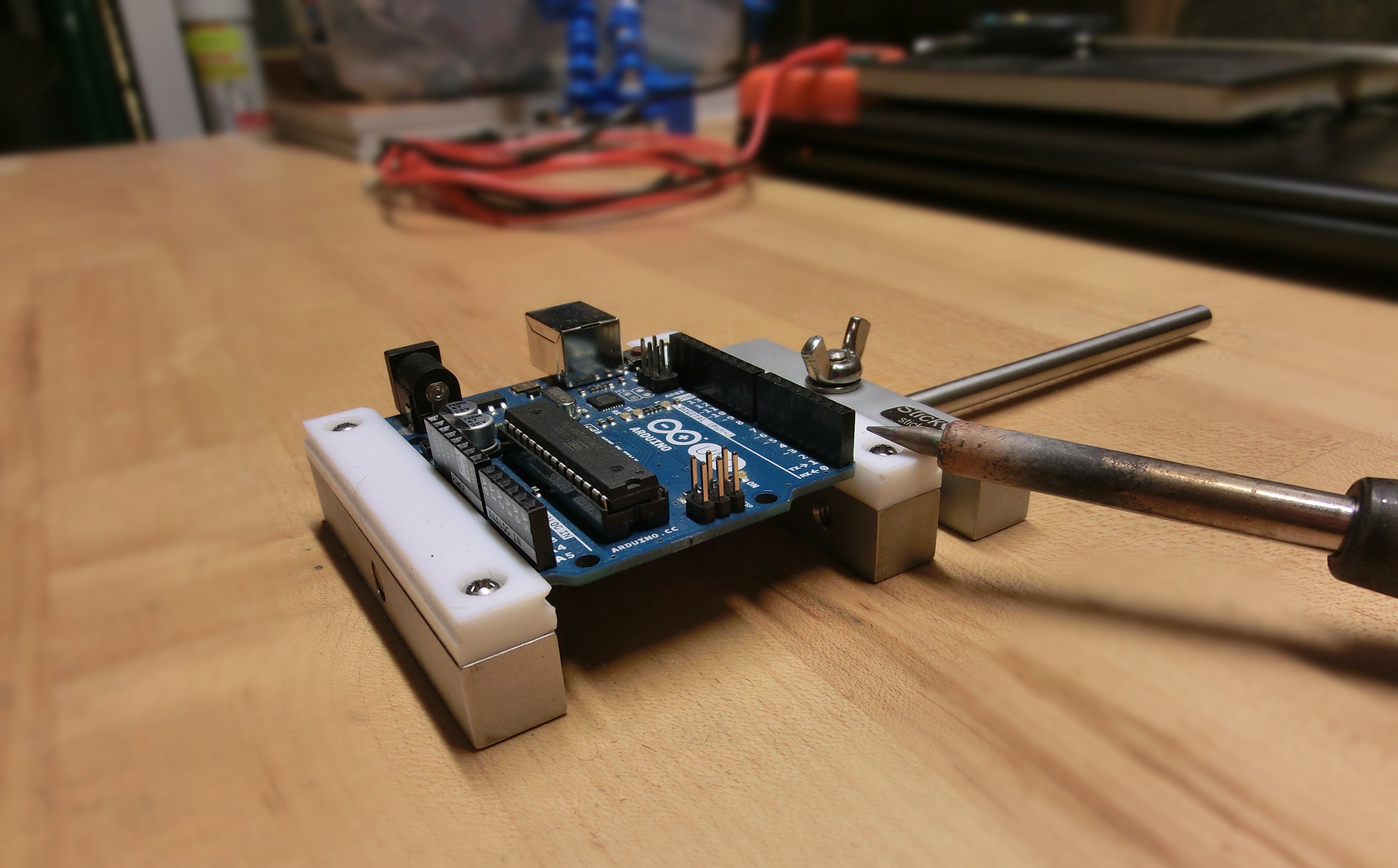

I recently machined several sets of prototype jaws made from Teflon (PTFE), shown in the picture below. The main advantage being high temperature resistance; you can take a hot soldering iron and touch it directly to the jaw plates without leaving a mark. I have to say, they are pretty cool and will last a lifetime of soldering.

I am thinking about making a few hundred sets of these to sell on Tindie, along with offering standard replacement nylon jaws and potentially other materials if there is demand. If you have a Stickvise, chime in with with your opinion -

1. Is this worthwhile? Is it something you'd pay $10-$12 a set for? My goal is not to make much money on these, but to ensure people with damaged jaws don't let their Stickvise collect dust.

