3D Printing Concepts:

http://3dprinterplans.info/how-to-3d-print-beginners-guide-to-3d-printing/

3D printing process:

FDM

FDM specific Concepts:

- Filament

3D printing flow:

software to create 3D model >> software to "slice" 3D model >> software to send it to 3D printer >> 3D printer firmware (interprets commands for movement)

These sections will utilize the following hardware:

- Computer to be used up to sending the program to the 3D printer

- Printer Mechanical

- Printer Electronics

3D modeling software:

To be determined. . .3D slicer:

Repeteir Host

Sending Commands to Printer:

This hinges on what printer electronics are used. Either to have Repetier control the printer direct, or to drop some G-code onto an SD card that is used by the printer.

Currently using Repeteir Host to send G code commands to UNO without use of SD card. Would like to have SD card capability.

Printer Electronics:

Not sure which direction I will go yet (not in the order of preference):

- Smoothieboard

- Teensy 3.1 / RAMPS

- Mega / RAMPS

- **Currently testing with Teacup without RAMPS board** UNO / RAMPS

Printer Hardware:

- **Not Used** The first go around of this will just be a simple x/y/z table that I had built long ago using a scanner bed. The bed has been scavenged for the mill, so a new one will be needed. Modification will be required.

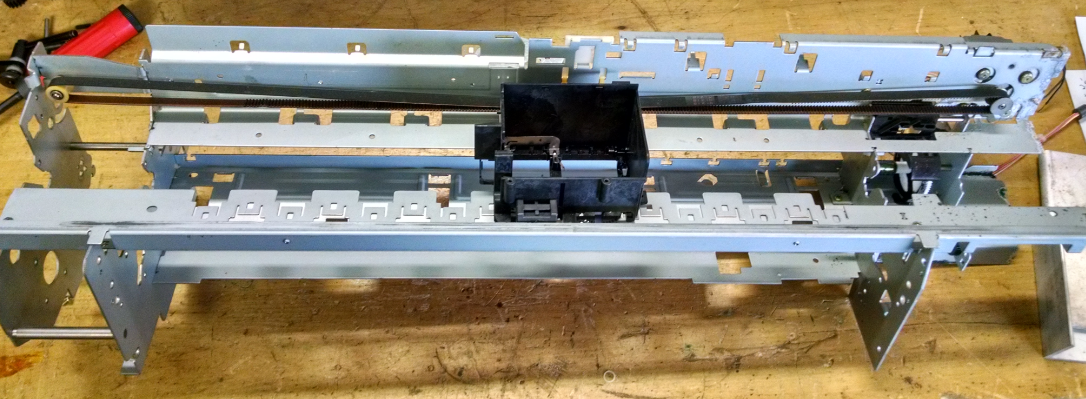

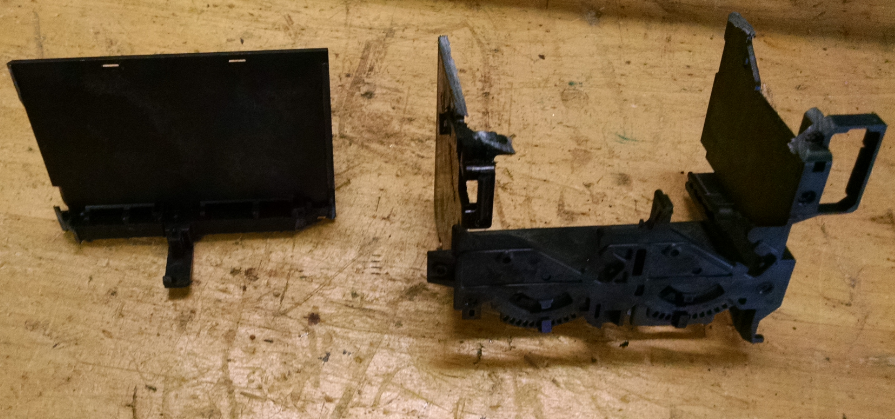

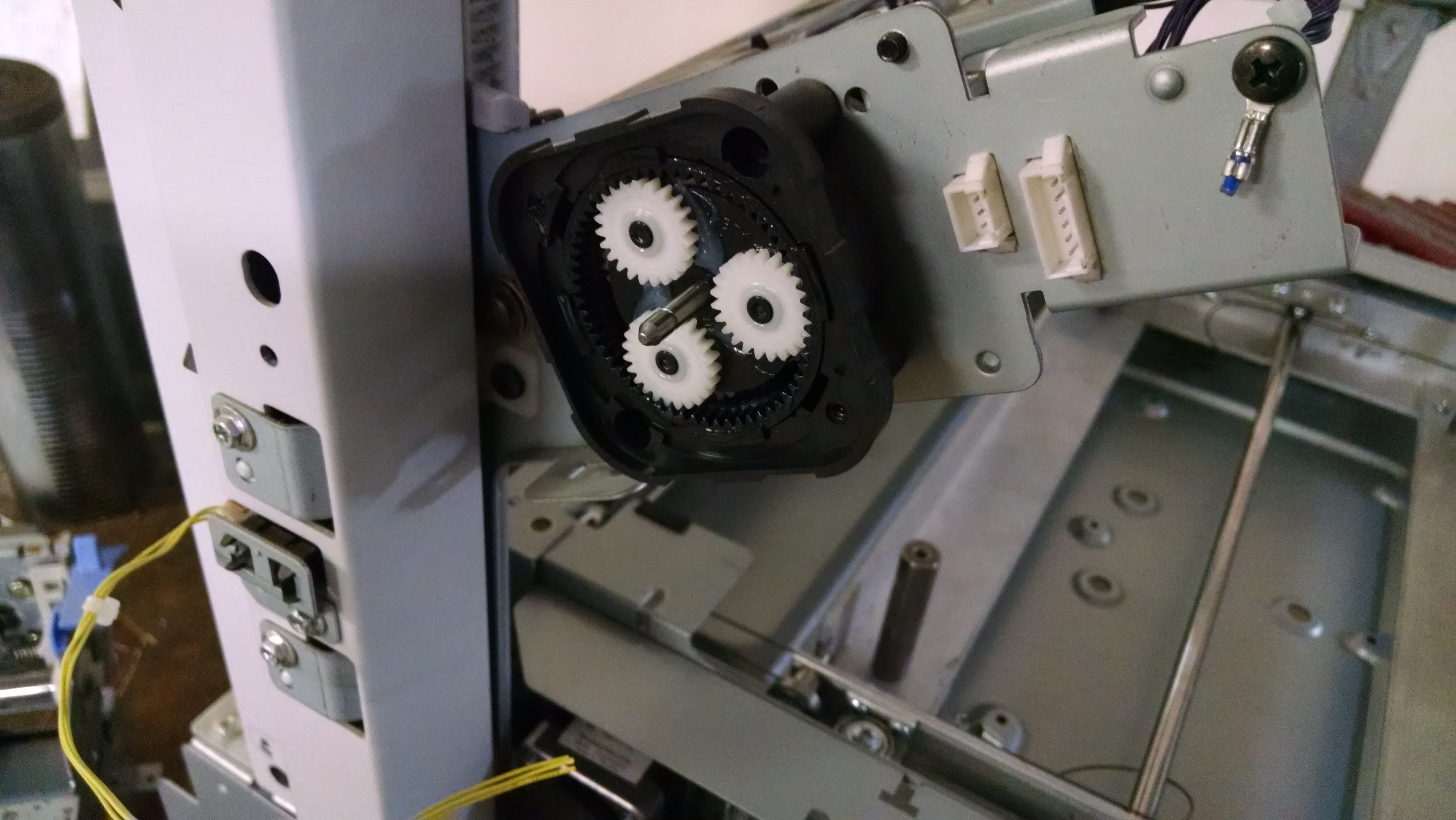

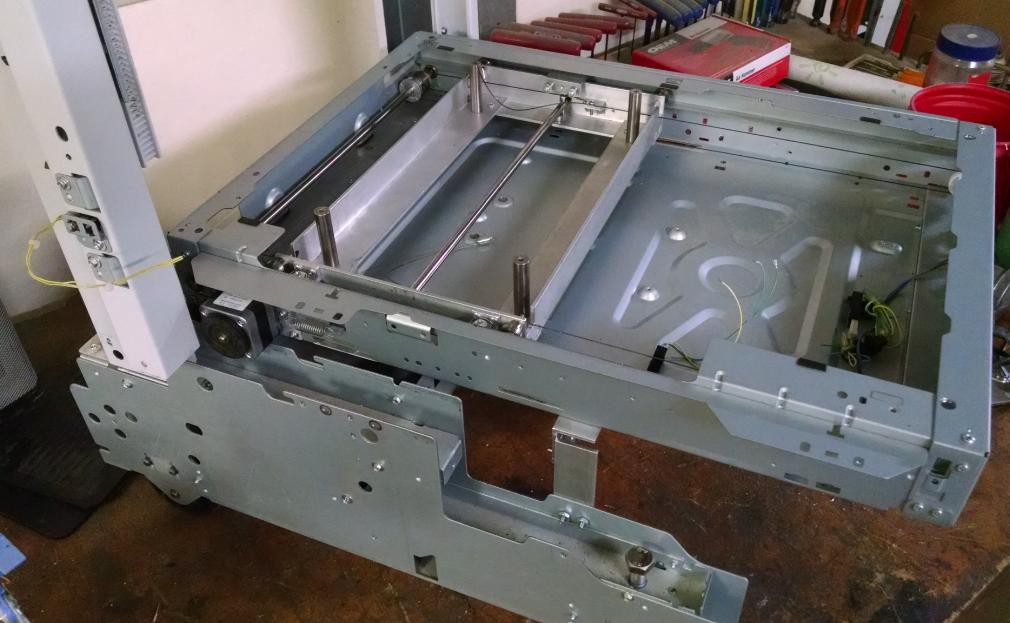

- Looking at the stripped printer/copier parts I have on hand, I am leaning towards using a copy machine scanner bed as the y axis, a stepper driven printer as the x axis and a copy machine paper selection tray as the z axis (which uses a rack and pinion). This would be a mix match of parts, but it would give me more travel than the prior hardware option.

