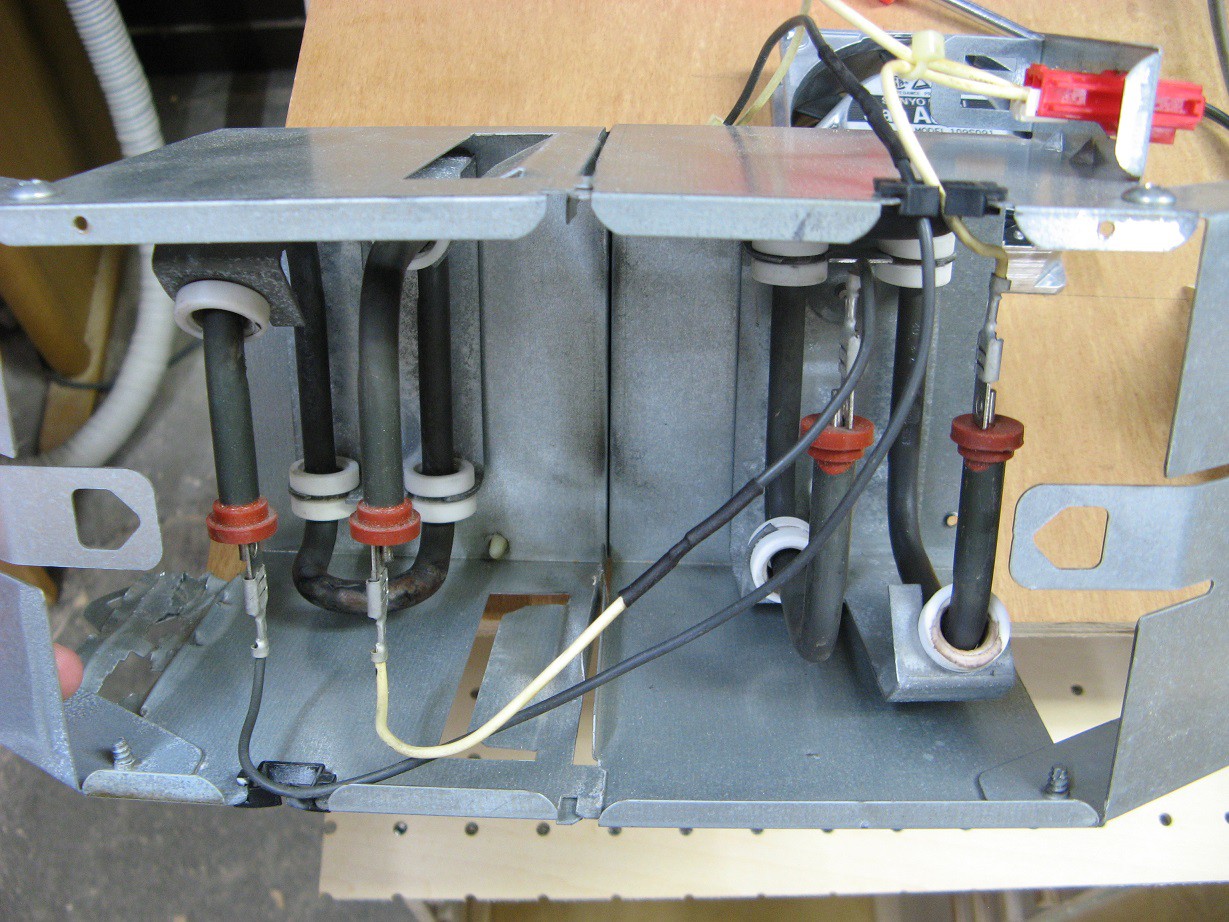

10/16/2017 at 07:32 • 0 commentsThe 150w heater was rewired to make it 300w. Here's a look inside the heater(before the change) to show you how easy that was to do. I just moved one wire and it now only powers one of the elements.

Then I replaced the filter with window screen to increase flow. Once I get a less restricting filter made, I'll change this. Now we're ready for test two.

The air coming out is now significantly warmer, but not hot. The flow rate is also much higher. I think if I left on the more restricting filter the air would be much warmer still. I may keep that in mind for a future test.

Yes, I know I would need to dry more persimmons to properly compare this test to the last, but there are no more ripe ones on the tree yet, so I used an apple. Again it was sliced to about 7mm and placed on the second from bottom rack. About 20 hours later the slices were nicely desiccated. They were about 2mm thick with a flexible leathery feel. Again, I can't properly compare the drying performance with different fruit, but it does seem faster. On the other hand, it uses twice as much power.

Testing Plan - Science is good, so I'll have to set up some proper experiments. Once the persimmons ripen and I have buckets full of them, which is one of the reasons I wanted a dehydrator in the first place, I'll do some proper comparisons using a scale to measure moisture loss over time with different configurations. We'll just have to wait a few more weeks. In the meantime, here is an apple.

-

log 2: notes and ideas

10/15/2017 at 00:46 • 0 commentsI let the first test fruits dry over one more night bringing the run to about 36 hours. However, I didn't notice much of a change over the last 12 hours, so the fruit was pretty much finished drying in 24 hours. Commercial units claim to work faster(nesco dehydrator manual), so I think there is room for improvement. First I'll list some observations, then some changes I'd like to try.

- The heater was probably under powered because the air coming out was just barely warmer than ambient and the inside of the box was only heated maybe one or two degrees.

- The fruit on the lower rack seemed to dry a little faster. Maybe it's because it was a little warmer close to the heater, or maybe it's because the air passed over it first. Anyway, the difference wasn't so dramatic.

- The filter was more restricting than I would like. There was a very big difference in flow with the door oven vs. closed. I think that more air flow would greatly improve drying ability, but would also make it less efficient to heat. There's probably an ideal balance that could be found with experimentation.

Here are some things I want to change for the second test.

- Double the heater power. The 150w heater is actually two 300w elements in series, so I'll just move the wires to only use one. Heat transfer won't be as good, but it might work well enough. Another idea would be to use a couple big diodes to send half the AC wave through one element and half through the other. Then I would have 300w with all of the element surface area.

- A much less restrictive filter. A piece of window screen would keep out the bugs and big stuff, but dust would go right through. If I use the same filter element(one ply of a surgical mask), but with a much larger surface area, I would get more flow and good dust filtering. Unfortunately This would require an attachment that would increase size and complexity. Ultimately I would like to go with the attachment, but temporarily I will put on a screen.

To summarize, I will rewire the heater to use 300w and temporarily replace the filter with window screen.

-

log 1: First test food

10/14/2017 at 14:05 • 0 commentsLast night I went out to the garden and found two almost ripe persimmons for this test. They were cut into discs about 7mm thick. Some pieces were placed on the second to top rack and others on the second to bottom. This was to see if they dried at different rates in different places. I checked the progress several times over the last 24 hours and I'll discuss my observations in the morning(I'm having a hard time keeping my eyes open), but here is the result of one day of drying.

Can you see that? That's some dehydrated persimmon. Also known as success.

I was right. It really is that simple. Those ones for sale really are too expensive. I need to investigate this further and spread what I learn. This project might... matter. Alright, I'm throwing it into the HaD prize.

Food dehydrator - simple and cheap

Food dehydrators are conceptually very simple. Let's see if they are that easy in practice.

shlonkin

shlonkin