This is not a super elaborate code that controls the universe and everything.

Instead it's just a very simple piece of code that allows driving a display, debouncing a switch, reading two potentiometers, and drive a relay. That's it.

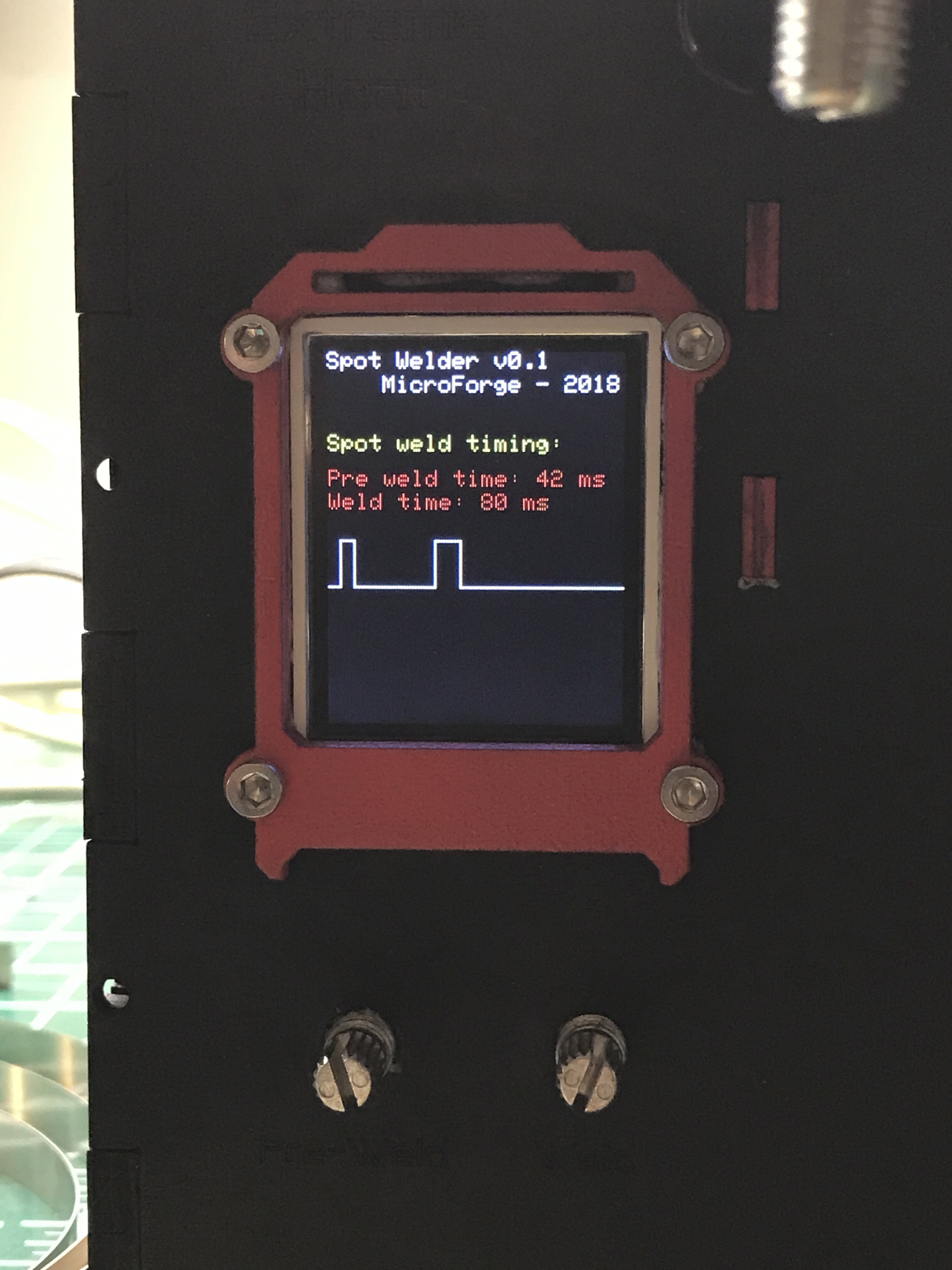

I use busy waiting to execute the read potentiometer values and I use very simple line drawing to visualize the pulse pattern.