- Y axis

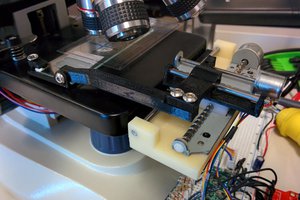

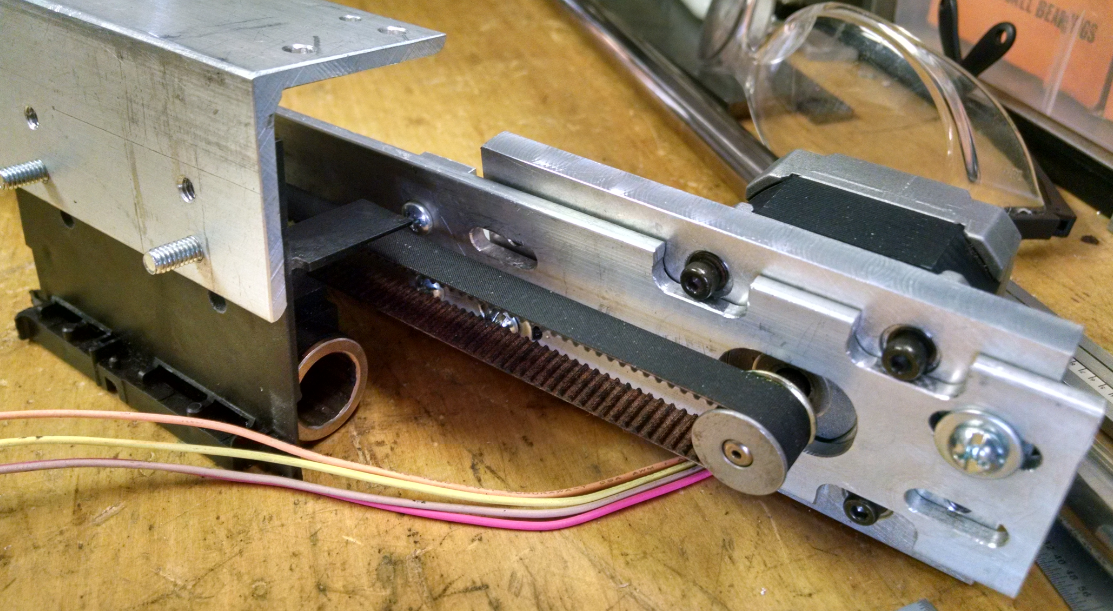

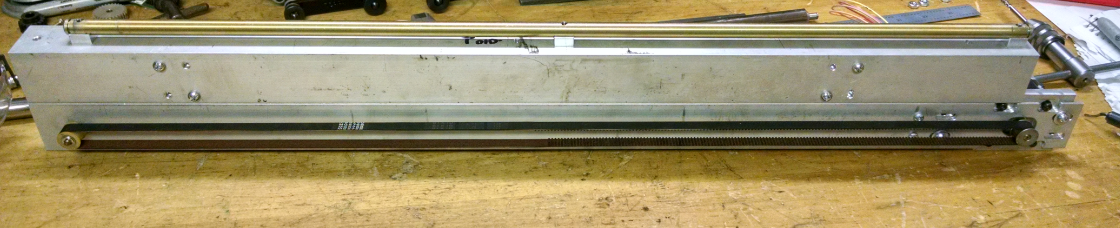

- Copier Scanner bed carriage is in progress

- X Axis

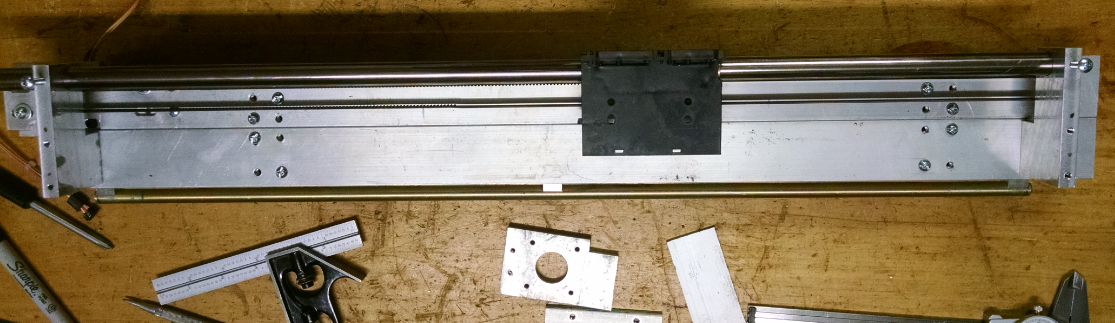

- Using same style of industrial printer that was used for claw machine. This is longer than is needed, but everything else I had would not be long enough.

- Z Axis

- The paper selector has been chosen, but nothing more has been done.

- Y axis

Printer extruder. Intentions are to build one.

Extruder design options:

- http://www.3ders.org/articles/20131231-all-metal-next-gen-3d-printer-extruder-from-micron.html

- Removable Nozzles

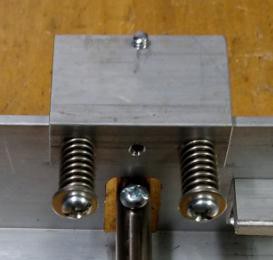

- Spring loaded tensioner for clamping onto plastic wire

- MB Plus RepRap Hot End (on Thinigverse)

- http://reprap.org/wiki/Geared_extruder_nozzle

- http://reprap.org/wiki/Extruder_Nozzle_Variation

- http://reprap.org/wiki/Hot_End_Comparison

Extruder wants. (keep in mind I have no experience in 3D printing):

