Latest Status Update:

This project is currently on hold while I get to the point where I can make PCB's with the toner transfer method. My current iron is erroding away rappidly so I have to get back to this 'soon'.

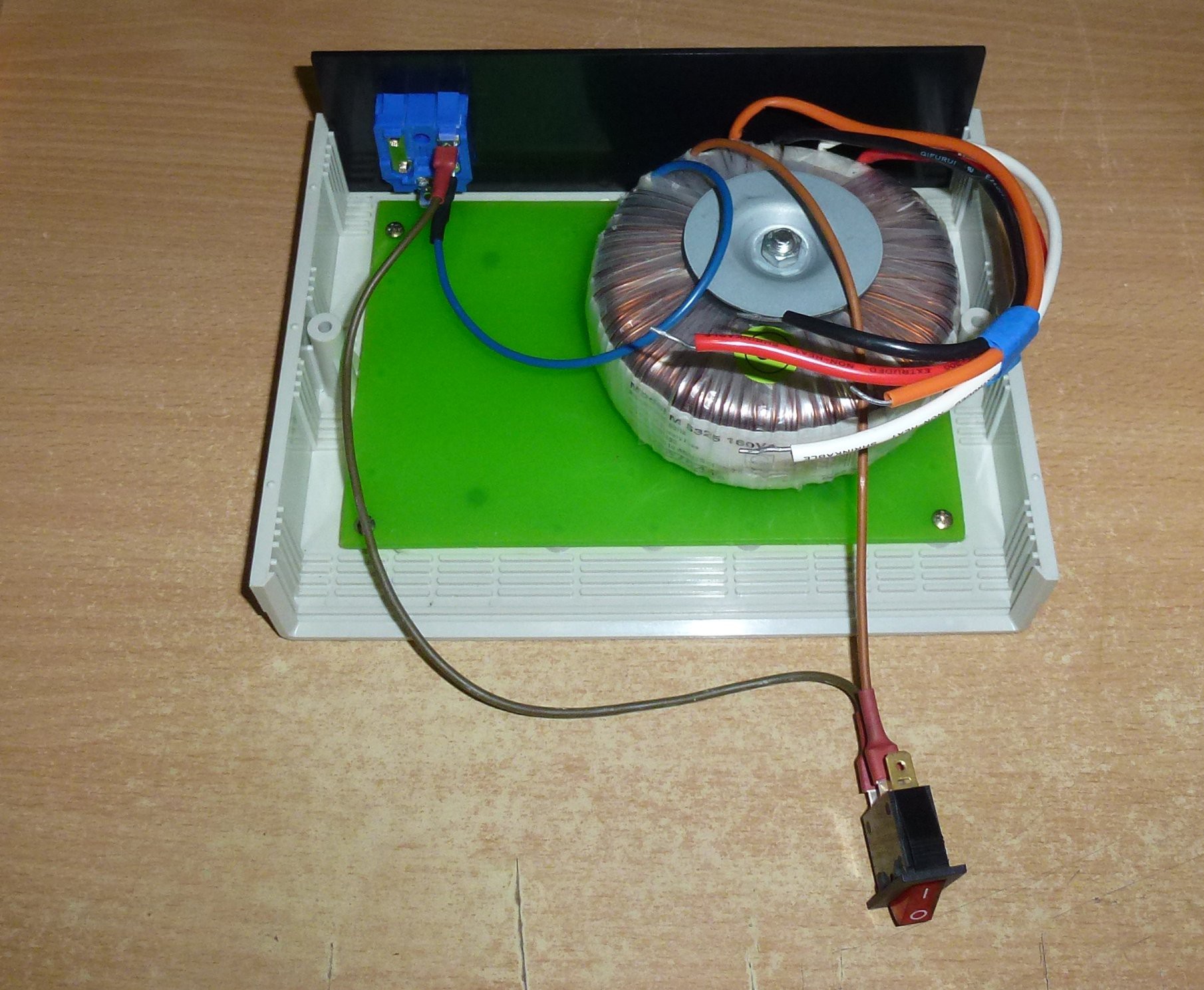

THIS PROJECT CONTAINS MAINS WIRING. DO NOT ATTEMPT UNLESS YOU HAVE THE ABILITY TO ASSESS ALL ASPECTS OF SAFETY AS NECESSARY.

