-

Documentation First Draft Complete

04/15/2015 at 06:28 • 0 commentsSpent some time scribbling down all my mental notes and converting gibberish in to "documentation".

To me it seems good, but I'm sure I missed some things. I'm going to host it on GitHub using Markdown as that seems to be the thing to do to these days. I like to think that people will send pull requests to fix typos and open issues on things that need clarification, but that may be just wishful thinking.

Check it out github.com/kylemanna/cleanhawk250. Comments welcome.

-

Half of First Batch Built

04/13/2015 at 15:52 • 0 commentsSpent the weekend hand placing components and built the first batch. Now all the parts are off to MassiveRC for pre-order fulfillment.

Assembled and tested

![]()

Then bagged

![]()

-

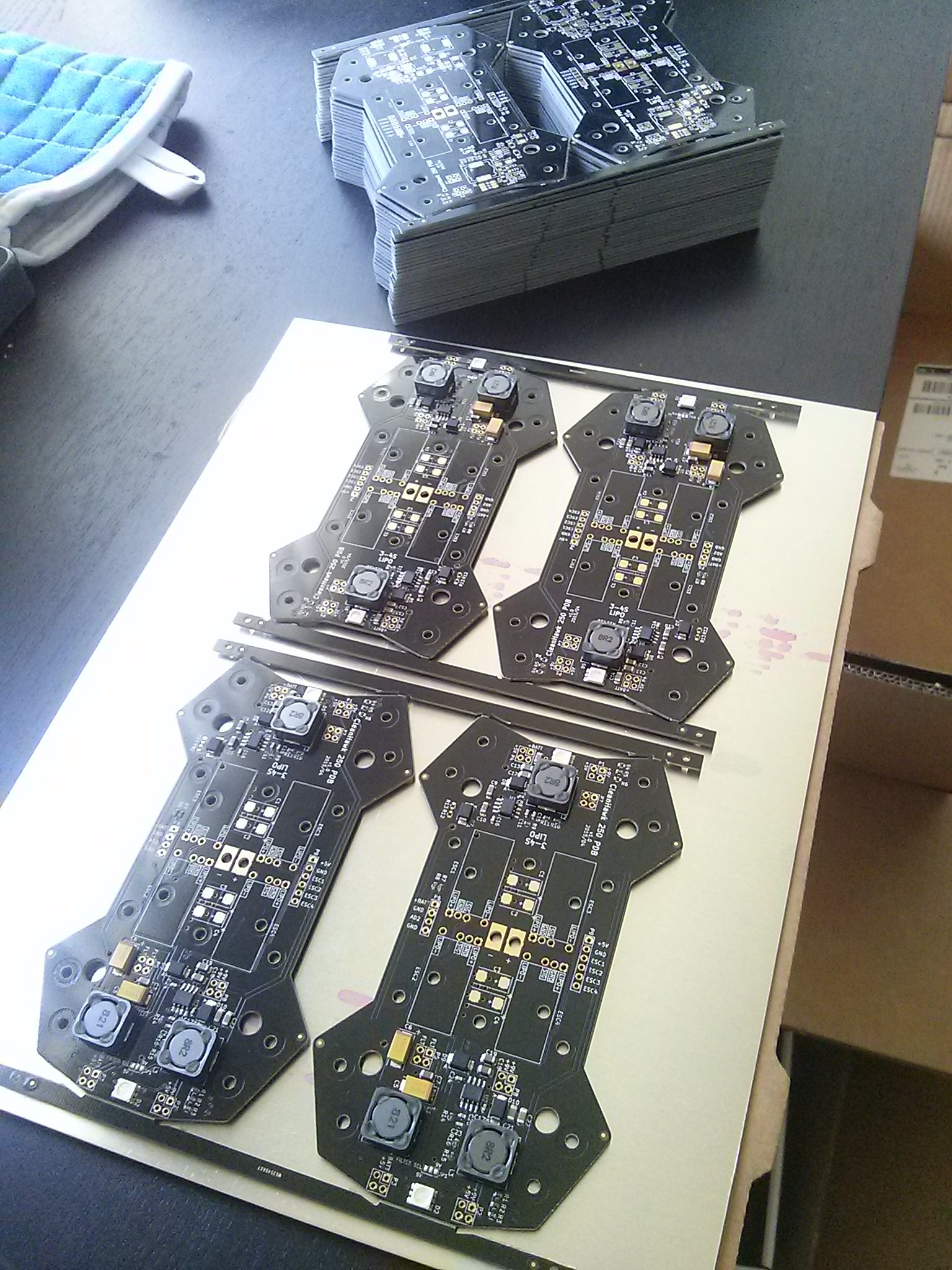

First Panels Delivered

04/10/2015 at 16:34 • 0 commentsThe building begins!

![]()

-

Bit.ly Bundles Shutting Down

04/01/2015 at 03:18 • 0 commentsI thought putting a QR code that points to a bit.ly bundle would be a great way to direct people to documentation. The QR code and link to the bundle would be frozen in stone, but I planned to update the links in the bundle. Not so fast.

It appears bit.ly is shutting down the bundles service. What does this mean? I have no clue. I assume the bundle is frozen in stone and crippled from now on. Sigh. Ironically I ordered 100 PCBs last night that have started production. FML.

-

Tweaks Complete

03/30/2015 at 13:50 • 0 commentsI've been putting off creating my final tweaks until more testing was done and the pre-order was closer to hitting it's mark. This weekend I finally got time to knock this out. There are many minor details that nobody except me will ever see... but will improve the board.

