This is the successor of #vapsy and hopefully it will be better.

First things first, I need concepts for a lot of topics:

- safety

- chamber construction

- heating

- insulation

- cooling

- sensors

- control

- user interface

- pcb handling

First of all: safety. After not being too surprised about boiling galden being spilled by #vapsy I will try to keep safety in mind during all stages.

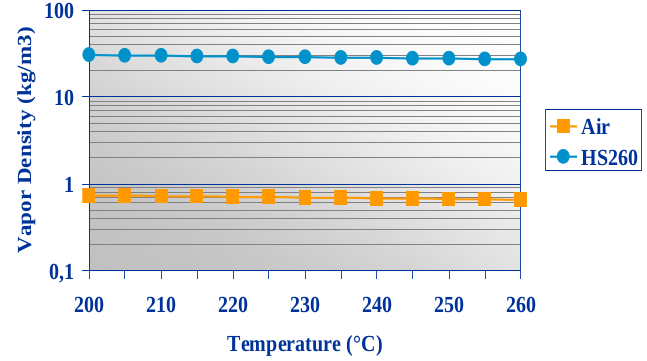

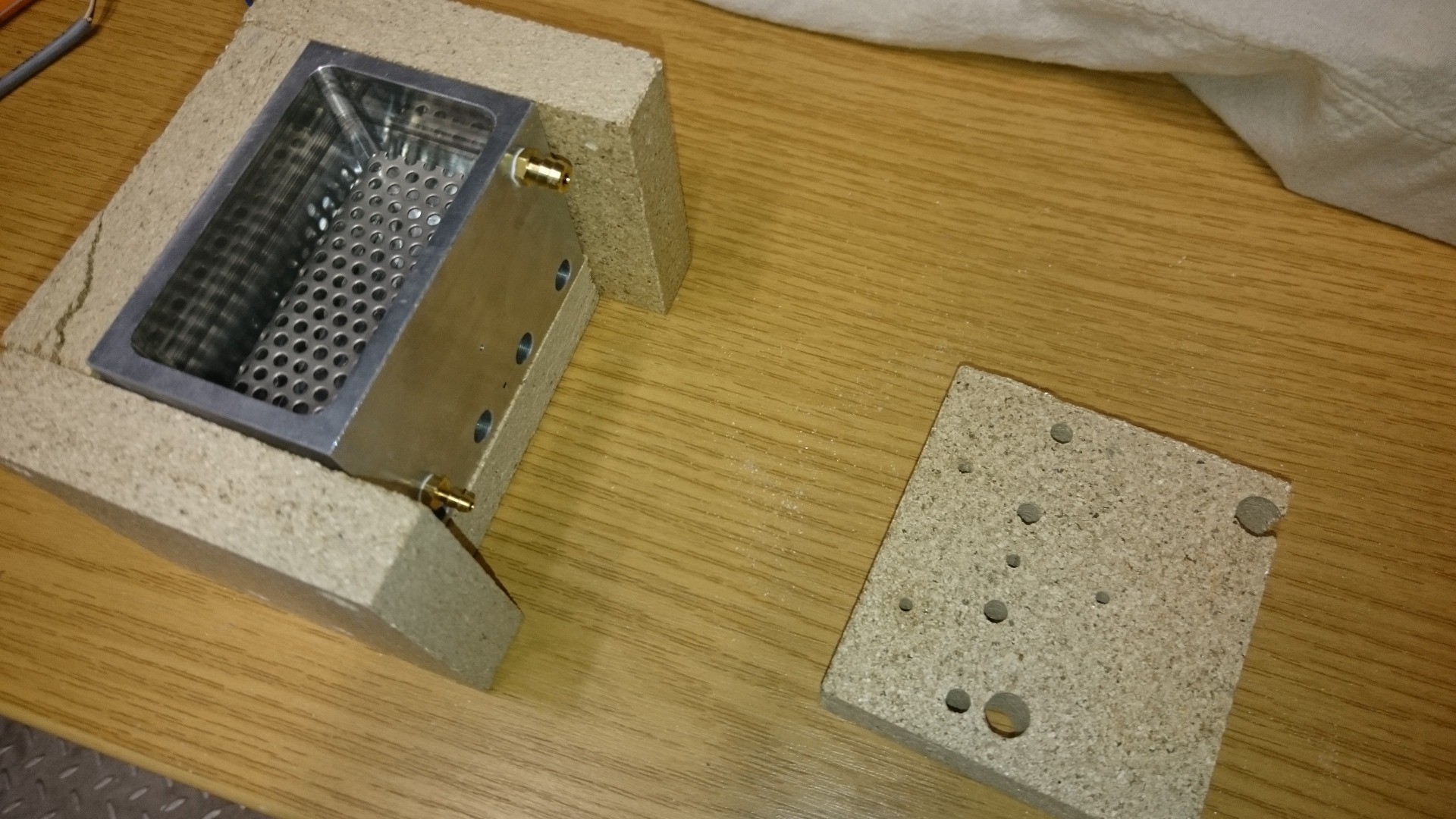

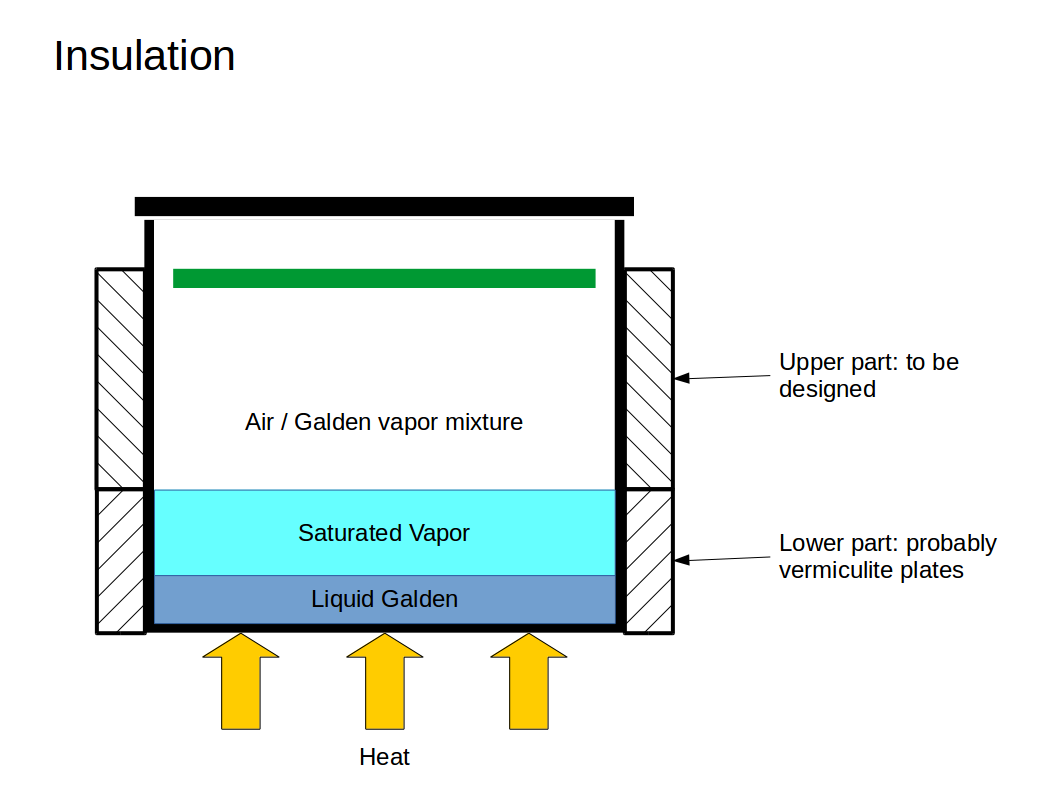

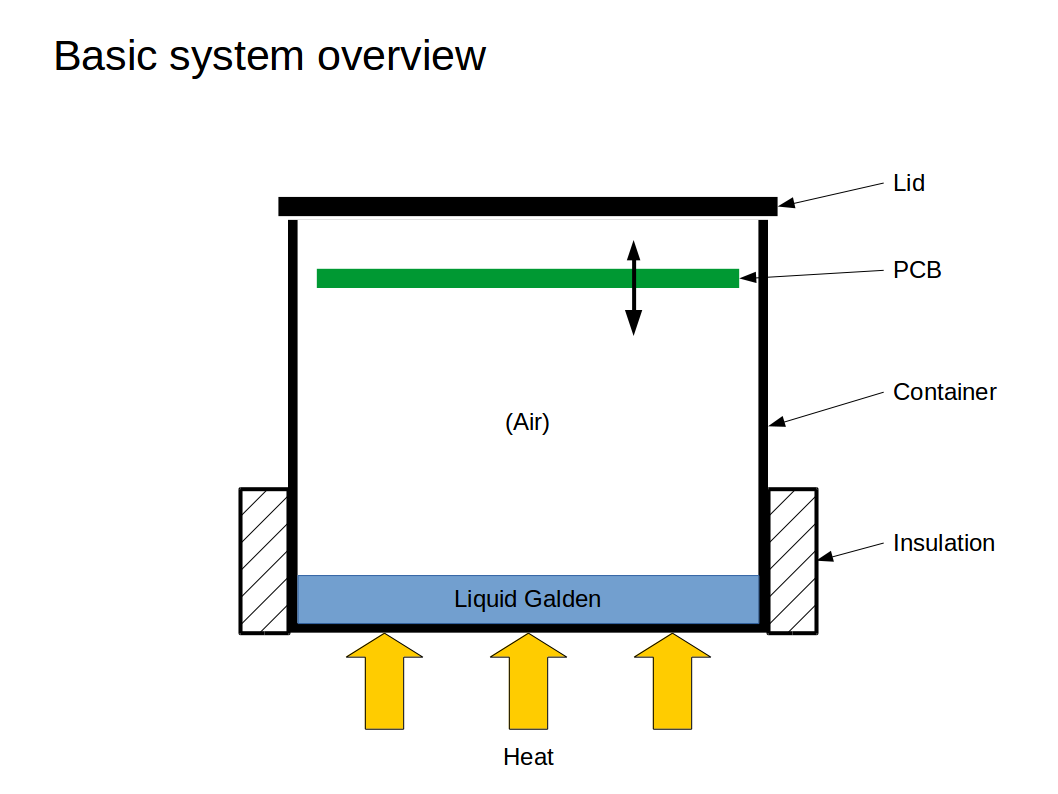

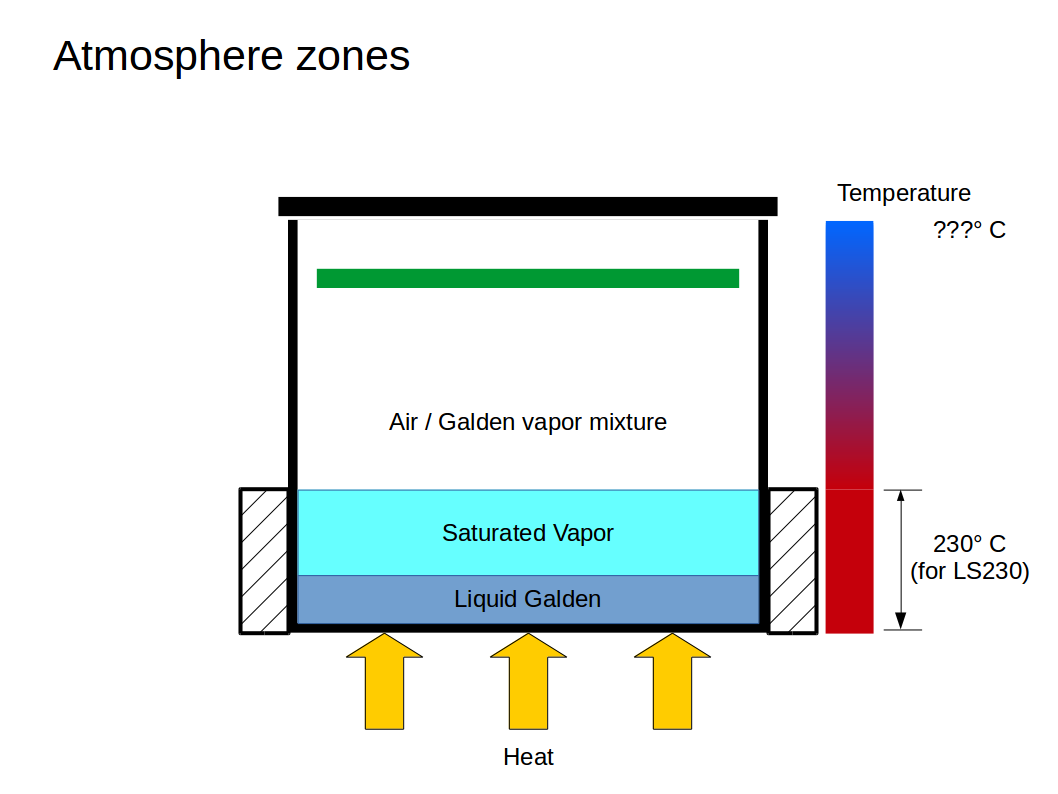

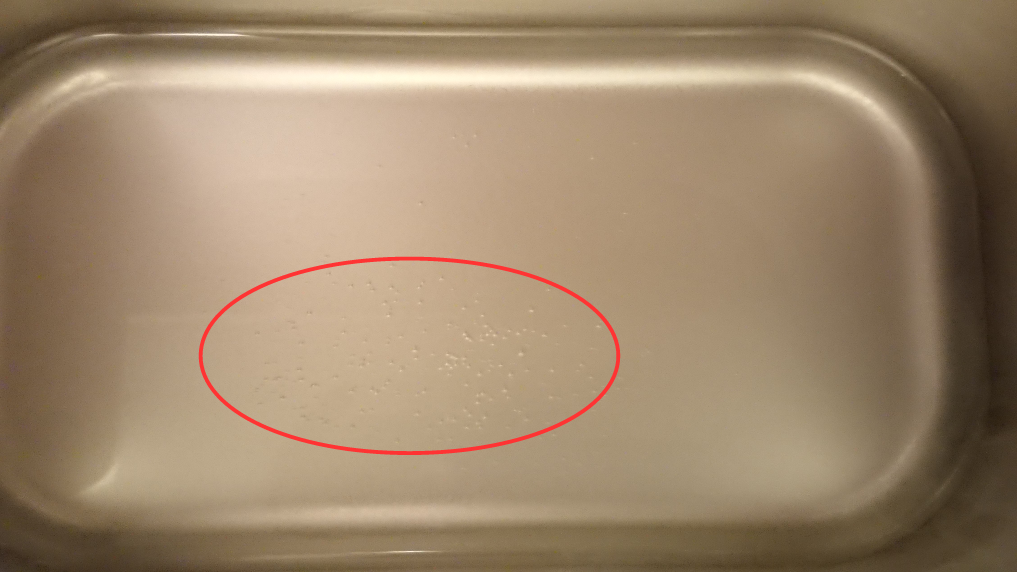

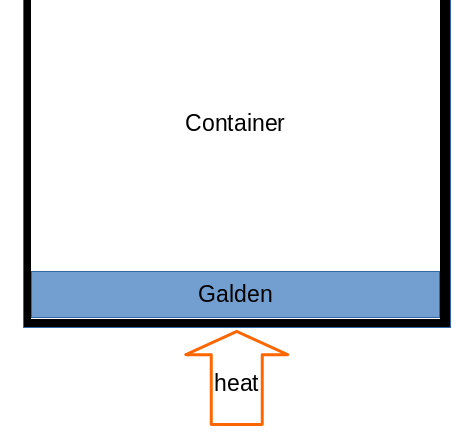

Chamber "construction" was quite an effort in the previous model: a milled aluminum block. The raw part was found in a drawer and already had holes for heaters, so I built the oven around it. Now a mill is not in sight and the raw block for the size of oven I have in mind will most probably not fit in any normal drawer. Something else will have to serve as a base. The chamber should be high in order to have three zones: liquid at the bottom, saturated vapor above that and a vapor/air mix with decreasing vapor content on top.

Heating is closely coupled with chamber construction since low thermal resistance is desired between the heater (however that may look) and the chamber's bottom. The heater(s) can be immersed in galden, which would require a sufficient liquid level. That's probably pretty expensive. Heating from outside can be done with halogen bulbs, a flat heating pad, a stove, a hot air gun - the list of possibilities is long.