I divided the welding process into two steps:

- Pre-welding the material to heat it up, make it soft and establish excellent conductivity between all materials to be welded

- Welding the material together with a potentially longer pulse.

During my initial tests and from what I have read online in several articles, the typical pre weld time is around 50 ms and the typical weld time is around 100 ms. I used this as a base line since most people don't seem to weld with 1750 Watts. I wanted to be able to adjust my welding times between 25 ms and 275 ms by adjusting two potentiometers. I also added a cooldown time in between the two weld actions of 250 ms. That's a pure guess and should have been adjustable with another potentiometer as well but I didn't see the immediate need for it. If you need it, please add a third pot to the code and to your welder. I don't think it's necessary for making battery packs.

#include <Adafruit_GFX.h> // Core graphics library

#include <Adafruit_ST7735.h> // Hardware-specific library

#include <SPI.h>

// For the breakout, you can use any 2 or 3 pins

// These pins will also work for the 1.8" TFT shield

#define TFT_CS 10

#define TFT_RST 9

#define TFT_DC 8

#define TFT_SCLK 13

#define TFT_MOSI 11

#define MINWELDTIME 25

#define MAXWELDTIME 250

#define COOLDOWNTIME 250

#define ADCRESOLUTION 1023

#define GRAPHDIVIDER 7 // devides the values for displaying the graph to something that can be displayed

// use the hardware SPI pins (for UNO thats sclk = 13 and sid = 11) and pin 10 must be an output.

Adafruit_ST7735 tft = Adafruit_ST7735(TFT_CS, TFT_DC, TFT_RST);

// constants won't change. They're used here to

// set pin numbers:

const int buttonPin = 5; // the number of the pushbutton pin

const int ledPin = 12; // the number of the LED pin

const int relayPin = 2; // the number of the relay pin

const int preWeldSensorPin = A0; // the number of the potentiometer ADC pin

const int weldSensorPin = A1; // the number of the potentiometer ADC pin

// Variables will change:

int ledState = LOW; // the current state of the output pin

int buttonState; // the current reading from the input pin

int lastButtonState = LOW; // the previous reading from the input pin

int preWeldSensorValue = 0; // variable to store the value coming from the potentiometer

int weldSensorValue = 0; // variable to store the value coming from the potentiometer

bool redrawGraph = true; // Did we change the times and need to redraw the graphs?

int lastPreWeldTime = 0; // Storage for the previously set weld times

int lastWeldTime = 0; // So that we don't run into flickering numbers on the display

// the following variables are unsigned long's because the time, measured in miliseconds,

// will quickly become a bigger number than can be stored in an int.

unsigned long lastDebounceTime = 0; // the last time the output pin was toggled

unsigned long debounceDelay = 50; // the debounce time; increase if the output flickers

void setup() {

pinMode(buttonPin, INPUT);

pinMode(ledPin, OUTPUT);

pinMode(relayPin, OUTPUT);

// set initial LED state

digitalWrite(ledPin, ledState);

digitalWrite(relayPin, HIGH);

Serial.begin(115200); // opens serial port, sets data rate to 115200 bps

Serial.println("Spot Welder Version 0.1 - Timo Birnschein - MicroForge 2018");

Serial.println("email: timo.birnschein@microforge.de");

displayInitScreen();

}

void loop() {

// read the value from the sensor:

preWeldSensorValue = analogRead(preWeldSensorPin);

weldSensorValue = analogRead(weldSensorPin);