The highlights are:

- Switched from 10V to 9V regulator to address dropout issues at very low battery

- Enlarge KISS holes to facilitate 20AWG wire in addition to pin headers

- Remove old ESC solder pads. Hard to use and pointless, re-use KISS ESC through hole pads for external / alternative ESCs

- Tweak some layout details issues to reduce potential for yield problems

- Move center pin headers away from center to align in frame cut out and increase distance from ESC mounts as the wires exiting KISS ESCs were tight before.

- Add 30.5mm flight controller mounts

-

Waiting to Pull the Trigger

03/18/2015 at 16:48 • 0 commentsThere are a few hours of work left to polish the design, send it in for a review and then order the production quantity PCBs. After that it's probably ~4 weeks until the products ship to customers. Now I play the waiting game while I wait for the pre-orders to justify the monetary risk of buying such quantities. And so we wait!

The risk I carry here is something alot of the buyers don't see. At the end of this project I will have several thousand leftover raw parts (and hence over a thousand dollars) that I can't use and must carry over to the next production run (I hope there is such demand!). The other big problem is the parts come on reels of varying quantities, 5000 resistors, 2500 diodes, 600 inductors, 500 capacitors each with varying number of placements per board from 1 to 6 items per board. I could never buy the "perfect" number for a build and will always have wasted inventory at the end of every build. This is a hobby project and I don't have tons of capital to put on the line. At the same time, I can understand that people don't pre-order until it's ready. Chicken and Egg problem, and I'm in the middle. The comments and encouragement are what help with this frustration. :)

I'm very appreciative of the people that have backed me already via MassiveRC's pre-order! The more orders, the sooner it happens!

-

For What Price

03/16/2015 at 01:38 • 0 commentsOriginally I price the board at $60 after I had initial quotes for assembly and while trying to source the parts. There were alot of unknowns and the price apparently wasn't aggressive enough.

Now with some of the unknowns answered and additional details such as assembly negotiated down, I'm able to hit a much more attractive price @ $40. I'm not a business development guy or a marketer. I'm an engineer. I'm learning.

Never stop learning...

-

RGB LEDs and the Quest for White

03/11/2015 at 07:11 • 0 commentsFor this project LEDs were added since they'd be convenient. To keep costs low 5x5mm (aka 5050) Chinese RGB LEDs were selected. This means only one line item for both from and rear LEDs, only one reel to pay for and stupid cheap. While the rest of my parts are sourced from American distributors (counterfeit parts scare me on Alibaba) I had no fear in ordering LEDs that should they fail won't result in a catastrophic failure of the system.

These LEDs were never intended to be fancy, ultra bright, or flight controller controlled. They were cheap and added some value to the board. So they were designed in.

Now, the LEDs in the back have just the red series resistor populated to drive only the red LEDs in the packages. Kind of like tail lights. They look great.

The front LEDs kind of bug me a little bit. They aren't quite "white" despite my best efforts to match the current and forward voltage drop. I guess that's the reason the Chinese LEDs are stupid cheap and have no data sheet.

In the end, I'm going to tweak one resistor and leave it. They'll have a slight hue, but the name of the game lately is to keep it cheap. Worst case I ship the boards with all the resistors populated for the front white LEDs and then people remove the resistors for the colors they don't want. I know I'd prefer green up front and red in the back. Or maybe blue up front. Oh the luxury of choice...

-

LC Filter Testing

03/11/2015 at 07:03 • 0 commentsYesterday I assembled 4 boards with my neighbor, one of which he flew on today with success (other then the 10V regulator whining at low battery).

While finishing up the build I got a chance to probe the Vbatt rail and LC filter rail while he ramped the motors up and down without props. The result:

![]()

Green is the filtered rail and damn near silent (would be even quiter if the oscilloscope probe reached the analog ground. Yellow is Vbat. AC couple of course. Another design tested out and as good as expected. :)

I wonder if installing the low ESR tantalum capacitors on the Vbat rail would improve the situation? Unfortunately they are way too expensive to do in production. At least people have an option and there is already a home for four of them on the board.

-

PCB Manufacturer Selection

03/11/2015 at 06:59 • 0 commentsOh yeah, forgot to mention PCB selection from yesterday. I originally ordered 10 PCBs from two different board houses.

First supplier:

- Quality was "meh"

- The silkscreen wasn't sharp

- The soldermask was sloppy and dithered on the edges due to a rotational misalignment of the PCB with the printer axis.

- Top copper layer were damaged near the board edge when they routed.

- The copper fill between the pins of my SOIC 8 were removed (wtf? these are within spec)

- Drill hits were "ok"

- Ordered a stainless steel stencil from them, but it definitely didn't match my solder paste gerbers, wtf? They must have derived solder paste. Qualtity of stencil was fine, frame was clumsy to handle though.

- Extended voids between copper pads for the LEDs. Apparently the clearance was insufficient.

- tl;dr never again.

Second supplier:

- No problems!

- Silkscreen was much sharper

- Drill hits slightly better

- Soldermask was sharper

- No copper drama

- Edge routing quality wasn't quite as good

- One board has a short between the LC filter rail and ground. None of the others boards had this problem and I'll be on the lookout in the future before assembly. The short was "resolved" by blowing it away by hooking up the battery directly and converting copper to magic smoke. Boom baby.

- Ordered 10 boards, got 11.

- Board cost is cheaper (What the hell? HOW!? China, sometimes I love you.)

I've ordered a USB microscope and will do post on my blog at some point I think with high rest pictures.

CleanHawk 250 Quadcopter Power Distribution Board

Distribute power to all the things running on an Emax / Nighthawk 250 quadcopter

2bluesc

2bluesc