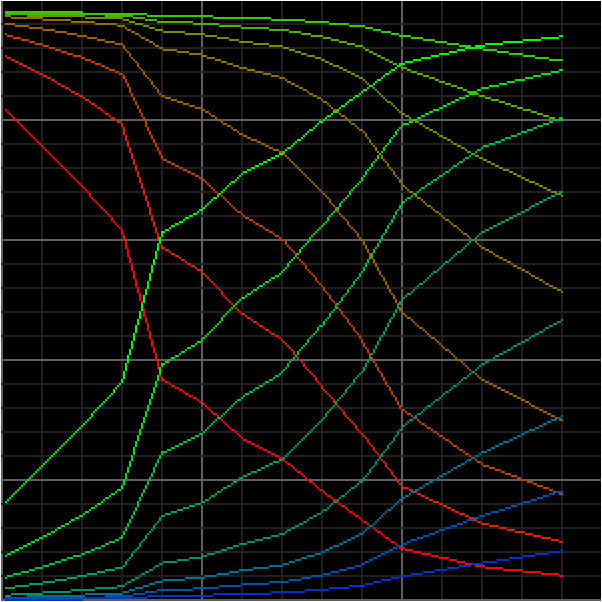

I don't actually know anything about PID. Perhaps I will learn this in the process.

I do however have a very good understanding of math and physics so my approach may be somewhat unusual.

This project will be based on the cheap ebay clones of the HAKKO 907 / 937 irons.

