The motors of the robot are mounted under the base plate. They are equipped with magnetic quadrature encoder disks, fitted directly on the motor axis prior to the gearbox. This wheel thus has no torque, and if something touches it, it will stall the motor. Furthermore, there are cables with fragile connections leaving the sensor board.

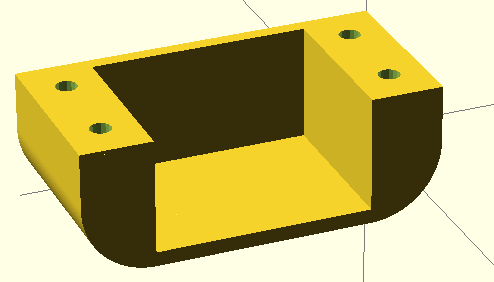

Long story short, there are sensitive parts that needs to be protected. In order to do so, i designed a protection in openscad :

The front and back sides are rounded, so that an obstacle on the ground hitting this part will slide onto it rather than getting the robot stuck.

There is one protection per motor, and the two pieces are identical, so that they are interchangeable. I am using generic parts as much as possible for this robot rather than a specific part for the left or right, as much as possible. This simplifies the design, but also the logistics and construction, since the piece that fits is the good one :) .

The piece has 3mm screw holes, and M3 machine screws works well out of the box, without the need of a nut.

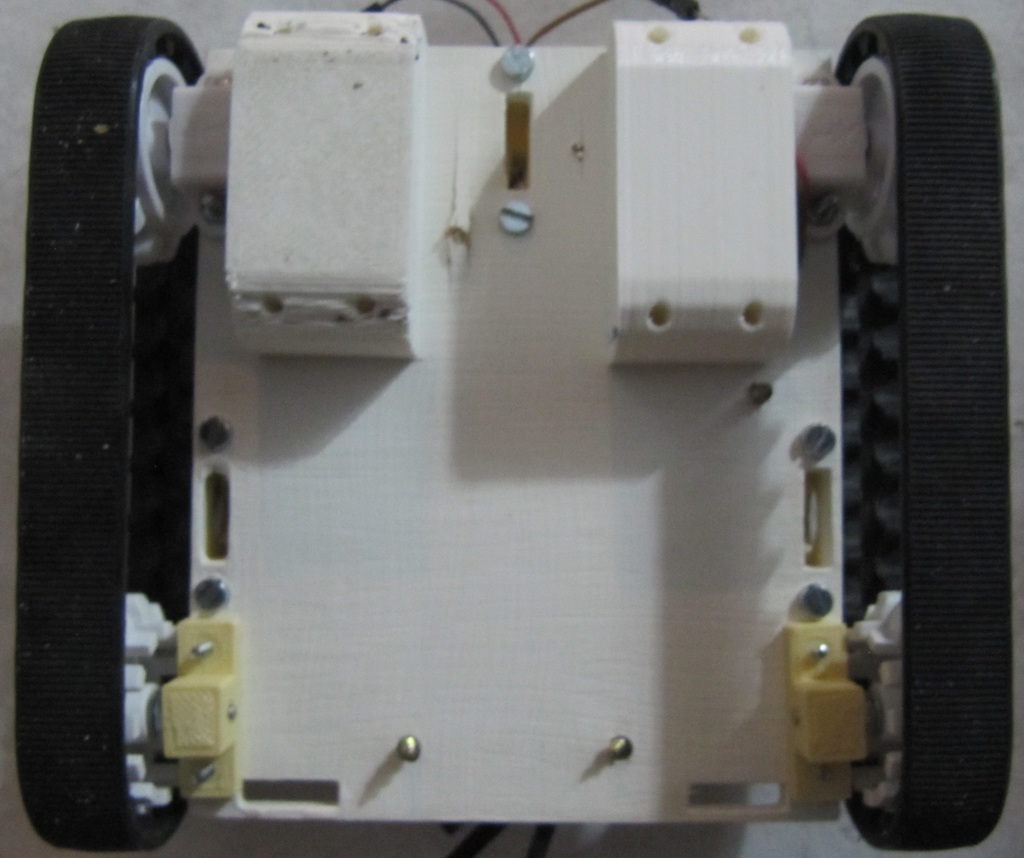

Once in position, this is how it looks :

The left one was printed with the underside on the printbed, causing bridging problems. The left part was printed with the other flat side of the part on the bed, causing a much better print.

Here is the link to the scad file for this motor protection, and here is the link to the stl file for this motor protection. I printed it with a printrbot simple metal, in PLA. Those links are for a revised version of this part. I increased the curve level (same shape, but a "rounder" curve, with more segments). This causes a smooth curve rather than the "steps" visible on the right part (i printed and tested one, to replace the left one).

Don't forget to rotate the part for best results! I will update the stl file so that it is already oriented correctly. There is another advantage to printing this way : the layers causes little lines on the print. When printed rotated, the lines are in the same direction of the movement of the robot, causing less friction than in the other way.

Audrey Robinel

Audrey Robinel

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.