// Read analog signal to determine time to weld

int preWeldTime = (int)((float)MINWELDTIME + (((float)MAXWELDTIME / (float)ADCRESOLUTION) * (float)preWeldSensorValue)); // Scale 10 bit value to something with an offset

int weldTime = (int)((float)MINWELDTIME + (((float)MAXWELDTIME / (float)ADCRESOLUTION) * (float)weldSensorValue)); // Scale 10 bit value to something with an offset

// Check for errors

if (preWeldTime <= 0) preWeldTime = (float)MINWELDTIME;

if (weldTime <= 0) weldTime = (float)MINWELDTIME;

if ((preWeldTime > (lastPreWeldTime + 1)) || (preWeldTime < (lastPreWeldTime - 1)))

{

redrawGraph = true;

}

if ((weldTime > (lastWeldTime + 1)) || (weldTime < (lastWeldTime - 1)))

{

redrawGraph = true;

}

if (redrawGraph == true)

{

redrawGraph = false;

String strBuffer = String(" " + String(lastPreWeldTime) + " ms");

tftPrintText(strBuffer, 0, 50, 1, ST7735_BLACK);

strBuffer = String("Pre weld time: " + String(preWeldTime) + " ms");

tftPrintText(strBuffer, 0, 50, 1, ST7735_RED);

strBuffer = String(" " + String(lastWeldTime) + " ms");

tftPrintText(strBuffer, 0, 60, 1, ST7735_BLACK);

strBuffer = String("Weld time: " + String(weldTime) + " ms");

tftPrintText(strBuffer, 0, 60, 1, ST7735_RED);

tft.drawFastHLine(0, 100, 6, ST7735_BLACK);

tft.drawFastVLine(5, 80, 20, ST7735_BLACK);

tft.drawFastHLine(5, 80, (lastPreWeldTime / GRAPHDIVIDER), ST7735_BLACK);

tft.drawFastVLine(5 + (lastPreWeldTime / GRAPHDIVIDER), 80, 20, ST7735_BLACK);

tft.drawFastHLine(5 + (lastPreWeldTime / GRAPHDIVIDER), 100, (COOLDOWNTIME / GRAPHDIVIDER) + 1, ST7735_BLACK);

tft.drawFastVLine(5 + (lastPreWeldTime / GRAPHDIVIDER) + (COOLDOWNTIME / GRAPHDIVIDER), 80, 20, ST7735_BLACK);

tft.drawFastHLine(5 + (lastPreWeldTime / GRAPHDIVIDER) + (COOLDOWNTIME / GRAPHDIVIDER), 80, (lastWeldTime / GRAPHDIVIDER), ST7735_BLACK);

tft.drawFastVLine(5 + (lastPreWeldTime / GRAPHDIVIDER) + (COOLDOWNTIME / GRAPHDIVIDER) + (lastWeldTime / GRAPHDIVIDER), 80, 20, ST7735_BLACK);

tft.drawFastHLine(5 + (lastPreWeldTime / GRAPHDIVIDER) + (COOLDOWNTIME / GRAPHDIVIDER) + (lastWeldTime / GRAPHDIVIDER), 100, COOLDOWNTIME, ST7735_BLACK);

tft.drawFastHLine(0, 100, 6, ST7735_WHITE);

tft.drawFastVLine(5, 80, 20, ST7735_WHITE);

tft.drawFastHLine(5, 80, (preWeldTime / GRAPHDIVIDER), ST7735_WHITE);

tft.drawFastVLine(5 + (preWeldTime / GRAPHDIVIDER), 80, 20, ST7735_WHITE);

tft.drawFastHLine(5 + (preWeldTime / GRAPHDIVIDER), 100, (COOLDOWNTIME / GRAPHDIVIDER) + 1, ST7735_WHITE);

tft.drawFastVLine(5 + (preWeldTime / GRAPHDIVIDER) + (COOLDOWNTIME / GRAPHDIVIDER), 80, 20, ST7735_WHITE);

tft.drawFastHLine(5 + (preWeldTime / GRAPHDIVIDER) + (COOLDOWNTIME / GRAPHDIVIDER), 80, (weldTime / GRAPHDIVIDER), ST7735_WHITE);