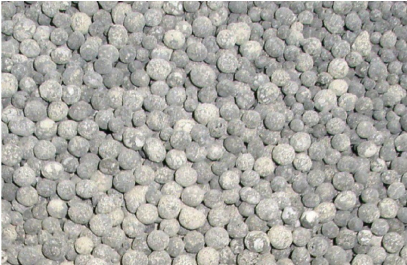

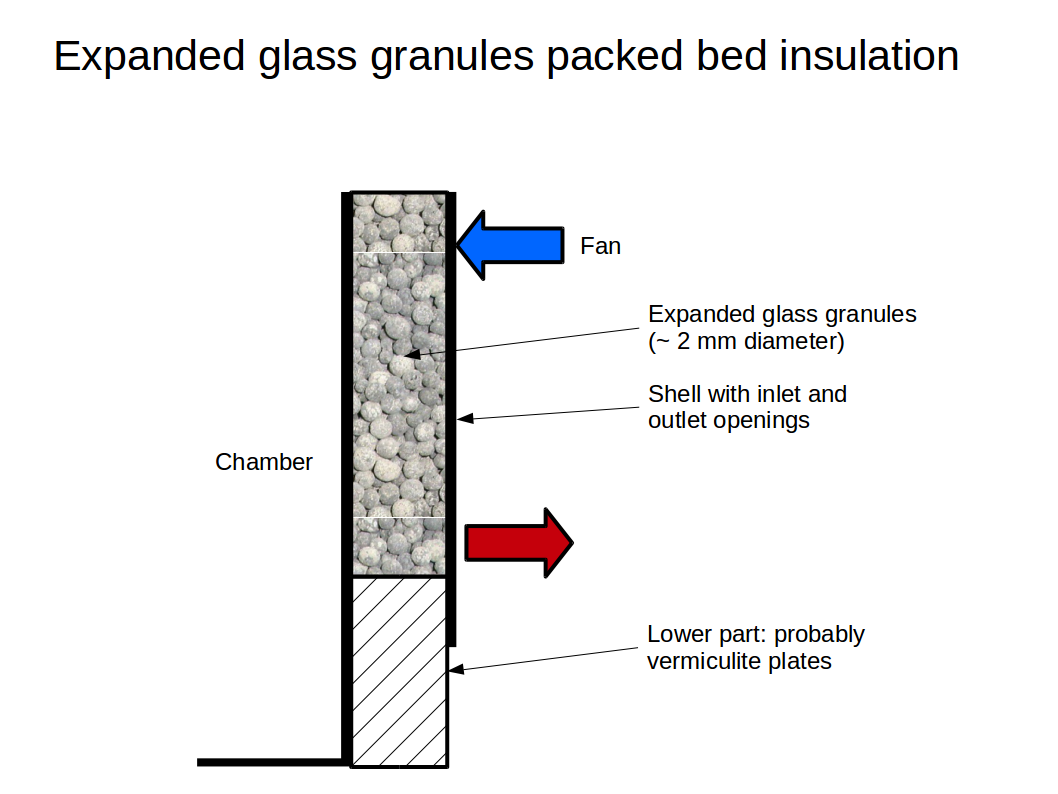

Insulation: Again closely coupled with chamber construction. Insulating a round chamber will call for something more flexible than stiff plates. A rectangular chamber, though, can be insulated with easy to cut (and cheap) vermiculite plates. A solid insulation is not even necessary and might even get in the way: I could build an outer shell around the chamber and fill it with some granular insulation (think expanded glass granules) that can later be cooled with air - maybe an interesting option.

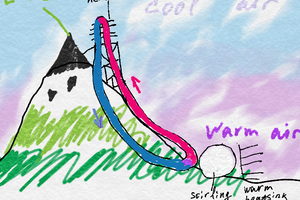

Cooling: When the reflow profile comes to its end it goes down to room temperature again, and the time at reflow temperature shouldn't exceed certain limits. Good insulation will extend the time needed to get out of the reflow zone, so cooling will be an issue.

Sensors: Most sensors will be temperature sensors. I've made good experience with thermocouples and I'll probably stick with them. Maybe even make my own since I have some professional thermocouples to compare them with. Thermocouple wire is cheap.

Control: Should be as simple as possible, but not simpler. A simpler control system is easier implement and check for errors and safety issues. Safety measures must work without a computer attached.

User interface: Not sure yet. touch screen, computer or web interface would be ok.

PCB handling: To get a board into vapsy, I had to grab it with tweezers or whatnot and insert it into the chamber from above. The improved version will have a better way, either from the side or some kind of mechanism to lower boards into the chamber.

Christoph

Christoph

DeepSOIC

DeepSOIC

mr.jb

mr.jb

Andrew Shevchuk

Andrew Shevchuk