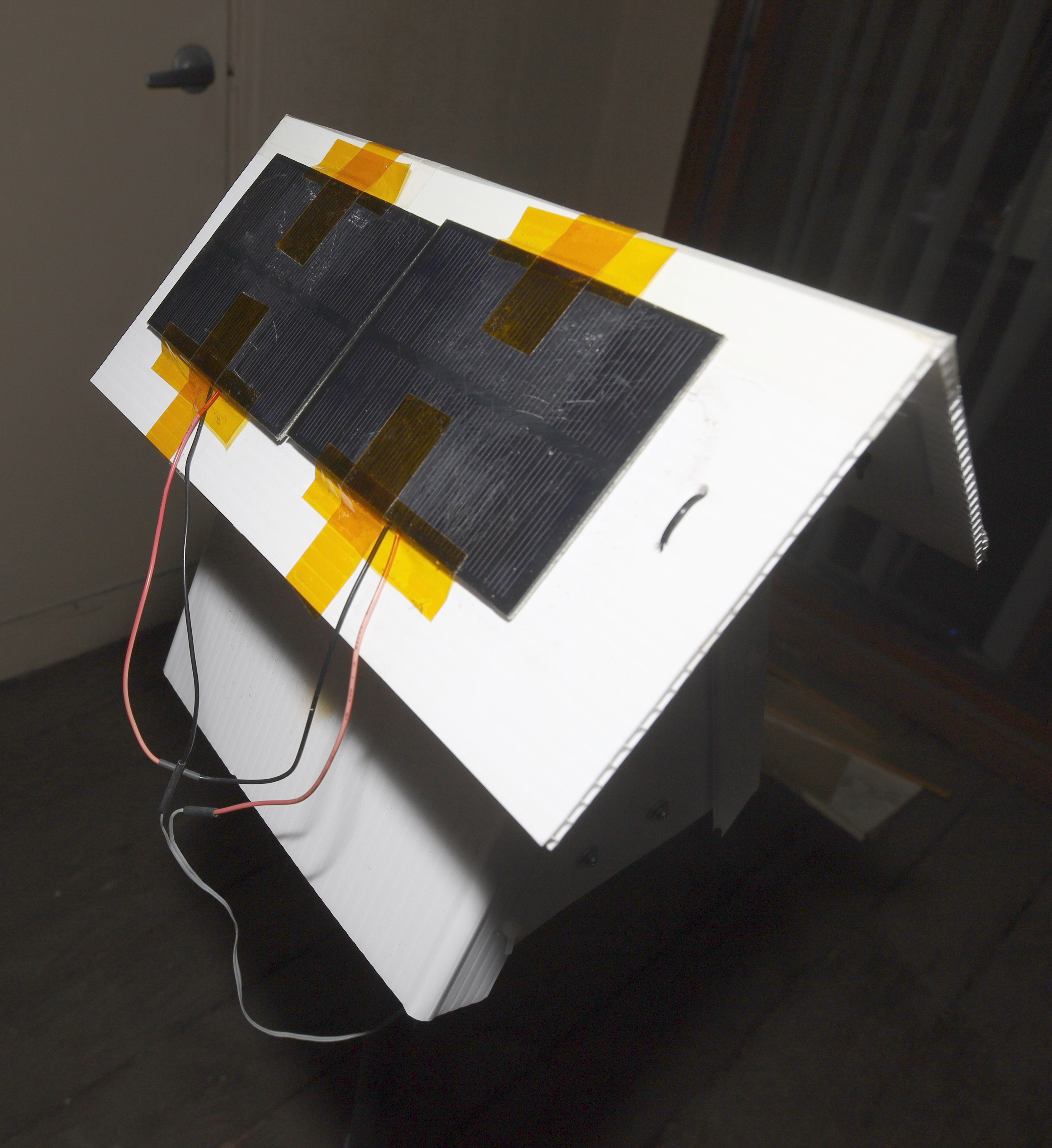

Only 7 months later, the solar panels lay on the floor after their packing tape farsteners decomposed & their hot glue wire harnesses melted.

