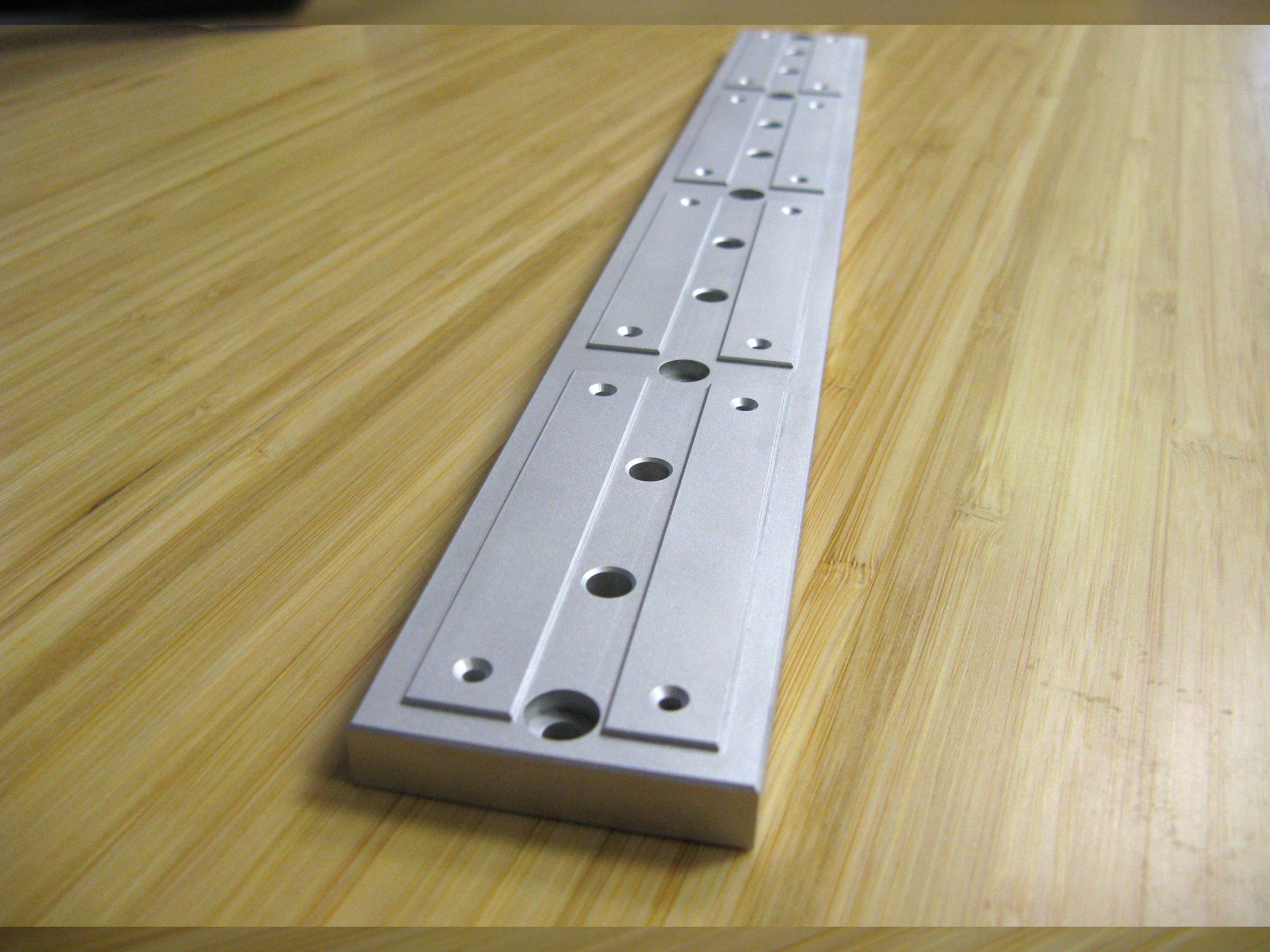

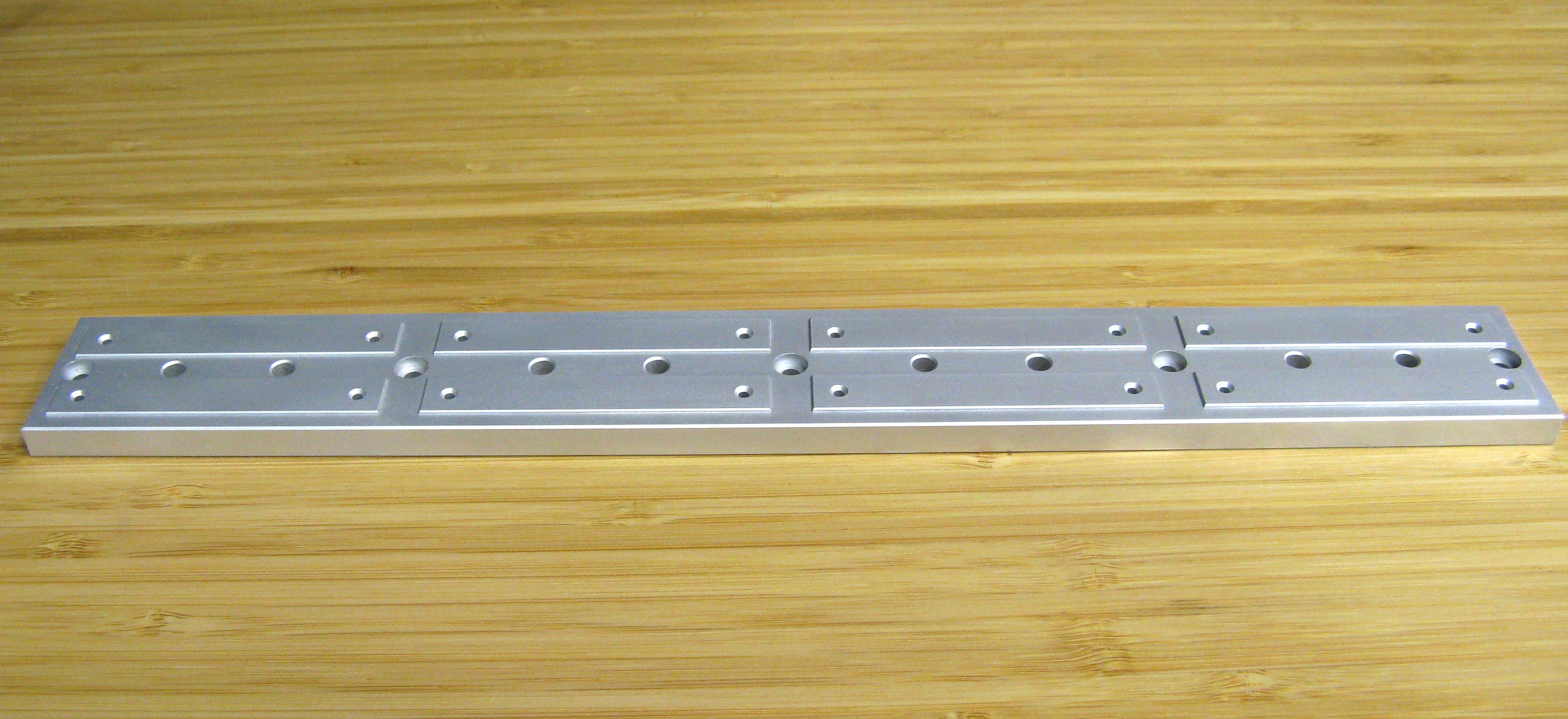

Check it out, fixture is done. I milled the aluminum on a Tormach 770, really an excellent machine.