- Be able to switch between 3mm and 1.75mm

- Removable nozzles to switch between different sizes

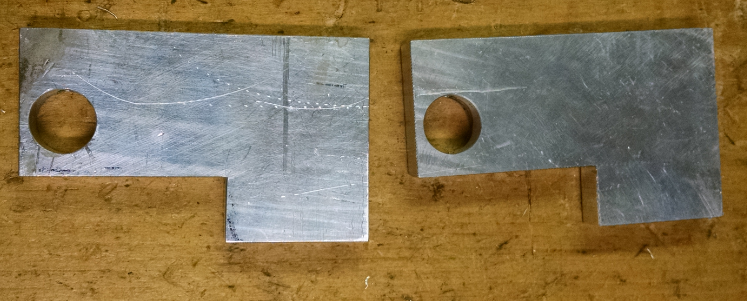

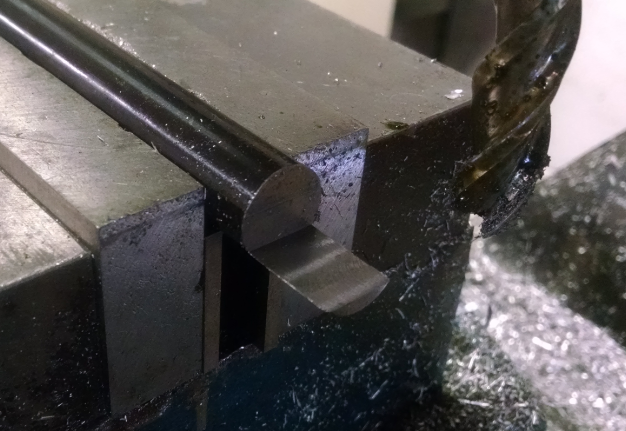

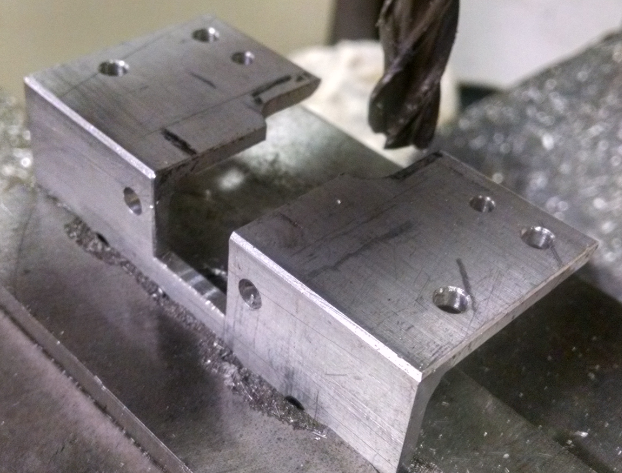

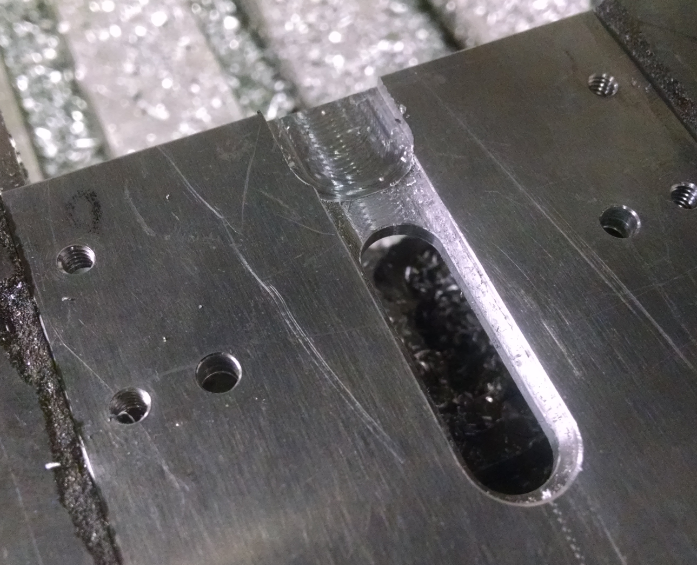

