-

A working display!

01/21/2014 at 22:42 • 0 commentsFinally Ivan screwed the backboard into place. One of the great things about using Foamed PVC is you can basically treat it like wood, it holds a screw well and is easy to cut and saw.

![]()

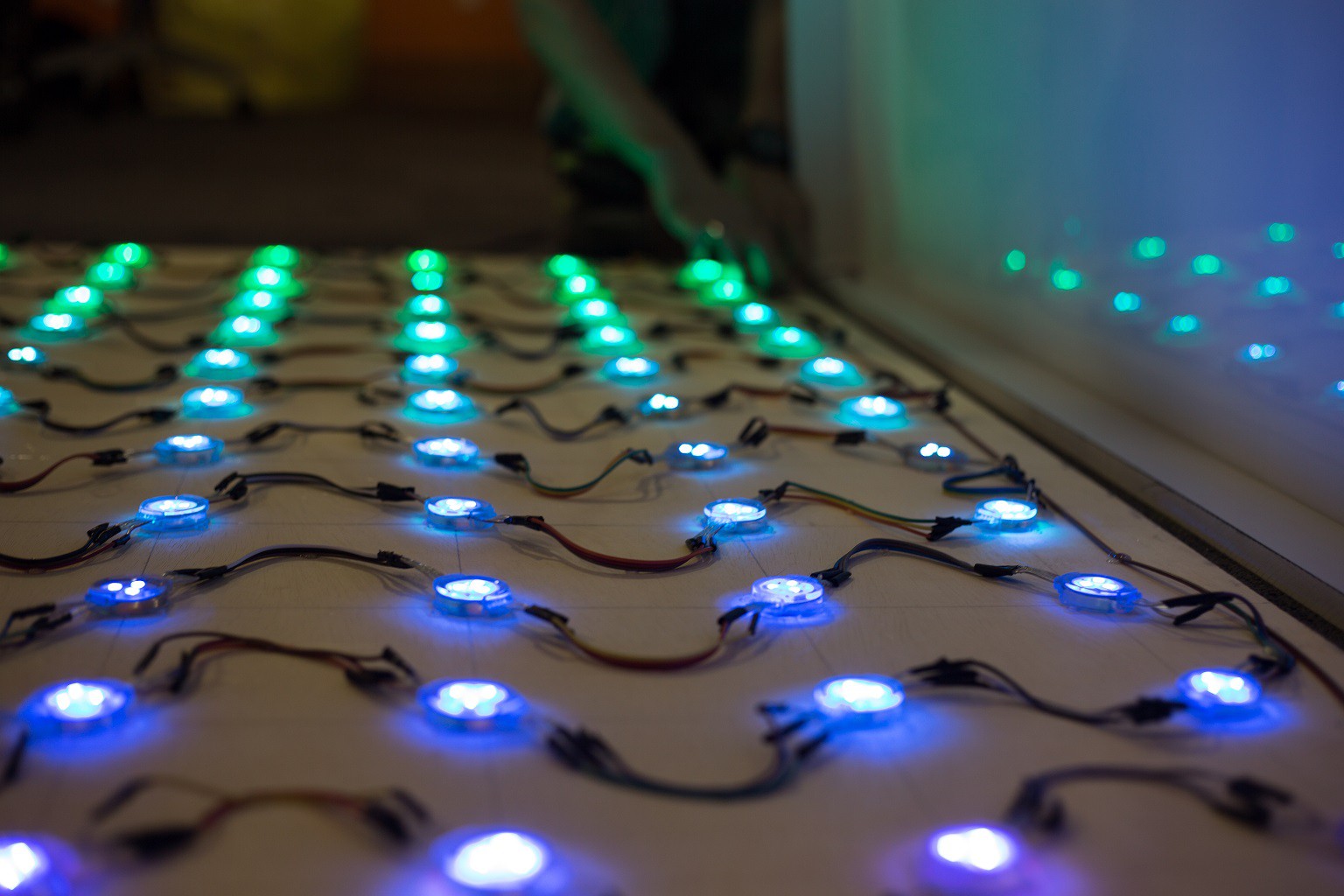

With our fingers crossed we switched it on, and to our delight we were treated to strandtests beautiful colors! Everyone was really happy with the look of it and we lost almost an hour staring at the pretty blikenlights.

![]()

![]()

![]()

-

Adding the electronics

01/21/2014 at 22:37 • 0 commentsTo drive this system we decided to use a Raspberry Pi and Arduino Micro combination.