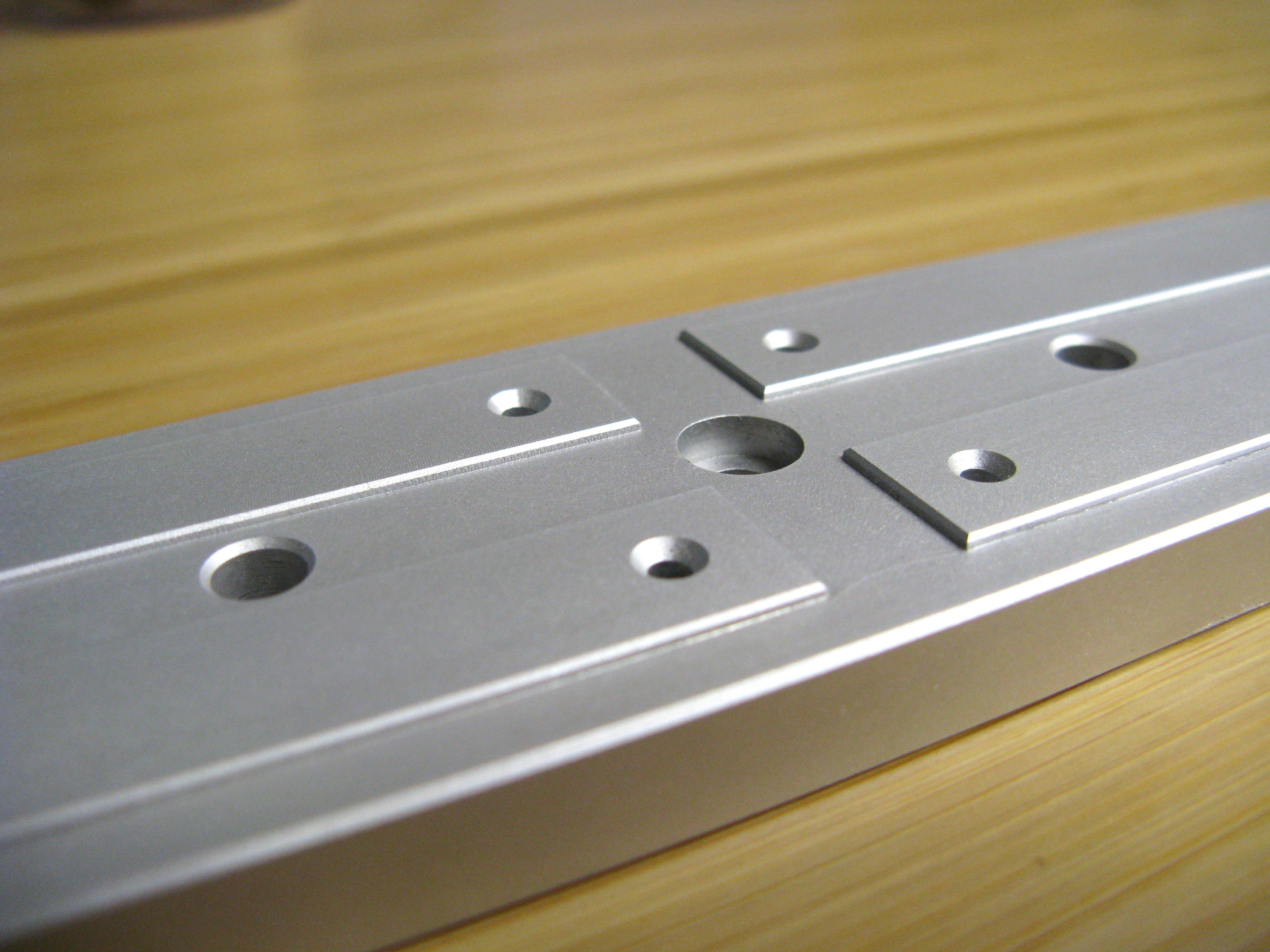

One fun thing about CNC is you can do things that wouldn't be feasible on a manual mill. I decided to go in and chamfer all of my edges using a Maritool 90 degree chamfer mill. You can see in the pics below there are perfect little beveled edges on everything, even the circles. It would have been overly tedious to do this on a manual machine, so you invariably would have hand filed. Nothing wrong with that technique, just doesn't look as cool!

On top of that, I had some fun adding a bead blasted finish just to top it all off. I use an inexpensive Grizzly sandblast cabinet, and some fine glass bead media that I bought from McMaster years ago. This final step really makes tool marks disappear and leaves a nice matte finish, didn't need to sand or polish anything.

Couple notes

- tapping not done yet, will do that next

- Thanks to @Jan for advice on my initial design. I added extra holes for clamping each part in two places instead of just one. I'm sure I won't regret that decision. We'll see how this works soon, stay tuned...

below is the Maritool chamfer mill I used

Alex Rich

Alex Rich

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Wow, looks beautiful!

Are you sure? yes | no

thanks! It's all about the bead blasting

Are you sure? yes | no

I wanna second that. Amazing build quality!

Now the PTFE jaws just HAVE to turn out equally well, I'm sure about that!

On a second note: I think the sand blasted surface will further add grip while clamping... Good idea!

Are you sure? yes | no