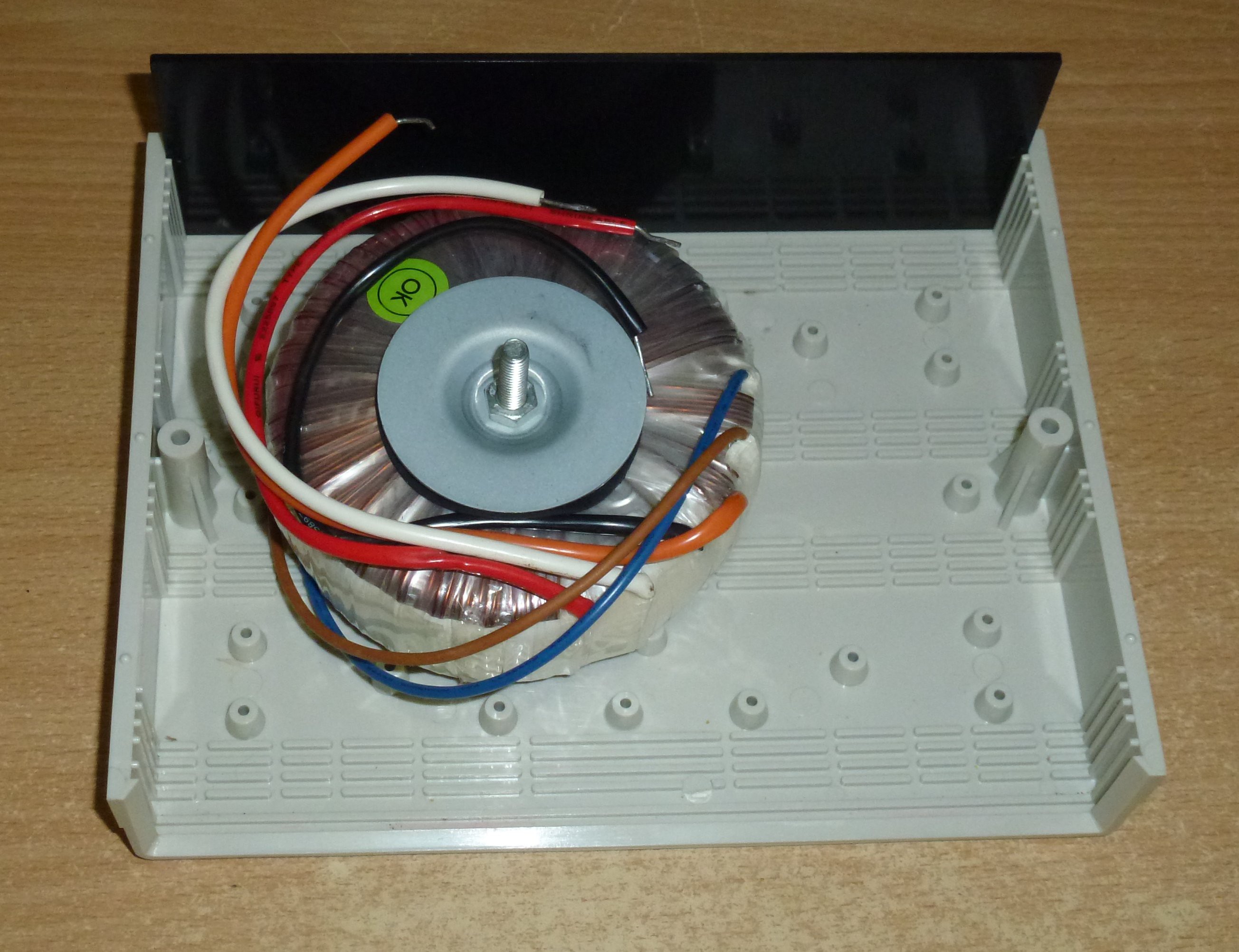

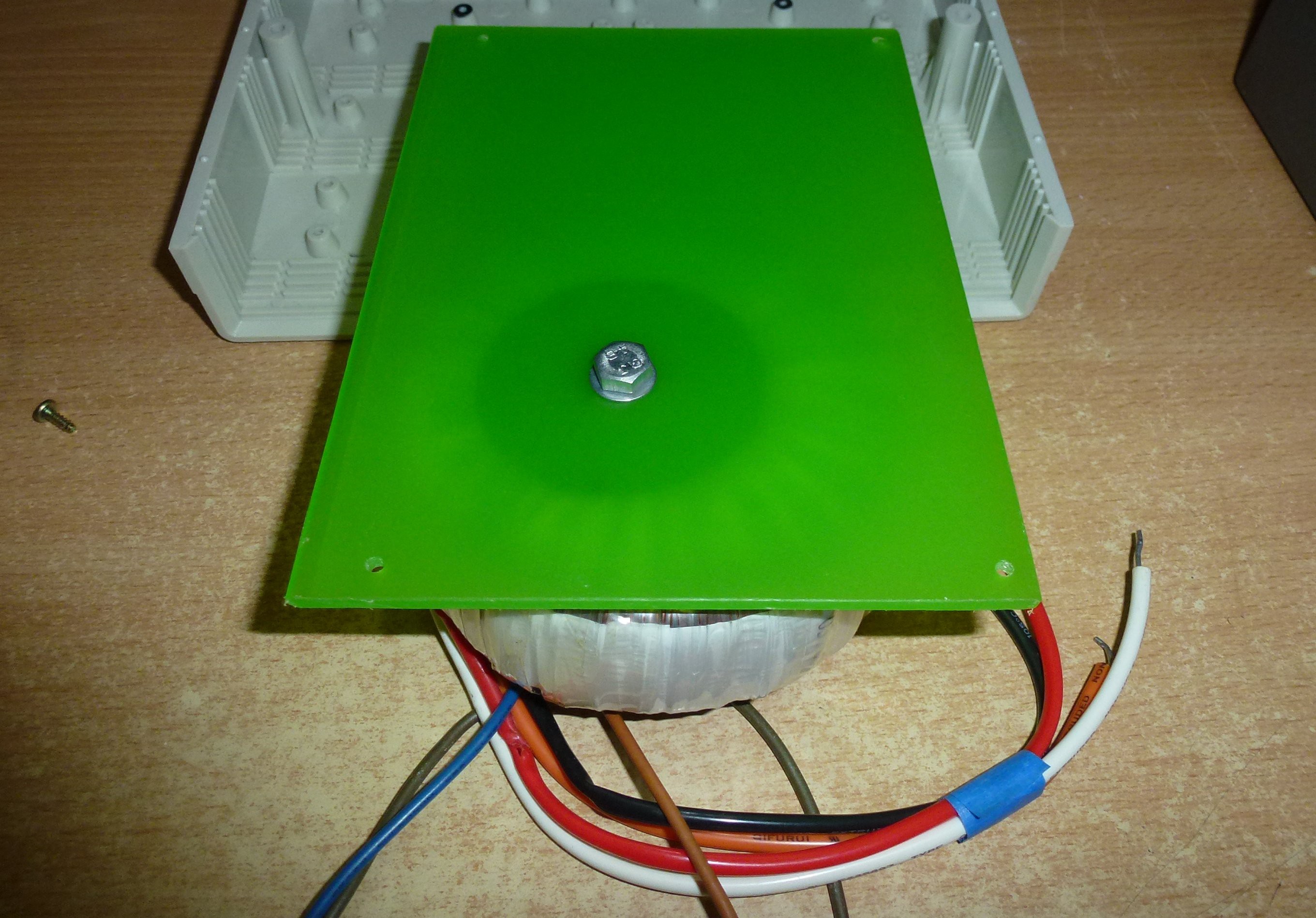

The iron will be supplied with AC from a toroidal transformer with zero crossing detection and switching under control of a micro-controller.

I may use an Arduino board as a plug in module so that it easily repeatable and the code can be experimented with.

Hacker404

Hacker404

Measuring the amount of power drawn away from the soldering iron is a nice idea. Things like "there was nearly no power draw for 5 minutes, iron goes to standby at 50°C and ramps back up if there is more than a specific power necessary to hold this temp (user touches something to solder)" or "power draw is at max for 15 seconds now, user seems to solder massive ground planes, increase set temperature" etc. come to mind. Maybe "fuzzy logic" can help (?).