The Raspberry Pi runs a stack of Nginx, Memcached and NodeJS which then feeds desired LED colors to the Arduino Micro which streams them out over the WS2811 protocol to the LEDs. We'll cover this in more detail later.

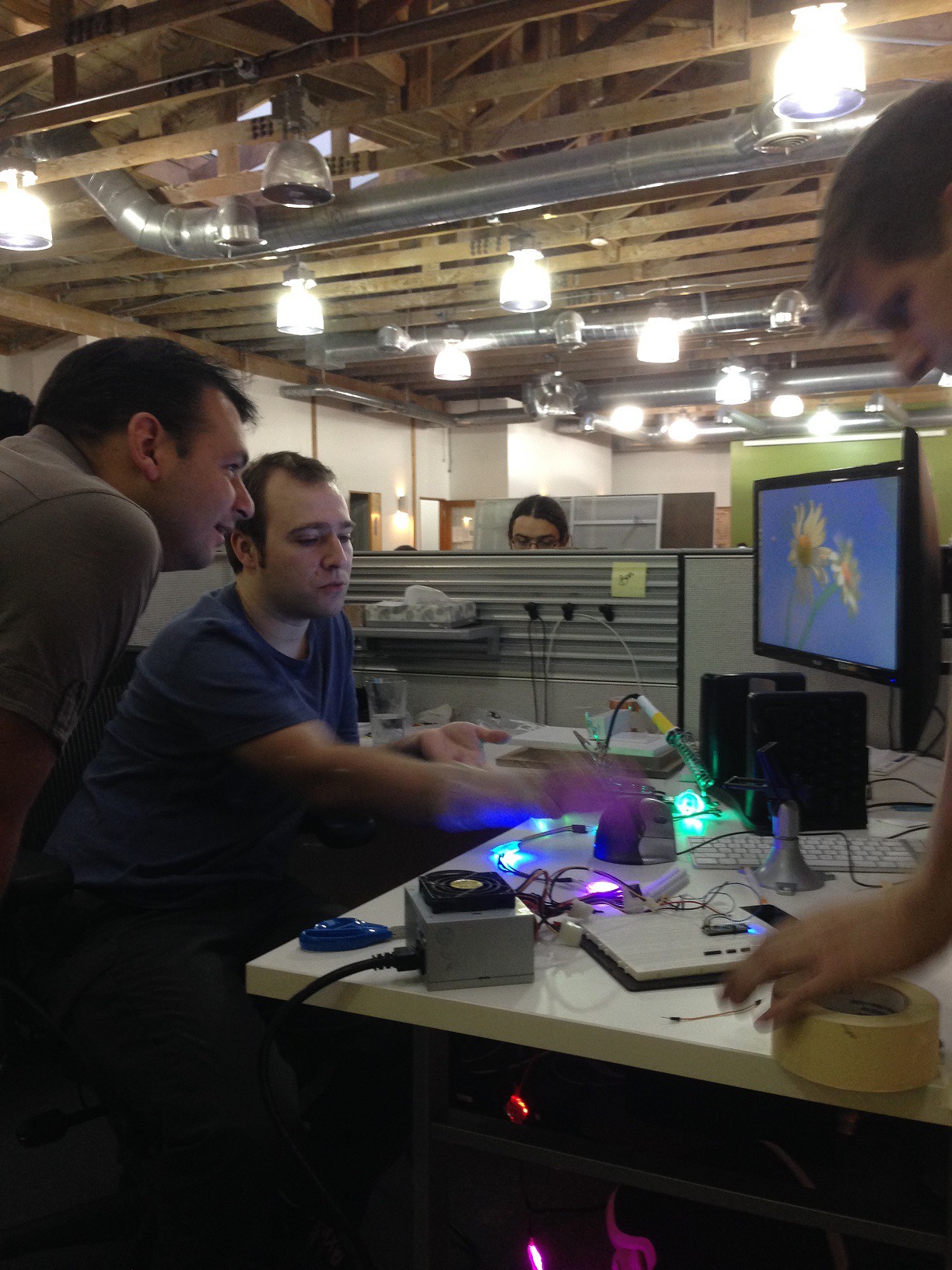

First we got this setup working on the breadboard:

Then we attached the electronics to the backboard using double sided adhesive tape and tested it with the LEDs.

-

Making the frame

01/21/2014 at 22:32 • 0 commentsNow we wanted this display to look really sweet since it will be on our office wall for some time to come. To make it look gorgeous we decided to make the frame out of white foamed PVC board, and the front diffuser out of 1/4" thick white acrylic.

First off we had to sand down the PVC board since it needs a nice smooth surface to create a good join with the acrylic, John did this in short order using a palm sander.