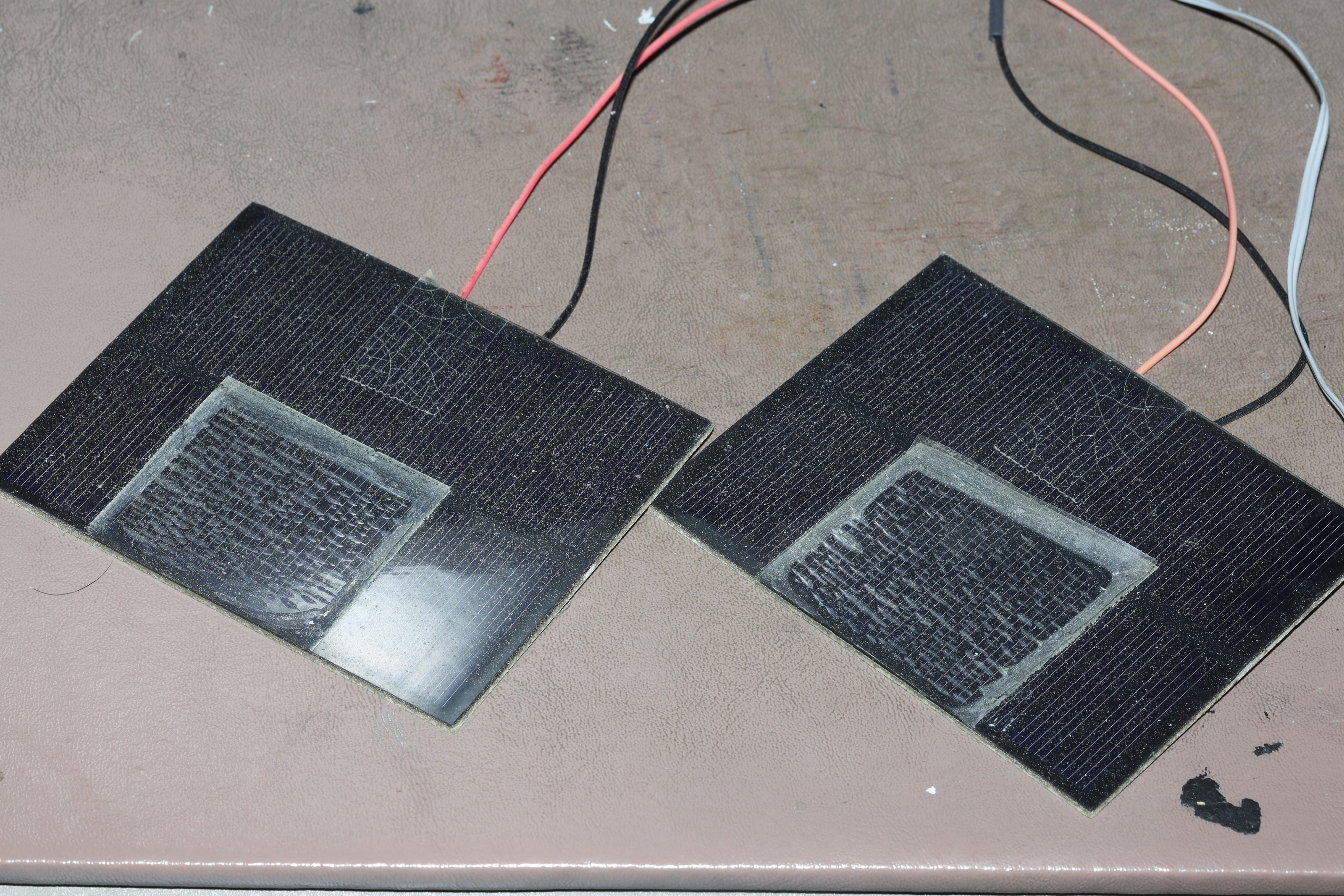

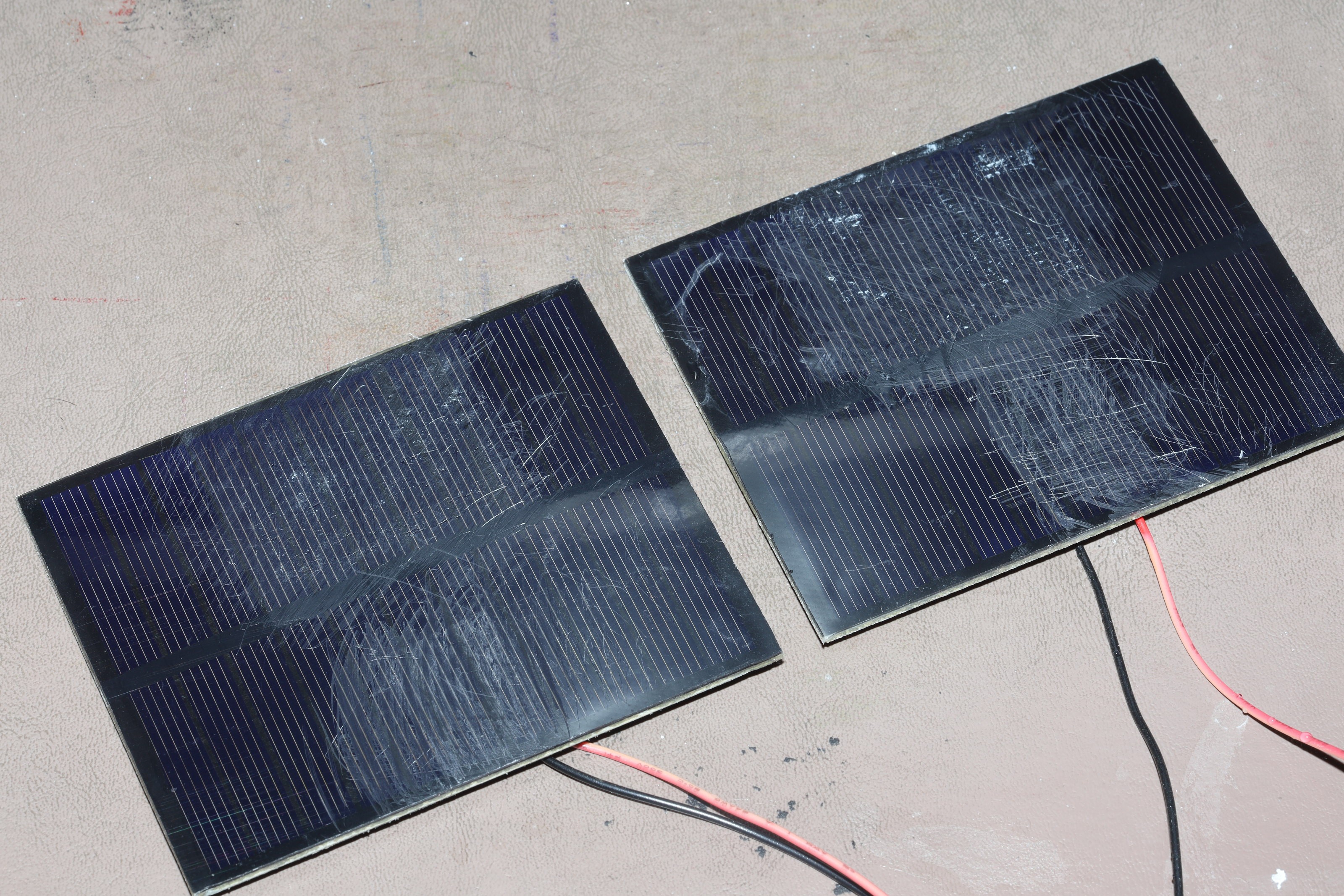

After scraping off the packing tape residue, the panels had bald spots. They weren't glass but epoxy. Scraping off the packing tape scraped off the gelcoat, so they were now less efficient.

So the way the internet farstens solar panels is by putting their wires through holes & hot snotting the holes. Higher end panels are clamped between 2 metal angle rods. Doubt anything besides metal would last.

Tried captain tape to make a short term solution at the expense of efficiency. It didn't stick at all to the coroplastic. It's amazing that the coroplastic & zip ties fended off the Calif* heat, but they haven't experienced the true fury of summer.

This captain tape bodge with the scratched epoxy actually didn't affect the battery voltage. It must be saturating the NiMH's.

Another idea emerged whereby the panels would be under a sheet of acrylic. The acrylic could have some borders made of PETG to retain the panels. Then, captain tape would farsten the panels to the acrylic from the back. Acrylic too would degrade, but might buy more than 7 months until the lion kingdom decided to risk cutting glass again.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.