-

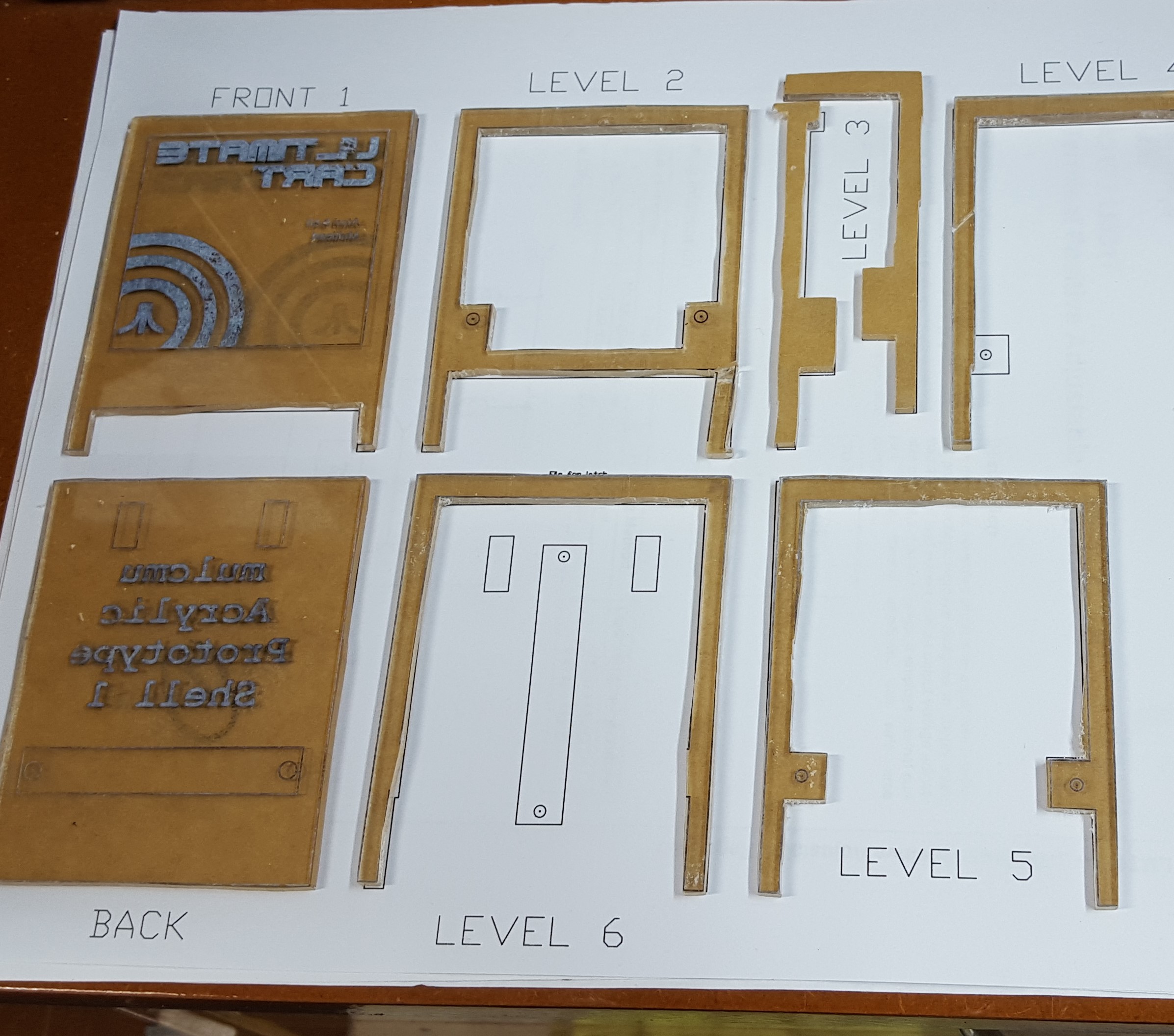

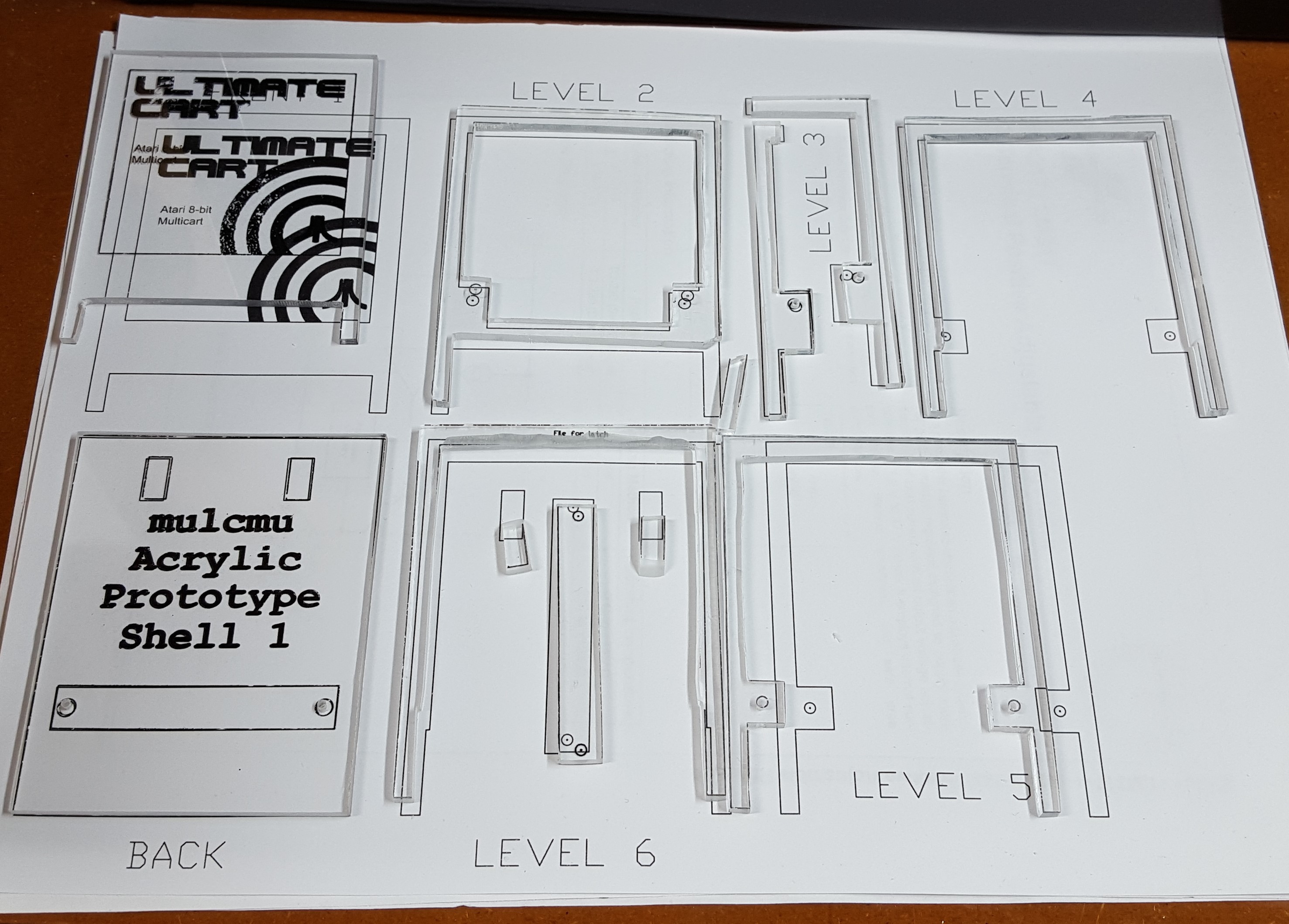

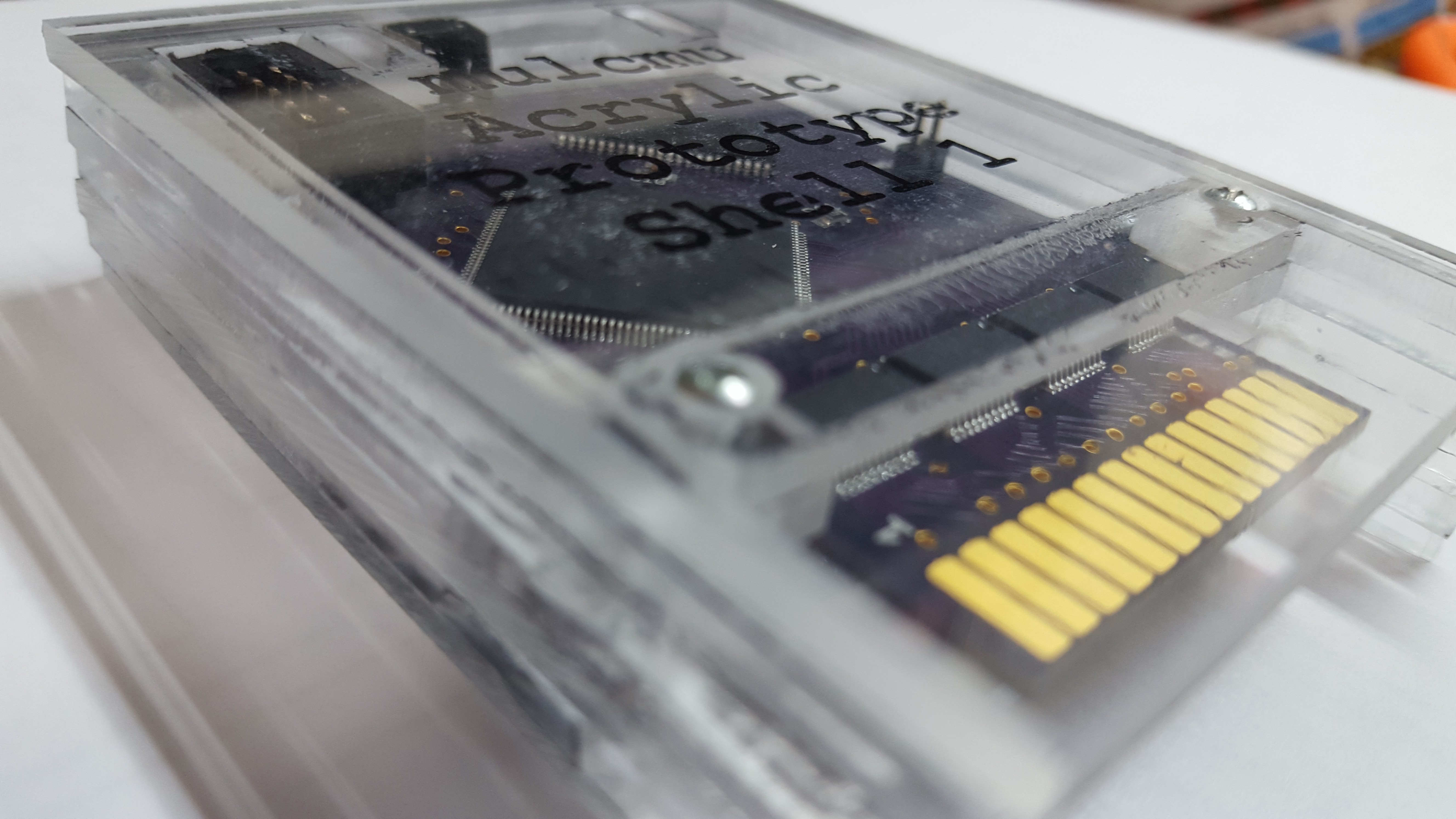

Ultimate Cart Case Prototype

11/20/2016 at 02:46 • 0 commentsGot the cold toner transfer to acrylic working well. Transferred cut marks and decals to 3mm acrylic sheet. Cut layers out by hand and glued up the case. Sloppy application of the acrylic solvent messed up the logo a bit.

![]()

![]()

![]()

![]()

-

More Acrylic Testing

03/09/2016 at 02:04 • 0 commentsTested transfer of a full letter size sheet to a 12"x12" sheet of 3mm acrylic. Heat from iron warped it instantly. Not so much due to the size or soft surface from the last test. Attempting to transfer pattern to plastic for cutting.

Started using Hammermill color laser gloss paper instead of the of the prior gloss inkjet paper. Much better transfers and release than the prior stuff I was fighting with. After 2 minutes of soaking the paper had floated away from the acrylic on its own.