We then had to cut the board to size, for this we had to make a quick trip to Harbor Freight to pickup a Mitre Saw.

![]()

We then laid out the board on the office dining table and used Weldon #16 to join the pieces of the frame together.

Finally we had to very quickly apply glue to the edges of the frame and then lay the acrylic sheet down in place.

-

Securing the LEDs

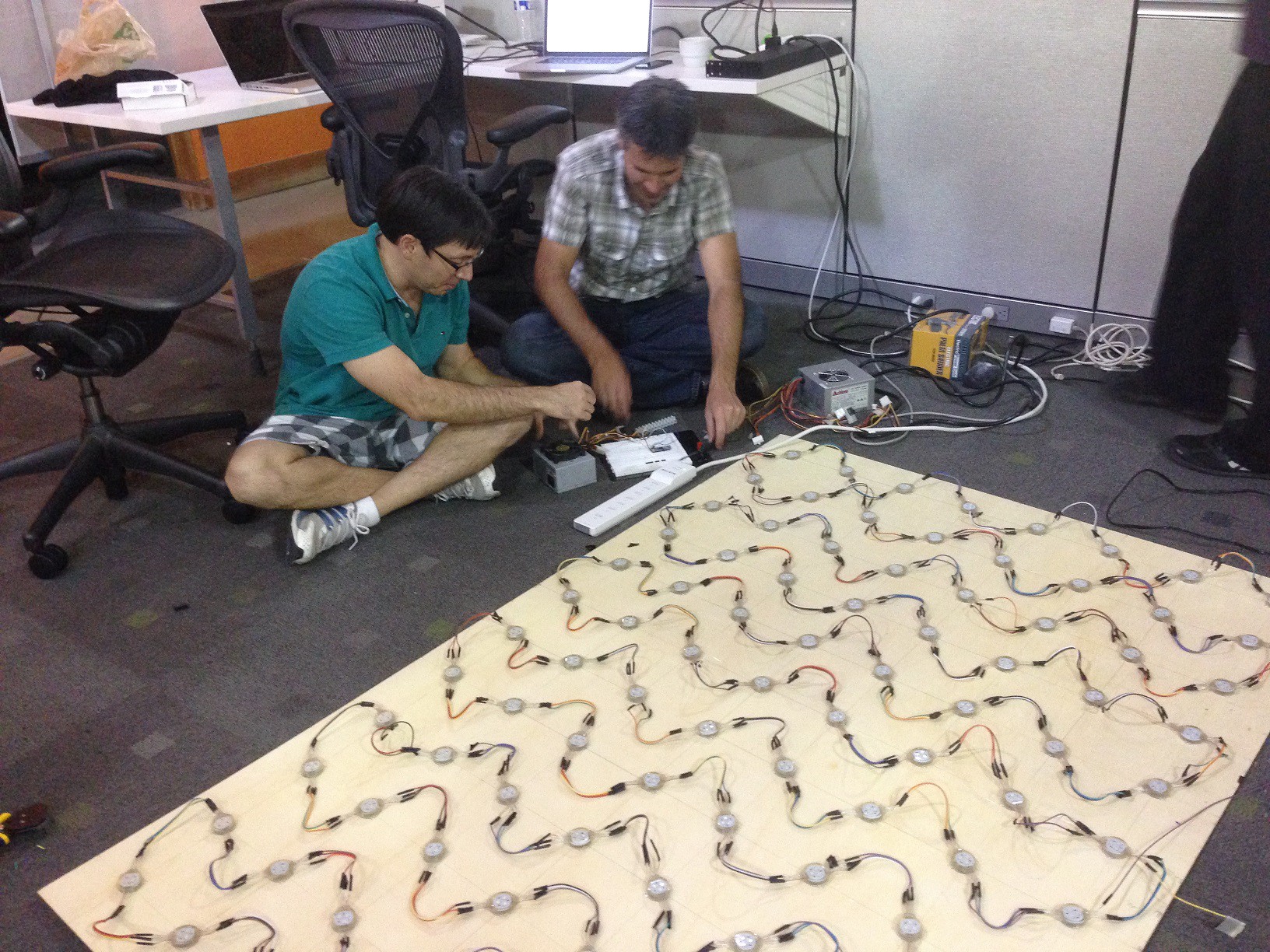

01/21/2014 at 22:19 • 0 commentsNow that we had most of the LEDs it was time to start fixing them to the backboard.

First off we hot glued all the LEDs into place on the backboard which was a sheet of plywood. This took a little while but John P, Tom M, and Albert all pitched in and got this done in no time.