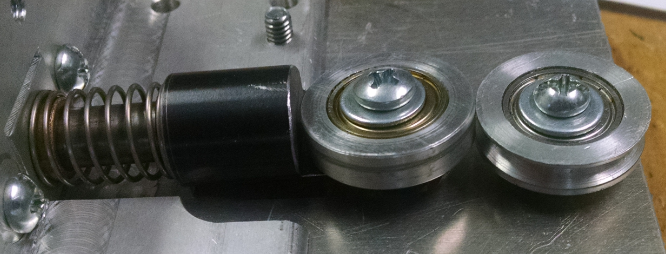

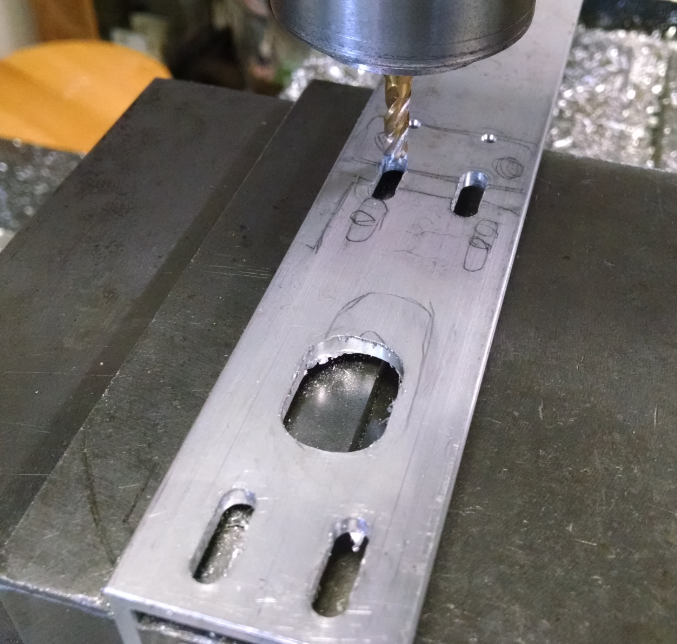

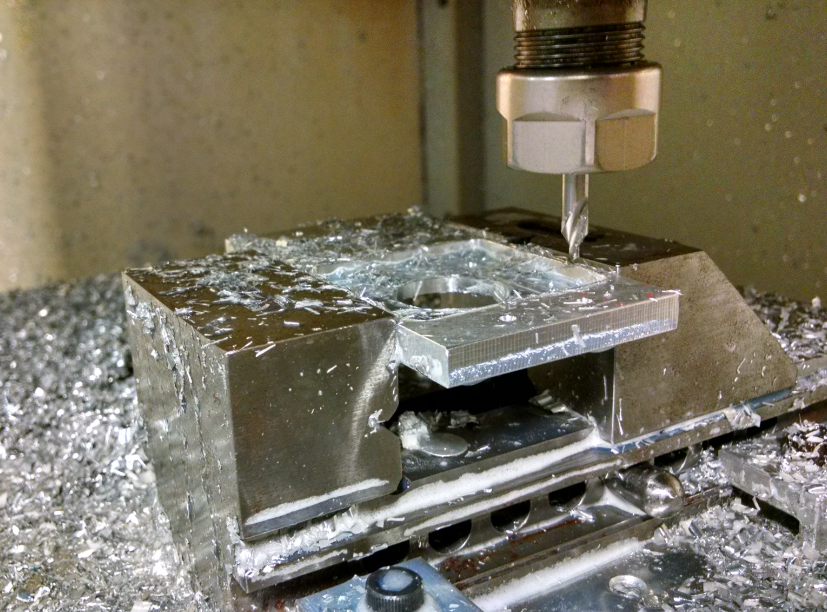

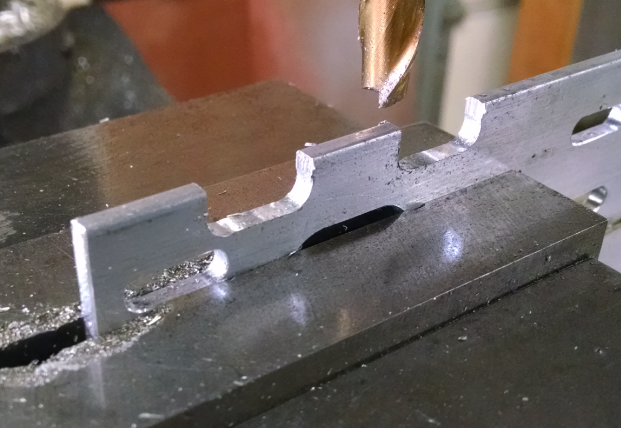

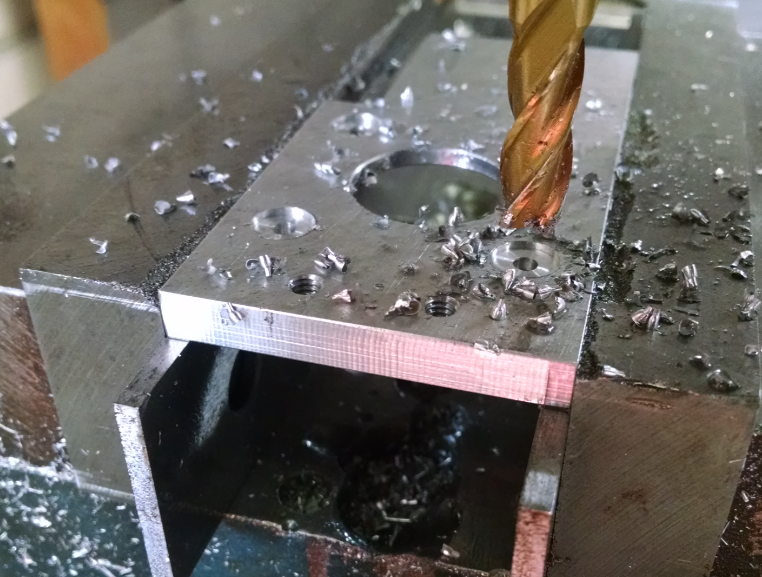

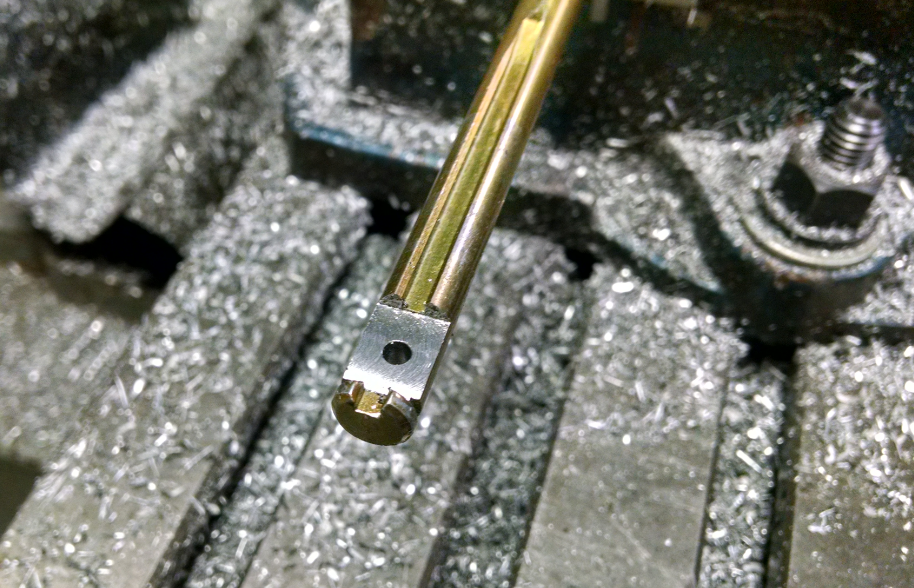