Messed around with some cold toner transfer using mixture of acetone and denatured alcohol. Didn't keep good track of the ratio. Works great to acrylic so far. One transfer had some crazing, but this might have been due to stress from excessive clamping force and not the solvent.

-

Toner transfer test

01/19/2015 at 02:14 • 0 commentsTested toner transfer to 1/8 thick clear acrylic sheet using glossy photo paper. This was done with iron on fabric covered ironing board. The plastic heated enough that it deformed a bit. A flat heat resistant surface should work better. The iron was cranked up to the linen setting. Might not need the iron as hot as for PCB fab. The plastic toner might fuse quicker with the heated acrylic than copper. Transferred ok, a few spots had holes due to the print as well as being a little too aggressive in brushing of the paper after soaking in water.

Spray painted the back with silver spray paint as I planned to mount this tag to a white door. (Sometimes there is confusion over the primary function of the room that also houses the clothes washer and dryer. This little plaque will be used to clarify.)

![]()

![]()

-

Future ideas:

12/06/2014 at 18:39 • 0 commentsToner transfer the markings to the internal side of a clear project box. Flat acrylic face plate could be used. Toner transfer with color laser printer for full color legends or just unique way to frame a picture? Weld-on 4 to glue LEDs to the face plate for indicators before spray painting.

Clear enclosure project box legends

Not a project per se but a technique for enclosure fabrication.

mulcmu

mulcmu