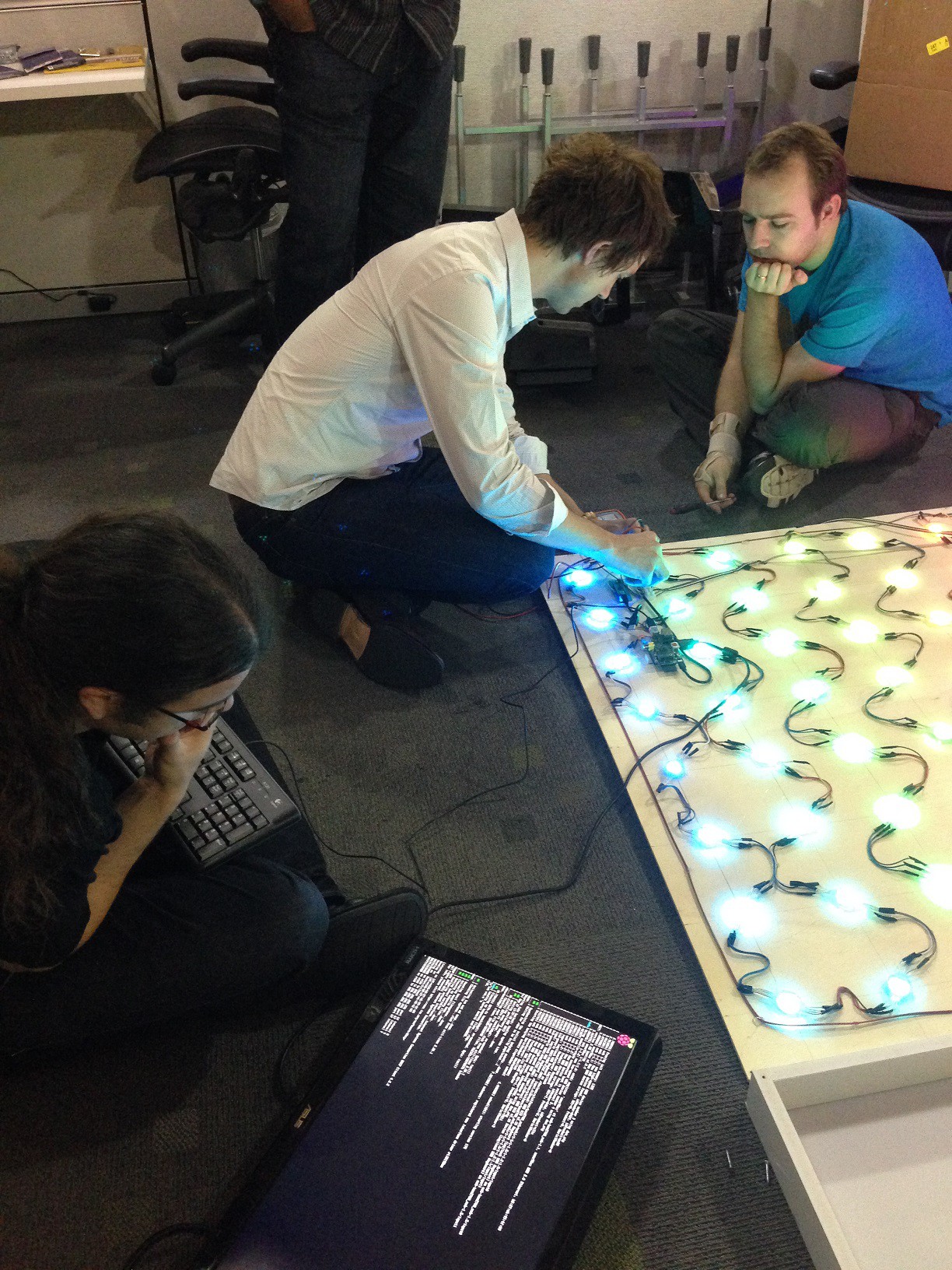

Next up we needed to do a quick electronics test to make sure everything was working properly....this went surprisingly well, look at all those pretty colors! (Who doesn't love Strandtest?).

![]()

![]()

-

01/21/2014 at 22:11 • 0 commentsSo we had an idle Friday afternoon here at SupplyFrame HQ and our evil overlord Alek asked us to build something cool for the office.

With the restriction of only having a day to build we didn't have many choices in what we could source components for, thankfully though I had about 100 WS2811 based RGB LEDs knocking around from my Diodome project. So we decided to build a really nice looking LED matrix display.