tft.drawFastVLine(5 + (preWeldTime / GRAPHDIVIDER) + (COOLDOWNTIME / GRAPHDIVIDER) + (weldTime / GRAPHDIVIDER), 80, 20, ST7735_WHITE);

tft.drawFastHLine(5 + (preWeldTime / GRAPHDIVIDER) + (COOLDOWNTIME / GRAPHDIVIDER) + (weldTime / GRAPHDIVIDER), 100, COOLDOWNTIME, ST7735_WHITE);

lastPreWeldTime = preWeldTime;

lastWeldTime = weldTime;

}

// read the state of the switch into a local variable:

int reading = digitalRead(buttonPin);

// check to see if you just pressed the button

// (i.e. the input went from LOW to HIGH), and you've waited

// long enough since the last press to ignore any noise:

// If the switch changed, due to noise or pressing:

if (reading != lastButtonState) {

// reset the debouncing timer

lastDebounceTime = millis();

}

if ((millis() - lastDebounceTime) > debounceDelay) {

// whatever the reading is at, it's been there for longer

// than the debounce delay, so take it as the actual current state:

// if the button state has changed:

if (reading != buttonState) {

buttonState = reading;

// only toggle the LED if the new button state is HIGH

if (buttonState == HIGH) {

ledState = !ledState;

//**************************************************************************************************

Serial.print("Pre weld time set to: ");

Serial.print(preWeldTime);

Serial.print(" ms\n\r");

Serial.print("Weld time set to: ");

Serial.print(weldTime);

Serial.print(" ms\n\r");

String strBuffer = String("!WELDING!");

tftPrintText(strBuffer, 10, 125, 2, ST7735_RED);

// Do pre heating sequence based on predefined fraction of the total welding time

digitalWrite(relayPin, LOW); // Relay is active low

digitalWrite(ledPin, HIGH); // LED is active high

delay(preWeldTime);

digitalWrite(relayPin, HIGH);

digitalWrite(ledPin, LOW);

delay(COOLDOWNTIME);

// Do welding

digitalWrite(relayPin, LOW);

digitalWrite(ledPin, HIGH);

delay(weldTime);

// Reset all ports

digitalWrite(relayPin, HIGH);

digitalWrite(ledPin, LOW);

tftPrintText(strBuffer, 10, 125, 2, ST7735_BLACK);

// Restart loop

//**************************************************************************************************/

}

}

}

// save the reading. Next time through the loop,

// it'll be the lastButtonState:

lastButtonState = reading;

}

void displayInitScreen(void)

{

tft.initR(INITR_BLACKTAB); // initialize a ST7735S chip, black tab

tft.setRotation(0);

tft.fillScreen(ST7735_BLACK);

char display_buffer [20];

memset(display_buffer, 0, 20);

sprintf(display_buffer, "Spot Welder v0.1");

tft.setTextColor(ST7735_WHITE);

tft.setTextSize(1);

tft.setCursor(0, 0);

tft.print(display_buffer);

memset(display_buffer, 0, 20);

sprintf(display_buffer, " MicroForge - 2018");

tft.setTextColor(ST7735_WHITE);

tft.setTextSize(1);

tft.setCursor(0, 10);

tft.print(display_buffer);

//delay(1000);

//tft.fillScreen(ST7735_BLACK);

String strBuffer = String("Spot weld timing:");

tftPrintText(strBuffer, 0, 35, 1, ST7735_YELLOW);

}

void tftPrintText(String textBuffer, int x, int y, int textSize, int color)

{

if (textSize == 0) textSize = 1;

tft.setTextColor(color);

tft.setTextSize(textSize);

tft.setCursor(x, y);

tft.print(textBuffer.c_str());

}

Here is the resulting visualization for both peeks as well as the exact times of both weld actions.

Timo Birnschein

Timo Birnschein

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.