2. Are there other materials you'd like to see? Is aluminum or steel interesting to you? Let me know in the comments, thanks!

Alex Rich

Alex Rich

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

I will post soon about the design of a fixture plate to mill these in one setup hopefully, I'm thinking I will buy sheets of PTFE and cut them to rough size on a table saw with a thin blade, then do finishing on the mill

Are you sure? yes | no

Great idea there Alex! Regarding the price point: I'd happily pay 10$ for an "lifetime-addon" for a device I use for all of my soldering projects.

A pity DELRIN hasn't got the same heat resistance. That stuff would be ideal. I think coating something more sturdy like aluminum just doesn't give you all the good features of PTFE. So why not just go with that stuff!?

It 's always hard to estimate demand from just a few comments/feedback but I hope you'll be able to sell all of your jaws to make a great tool even better!

Are you sure? yes | no

Yeah I think you're right, coating aluminum might save some money in material but it will cost me time and headache, plus it won't be as good.

Are you sure? yes | no

Very useful addition to an already very useful tool. PTFE is probably the best material for this in terms of heat resistance. Maybe bit slippery, i don't know (?). There might be cheaper materials, like tufnol, HPL or FR4 to machine them from. Maybe casting them from high temperature silicone (that stuff is really cheap, used for baking oven window etc.) could also result in nice both heat and skid resistant jaws.

Are you sure? yes | no

Thanks for the feedback, I thought slipping would be an issue, but it doesn't seem to be particularly bad when using the v-groove. Partly because most PCBs have really rough edges that bite into the soft PTFE. Anything smooth would slide though. I looked into fiberglass but the price was about the same as PTFE in small quantities. Amazing how expensive this stuff is, like 10 times the cost of aluminum. Maybe a good option would be to use Aluminum and then paint it with a high temp paint or something.

Are you sure? yes | no

Hm, if the price point matters, the design of the jaws kind of dictates a cheap material. They're certainly bigger than they have to be to do the clamping, most of them is mounting meat and structural support. So yes, aluminium is a good way to go, but it would be good to have a second, rubbery material where it clamps the PCB, like the high temp paint you mentioned, or a powder coating, or a rubber ring gasket, that runs in a groove around the whole jaw.

Are you sure? yes | no

https://en.wikipedia.org/wiki/Polytetrafluoroethylene

>While PTFE is stable and nontoxic at lower temperatures, it begins to deteriorate after the temperature of cookware reaches about 260 °C (500 °F)

I hope to see slightly higher temperature material that can be used for hot air rework.

Are you sure? yes | no

True, but the jaws are not intended for dual-use as a solding iron stand I guess. So short contact should be ok. Desolder pump tips are made of PTFE as well. These last a long time too...

Are you sure? yes | no

I mainly do hot air soldering/rework these days for SMT parts.

Not sure where the solder iron stand come from.

Are you sure? yes | no

Yeah the PTFE is going to ward against incidental soldering iron contact, it doesn't transfer heat too well from what I have seen so even if you leave an iron resting on it, you won't see it melt. For hot air I think you'd need aluminum jaws, I will probably offer those as well. Once I have a fixture plate to machine these in reasonable bulk (rather than one at a time in a vise) I will be able to churn out jaws in any material I want. Ceramics can be machined, but they are really expensive to get a hold of.

Are you sure? yes | no

You have a nice nozzle that will keep the heat just on the part you're soldering. I have had no problem soldering / desoldering parts with a nozzle and targeted hot air even using the nylon or 3d printed jaws.

Are you sure? yes | no

The boards I work on are small and parts are close to edge. (see my projects to get a feel on what I could use.) So chances are that the jaws have to handle hot air.

Right now I have copper tape and a couple of layers of polyamide tape to protect the stick vise if the jaws could actually fit. (That's a mechanical issue not material issue.)

Kind of a waste to reflow stuff on $0.5 heatsinks.

Are you sure? yes | no

Looks like mcmaster sells an $8 can of high temperature silicone spray paint, that would do the trick for adding insulation to aluminum.

http://www.mcmaster.com/#7832t1

We'll see, I'm going to have to play around with it I think

Are you sure? yes | no

In my experience getting a coating right + the time to clean and coat (and burn in as with the paint you mentioned) everthing just adds up. In that time your CNC/router produces at least a few sets of jaws (of slightly more expensive material) you won't have to handle/manipulate a second time. Just sell em.

I guess you'd have to do the math what'll be more cost effective. Anyway, one problem still is the durability of coatings. It will chip at some point...

But @ 8USD just try it I guess!

Are you sure? yes | no