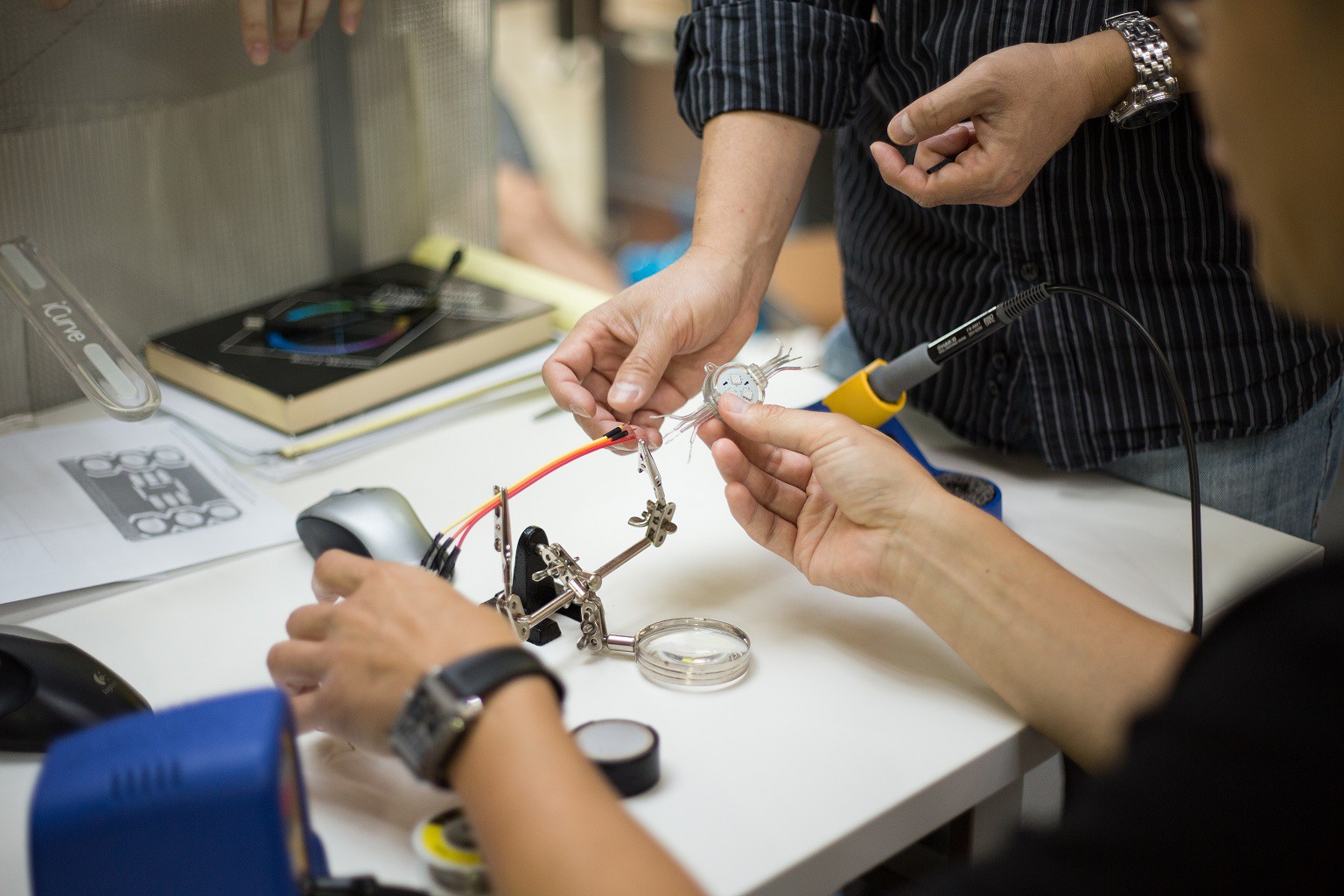

Unfortunately all my LEDs were already cut up from a long strip into individual LEDs so we had to solder wires back onto each of them and make long strips we could use in the matrix. Thankfully we had many willing hands in the office so a day of cutting, stripping, and soldering ensued.

![]()

![]()

![]()

![]()

We made quite a mess, but by the end of the day we had about 90% of the LEDs we needed soldered together. However, we did totally fail on our one day project. Thankfully SupplyFrame is a great place to work so we were allowed to spend another day on the project the following Monday...

FLED

An LED display showing visualizations and rendering data from a variety of TCP sources over the Open Pixel Control protocol

Ben Delarre

Ben Delarre