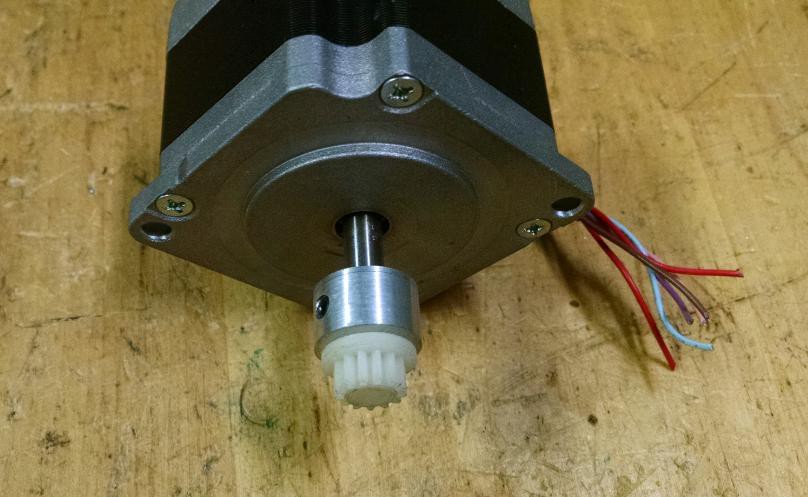

The motor mount also required relief for the fastener washers. Using an end mill the counterbores were machined.

The motor mount also required relief for the fastener washers. Using an end mill the counterbores were machined.

