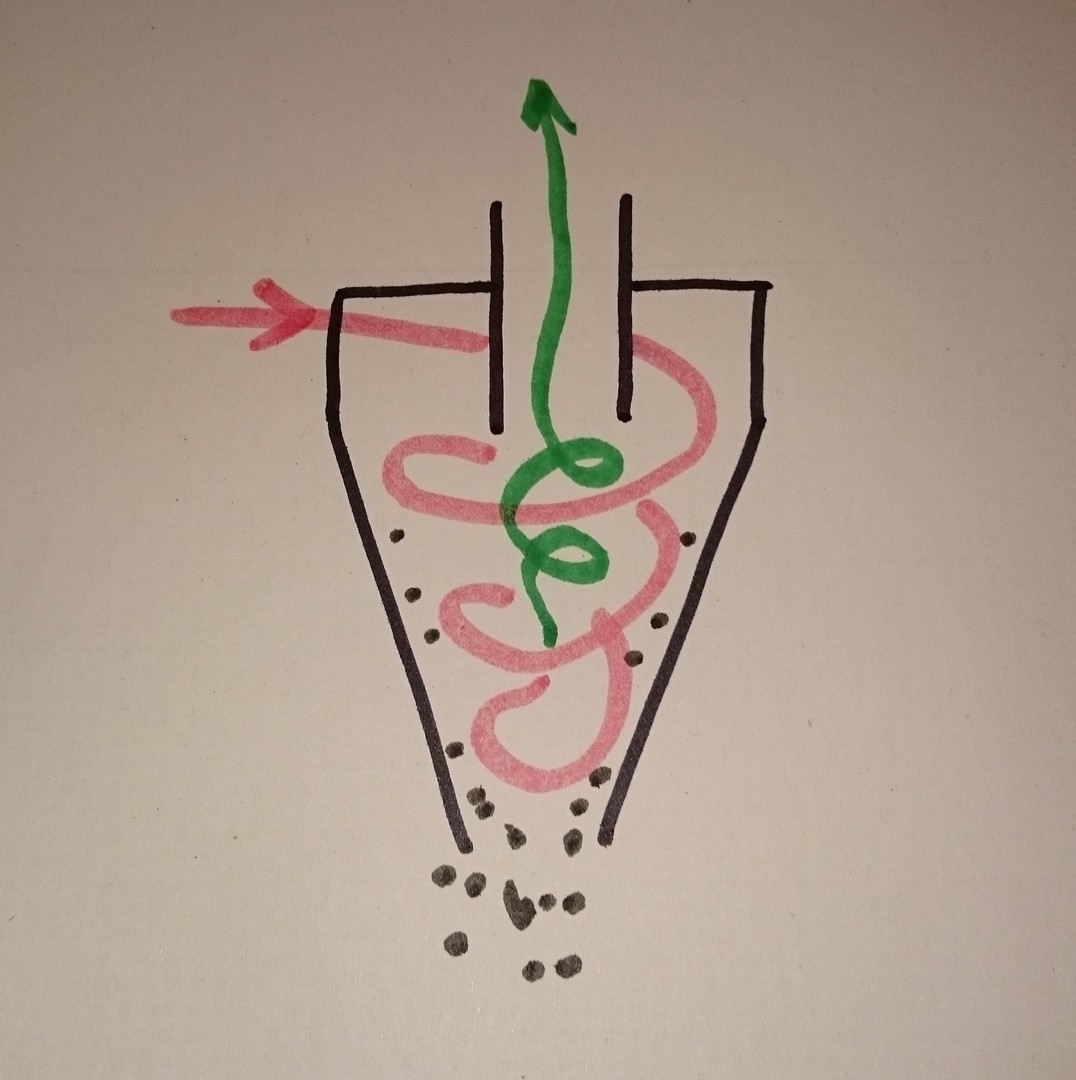

Cyclone separators are very simple and common devices in process engineering. In such a separator, centrifugal force is utilized to separate particles from the raw air, which is passed into the device tangentially. The cleaned air exits through a straight pipe in the top lid:

The first thing to note here is that the barrel I used doesn't change in diameter, but it works anyway.

This device is very simple to build, it's robust, and it will make cleaning a fun thing. Depending on the barrel, it's also

- easy to carry around

- easy to open

- easy to empty

- and easy to close.

Here are some images of the dirt barrel in use. After cutting some wood parts, the floor in our workshop looked like this:

Vacuum cleaner and barrel are ready to go:

(skipping the cleaned floor image, I don't have one)

The dirt is not in the bag...

...but in the barrel:

I think I won't have to empty that dungeon until 2016.

Christoph

Christoph

Robin

Robin

Tony

Tony

Chuck Glasser

Chuck Glasser

Have you considered adding a Thien baffle? Here's a characterization of cyclone performance with one, and here's a conversation with the inventor on the advantages and disadvantages of the baffle.