It started at a new years party as we saw in 2014. I drunkenly commited to doing everything in my power as an engineer to make a hoverboard work by 'the date' 21/10/15. I get the impression I am not the only one...

I roped my Maker Faire buddy Mark, the other half of Jelly and Marshmallows (www.jellyandmarshmallows.co.uk) to assist, and we started work.

We researched various technologies for levitation, from aerodynamic to ultrasonic, but always the most convincing was magnetics. A while back (2008!) I had bought a strong magnet with the sole purpose of investigating whether permanent magnets could be used to generate eddy current levitation similar to Laithwait's 70s magnetic river demonstrations It turned out they could, and that as far as I knew the principle hadn't been explored much.

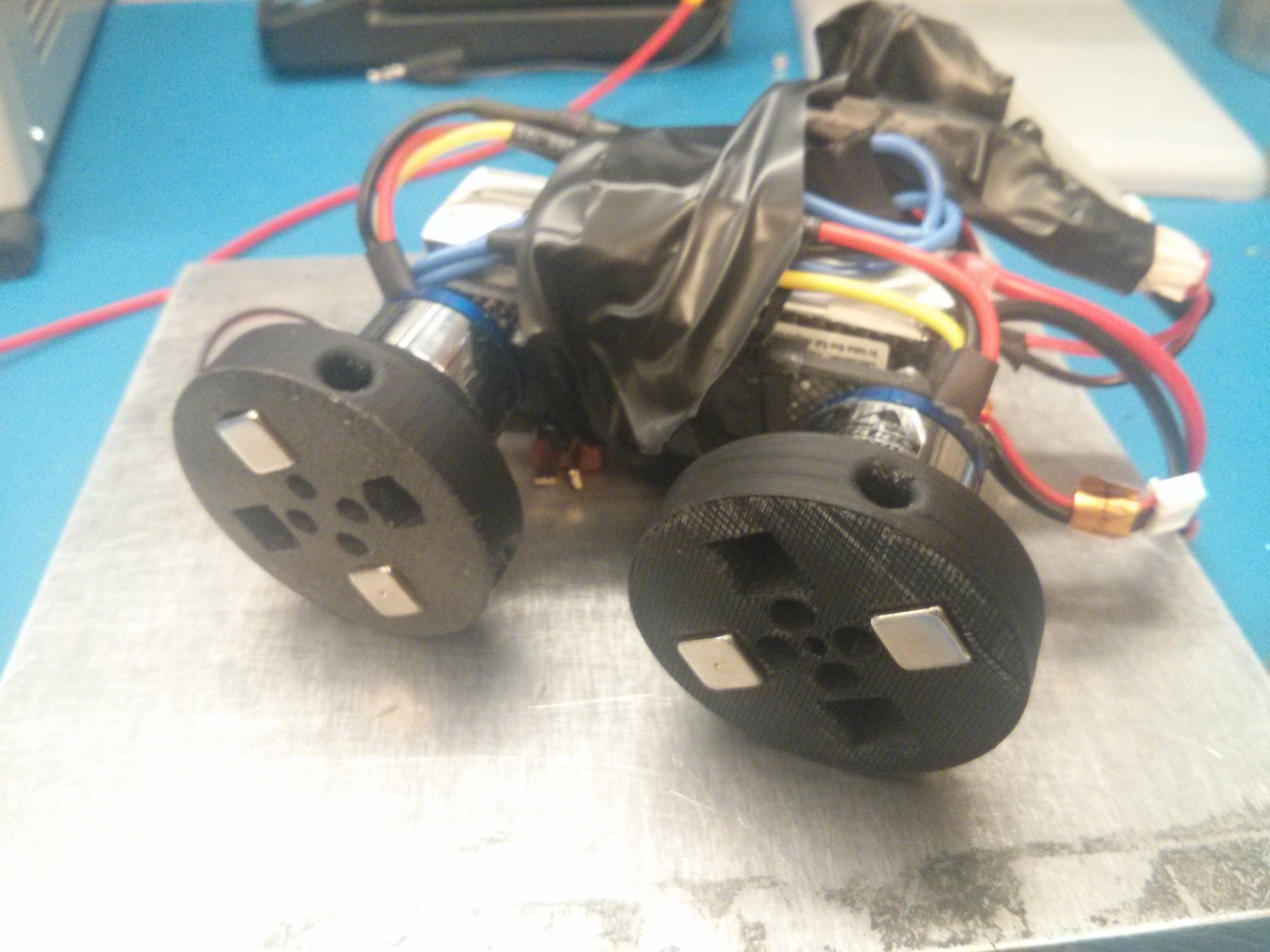

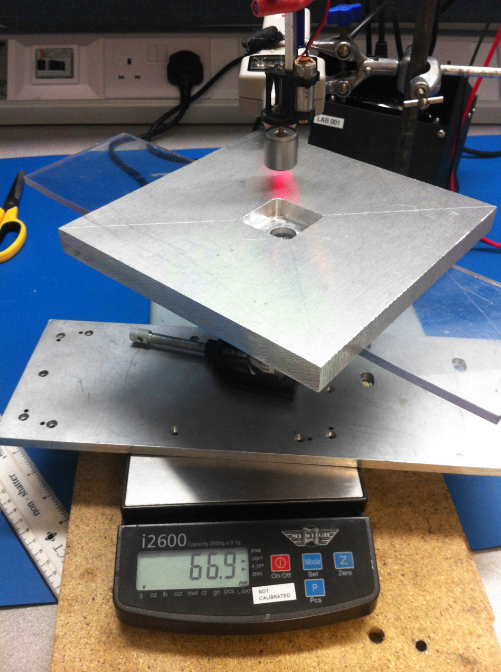

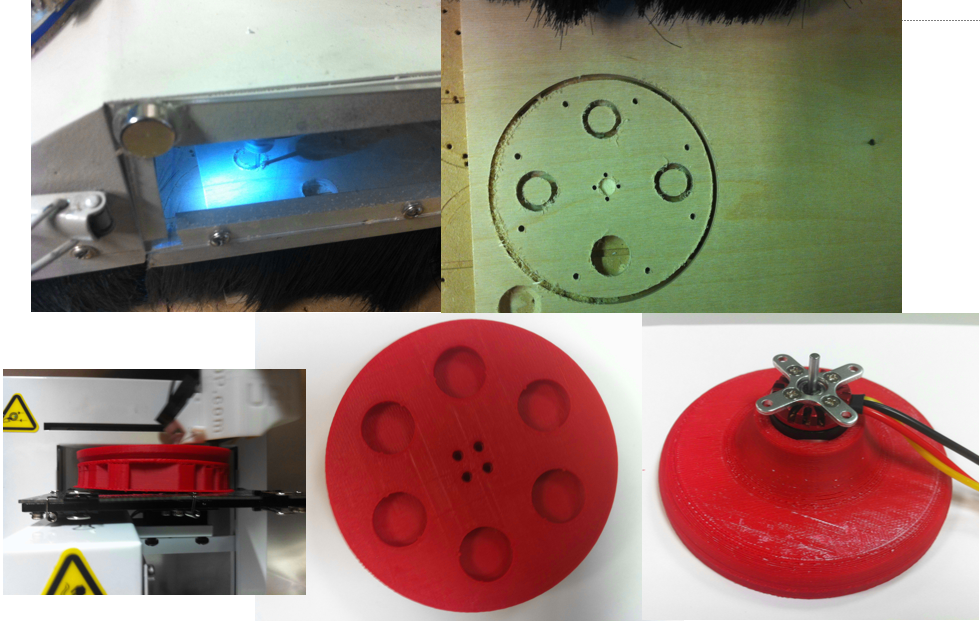

Our next step was to make an array of 8 magnets in a 3D printed rotor that could be spun by a drill. The magnets are 20mm N35 neodymium magnets, alternating north south as you go around the circle. We bench tested this over a set of scales with some 3/4" aluminium on.

This achieved 2kg of lift at 1cm and 1kg at 1 inch separation. Not bad for a first try.

The power loss is created by drag from magnetic breaking, and the 3kg aluminium plate was on the verge of spinning, highlighting that long term this would need to be done in counter rotating pairs. Miniture test below lowered the torque to a level our meter would measure. This test had lift, torque, RPM, motor voltage and current all recorded... science folks!