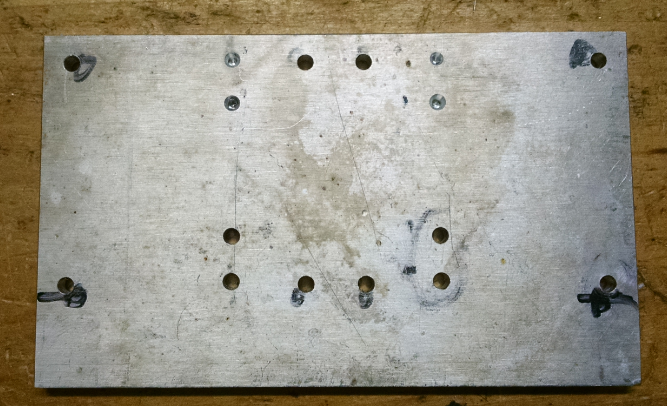

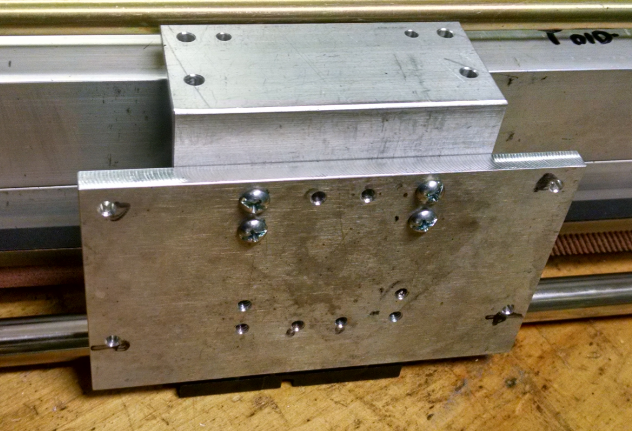

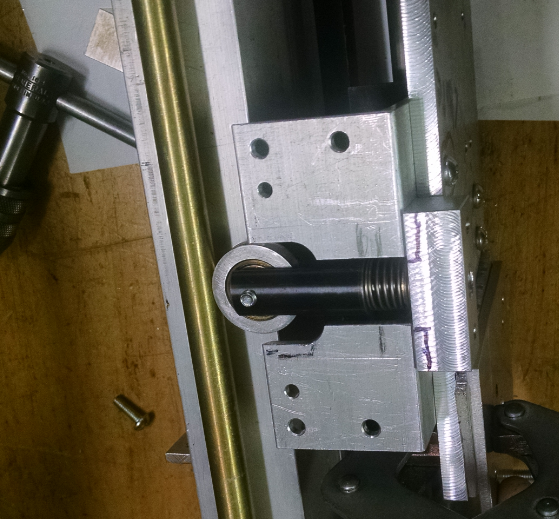

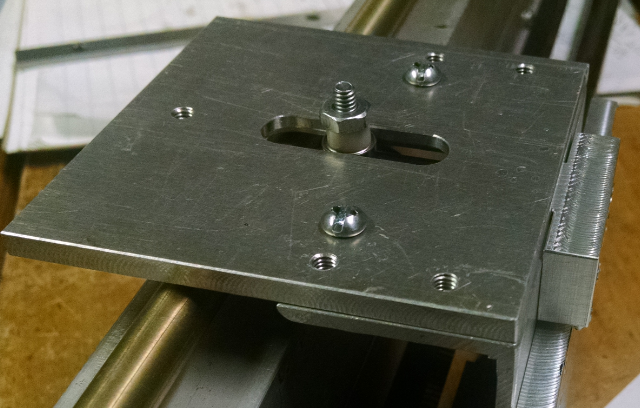

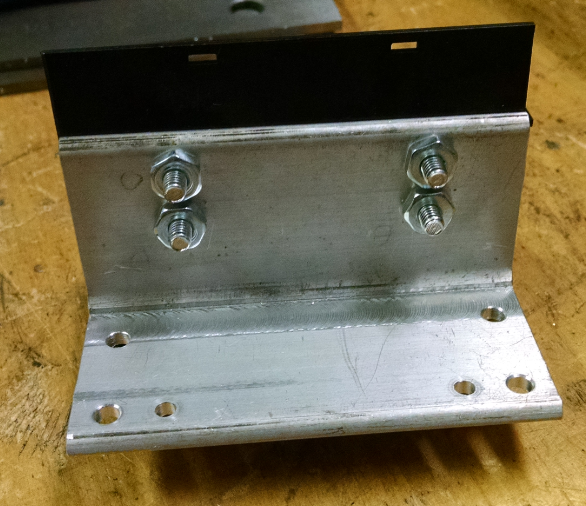

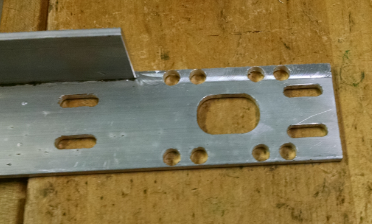

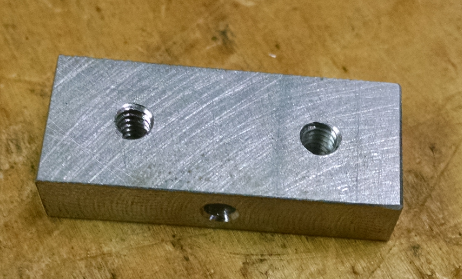

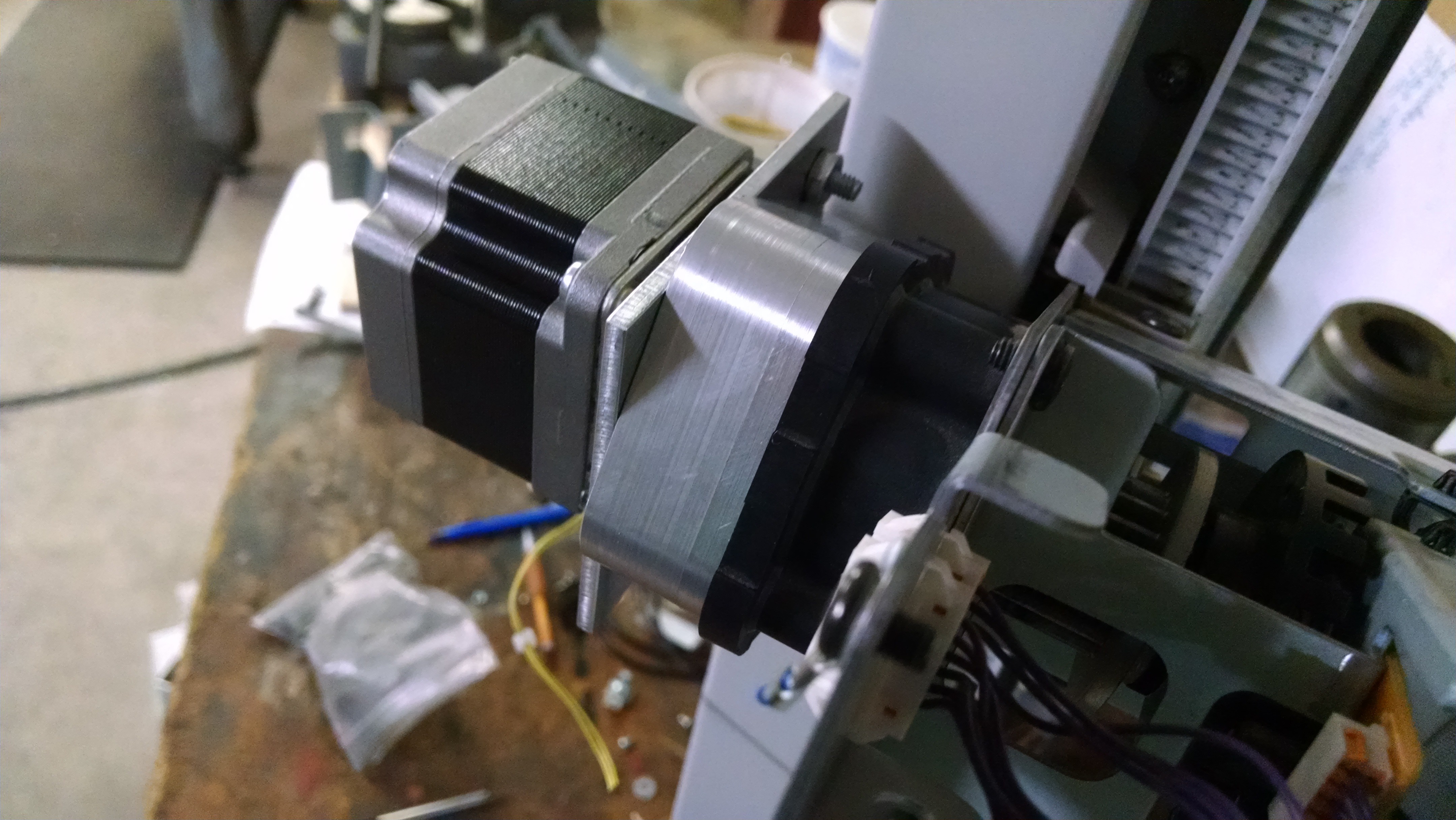

Between the housing and the stepper motor, an adapter plate was required. This allowed for a larger motor mounting bolt hole pattern. Not as good looking as the housing but it got the job down with a few speed holes.

Between the housing and the stepper motor, an adapter plate was required. This allowed for a larger