A

few variations to explore array arrangement and trying laser cut and routed plywood, along with more accurate lift efficiency tests and we were soon ready to make a chassis with a pair of rotors. Pardon the untidy tape holding the cables in.

Testing showed we could easily achieve lift of up to 2cm but it was like trying to balance a stationary bike that is twitching sideways. Impossible. Still by holding the cable ties it could be kept from rolling or sliding away and you can see the hovering:

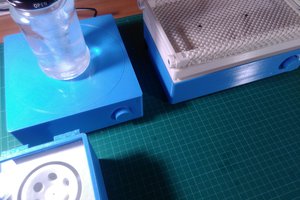

From there we realised it was best to go quad rotor so we quickly put together a quad rotor chassis in time to demo it at Maker Faire Brighton, UK. As yet I don't have a decent video of it but this was a walk around of our stand at Maker Faire

When it is sliding around and not making a horrible clattery noise it is hovering. The lowest part is the rotors because we broke the surround we made, so whenever it gets too low as it moves the spinning magnets clatter against the aluminium. The motion is Mark attempting to steer it (you can see he is holding a wii nunchuck). The control is VERY difficult at present and still very much in development so it needs help quite regularly to stay on the alu sheet.

I will post more videos when I get the chance to take them!

jellmeister

jellmeister

Jesús Tamez-Duque

Jesús Tamez-Duque

Hacker House

Hacker House

ProgressTH

ProgressTH

I am using a dc motor for powering the engines as the motor is placed near the aluminium plate the speed of the motor is decresing and the motor eventuaally stop what is the reason for it?