motor mounting bolt hole pattern. Not as good looking as the housing but it got the job down with a few speed holes.

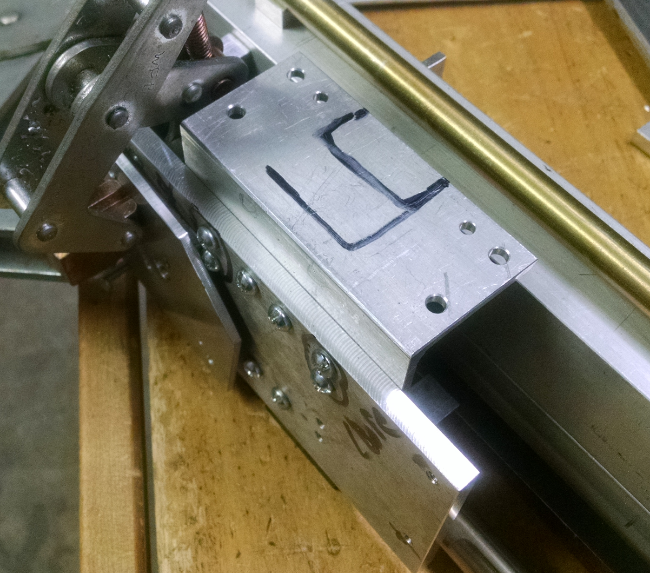

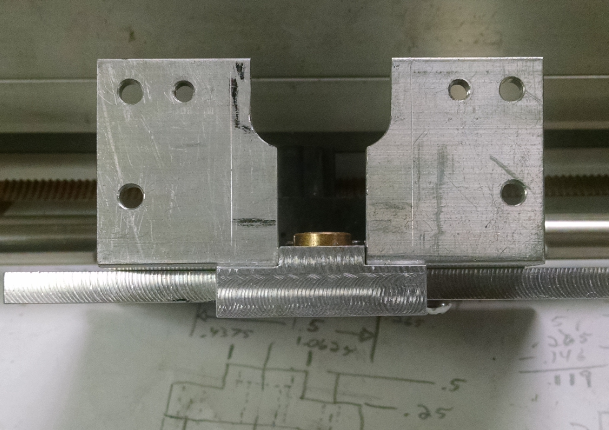

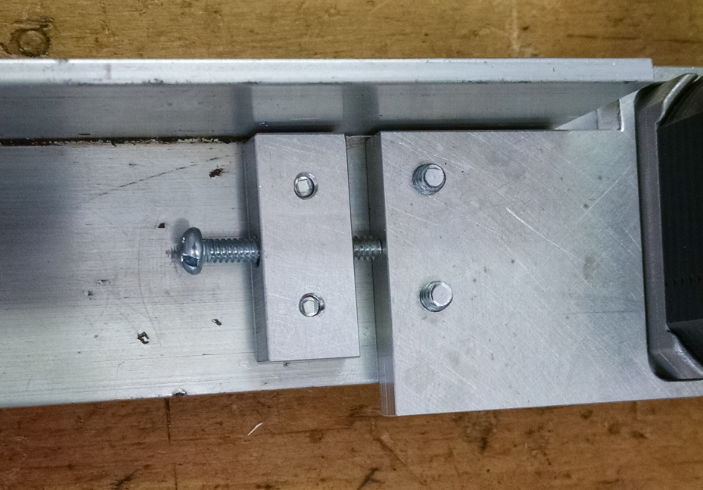

And here is a 3/4 view of the completed Y axis mounting. In this picture, pay notice to the upright shafts that stick off of the bottom of the angles. These will eventually support the table.

And here is a 3/4 view of the completed Y axis mounting. In this picture, pay notice to the upright shafts that stick off of the bottom of the angles. These will eventually support the table.

Rui Caldas

Rui Caldas